Spray polyurea elastomer applied to anticorrosion of offshore drilling platform and its preparation method and construction method

An offshore drilling platform, polyurea elastomer technology, applied in anti-corrosion coatings, coatings, devices for coating liquids on surfaces, etc., can solve problems such as poor anti-corrosion, achieve good adhesion, excellent adhesion, and excellent material properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A: A prepolymer prepared by 51 parts of diphenylmethane diisocyanate and 50 parts of epoxy-modified polyether. The NCO content of the prepolymer was 16%.

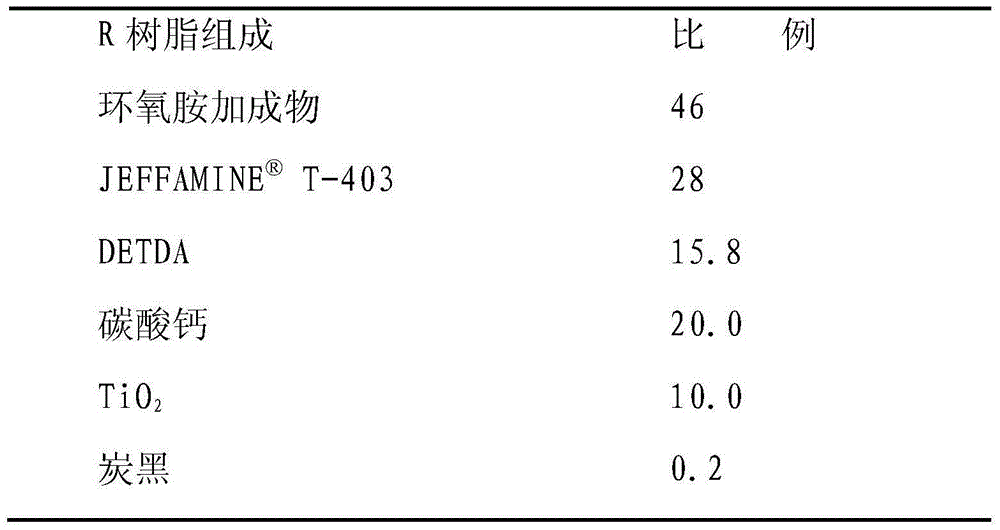

[0048] R: from epoxy amine adducts, T-403, DETDA amino resin and TiO2, carbon black, calcium carbonate mixture. Accurately weigh the various raw materials in the R component according to the formula, add them into the paint tank, and stir at high speed for 30 minutes with high-speed shearing and dispersing equipment.

[0049] The specific ratio is shown in the table below.

[0050]

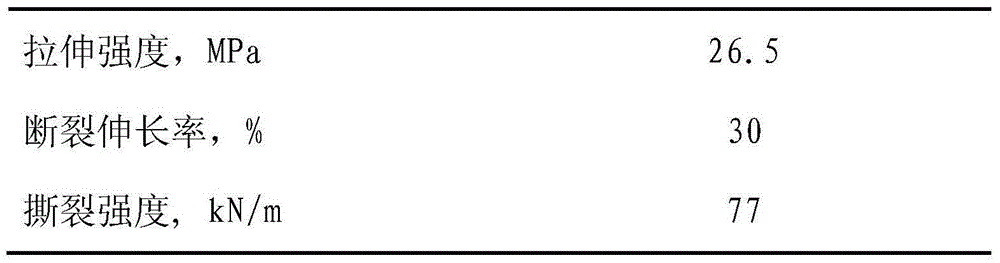

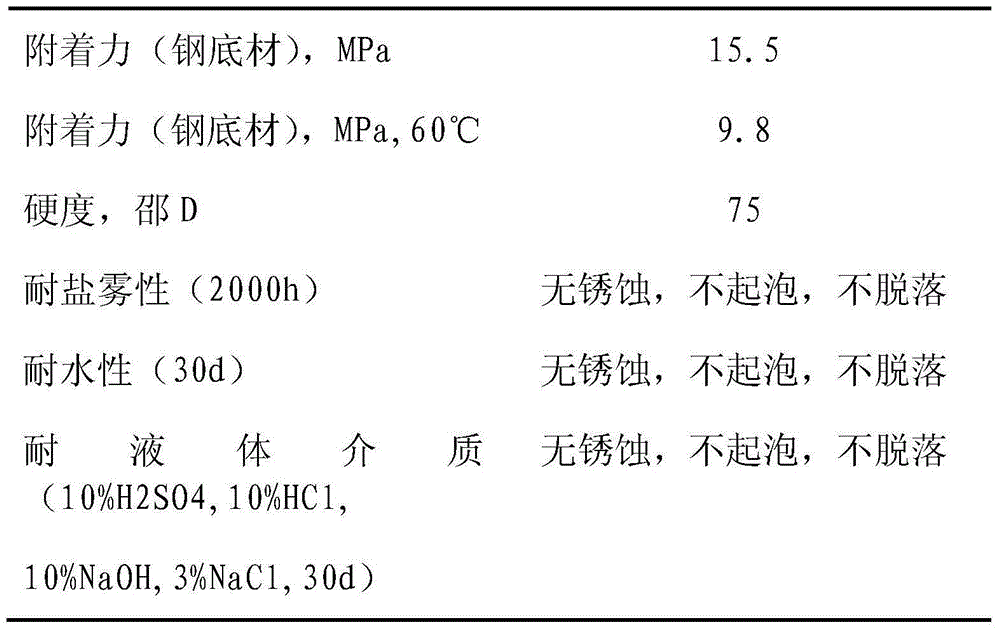

[0051] Main physical properties:

[0052]

[0053]

Embodiment 2

[0055] A is a prepolymer prepared from 30 parts of diphenylmethane diisocyanate and 44 parts of polyphenylmethane diisocyanate and 50 parts of epoxy-modified polyol. The NCO content of the prepolymer was 18%. The R component consists of epoxy amine adducts, D-400, DETDA amino resin and TiO2, carbon black, talcum powder, mica powder mixture. Accurately weigh the various raw materials in the R component according to the formula, add them into the paint tank, and stir at high speed for 30 minutes with high-speed shearing and dispersing equipment.

[0056] The specific ratio is shown in the table below.

[0057]

[0058] Main physical properties:

[0059]

Embodiment 3

[0061] A Prepolymer is prepared from about 30 parts of diphenylmethane diisocyanate and 44 parts of polyphenylmethane polyisocyanate and 50 parts of epoxy-modified polyol. The NCO content of the prepolymer was 18%. The R component consists of epoxy amine adducts, T-403 amino resin, T-5000, DETDA amino resin, TiO 2 , mica powder mixture. Accurately weigh the various raw materials in the R component according to the formula, add them into the paint tank, and stir at high speed for 30 minutes with high-speed shearing and dispersing equipment.

[0062] The specific ratio is shown in the table below.

[0063]

[0064]

[0065] Main physical properties:

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com