Autoclaved aerated concrete block using ceramic polishing waste and its preparation method

A technology of ceramic polishing waste and concrete blocks, which is applied in the direction of ceramic molding machines and manufacturing tools, and can solve the problems of affecting the hydration of micropowder, the decrease of concrete strength, and the decrease of relative concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

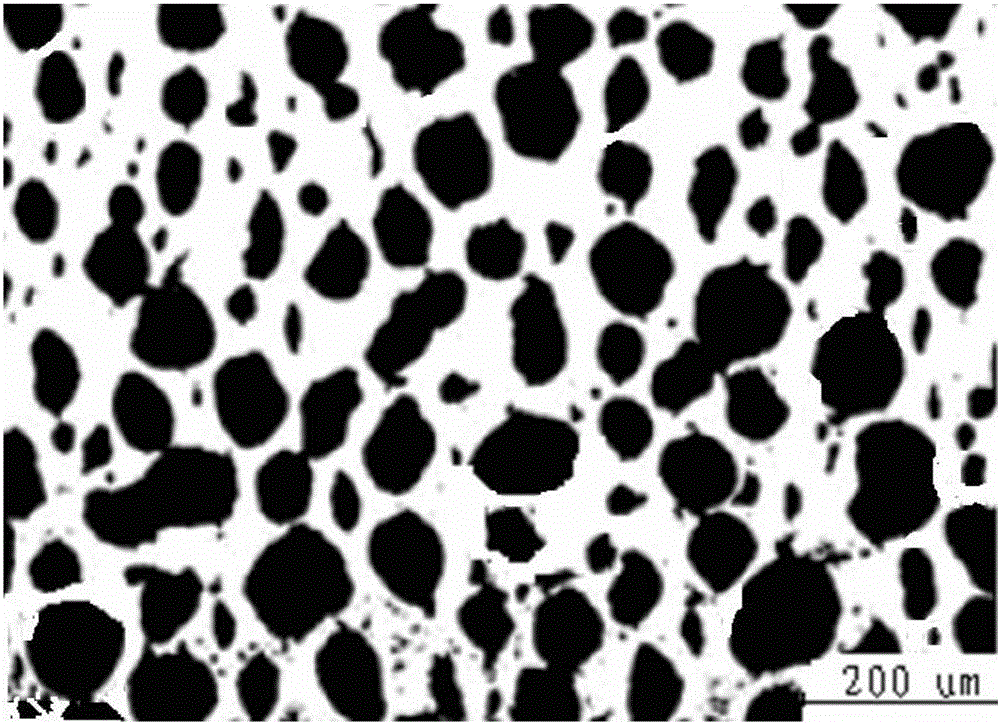

Image

Examples

Embodiment 1

[0090] One, the preparation of surface-treated ceramic polishing waste b):

[0091]The silane coupling agent gamma-aminopropyltriethoxysilane (or the aqueous solution form with 10wt% concentration) of 1.0kg is sprayed to the ceramic polishing waste dry powder (average particle size 0.21mm) of 100kg under high-speed stirring state , stir and disperse at high speed for 15-20 minutes, and then heat the mixture to 50-60° C. to obtain b) surface-treated ceramic polishing waste fine powder (average particle size 0.21 mm).

[0092] 2. Preparation of blocks

[0093] The consumption or proportioning (according to parts by weight) of the raw material that adopts is:

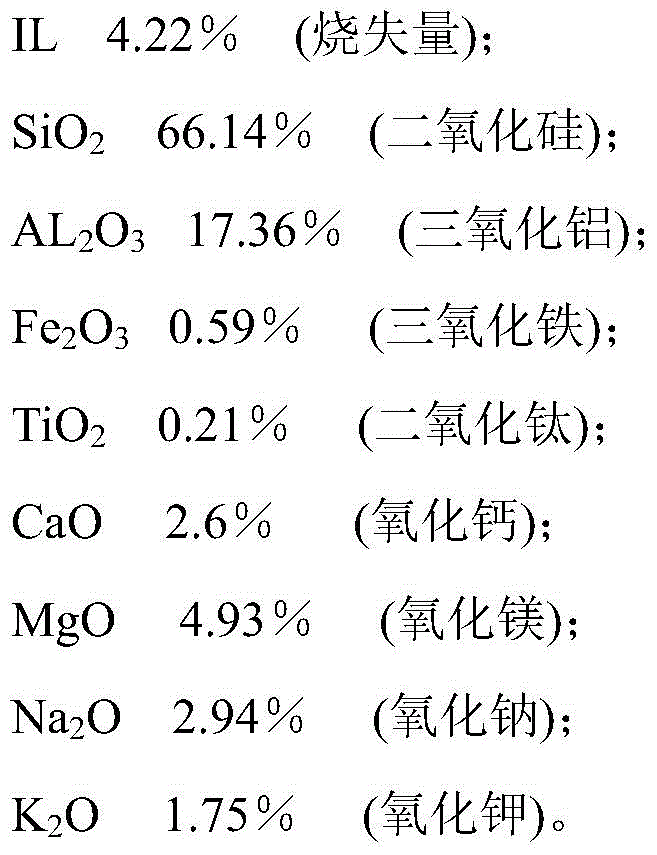

[0094] a) 500kg of ceramic polishing waste (taken from a ceramic factory in Foshan, with an average particle size of 0.06mm);

[0095] b) Surface treated ceramic polishing waste fine powder 70kg;

[0096] c) Fine sand (grain size: 60 mesh, 0.3mm) 80kg;

[0097] d) quicklime 200kg;

[0098] e) Cement (425#) 150kg;

[...

Embodiment 2

[0120] Repeat embodiment 1, just the consumption or proportioning (according to parts by weight) of the raw material that adopts is:

[0121] The consumption or proportioning (according to parts by weight) of the raw material that adopts is:

[0122] a) 500kg of ceramic polishing waste (taken from a ceramic factory in Foshan);

[0123] b) Surface-treated ceramic polishing waste fine powder 85kg;

[0124] c) Fine sand (particle size: 60 mesh, 0.3mm) 72kg;

[0125] d) quicklime 210kg;

[0126] e) Cement (425#) 160kg;

[0127] f) Aluminum powder (Foshan Junli Aerated Aluminum Paste Factory, GLS-65 aluminum powder) 0.5kg;

[0128] g) Silica fume (Shanghai Tiankai Silica Fume Material Co., Ltd., 920 type) 50kg;

[0129] h) rubber powder (synthetic styrene-butadiene rubber waste tire powder, average particle size 350um) 30kg;

[0130] i) 45 kg of hemihydrate gypsum; and

[0131] j) Water reducer (Hunan Pioneer Building Materials Co., Ltd., Dingli brand XF type): 20kg;

[013...

Embodiment 3

[0138] Repeat embodiment 1, just the consumption or proportioning (according to parts by weight) of the raw material that adopts is:

[0139] a) 500kg of ceramic polishing waste (taken from a ceramic factory in Foshan);

[0140] b) Surface-treated ceramic polishing waste fine powder 85kg;

[0141] c) Fine sand (particle size: 60 mesh, 0.3mm) 72kg;

[0142] d) quicklime 210kg;

[0143] e) Cement (425#) 160kg;

[0144] f) Aluminum powder (Foshan Junli Aerated Aluminum Paste Factory, GLS-65 aluminum powder) 0.5kg;

[0145] g) Silica fume (Shanghai Tiankai Silica Fume Material Co., Ltd., 920 type) 50kg;

[0146] h) rubber powder (synthetic styrene-butadiene rubber waste tire powder, average particle size 350um) 30kg;

[0147] i) 45 kg of hemihydrate gypsum; and

[0148] j) Water reducer (Hunan Pioneer Building Materials Co., Ltd., Dingli brand XF type): 20kg;

[0149] k) Slag powder: 42kg;

[0150] The finished blocks are inspected according to the national standard GB 119...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com