Silicon-cerium polishing liquid and preparation method thereof

A polishing liquid, silicon-cerium technology, applied to polishing compositions containing abrasives, etc., can solve the problems of polishing efficiency and polishing effect to be improved, and the particle size distribution of cerium oxide is wide, and achieves easy operation, high cutting rate and polishing efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment relates to the surface treatment of nano-scale ceria powder, which comprises the following steps

[0036](1) Add a modifier whose mass is 10wt% of nano-sized ceria powder into deionized water, and stir for 15 minutes at a stirring speed of 800~1000 rpm to form the first system with a concentration of 2.0wt%;

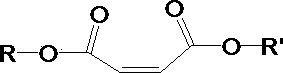

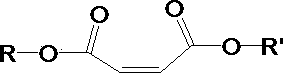

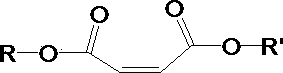

[0037] (2) Disperse the nano-sized ceria powder and acryloyloxyethyltrimethylammonium chloride with a mass of 8wt% of the nano-sized ceria powder in a The second system is obtained in the glycidyl methacrylate; the quality of the glycidyl methacrylate is 3.0 times the quality of the nano-sized cerium dioxide powder;

[0038] (3) Add the second system obtained in step (2) to the first system obtained in step (1), stir at a stirring speed of 1800~2000 rpm for 25 min to obtain a mixed solution, and transfer it to the reactor, N 2 Under the protection of the atmosphere, add dilauroyl peroxide with 0.5wt% glycidyl methacrylate mass under continuous st...

Embodiment 2

[0042] The silicon cerium polishing solution described in the present embodiment contains 3.0wt% micron-sized ceria powder, 1.20wt% nano-sized ceria powder, 15wt% colloidal silicon dioxide, and 0.5wt% alkyl Phenyl ether sulfosuccinate, 0.8 wt% AM / AMPS binary copolymer, and the balance water. Its preparation method is as follows: firstly add colloidal silicon dioxide into the container, then add alkylphenol ether sulfosuccinate and stir evenly to obtain the first system; then add micron-sized ceria powder to the first system respectively Body and nano-scale ceria powder and stirred evenly to obtain the second system; finally, AM / AMPS binary copolymer was added to the second system, and the rest of water was added to disperse evenly by ultrasonic waves to obtain a silicon cerium polishing solution.

Embodiment 3

[0044] The silicon cerium polishing solution described in this embodiment contains 6.0wt% micron-sized ceria powder, 1.75wt% nano-sized ceria powder, 20wt% colloidal silicon dioxide, and 0.8wt% alkyl Phenyl ether sulfosuccinate, 1.5 wt% AM / AMPS binary copolymer, and the balance water. Its preparation method is as follows: firstly add colloidal silicon dioxide into the container, then add alkylphenol ether sulfosuccinate and stir evenly to obtain the first system; then add micron-sized ceria powder to the first system respectively Body and nano-scale ceria powder and stirred evenly to obtain the second system; finally, AM / AMPS binary copolymer was added to the second system, and the rest of water was added to disperse evenly by ultrasonic waves to obtain a silicon cerium polishing solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com