Multicomponent oxide containing cobalt nickel and preparation and application thereof

A multi-component and oxide technology, applied in the field of high-energy electrochemistry, can solve the problems of short storage time of slurry without freezing, uneven product composition and performance, difficulty in mixing uniform precursor materials, etc., and achieve good processing behavior , good fluidity and uniformity, and strong process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

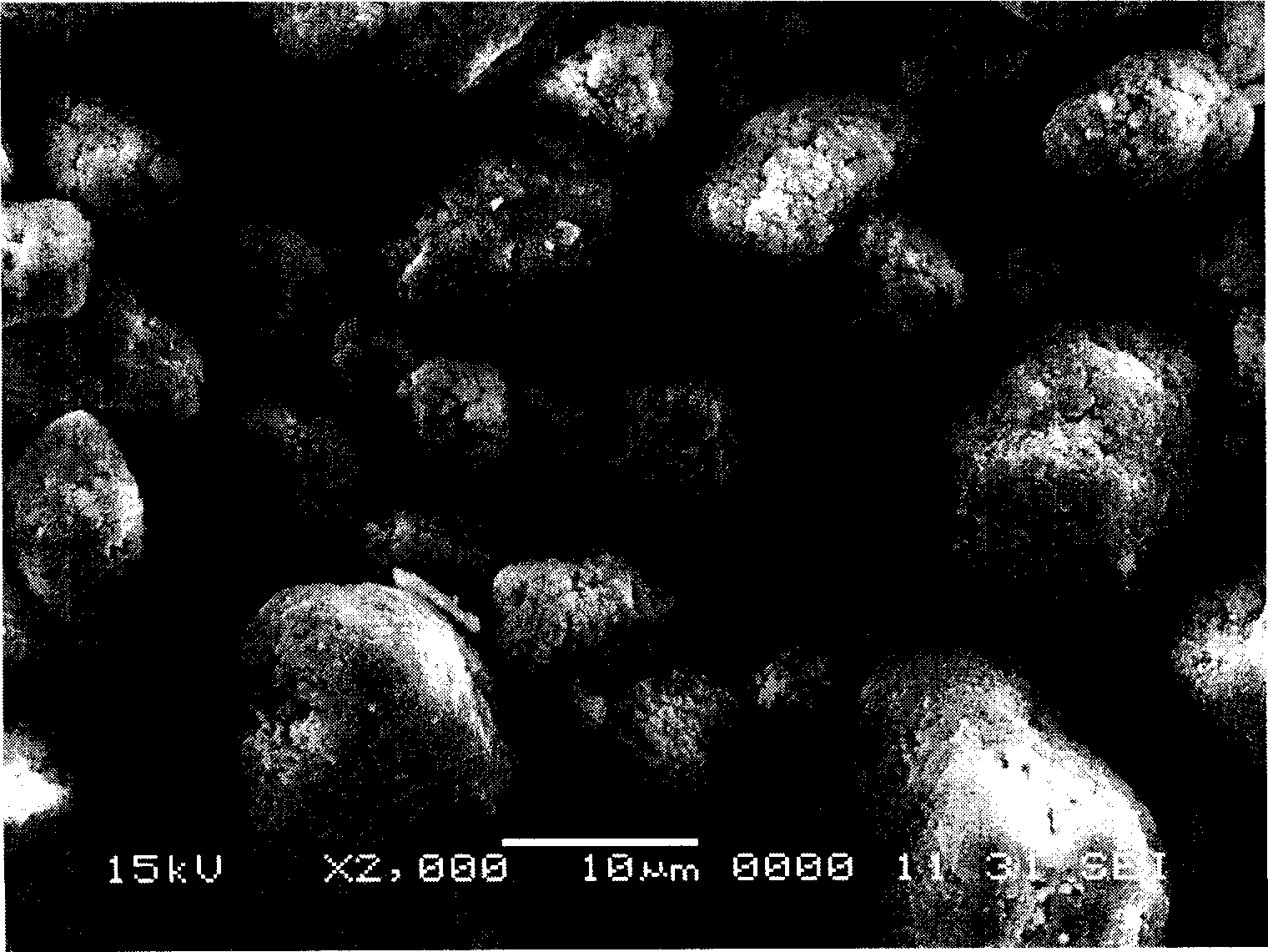

[0027] The preparation method of the multi-component oxide containing cobalt and nickel is to prepare a mixed complex solution of nickel, cobalt, metal M and ammonia in the ammonia water-amine salt or ammonia water-weak acid buffer solution with a pH value of 8-11, and then Slowly add the lye into the reaction kettle at the same time for coprecipitation reaction, wherein the coprecipitation reaction time is 4-10 hours, the reaction temperature is 40-80°C, the stirring speed is 240-1000rpm, and Ni-Co-M composite hydroxide is generated The Ni-Co-M composite hydroxide particles are aged, separated and washed to obtain ellipsoidal Ni-Co-M composite hydroxide particles with uniform particle size, high density and excellent electrochemical performance; Dry the Ni-Co-M composite hydroxide particles in an air atmosphere or a vacuum environment at 60-120°C for 16-36 hours, then mix with lithium hydroxide or lithium salt, and heat treat the mixture at 240-550°C 3-7 hours; and then heat-...

Embodiment 1

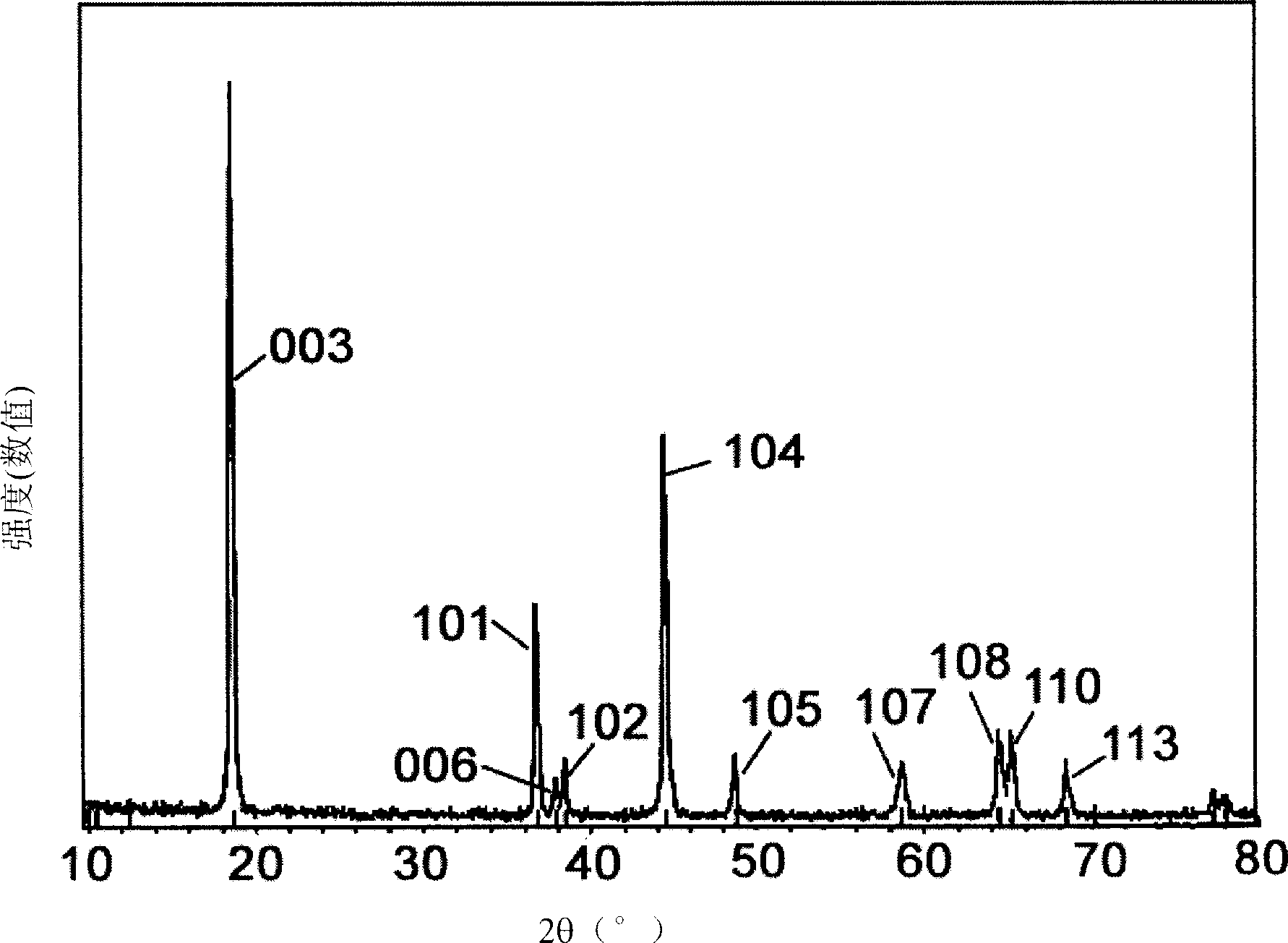

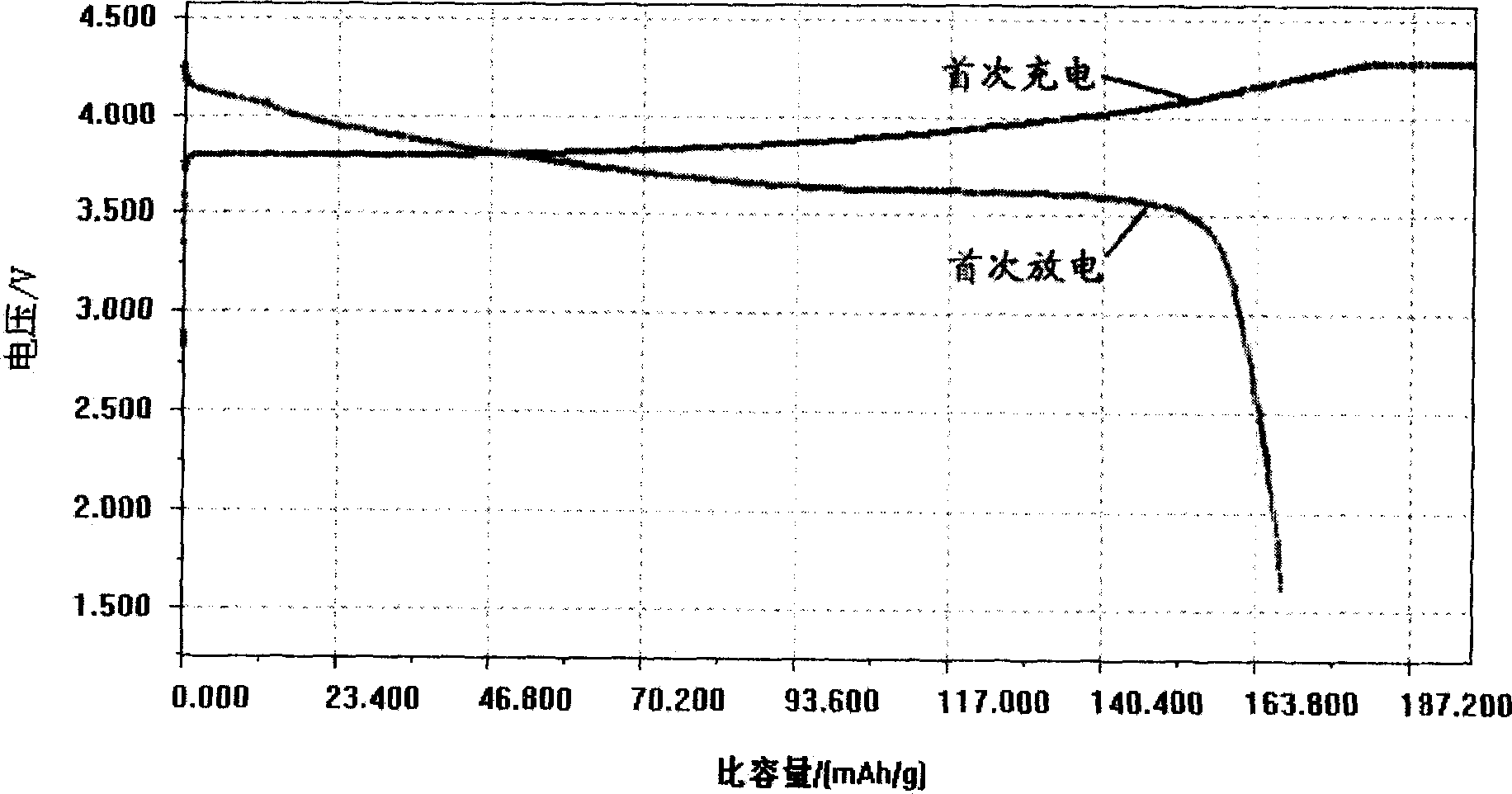

[0029] Embodiment 1: positive electrode active material LiNi 0.75 co 0.1 al 0.1 mn 0.05 o 2 The preparation and performance structure test

[0030] Take a total of 8.5 moles of nickel (Ni) and cobalt (Co) sulfates at a molar ratio of 0.75:0.1, and slowly add them into a buffer solution with a pH value of 10 prepared by ammonia water and ammonium sulfate under constant stirring to obtain nickel-cobalt Mix 10L of ammonia complex solution with 10L, 2.2M NaOH and 0.1M Al 2 (SO4) 3At the same time, the mixed aqueous solution was slowly dropped into a reaction kettle filled with 7L aqueous solution whose pH value was adjusted to 11 with 2.2M pure NaOH solution, the reaction temperature was 40°C, and the stirring speed was 400rpm. After 6 hours, the Ni-Co-Al composite hydroxide was isolated. After aging for 2 hours, it was washed several times with distilled water and then dried at 80°C for 16 hours. After grinding and sieving, the precursor was obtained. Manganese carbonate a...

Embodiment 2

[0032] Embodiment 2: positive electrode active material LiNi 0.85 co 0.1 mn 0.02 Ti 0.02 Cu 0.01 o 2 The preparation and performance structure test

[0033] According to the molar ratio of 0.85:0.1:0.02:0.01, a total of 9.8 moles of nickel (Ni), cobalt (Co), manganese (Mn), and copper (Cu) sulfates are added slowly under constant stirring to prepare from ammonia water and ammonium sulfate. In the buffer solution with a pH value of 9, 10L of nickel-cobalt-manganese-copper-ammonia mixed complex solution was prepared. Under constant stirring, it was mixed with 10L of 2.2M NaOH aqueous solution and slowly dripped into 7L of aqueous solution with 2.2 M pure NaOH solution adjusted its pH value to 10 in the reactor, the reaction temperature was 50 ° C, and the stirring speed was 600 rpm. After 7 hours, the Ni-Co-Mn-Cu composite hydroxide was isolated, aged for 1 hour, washed several times with distilled water, dried at 100°C for 10 hours, ground and sieved to prepare the precur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com