A kind of biodegradable medical nerve repair catheter and preparation method thereof

A nerve repair and biodegradation technology, applied in the medical field, can solve the problems of difficulty in ensuring the quality of the terminal catheter, complex preparation process, poor air permeability, etc., and achieve the effects of good elasticity, good biocompatibility, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

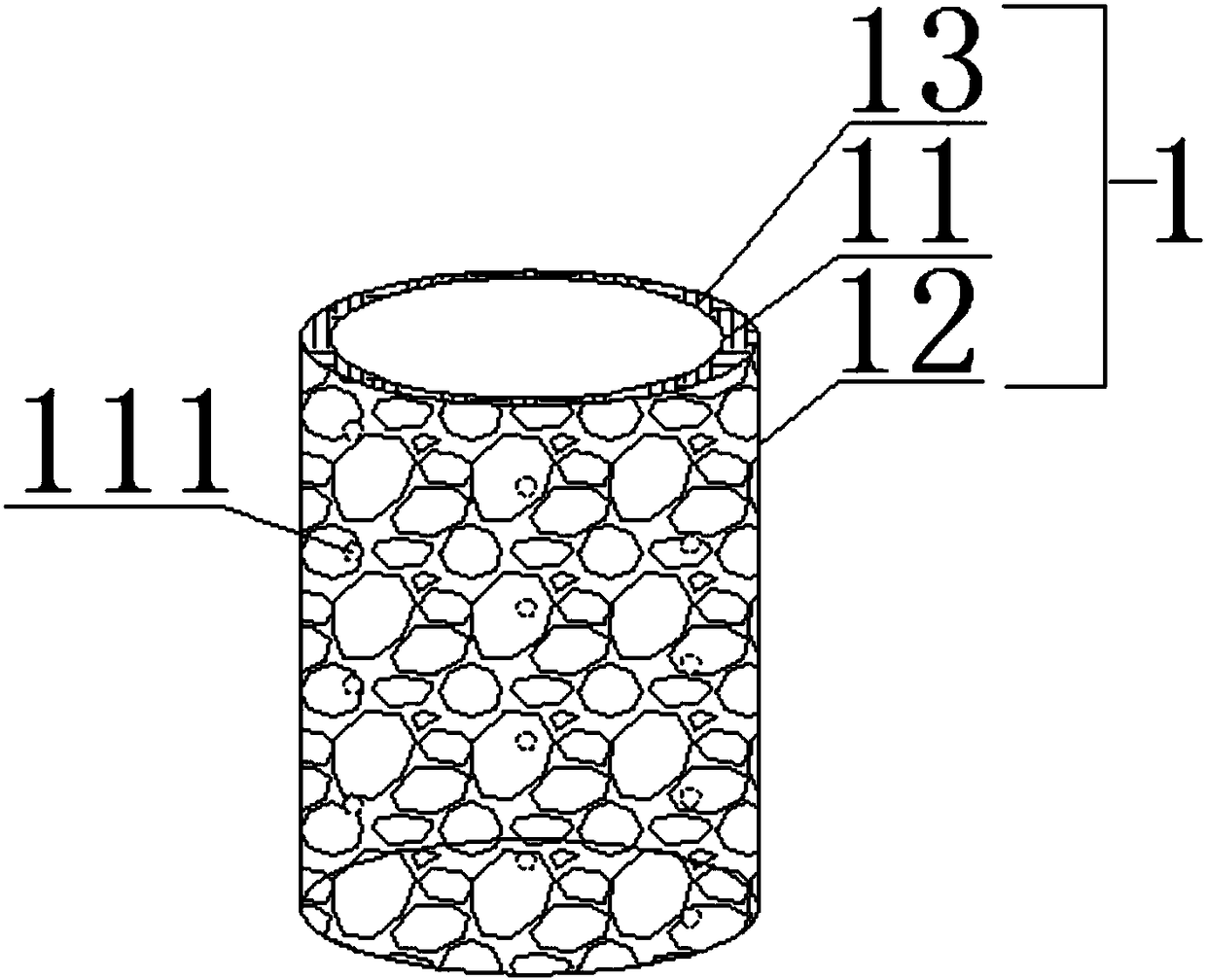

[0032] structure figure 1 A specific embodiment of the present invention is shown: a biodegradable medical catheter for nerve repair, including a catheter body 1, the catheter body 1 includes an inner tube 11 and an outer tube 12, and an outer tube 12 and an inner tube 11 are provided There is a fibrous film layer 13, and the fibrous film layer 13 is made by mixing silk fibroin fibers and polylactic acid fibers. The inner diameter of the outer tube 12 is 0.5 mm, and the wall thickness of the outer tube 12 is 0.05 mm. The inner diameter is 0.2 mm, the wall thickness of the inner tube 11 is 0.1 mm, and the wall thickness of the fiber film layer is 0.2 mm. The outer wall of the inner tube 11 is provided with some air holes 111, and the outer tube 12 is made of a porous material. , the porous material is composed of trimethylene carbonate, polyethylene lactide and silk fibroin.

[0033] In this embodiment, the inner tube 11 is composed of chitosan, collagen, lecithin and chitin. ...

Embodiment 2

[0046] structure figure 1 A specific embodiment of the present invention is shown: a biodegradable medical nerve repair catheter, including a catheter body 1, the catheter body 1 includes an inner tube 11 and an outer tube 12, and a There is a fibrous film layer 13, and the fibrous film layer 13 is made by mixing silk fibroin fibers and polylactic acid fibers. The inner diameter of the outer tube 12 is 1.5 mm, and the wall thickness of the outer tube 12 is 0.01 mm. The inner diameter is 1.2 millimeters, the wall thickness of the inner tube 11 is 0.2 millimeters, the wall thickness of the fiber film layer is 0.1 millimeters, and the outer wall of the inner tube 11 is provided with some air holes 111, and the outer tube 12 is made of a porous material , the porous material is composed of trimethylene carbonate, polyethylene lactide and silk fibroin.

[0047] In this embodiment, the inner tube 11 is composed of chitosan, collagen, lecithin and chitin.

[0048] In this embodimen...

Embodiment 3

[0059] structure figure 1 A specific embodiment of the present invention is shown: a biodegradable medical nerve repair catheter, including a catheter body 1, the catheter body 1 includes an inner tube 11 and an outer tube 12, and a There is a fibrous film layer 13, and the fibrous film layer 13 is made by mixing silk fibroin fibers and polylactic acid fibers. The inner diameter of the outer tube 12 is 1 mm, and the wall thickness of the outer tube 12 is 0.02 mm. The inner diameter is 0.2 mm, the wall thickness of the inner tube 11 is 0.3 mm, and the wall thickness of the fiber film layer is 0.5 mm. The outer wall of the inner tube 11 is provided with some air holes 111, and the outer tube 12 is made of porous material. , the porous material is composed of trimethylene carbonate, polyethylene lactide and silk fibroin.

[0060] In this embodiment, the inner tube 11 is composed of chitosan, collagen, lecithin and chitin.

[0061] In this embodiment, the raw material compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com