A Polyethylene Glycol Functionalized Montmorillonite/Polyether Copolyamide Mixed Matrix Membrane for Gas Separation

A polyether copolyamide and mixed matrix membrane technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of reducing gas separation performance, restricting gas separation, etc., achieving excellent mechanical properties, small loss, Good film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

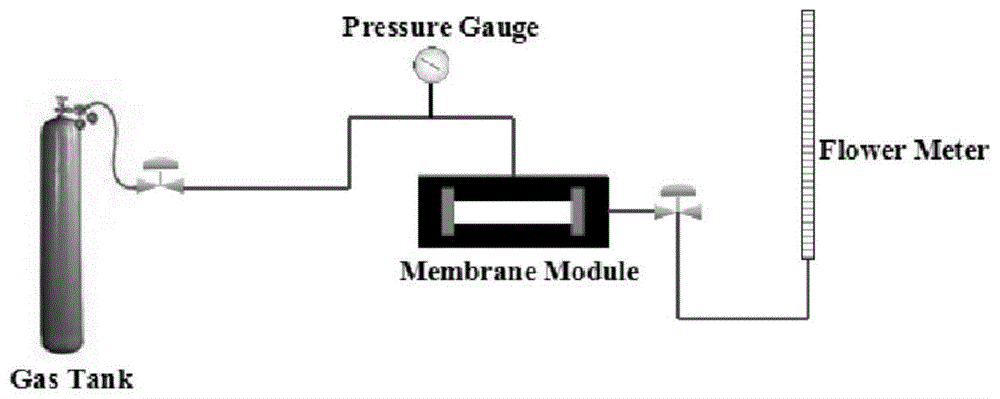

Method used

Image

Examples

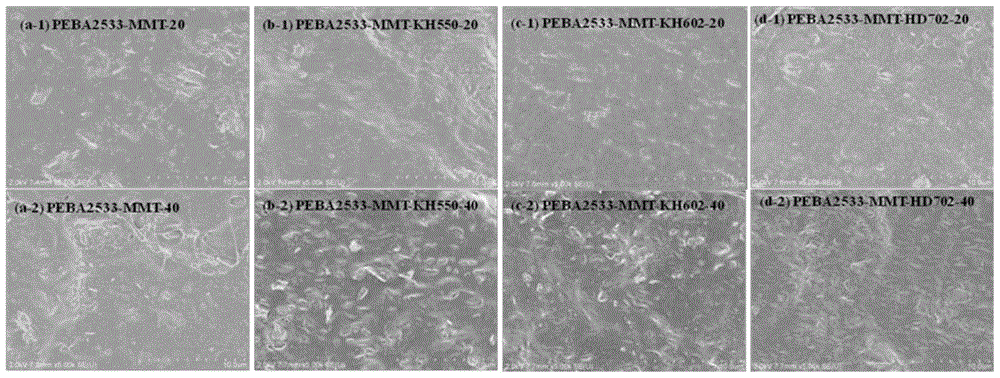

Embodiment 1

[0023] The preparation of polyethylene glycol functionalized montmorillonite / polyether copolyamide mixed matrix film comprises the following steps, and the described formula ratio is by mass percentage:

[0024] (1) Preparation of polyethylene glycol-functionalized montmorillonite: (a) Dissolve 4 parts of montmorillonite and 10 parts of silane coupling agent in 90 parts of toluene, stir and react at 80°C for 6h, then turn to room temperature Stir overnight. The precipitate is filtered, purified in a Soxhlet extractor for 15 hours, and dried in an oven overnight to obtain a light brown product; (b) 4 parts of polyethylene glycol (molecular weight 1000), 1 part of triethylamine and p- 15 parts of nitrophenyl chloroformate were dissolved in 80 parts of dry tetrahydrofuran, and the reaction was stirred at room temperature overnight. Then it was purified by silica gel chromatography and dried in vacuum to obtain a white product; (c) the (a) 4 parts of the product in (b) and 2 parts...

Embodiment 2

[0029] The preparation of polyethylene glycol functionalized montmorillonite / polyether copolyamide mixed matrix film comprises the following steps, and the described formula ratio is by mass percentage:

[0030] (1) Preparation of polyethylene glycol-functionalized montmorillonite: (a) Dissolve 6 parts of montmorillonite and 11 parts of silane coupling agent in 95 parts of toluene, stir and react at 80°C for 6h, then turn to room temperature Stir overnight. The precipitate is filtered, purified in a Soxhlet extractor for 15 hours, and dried in an oven overnight to obtain a light brown product; (b) 8 parts of polyethylene glycol (molecular weight 2000), 2 parts of triethylamine and p- 20 parts of nitrophenyl chloroformate were dissolved in 85 parts of dry tetrahydrofuran, and the reaction was stirred overnight at room temperature. Then it was purified by silica gel chromatography and dried in vacuum to obtain a white product; (c) the (a) 8 parts of the product in (b) and 4 part...

Embodiment 3

[0035] The preparation of polyethylene glycol functionalized montmorillonite / polyether copolyamide mixed matrix film comprises the following steps, and the described formula ratio is by mass percentage:

[0036] (1) Preparation of polyethylene glycol functionalized montmorillonite: (a) Dissolve 8 parts of montmorillonite and 12 parts of silane coupling agent in 94 parts of toluene, stir and react at 80°C for 6h, then turn to room temperature Stir overnight. The precipitate is filtered, purified in a Soxhlet extractor for 15 hours, and dried in an oven overnight to obtain a light brown product; (b) 8 parts of polyethylene glycol (molecular weight 5000), 2 parts of triethylamine and p- Dissolve 18 parts of nitrophenyl chloroformate in 85 parts of dry tetrahydrofuran, and stir and react overnight at room temperature. Then it is purified by silica gel chromatography and dried in vacuum to obtain a white product; (c) combine (a) 8 parts of the product in (b) and 4 parts of the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com