Method for recycling waste rare earth polishing powder and rare earth polishing liquid

A rare earth polishing powder and rare earth polishing technology, which is applied in the field of rare earth polishing liquid, can solve the problems of polluting the surrounding environment, waste of rare earth resources, and low recycling rate, and achieve the effects of resource saving, easy operation, and high cutting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

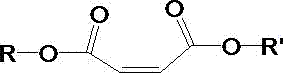

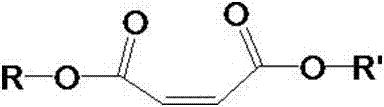

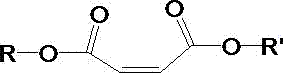

Image

Examples

Embodiment 1

[0037] Get 40 grams of ground waste polishing powder, the ingredients of which are shown in Table 1, place the ground waste polishing powder in a beaker, add 120 milliliters of nitric acid solution with a concentration of 63 wt%, stir at 80 ° C, and pass through a pipe to the bottom of the solution, gradually add H 2 o 2 15 mL of hydrogen peroxide with a volume concentration of 30% to obtain a solution containing rare earth elements, and then remove insoluble substances; continue stirring and add ammonia (NH 3 :H 2 O=1:1) adjust the pH to 5.5, heat to 55°C, add 10mL of H 2 o 2 Hydrogen peroxide with volume concentration of 30%, add 1.0 g Ce(OH) 4 Then heated to 80°C, stirred and left for 10 hours, washed the precipitate with water until neutral, filtered, dried to obtain hydroxide; then roasted at 950°C for 3 hours, and sieved to obtain rare earth particles with a particle size of less than 2 μm Oxides, the composition of the rare earth oxides is shown in Table 1.

Embodiment 2

[0039] Take 40 grams of ground waste polishing powder, the ingredients of which are shown in Table 1, place the ground waste polishing powder in a beaker, add 130 milliliters of nitric acid solution with a concentration of 63 wt%, stir at 60 ° C, and pass through a pipe to the bottom of the solution, gradually add H 2 o 2 18 mL of hydrogen peroxide with a volume concentration of 30% was obtained to obtain a solution containing rare earth elements, and then the insoluble substances were removed; then continue to stir and add ammonia (NH 3 :H 2 O=1:1) adjust the pH value to 6.0, heat to 50°C, add 8 mLH 2 o 2Hydrogen peroxide with volume concentration of 30%, add 1.0 g Ce(OH) 4 Then heated to 80°C, stirred and left for 8 hours, washed the precipitate with water until neutral, filtered, dried to obtain hydroxide; then roasted at 900°C for 3 hours, and sieved to obtain rare earth particles with a particle size of less than 2 μm Oxides, the composition of the rare earth oxides ...

Embodiment 3

[0045] This embodiment relates to the surface treatment of nano-scale ceria powder, which comprises the following steps

[0046] (1) Add a modifier whose mass is 10wt% of nano-sized ceria powder into deionized water, and stir for 15 minutes at a stirring speed of 800~1000rpm to form the first system with a concentration of 2.0wt%;

[0047] (2) Disperse the nano-sized ceria powder and acryloyloxyethyltrimethylammonium chloride with a mass of 8wt% of the nano-sized ceria powder in a The second system is obtained in the glycidyl methacrylate; the quality of the glycidyl methacrylate is 3.0 times the quality of the nano-sized cerium dioxide powder;

[0048] (3) Add the second system obtained in step (2) to the first system obtained in step (1), stir at a stirring speed of 1800~2000rpm for 25 minutes to obtain a mixed solution, and transfer it to the reactor, 2 Under the protection of the atmosphere, add dilauroyl peroxide with 0.5wt% glycidyl methacrylate mass under continuous st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com