Hemispherical drill stem for rotary drilling rig

A rotary drilling rig and hemispherical technology, which is applied in the directions of rotary drilling rig, drill pipe, rotary drilling, etc., can solve the problems of time delay of drill pipe and drilling tool joint, damage to power head and drilling tool, and inconvenient construction, etc. Achieve good strength, reduce vibration and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

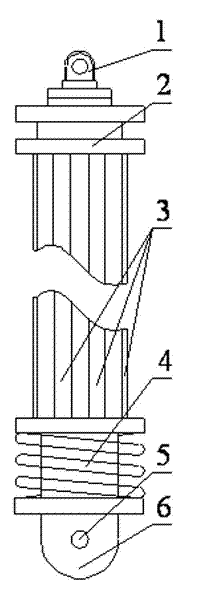

[0014] refer to figure 1 , this embodiment includes a cylindrical drill pipe body, the upper end of the drill pipe body is provided with a shock absorber ring 2, the top of the shock absorber ring 2 is provided with a flat head 1, the drill pipe body is provided with a guide drive groove 3, and the lower end of the drill pipe body is spherical Joint 6, the front end of the drill pipe body between the guide drive groove 3 and the spherical joint 6 is provided with a compression spring 4, and the spherical joint 6 is provided with a connection lock hole (not shown in the figure), and the cylindrical drill pipe body and The hinged end of the drilling tool is hemispherical, and a hinge hole 5 for fixing and transmitting the power given by the power head is provided on the diameter direction of the spherical hinge joint 6 .

[0015] The radius of the spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com