Silicon carbide polishing solution and application thereof

A technology of silicon carbide and polishing liquid, applied in polishing compositions containing abrasives, etc., can solve the problem of low polishing efficiency, and achieve the effects of improving polishing efficiency, high cutting rate, and easy long-term storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the present invention, there is no special limitation on the preparation method of the silicon carbide polishing liquid, which can be prepared by the preparation method of the composition well known to those skilled in the art.

[0033] The present invention also provides the application of the silicon carbide polishing liquid described in the above technical solution, wherein the silicon carbide polishing liquid is used in combination with a polishing pad material for polishing silicon-containing and silicon-containing compounds.

[0034] In the present invention, the Shore hardness of the polishing pad material is preferably greater than 80A, more preferably greater than 90, most preferably greater than 95, and the compression ratio is preferably less than 10%, more preferably less than 5%, most preferably less than 3%.

[0035] In the present invention, the material of the polishing pad is preferably foamed polyurethane, more preferably foamed polyurethane containi...

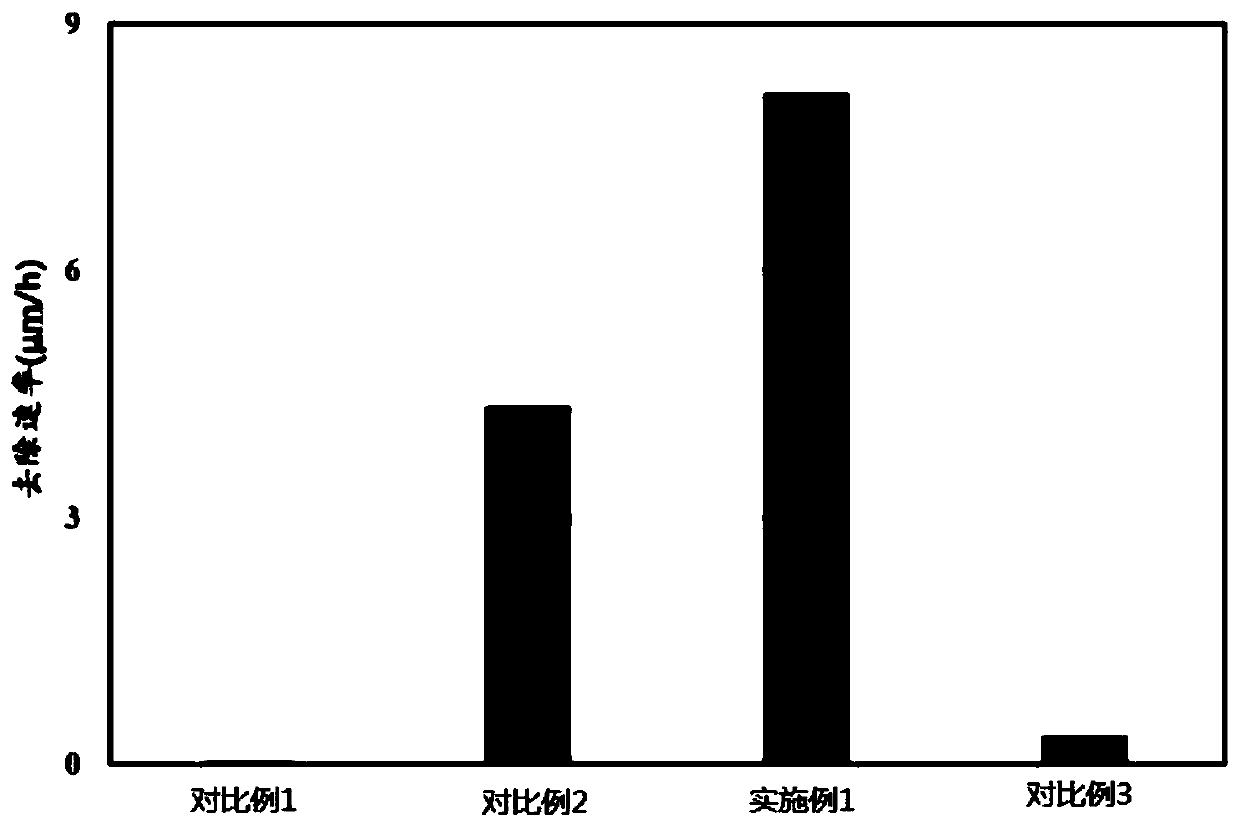

Embodiment 1

[0038] This embodiment provides a silicon carbide polishing liquid, in which ethylene glycol, diamond (particle size: 1.0 μm), chlorous acid and nitric acid are uniformly mixed to obtain a silicon carbide polishing liquid. Wherein the molar concentration of chlorous acid in the silicon carbide polishing liquid is 0.15 mol / L, the pH value of the silicon carbide polishing liquid is 4, and the mass fraction of diamond is 0.15%.

Embodiment 2

[0047] This embodiment provides a silicon carbide polishing liquid, which is uniformly mixed with isopropanol, aluminum oxide (with a particle size of 50 nm), chlorous acid and potassium hydroxide to obtain a silicon carbide polishing liquid. Wherein the molar concentration of potassium permanganate in the silicon carbide polishing liquid is 3mol / L, the pH value of the silicon carbide polishing liquid is 10, and the mass fraction of diamond is 0.35%. The polishing efficiency of the silicon carbide polishing liquid obtained in this embodiment is 17.2 μm / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com