Dopamine-modified metal organic compound/polyether co-polyamide mixed substrate membrane and preparation and application thereof

A polyether copolyamide and organic compound technology, which is applied in the field of gas membrane separation membrane preparation, can solve the problems that have not been reported in the research, and achieve the effect of excellent separation performance, long-lasting physical structure and performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

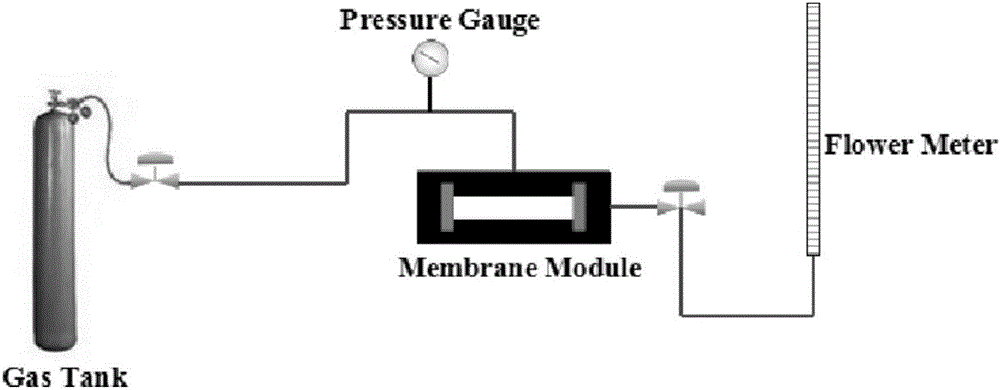

Method used

Image

Examples

Embodiment 1

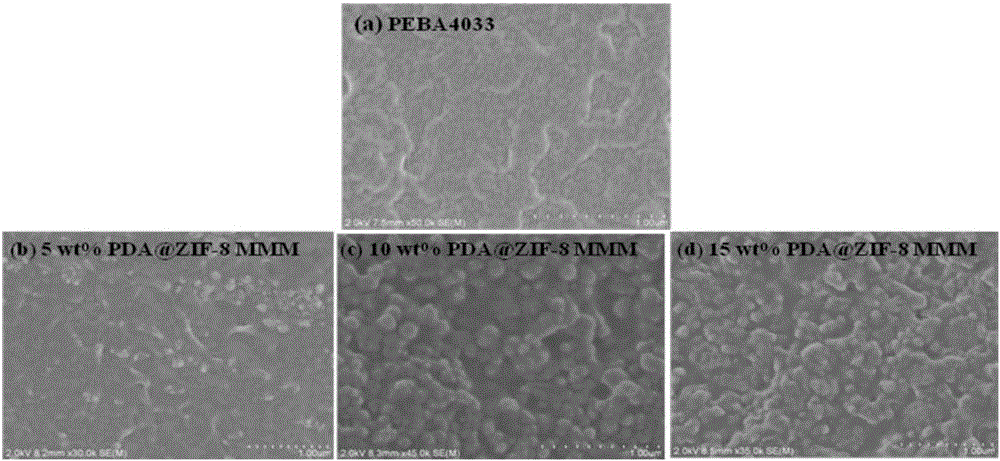

[0020] The preparation of dopamine-modified metal-organic compound / polyether copolyamide mixed matrix film comprises the following steps, and the formula ratio is by mass percentage:

[0021] (1) Preparation of dopamine-modified metal-organic compounds: Add dopamine to tris buffer at pH 8.0 to configure a dopamine solution with a concentration of 1 mg / ml, according to the mass of metal-organic compounds (ZIF-8) and dopamine The ratio is 1:2, ZIF-8 is added to the above solution, stirred and reacted at room temperature for 3 hours, centrifuged, washed with water, and dried to obtain a black dopamine-modified metal organic compound (PDA@ZIF-8);

[0022] (2) Preparation of mixed matrix membrane: dissolve polyether block copolyamide (PEBA4033) in n-butanol, and configure a polyether block copolyamide solution with a concentration of 3%; according to PEBA4033 and PDA in step (1) The mass ratio of @ZIF-8 is 0.85:0.15. Add PDA@ZIF-8 to the above PEBA4033 solution, stir at room temper...

Embodiment 2

[0025] The preparation of dopamine-modified metal-organic compound / polyether copolyamide mixed matrix film comprises the following steps, and the formula ratio is by mass percentage:

[0026] (1) Preparation of dopamine-modified metal-organic compounds: Add dopamine to tris buffer at pH 8.0 to configure a dopamine solution with a concentration of 1 mg / ml, according to the mass of metal-organic compounds (ZIF-8) and dopamine The ratio is 1:5, ZIF-8 is added to the above solution, stirred and reacted at room temperature for 12 hours, centrifuged, washed with water, and dried to obtain a black dopamine-modified metal organic compound (PDA@ZIF-8);

[0027] (2) Preparation of mixed matrix membrane: dissolve polyether block copolyamide (PEBA2533) in n-butanol, and configure a polyether block copolyamide solution with a concentration of 10%; according to PEBA2533 and PDA in step (1) The mass ratio of @ZIF-8 is 0.95:0.05. Add PDA@ZIF-8 to the above PEBA2533 solution, stir at room temp...

Embodiment 3

[0030] The preparation of dopamine-modified metal-organic compound / polyether copolyamide mixed matrix film comprises the following steps, and the formula ratio is by mass percentage:

[0031] (1) Preparation of dopamine-modified metal-organic compounds: Add dopamine to tris buffer at pH 8.0 to form a dopamine solution with a concentration of 1 mg / ml. The ratio is 1:5, ZIF-7 is added to the above solution, stirred and reacted at room temperature for 10 h, centrifuged, washed with water, and dried to obtain a black dopamine-modified metal organic compound (PDA@ZIF-7);

[0032] (2) Preparation of mixed matrix membrane: dissolve polyether block copolyamide (PEBA3533) in n-butanol, and configure a polyether block copolyamide solution with a concentration of 8%; according to PEBA3533 and PDA in step (1) The mass ratio of @ZIF-7 is 0.90:0.10. Add PDA@ZIF-7 to the above PEBA3533 solution, stir at room temperature for 20 hours, let it stand for 1 hour to defoam, and then apply it on a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com