Alumina polishing solution for copper polishing and preparation method thereof

A technology of alumina and polishing fluid, which is applied in the direction of polishing compositions containing abrasives, etc., can solve the problems that the cutting rate and flatness cannot meet the requirements of industrial production, and achieve the effect of reducing equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

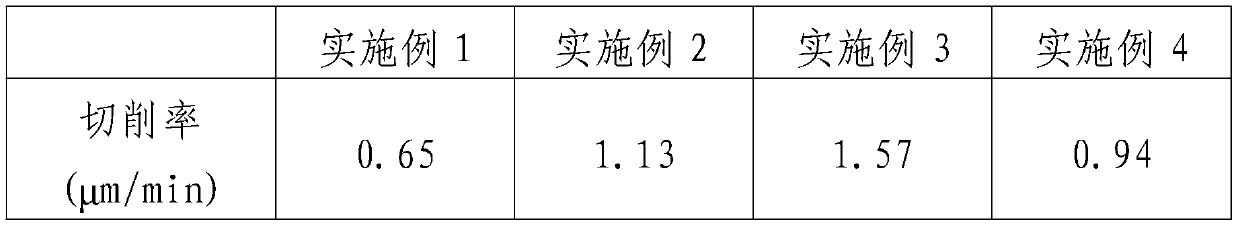

Examples

Embodiment 1

[0030] The preparation of the aluminum oxide polishing liquid for copper polishing of the present embodiment comprises the following steps:

[0031] A, material preparation: get respectively by weight:

[0032] 200 parts of alumina (α-alumina, with an average particle size of 0.5 μm), 10 parts of polyacrylic acid (surfactant), 20 parts of disodium hydrogen phosphate (corrosion inhibitor), ethylenediaminetetraacetic acid and aluminum chloride (mass The ratio is 1:1) (pH regulator) 50 parts, sodium hexametaphosphate (dispersant) 10 parts, magnesium aluminum silicate (suspension agent) 10 parts, deionized water 1000 parts, spare;

[0033] B. Initial mixing: add aluminum oxide and polyacrylic acid to deionized water, stir evenly to obtain the initial mixed solution, and set aside;

[0034] C. Compound mixing: Add sodium hexametaphosphate, magnesium aluminum silicate and disodium hydrogen phosphate to the initial mixed solution in sequence, stir evenly, and place it for 24 hours, ...

Embodiment 2

[0037] The preparation of the aluminum oxide polishing liquid for copper polishing of the present embodiment comprises the following steps:

[0038] A, material preparation: get respectively by weight:

[0039] 150 parts of alumina (α-alumina, with an average particle size of 1.5 μm), 20 parts of polyacrylic acid and sodium dodecylbenzenesulfonate (mass ratio 1:1) (surfactant), disodium hydrogen phosphate and hydroxyl Ethylenediphosphonic acid (mass ratio 1:1) (corrosion inhibitor) 40 parts, aluminum nitrate (pH regulator) 100 parts, polyethylene glycol-400 (dispersant) 20 parts, magnesium aluminum silicate (suspension agent) 20 parts, 1000 parts of deionized water, standby;

[0040] B. Initial mixing: Add aluminum oxide, polyacrylic acid and sodium dodecylbenzenesulfonate to deionized water, stir evenly to obtain the initial mixed solution, and set aside;

[0041] C. Compound mixing: add polyethylene glycol-400, magnesium aluminum silicate, disodium hydrogen phosphate, and ...

Embodiment 3

[0044] The preparation of the aluminum oxide polishing liquid for copper polishing of the present embodiment comprises the following steps:

[0045] A, material preparation: get respectively by weight:

[0046] 100 parts of alumina (α-alumina, with an average particle size of 2.5 μm), 30 parts of sodium benzoate and sodium dodecylbenzenesulfonate (1:1 by mass ratio) (surfactant), benzotriazole and Hydroxyethylidene diphosphonic acid (mass ratio 1:1) (corrosion inhibitor) 60 parts, citric acid and aluminum chloride (mass ratio 1:1) (pH regulator) 150 parts, sodium tripolyphosphate (dispersion agent) 30 parts, sodium carboxymethylcellulose (suspending agent) 30 parts, deionized water 1000 parts, standby;

[0047] B. Initial mixing: Add aluminum oxide, sodium benzoate and sodium dodecylbenzenesulfonate to deionized water, stir evenly to obtain the initial mixed solution, and set aside;

[0048]C. Compound mixing: Add sodium tripolyphosphate, sodium carboxymethylcellulose, benzo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com