Method for preparing nano-zeolite metal-organic framework compounds by microreactor

A metal-organic framework and micro-reactor technology, applied in the direction of zinc organic compounds, copper organic compounds, etc., can solve the problems of polluted environment particle structure, cumbersome reaction process, harsh reaction conditions, etc. Tuning, crystal structure controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

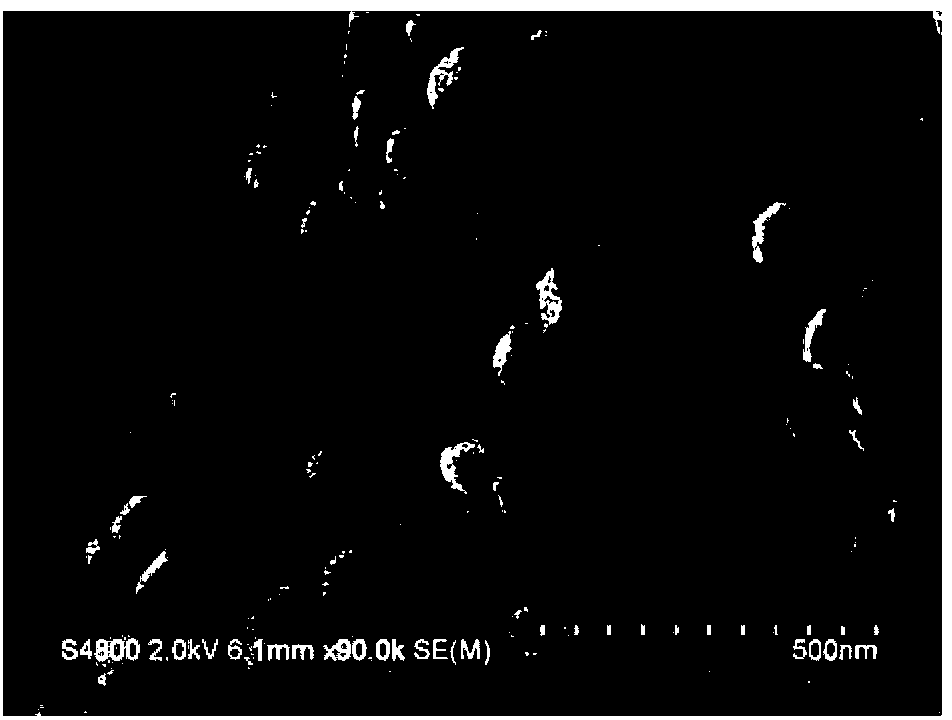

Image

Examples

Embodiment 1

[0015] (1) Solution configuration: Zinc nitrate and 2-methylimidazole were dissolved in methanol to prepare a metal precursor solution A with a concentration of 0.5 mol / L and an organic ligand solution B with a concentration of 0.5 mol / L.

[0016] (2) Mixing: Place A solution and B solution on both sides of a microfiltration membrane with a pore size of 0.01 microns, and control the pressure difference on both sides of the membrane to 0.02MPa, so that A solution can evenly pass through the membrane and enter B solution. The reaction temperature is 30°C, the type of reactor used is a flat membrane, and the membrane material is polyethersulfone (PES).

[0017] (3) Post-treatment: The white colloidal suspension obtained above was centrifuged at 10,000 r / min, washed twice with methanol, and dried at 80° C. for 10 h to obtain a nano-sized zeolite metal-organic framework compound.

[0018] The measured particle size is 32.44nm and the specific surface area is 980.4332m 2 / g.

Embodiment 2

[0020] (1) Solution configuration: Zinc nitrate and 2-ethylimidazole were dissolved in deionized water to prepare a metal precursor solution A with a concentration of 1mol / L and an organic ligand solution B with a concentration of 4mol / L.

[0021] (2) Mixing: Place A solution and B solution on both sides of the ultrafiltration membrane with a molecular weight cut-off of 50,000, and control the pressure difference on both sides of the membrane to 0.08MPa, so that the A solution can evenly pass through the membrane and enter the B solution. The reaction temperature is 40°C, the type of reactor used is coiled membrane, and the membrane material is polysulfone (PS).

[0022] (3) Post-treatment: centrifuge the white colloidal suspension obtained above at 12,000 r / min, wash with methanol twice, and dry at 100° C. for 12 hours to obtain a nano-sized zeolite metal-organic framework compound.

[0023] The measured particle size is 34.44nm and the specific surface area is 987.5348m 2 / ...

Embodiment 3

[0025] (1) Solution configuration: Dissolve copper nitrate and 2-ethylimidazole in deionized water to prepare metal precursor solution A with a concentration of 1mol / L and organic ligand solution B with a concentration of 1mol / L.

[0026] (2) Mixing: Place A solution and B solution on both sides of a microfiltration membrane with a pore size of 0.08 microns, and control the pressure difference on both sides of the membrane to 0.04MPa, so that A solution can evenly pass through the membrane and enter B solution. The reaction temperature is 35°C, and the type of reactor used is roll-type membrane, and the membrane material is polyvinylidene fluoride (PVDF).

[0027] (3) Post-treatment: centrifuge the white colloidal suspension obtained above at 12,000 r / min, wash with methanol twice, and dry at 90°C for 11 hours to obtain a nano-sized zeolite metal-organic framework compound.

[0028] The measured particle size is 33.56nm and the specific surface area is 1000.2225m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com