Adsorbing-catalyzing agent based on amino-functionalized ionic liquid and preparation method thereof

An amino-functionalized, ionic liquid technology, applied in physical/chemical process catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of high viscosity, high cost, restricted application of ionic liquids, etc. The effect of high rate and lower technology cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

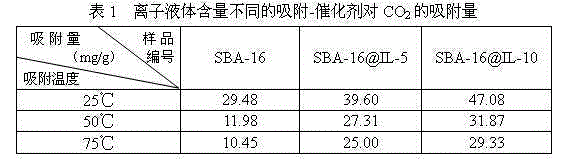

Examples

Embodiment 1

[0021] Weigh 0.274g (1mmol) N -[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole, 0.156g (1.2mmol) 3-chloropropylamine hydrochloride, added to 5mL of anhydrous acetonitrile, nitrogen protection, stirring Heating to 80°C under reflux for 24 hours. After the reaction, the solvent acetonitrile was removed by rotary evaporation, the obtained product was washed with absolute ethanol, and vacuum-dried at room temperature to obtain 0.4 g of amino functionalized ionic liquid.

[0022] Weigh 1 g of pure silicon mesoporous molecular sieve SBA-16, and disperse it together with the amino-functionalized ionic liquid prepared above in 50 mL of anhydrous acetonitrile, under nitrogen protection, and heat to reflux at 80°C for 24 hours under stirring. After the reaction was completed, the solid product was obtained by filtration, washed with absolute ethanol, dried, added to a Soxhlet extractor, extracted with dichloromethane for 48 hours, dried in vacuum, uniformly dispersed in 30 mL of absolu...

Embodiment 2

[0024] Weigh 0.822g (3mmol) N -[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole, 0.546g (4.2mmol) 3-chloropropylamine hydrochloride, added to 15mL of anhydrous acetonitrile, nitrogen protection, stirring Heating to 80°C under reflux for 36 hours. After the reaction was completed, the solvent acetonitrile was removed by rotary evaporation, the obtained product was washed with absolute ethanol, and vacuum-dried at room temperature to obtain 1.2 g of amino functionalized ionic liquid.

[0025] Weigh 1 g of pure silicon mesoporous molecular sieve SBA-16, and disperse it together with the amino-functionalized ionic liquid prepared above in 50 mL of anhydrous acetonitrile, under nitrogen protection, and heat to reflux at 80°C for 48 hours under stirring. After the reaction was completed, the solid product was obtained by filtration, washed with absolute ethanol, dried, added to a Soxhlet extractor, extracted with dichloromethane for 48 hours, dried in vacuum, uniformly dispersed in ...

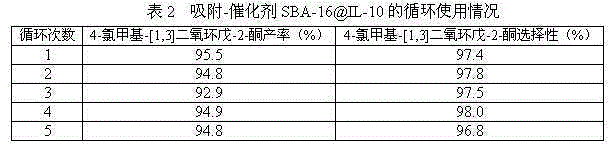

Embodiment 3

[0027] Weigh 1.370g (5mmol) N -[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole, 1.040g (8.0mmol) 3-chloropropylamine hydrochloride, added to 25mL of anhydrous acetonitrile, nitrogen protection, stirring Heated to 80°C under reflux for 48 hours. After the reaction was completed, the solvent acetonitrile was removed by rotary evaporation, the obtained product was washed with absolute ethanol, and vacuum-dried at room temperature to obtain 2.0 g of amino functionalized ionic liquid.

[0028] Weigh 1 g of pure silicon mesoporous molecular sieve SBA-16, and disperse it together with the amino-functionalized ionic liquid prepared above in 50 mL of anhydrous acetonitrile, under nitrogen protection, and heat to 80° C. for reflux reaction for 60 hours while stirring. After the reaction was completed, the solid product was obtained by filtration, washed with absolute ethanol, dried, added to a Soxhlet extractor, extracted with dichloromethane for 48 hours, dried in vacuum, uniformly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com