Perovskite quantum dot glass and preparation method and application thereof

A technology of quantum dot glass and perovskite, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of uneven size of quantum dots, uncontrollable volatilization of raw materials, low product yield, etc., to reduce raw materials The effect of volatilization, reducing thermal stress and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of perovskite quantum dot glass provided by the invention comprises the following steps:

[0034] (1) Accurately weigh various raw materials according to the composition of each sample, mix the weighed solid powder into a corundum mortar and grind evenly, pass through a 50 μm particle size sieve, and place the screened powder in graphite (or corundum) in the crucible;

[0035] (2) Place the graphite crucible with the raw material powder in the hot isostatic pressing furnace to ensure good airtightness, then raise the temperature from room temperature to 200-300°C at a rate of 2-15°C / min, keep it warm for 20min, and turn on the vacuum pump at the same time Vacuumize to remove the water and oxygen in the raw materials and the air to avoid oxidation of the graphite crucible and raw materials;

[0036] (3) Turn off the vacuum pump, raise the temperature from 200-300°C to 1100-1200°C at a rate of 1-10°C / min, keep it warm for 15-30min, and fill it with...

Embodiment 1

[0040] Example 1: Green light CsPbBr 3 Preparation of borosilicate glass with perovskite quantum dots

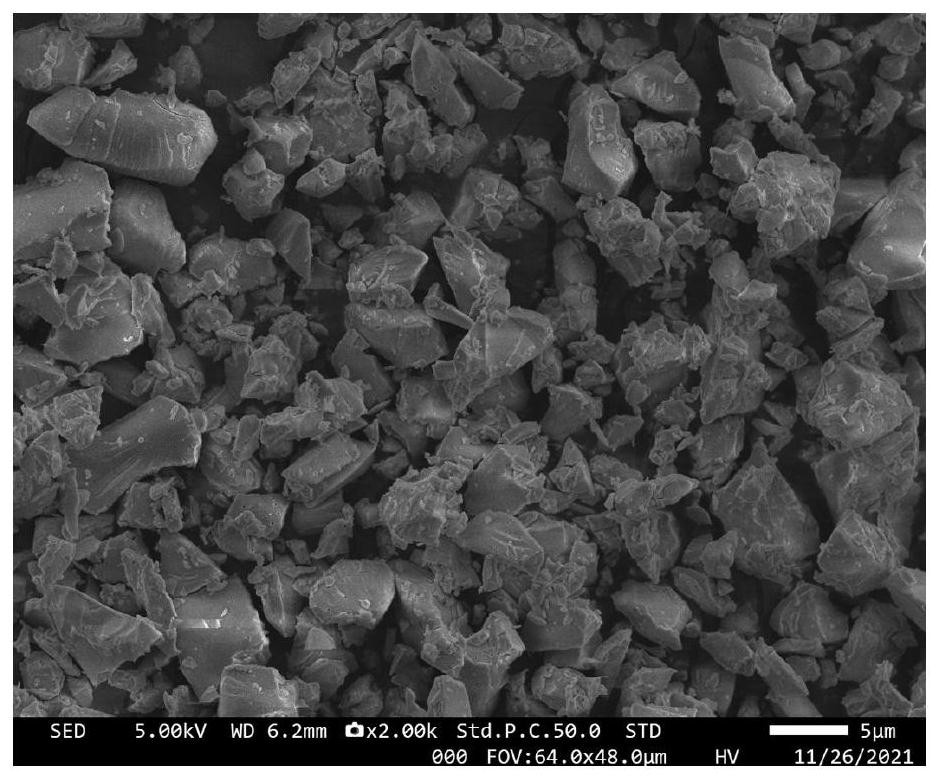

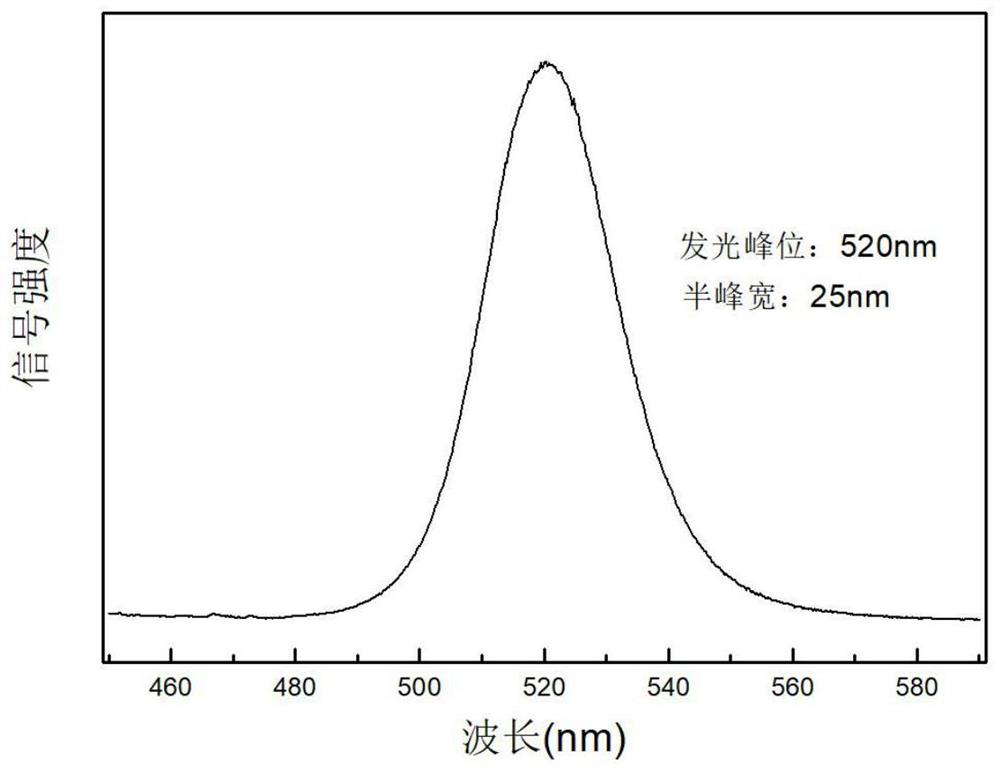

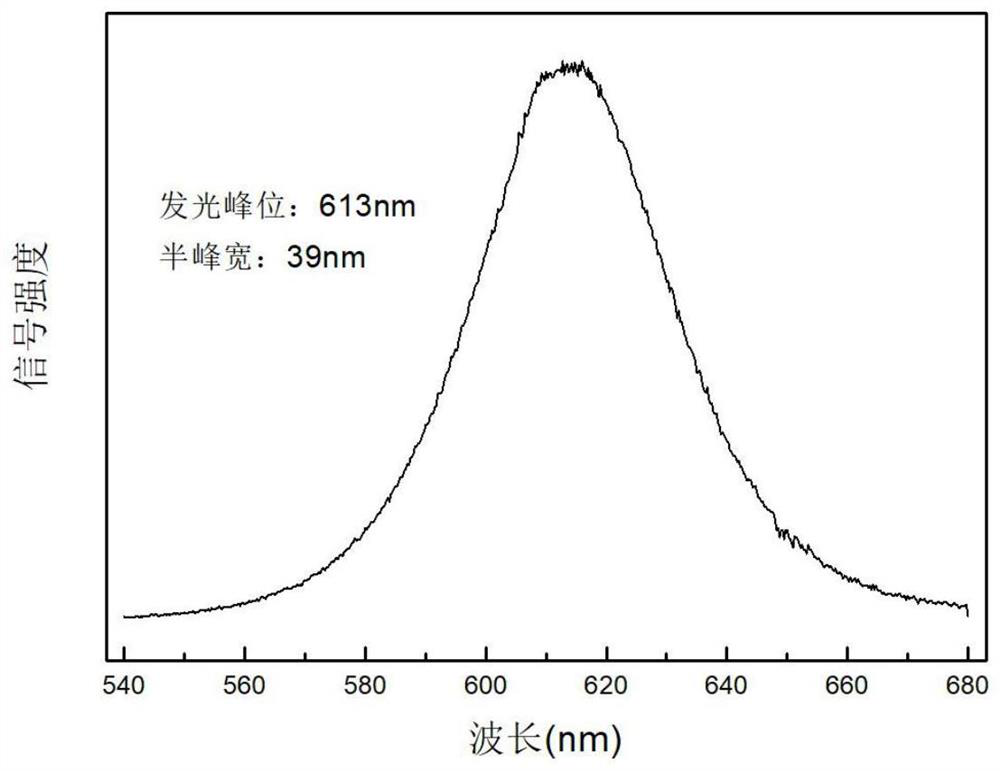

[0041] The glass matrix raw material and the quantum dot precursor raw material are according to the molar ratio of 30SiO 2 -30B 2 o 3 -20ZnO-10Cs 2 CO 3 -5PbBr 2 -5NaBr for proportioning, accurately weigh each raw material, pour the weighed solid powder into a corundum mortar and grind evenly, after screening with a particle size of 50 μm, place the screened powder in a graphite crucible. Place the graphite crucible with the sample in a hot isostatic pressing furnace to ensure good airtightness, then raise the temperature from room temperature to 300°C at a rate of 10°C / min, keep it warm for 20min, and turn on the vacuum pump to evacuate at the same time to remove water and oxygen. Turn off the vacuum pump, raise the temperature from 300°C to 1200°C at a rate of 5°C / min, control the pressure in the chamber to be constant at 5 MPa by filling with argon, and keep the t...

Embodiment 2

[0043] Example 2: Green light CsPbBr 3 Preparation of Perovskite Quantum Dot Phosphate Glass

[0044] According to molar ratio 56P 2 o 5 -10SiO 2 -10Cs 2 CO 3 -5PbBr 2 -6Sr 2 CO 3 -3Al 2 o 3 -10NaBr is used for proportioning. Since the melting point of phosphate glass is slightly lower, the melting temperature is set at 1150° C., kept for 20 minutes, and finally annealed at 500° C. for 4 hours. The other steps are the same as those in Example 1. The particle size of the ball-milled glass powder is about 6 μm, the luminescence peak is 522 nm, the half-maximum width is 24 nm, and the quantum efficiency is 42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com