Hollow polyester fiber microporous membrane and preparation method thereof

A technology of microporous membrane and fiber membrane, which is applied in the field of membrane separation to achieve the effects of high tensile strength, convenient operation and less pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

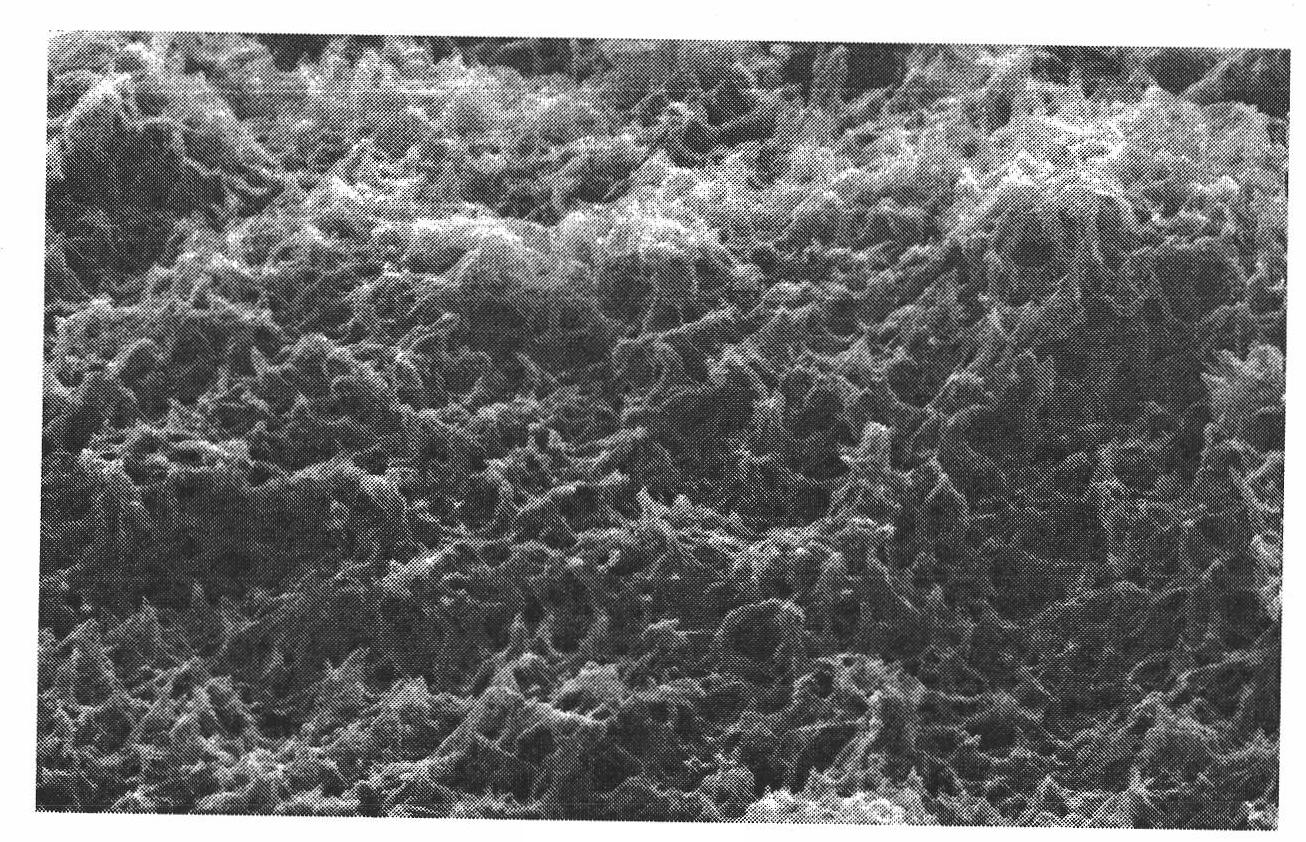

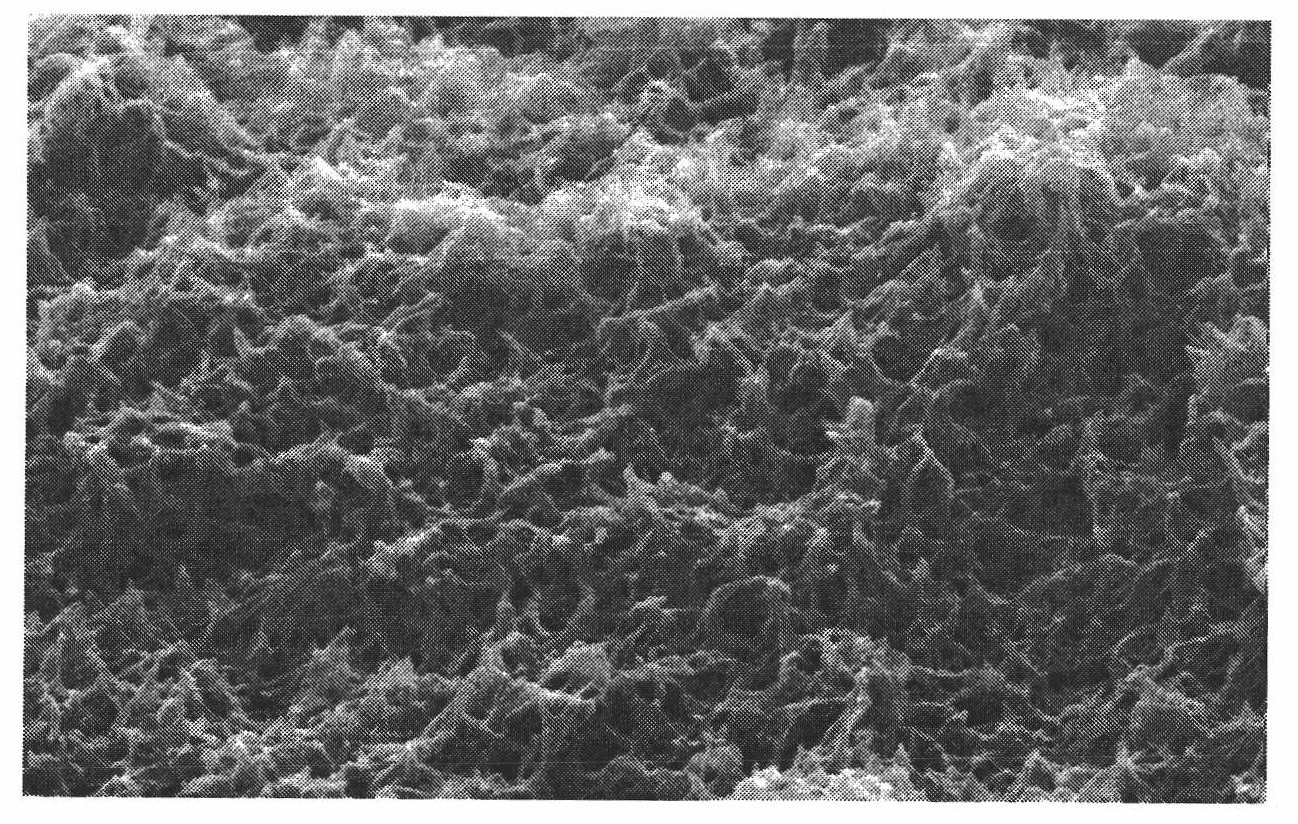

Image

Examples

Embodiment 1

[0035] A method for preparing a polyester hollow fiber microporous membrane of the present invention is characterized in that the preparation steps are as follows: the formula ratio is calculated by mass percentage:

[0036] (1) Preparation of film-making liquid melt: the molecular weight 5 × 10 5 , 15% polyethylene terephthalate and 85% dimethyl malonate are mixed, the mixed solution is added to the melting material kettle, filled with 0.2MPa nitrogen protection, stirring continuously, and the material is heated to 150°C, After melt blending for 5 hours, stand at 150°C for 30 minutes to degas to obtain a film-forming liquid melt;

[0037] (2) Preparation of the hollow fiber membrane precursor: take dimethyl malonate at 70°C as the core liquid, and the flow rate of the core liquid is 0.2m / s. The spinneret of the spinning machine at 140°C is extruded into a hollow fiber-shaped liquid film. The hollow fiber-shaped liquid film passes through a 10 cm long air gap and enters a col...

Embodiment 2

[0041] A method for preparing a polyester hollow fiber microporous membrane of the present invention is characterized in that the preparation steps are as follows: the formula ratio is calculated by mass percentage:

[0042] (1) Preparation of film-making liquid melt: the molecular weight of 1 × 10 4 , 60% poly(trimethylene terephthalate) and 40% dibutyl phthalate are mixed, the mixture is added to the melting tank, filled with 0.2MPa nitrogen protection, stirring continuously, heating the material to 240°C, melting After blending for 5 hours, stand at 210°C for 30 minutes to degas to obtain a film-forming liquid melt;

[0043] (2) Preparation of hollow fiber membrane precursor: take dibutyl phthalate at 120°C as the core liquid, and the flow rate of the core liquid is 0.2m / s. The spinneret of the spinning machine at ℃ is extruded into a hollow fiber-shaped liquid membrane, and the hollow fiber-shaped liquid membrane enters a 20°C cold water bath to solidify into a hollow fib...

Embodiment 3

[0047] A method for preparing a polyester hollow fiber microporous membrane of the present invention is characterized in that the preparation steps are as follows: the formula ratio is calculated by mass percentage:

[0048] (1) Preparation of film-making liquid melt: the molecular weight of 2 × 10 5 , 25% polybutylene terephthalate and 75% diethyl terephthalate are mixed, the mixture is added to the melt tank, filled with 0.2MPa nitrogen protection, stirring continuously, and the material is heated to 200°C , after melting and blending for 5 hours, standing at 190°C for 30 minutes to degas to obtain a film-forming liquid melt;

[0049] (2) Preparation of the hollow fiber membrane precursor: take diethyl terephthalate at 80°C as the core liquid, and the flow rate of the core liquid is 0.2m / s, and melt the core liquid and the membrane-making liquid prepared in step (1) Together, they are extruded into a hollow fiber-shaped liquid membrane through the spinneret of a spinning ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com