Hydroponic plant nutrient solution and preparation method thereof

A technology for hydroponic plants and nutrient solution, which is applied to fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of lack of plants, single types of nutrient elements, and inability to satisfy plants, etc., and achieves comprehensive nutrient elements, simple preparation method and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

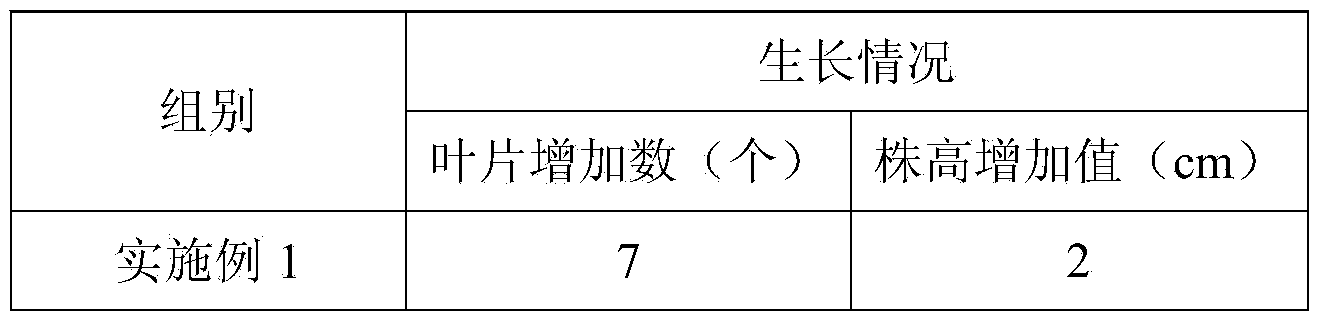

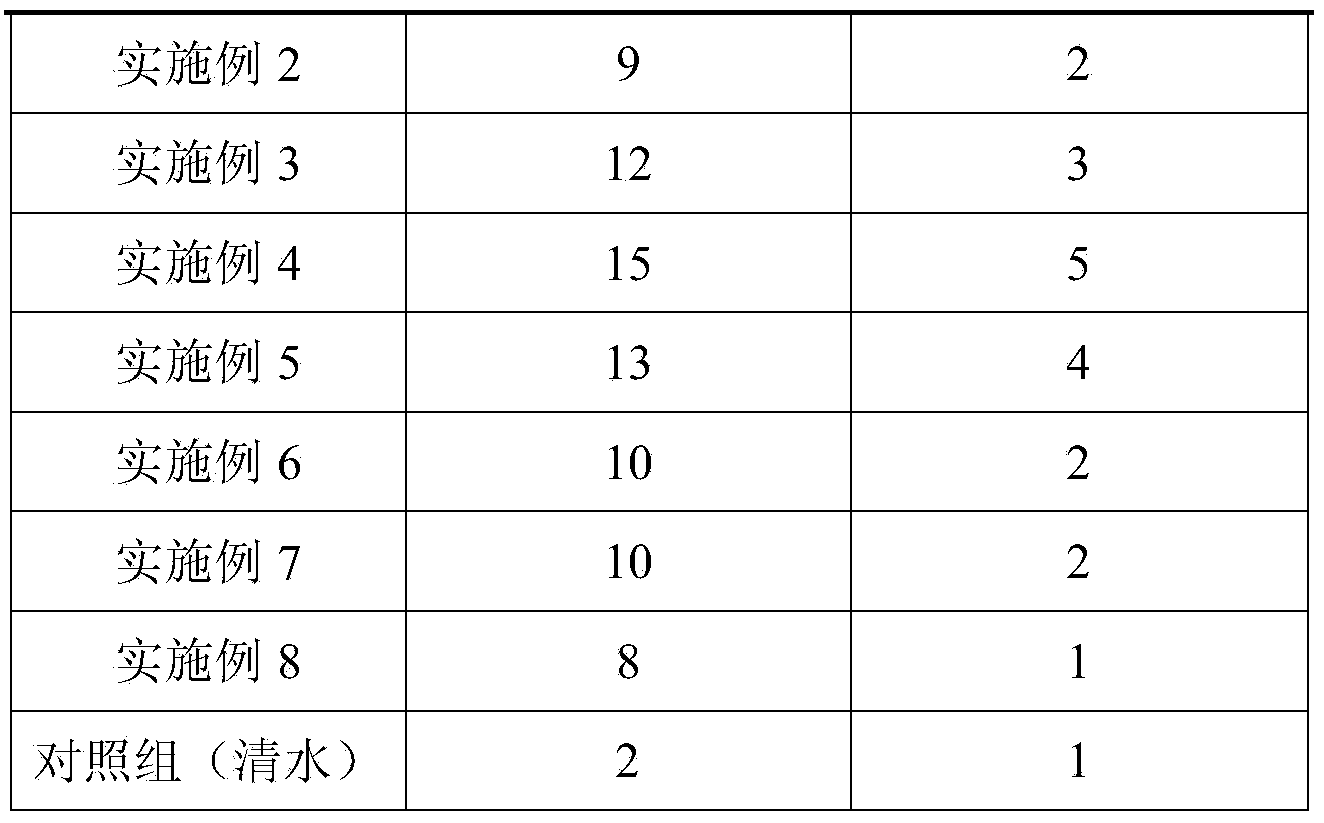

Examples

Embodiment 1

[0019] (1), preparation of liquid A: Weigh 10 parts of plant ash, 5 parts of livestock manure and 80 parts of water, place them in a glass container, stir evenly, let stand for more than seven days, filter, and use the filtrate for later use;

[0020] (2) Preparation of liquid B: Weigh 0.1 part of calcium nitrate, 0.2 part of boric acid, 0.01 part of manganese sulfate tetrahydrate, 0.01 part of zinc sulfate heptahydrate, 0.01 part of copper sulfate pentahydrate, 0.01 part of magnesium sulfate, and 0.01 part of sodium iodide , 0.2 parts of ammonium dihydrogen phosphate and 20 parts of water, mix and stir evenly, set aside;

[0021] (3) Preparation of nutrient solution: Mix liquid A prepared in step (1) and liquid B prepared in step (2) at a volume ratio of 1:1, stir evenly, let stand for more than three days, and add buffer to the nutrient solution solution, and adjust the pH value to neutral to obtain a nutrient solution for hydroponic plants.

Embodiment 2

[0023] (1), preparation of liquid A: Weigh 12 parts of plant ash, 6 parts of livestock manure and 80 parts of water, place in a glass container, stir evenly, let stand for more than seven days, filter, and the filtrate is ready for use;

[0024] (2) Preparation of liquid B: Weigh 0.1 part of calcium nitrate, 0.2 part of boric acid, 0.01 part of manganese sulfate tetrahydrate, 0.01 part of zinc sulfate heptahydrate, 0.01 part of copper sulfate pentahydrate, 0.01 part of magnesium sulfate, and 0.01 part of sodium iodide , 0.2 parts of ammonium dihydrogen phosphate and 21 parts of water, mix and stir evenly, set aside;

[0025] (3) Preparation of nutrient solution: Mix liquid A prepared in step (1) and liquid B prepared in step (2) at a volume ratio of 1:1, stir evenly, let stand for more than three days, and add buffer to the nutrient solution solution, and adjust the pH value to neutral to obtain a nutrient solution for hydroponic plants.

Embodiment 3

[0027] (1), preparation of liquid A: Weigh 14 parts of plant ash, 7 parts of livestock manure and 90 parts of water, place in an enamel container, stir evenly, let stand for more than seven days, filter, and the filtrate is ready for use;

[0028] (2), preparation of liquid B: weigh 0.2 part of calcium nitrate, 0.3 part of boric acid, 0.02 part of manganese sulfate tetrahydrate, 0.02 part of zinc sulfate heptahydrate, 0.02 part of copper sulfate pentahydrate, 0.01 part of magnesium sulfate, and 0.01 part of sodium iodide , 0.3 parts of ammonium dihydrogen phosphate and 22 parts of water, mix and stir evenly, set aside;

[0029] (3) Preparation of nutrient solution: Mix liquid A prepared in step (1) and liquid B prepared in step (2) at a volume ratio of 1:1, stir evenly, let stand for more than three days, and add buffer to the nutrient solution solution, and adjust the pH value to neutral to obtain a nutrient solution for hydroponic plants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com