Positively charged polyvinyl chloride hollow fiber nanofiltration membrane and preparation method thereof

A polyvinyl chloride, positively charged technology, applied in the field of membrane separation, can solve the problems of high cost of raw materials, and achieve the effects of strong anti-pollution, low requirements for influent pretreatment, and strong capacity of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

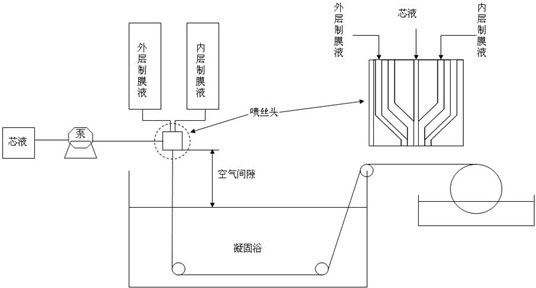

[0032] The steps of the preparation method of the positively charged polyvinyl chloride hollow fiber nanofiltration membrane are as follows:

[0033] 1) 20-30% by weight of polyvinyl chloride, 3.33-20% by weight of cationic copolymer, 1-5% by weight of pore size regulator, and 0.1-1% by weight of heat stabilizer Mix with a solvent with a weight percentage of 54-75%, stir and dissolve at 50-70°C to form a film-making solution with a uniform positively charged dense skin layer; the pore size regulator is polyvinylpyrrolidone, polyethylene glycol or Glycerol, the number average molecular weight of polyvinylpyrrolidone is 1×10 3 -1×10 4 , The number average molecular weight of polyethylene glycol is 1×10 2 -1×10 3 ;

[0034] 2) Combine 15-25% by weight of polyvinyl chloride, 1-5% by weight of pore size regulator, 0-2% by weight of inorganic filler, 0.1-1% by weight of heat stabilizer and Mixing 67-84% solvent by weight, stirring and dissolving at 50-70°C to form a membrane-ma...

Embodiment 1

[0043] 1) Mix 330g polyvinyl chloride (PVC), 200g allyltriphenylphosphine chloride-vinyl chloride copolymer, 35g polyethylene glycol, 2g tributyltin chloride and 1000g N,N'-dimethyl Acetamide (DMAc) was mixed, stirred and dissolved at 70°C for 24 hours to form a film-making solution (cortex) with a uniform positively charged dense skin layer;

[0044] 2) Mix 250g of polyvinyl chloride, 40g of polyethylene glycol, 5g of silicon nitride, 2g of tributyltin chloride and 1000g of N,N'-dimethylacetamide (DMAc), stir and dissolve at 70°C to form Membrane-making solution (support layer) for uniform charge-neutral porous support layer;

[0045] 3) Pass the core liquid at 60°C through the central tube of a spinneret with a double-layer structure, and the film-making liquid with a positively charged dense skin layer at 70°C pass through the inner ring of a spinneret with a double-layer structure at 70°C. The film-forming solution of the electrically neutral porous support layer passes t...

Embodiment 2

[0056]1) Mix 450g polyvinyl chloride (PVC), 48.3g trimethylallylammonium chloride-vinyl chloride copolymer, 14.9g polyethylene glycol, 1.5g tributyltin chloride and 1000g N,N'- Dimethylformamide (DMF) was mixed, stirred and dissolved at 50°C for 24 hours to form a film-making solution (skin layer) with a uniform positively charged dense skin layer;

[0057] 2) Mix 330g of polyvinyl chloride, 67g of polyethylene glycol, 0g of silicon nitride, 2g of tributyltin chloride and 1000g of DMF, stir and dissolve at 50°C to form a uniform film-making solution for the electrically neutral porous support layer (support layer);

[0058] 3) Pass the core liquid at 30°C through the central tube of a spinneret with a double-layer structure, and the film-making liquid with a positively charged dense skin at 50°C pass through the outer ring of a spinneret with a double-layer structure at 50°C. The film-making liquid of the electrically neutral porous support layer passes through the inner ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com