Preparation method for methotrexate/layered double hydroxide nanocomposite

A nano-composite material, layered bimetal technology, applied in the direction of drug combination, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc. resources and other issues, to achieve the effect of low equipment cost, energy saving and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) At room temperature, Mg(NO 3 ) 2 ?6H 2 O and Al(NO 3 ) 3 ?9H 2 O carry out pre-grinding 2min;

[0034] 2) Prepare a NaOH solution with a concentration of 10.5mol / L;

[0035] 3) Weigh 0.7692g Mg(NO 3 ) 2 ?6H 2 O and 0.5627g Al(NO 3 ) 3 ?9H 2 O placed in an agate mortar in which Mg 2+ / Al 3+ =2:1; add 0.3408g MTX, then drop 1.15ml of the NaOH solution prepared in step 2), mix well, and grind at a constant speed for 60min. Centrifuged and washed 4 times with distilled water to obtain the MTX / LDH precursor;

[0036] 4) Add water to the precursor prepared in step 3) and sonicate to prepare a 2mol / L precursor solution, and then put it into a polytetrafluoroethylene-lined reactor for peptization. The peptization temperature is 80°C. The melting time was 24 hours, and the product was dried to obtain the MTX / LDH nanocomposite material.

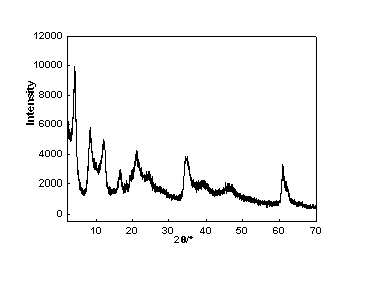

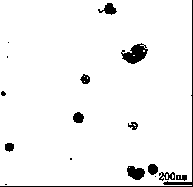

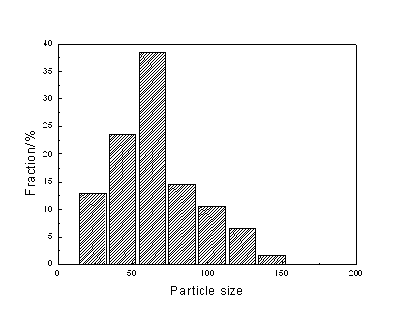

[0037] figure 1 The XRD pattern of the MTX / LDH nanocomposite material that is the present embodiment made, figure 1 showed...

Embodiment 2

[0041] 1) At room temperature, Zn(NO 3 ) 2 ?6H 2 O and Al(NO 3 ) 3 ?9H 2 O carries out pre-grinding 5min;

[0042] 2) Prepare NH with a concentration of 8mol / L 3 ?H 2 O solution;

[0043] 3) Weigh 0.9520g Zn(NO 3 ) 2 ?6H 2 O and 0.5627g Al(NO 3 ) 3 ?9H 2 O is placed in a grinding tool, where Zn 2+ / Al 3+ =2:0.8; add 0.3636 gMTX, then drop 2.8ml of NH prepared in step 2) 3 ?H 2 O solution, mix evenly, and grind at a constant speed for 40 minutes. Centrifuged and washed 3 times with distilled water to obtain the MTX / LDH precursor;

[0044] 4) Add water to the precursor prepared in step 3) and sonicate to prepare a 0.5mol / L precursor solution, put it in the reaction kettle for peptization, the peptization temperature is 100°C, and the peptization time is 48h, and the product is dried. Prepared MTX / LDH nanocomposites.

[0045] The resulting XRD pattern shows that: with the parent LDH-NO 3 Compared to the composite d 003 The characteristic diffraction peak shi...

Embodiment 3

[0047] 1) At room temperature, Mg(NO 3 ) 2 ?6H 2 O and Fe(NO 3 ) 3 ?9H 2 O carries out pre-grinding 3min;

[0048] 2) Prepare a NaOH solution with a concentration of 12mol / L;

[0049] 3) Weigh 0.6410 g Mg(NO 3 ) 2 ?6H 2 O and 0.6060g Fe(NO 3 ) 3 ?9H 2 O placed in the grinding utensils, wherein, Mg 2+ / Fe 3+ =2:1.2; Add 0.2840 gMTX, then drop 1.57ml of the NaOH solution prepared in step 2), mix well, and grind at a constant speed for 160min. Centrifuged and washed 4 times with distilled water to obtain the MTX / LDH precursor;

[0050] 4) Add water to the precursor prepared in step 3) and sonicate it to prepare a 3mol / L precursor solution, and put it into a polytetrafluoroethylene-lined reactor for peptization. The peptization temperature is 120°C. The time was 12 h, and the product was dried to obtain the MTX / LDH nanocomposite material.

[0051] The resulting XRD pattern shows that: with the parent LDH-NO 3 Compared to the composite d 003 The characteristic dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com