Preparation method for SiO<x>-C-CNT composite material of lithium-ion battery negative electrode

A technology of lithium-ion batteries and composite materials, which is applied in the field of preparation of SiOx-C-CNT composite materials, can solve the problems of rapid capacity decay of negative electrode materials, large volume effect of silicon negative electrode materials, and low cycle life, and achieve improved reversible capacity, The experimental operation is simple and easy, and the cycle performance is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

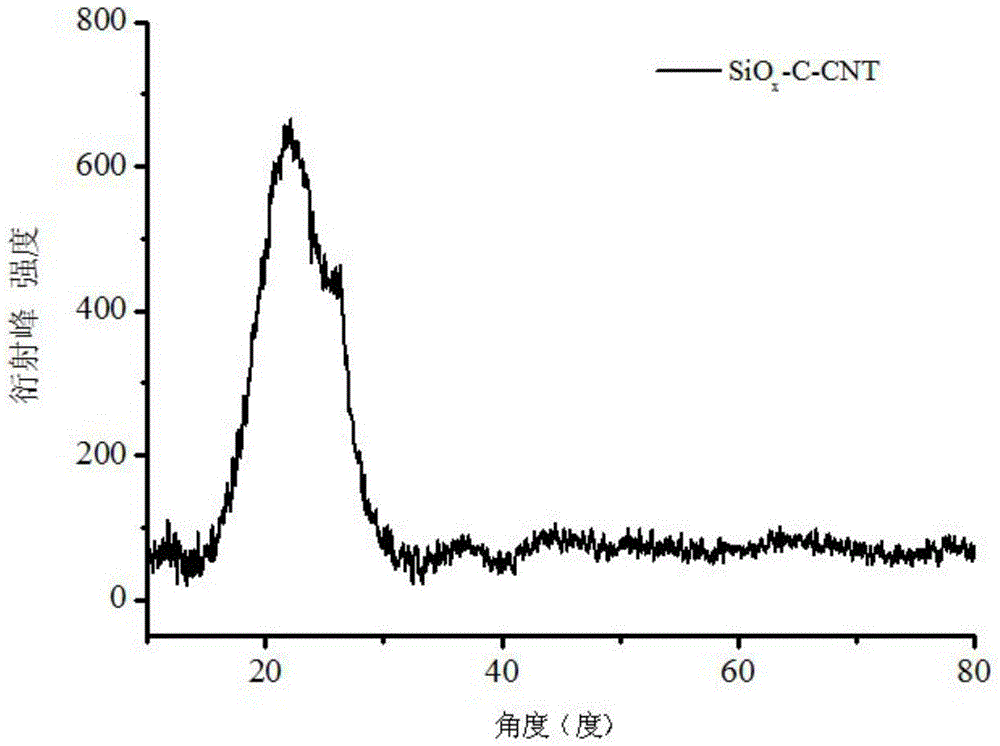

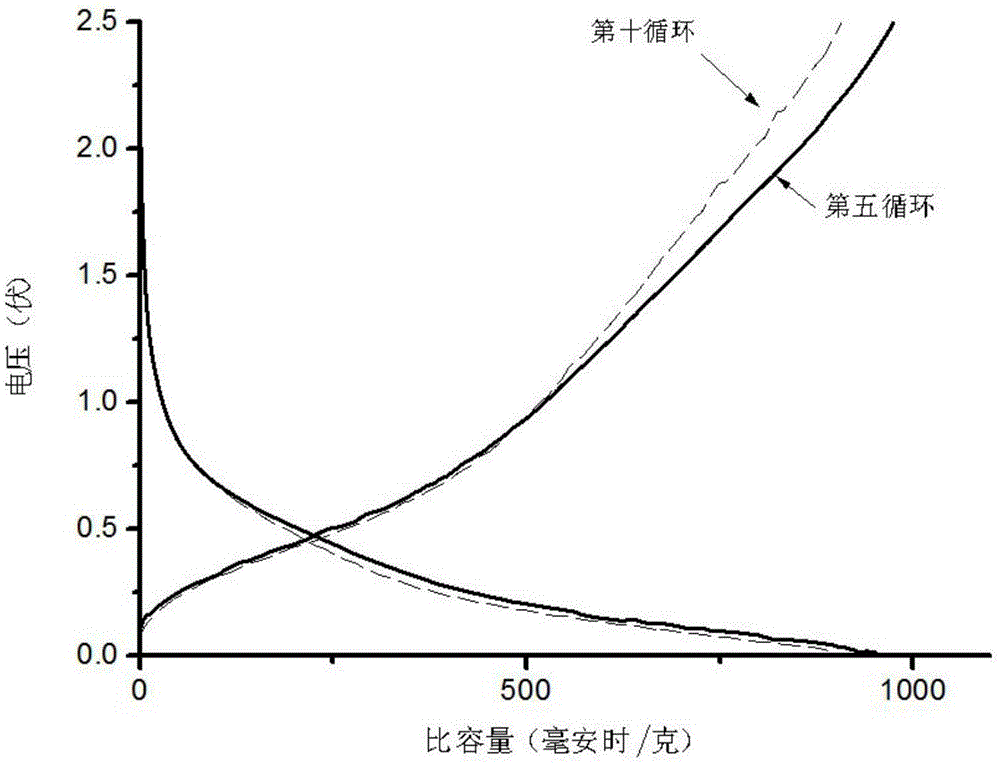

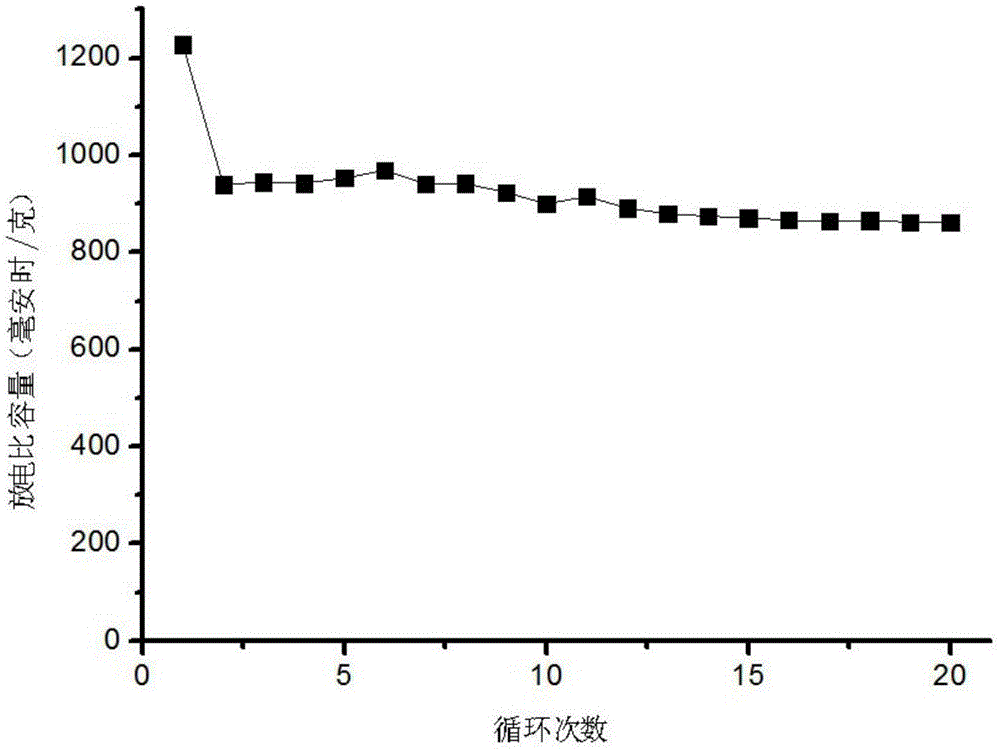

[0032] The first step is to prepare SiO x -C-CNT composite material:

[0033]Weigh 8.33g of tetraethyl orthosilicate and 16.66g of 0.1mol / L hydrochloric acid, dissolve in 24.99g of absolute ethanol, so that the mass ratio of tetraethyl orthosilicate: 0.1mol / L hydrochloric acid: absolute ethanol = 1:2 : 3; Stir at 200r / min for 1h, and use this as the silicon source solution. Weigh 3.8428g of citric acid, 1.9214g of ethylene glycol and 1.9214g of carbon nanotube suspension (carbon nanotube content is 9.0wt%, average diameter of 10nm) dissolved in 10g of deionized water, stirred at 200r / min for 1h, This was used as a carbon source solution. The molar ratio of citric acid: ethyl orthosilicate = 1:2. Pour the carbon source solution into the silicon source solution, and stir at 200 r / min for 30 min to obtain a sol. The sol was poured into a glass petri dish, and the glass petri dish was dried at room temperature for 30 h to form a 0.5mm film. Take the film out of the glass petr...

Embodiment 2

[0040] The first step is to prepare SiO x -C-CNT composite material:

[0041] The preparation of silicon source solution and carbon source solution and the steps of forming a film on a glass petri dish are the same as in Example 1, except that the temperature of the obtained material is raised to 800°C at 5°C / min, kept for 1h, and the temperature drops to room temperature. That is, SiO x - C-CNT composite samples.

[0042] The second step, the preparation of the negative electrode sheet of the battery and the assembly of the half-cell: the same as in Example 1.

[0043] The resulting product is also amorphous SiO x -C-CNT composite material; compared with Example 1, the material obtained in this example has an initial discharge capacity of 1215mAh / g at a rate of 0.1C, and a reversible capacity of 833mAh / g after 20 cycles.

Embodiment 3

[0045] The first step is to prepare SiO x -C-CNT composite material:

[0046] The preparation of silicon source solution and carbon source solution and the steps of forming a film on a glass petri dish are the same as in Example 1, except that the temperature of the obtained material is raised to 1000°C at 5°C / min, kept for 1h, and the temperature drops to room temperature. That is, SiO x - C-CNT composite samples.

[0047] The second step, the preparation of the negative electrode sheet of the battery and the assembly of the half-cell: the same as in Example 1.

[0048] The resulting product is also amorphous SiO x -C-CNT composite material; compared with Example 1, the material obtained in this example has an initial discharge capacity of 1220mAh / g at a rate of 0.1C, and a reversible capacity of 849mAh / g after 20 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com