Surface fixed taurine ligand porous membrane material, preparation method and its application in blood fat adsorption separating

A surface-fixed, porous membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, blood filtration, etc., to achieve the effects of easy control of process conditions, good production repeatability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

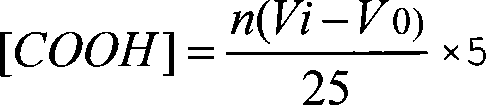

[0092] Cut the medical polypropylene non-woven fabric with an average pore size of 0.10 μm into 5cm×5cm 2 The samples were ultrasonically cleaned in acetone and water for 15 to 30 minutes, and dried in vacuum for later use. Then, soak the above-mentioned sample in an aqueous solution containing 10% (mass percentage) of acrylic acid monomer, which additionally contains 1.0wt% ferrous sulfate polymerization inhibitor and 0.5wt% sulfuric acid catalyst. After soaking for 24 hours, place the sample At 60 In the radiation field of Coγ-ray source, the total cumulative irradiation dose is controlled to 30KGy. After the above-mentioned irradiation treatment sample was taken out, it was washed, dried, weighed and calculated to obtain a copolymerization grafting rate of acrylic acid of 30 wt%, and the corresponding surface carboxyl group content of the obtained porous membrane carrier material was 25 μmol / cm 2 , ATR-FITR infrared spectrum analysis found that the sample was at 1700cm -...

Embodiment 2

[0094] Cut the 0.45μm medical polypropylene non-woven fabric into 5cm×5cm 2 The samples were ultrasonically cleaned in acetone and water for 15 to 30 minutes, and dried in vacuum for later use. The above samples were then soaked in an aqueous solution containing 15% acrylic acid monomer. Contain the ferrous sulfate polymerization inhibitor of 0.5wt% in the solution, the sulfuric acid catalyst of 1.0wt% simultaneously, after soaking for 24 hours, the sample is placed in 60 In the Coγ-ray source radiation field, the total cumulative irradiation dose is controlled to be 20KGy. After taking out the above-mentioned radiation treatment sample, wash, dry, weigh and calculate the copolymerization grafting rate of acrylic acid to be 84wt%, quantitative titration surface carboxyl content is 70μmol / cm 2 . ATR-FITR infrared spectrum analysis found that at 1700cm -1 A strong absorption peak appears at , corresponding to the characteristic absorption signal of the carboxyl group, indica...

Embodiment 3

[0096] Cut the 1.0μm medical polypropylene non-woven fabric into 5cm×5cm 2 The samples were ultrasonically cleaned in acetone and water for 15 to 30 minutes, and dried in vacuum for later use. The above sample was then soaked in an aqueous solution containing 15% by weight of acrylic acid monomer. Contain the ferrous sulfate polymerization inhibitor of 0.5wt% in the solution, the sulfuric acid catalyst of 0.5wt% simultaneously, after soaking 24 hours, the sample is placed in 60 In the Coγ-ray source radiation field, the total cumulative irradiation dose is controlled to be 30KGy. After taking out the above-mentioned irradiation treatment sample, wash, dry, weigh and calculate the copolymerization grafting rate of acrylic acid to be 75wt%, quantitative titration surface carboxyl content is 96μmol / cm 2 . ATR-FITR infrared spectrum analysis found that at 1700cm -1 A strong absorption peak appears at , corresponding to the characteristic absorption signal of the carboxyl group...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com