Patents

Literature

267results about How to "Adjust the clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

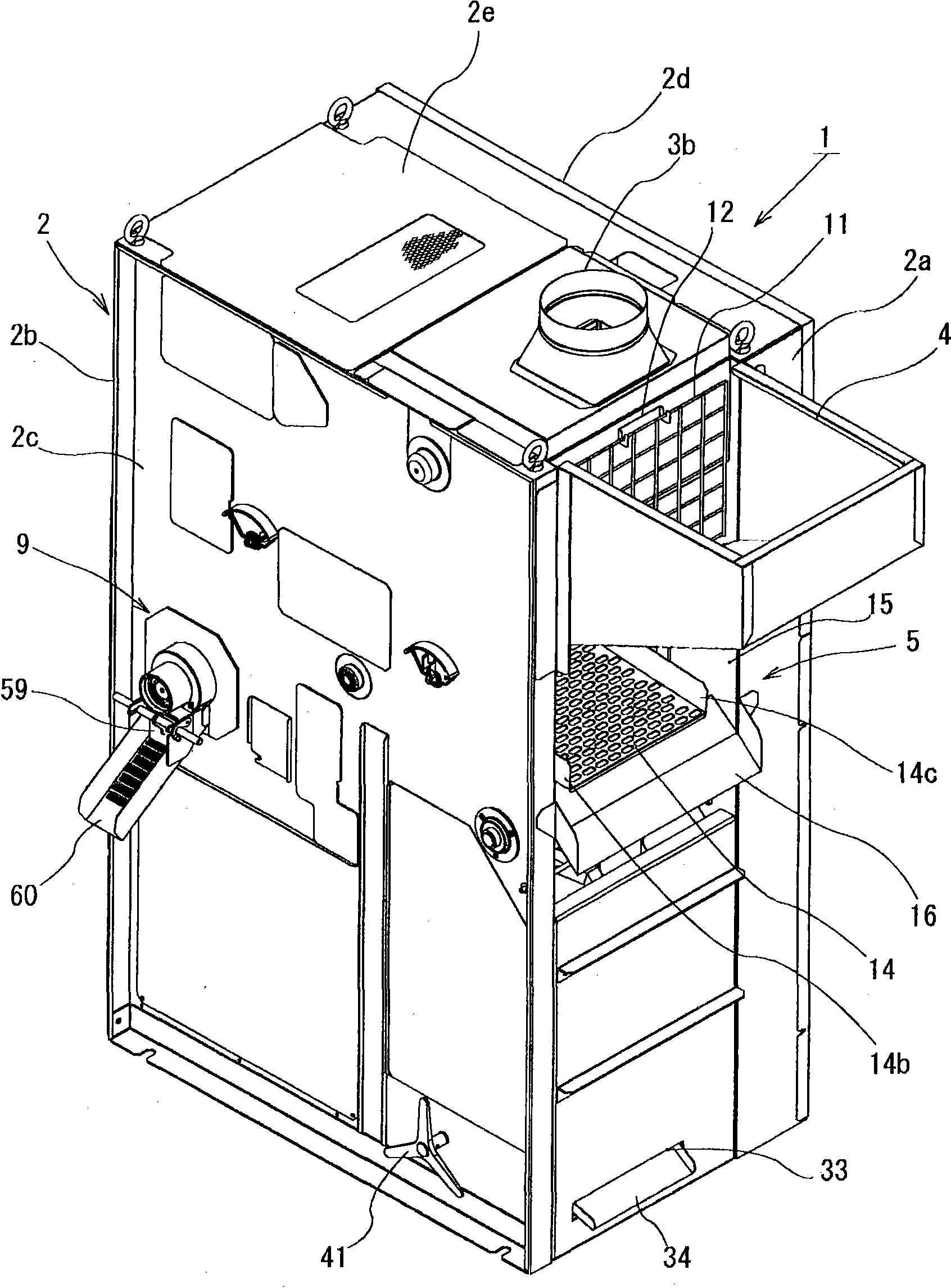

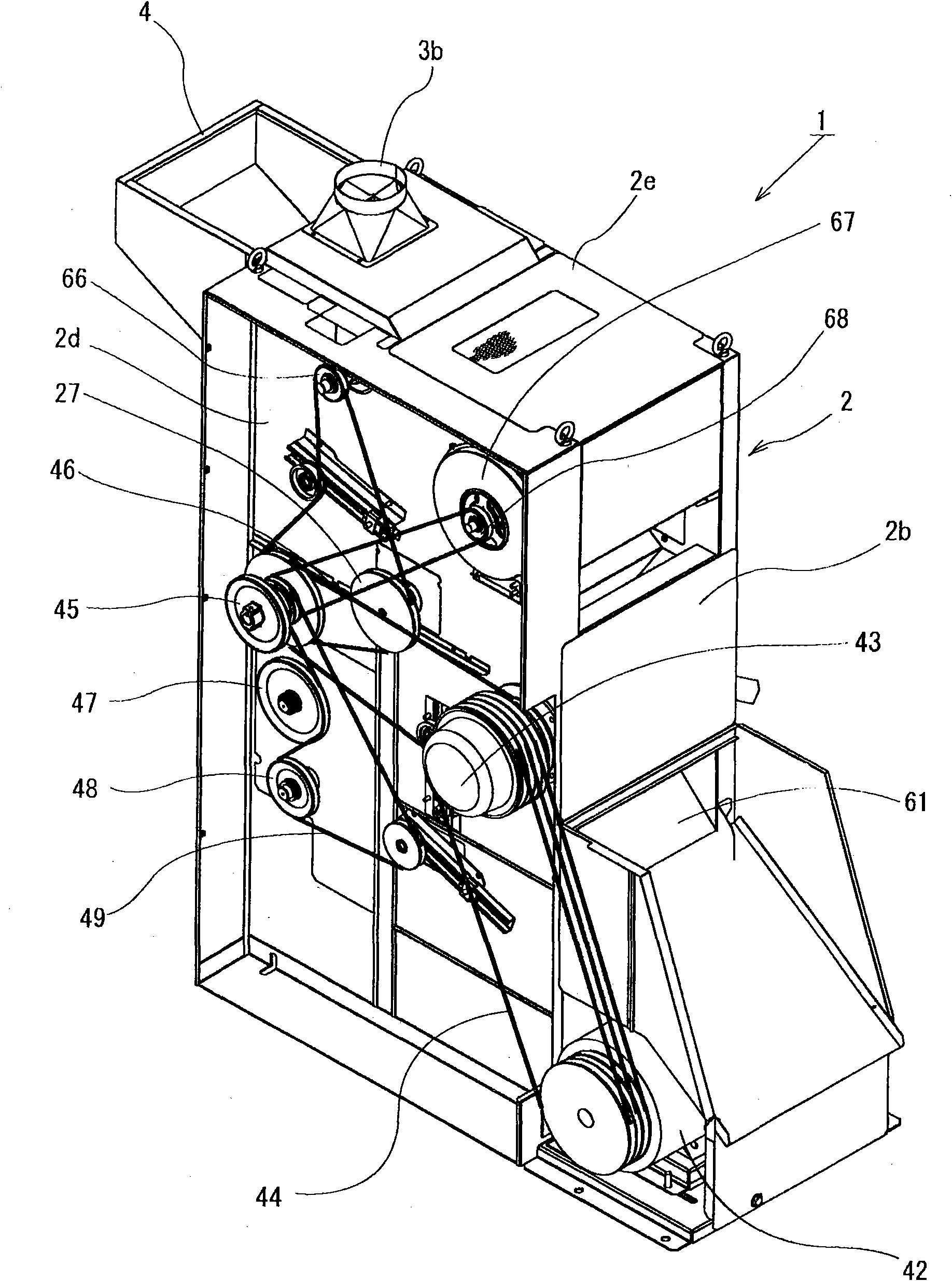

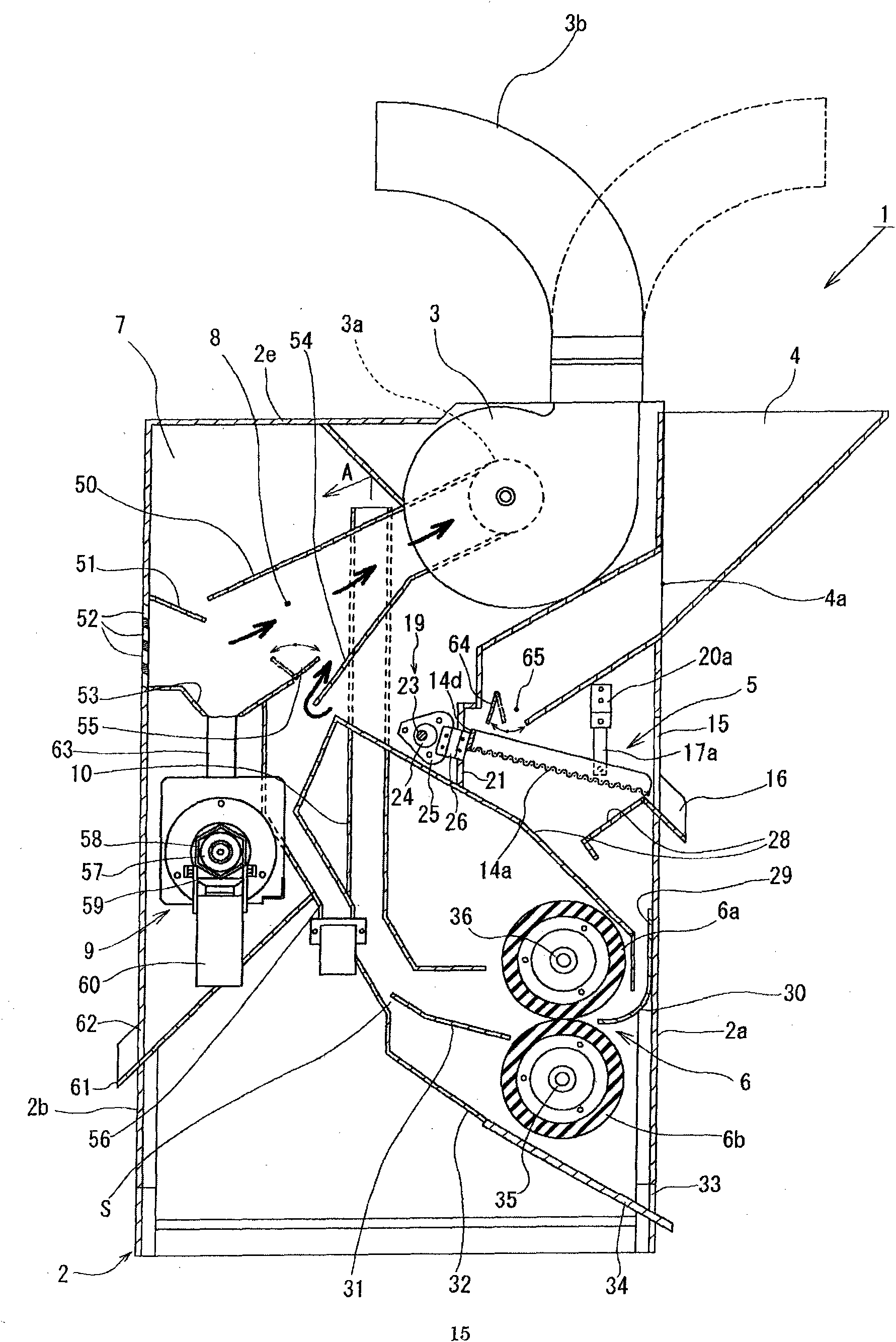

Paddy shelling rice-polishing mill

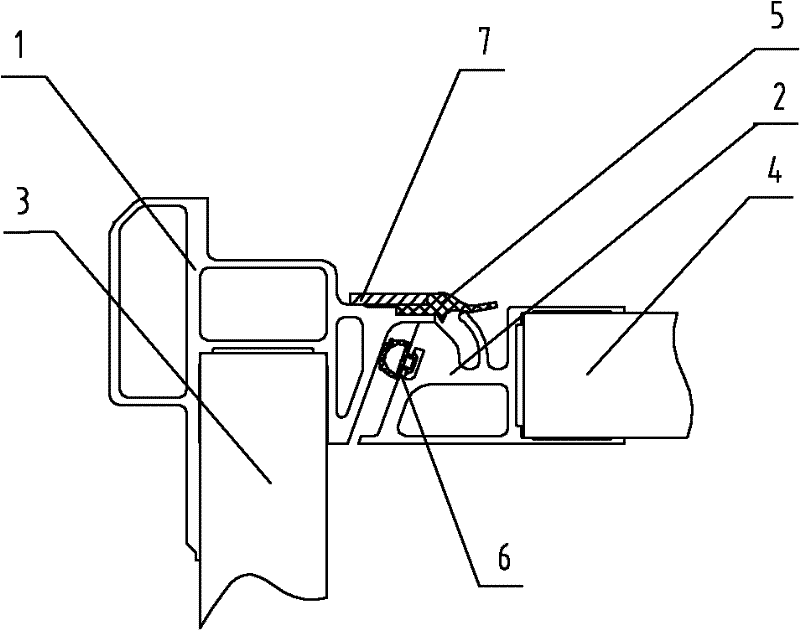

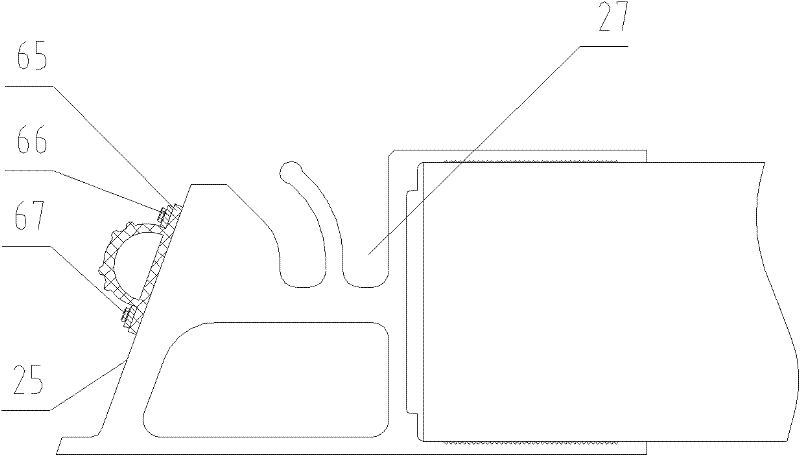

InactiveCN101961666AReduce areaImprove workabilityGrain huskingGrain polishingForeign matterEngineering

The invention provides a paddy shelling rice-polishing mill, capable of making the height of the mill low and easily loading the paddy even through a coarse screening part is loaded on the paddy shelling rice-polishing mill and making a rice discharge of a rice receiving bag low and being convenient used. A foreign matter removing part (5) is arranged in the middle of an approximate cuboid case (2) and a paddy hopper (4) and an exhaust fan for air classification (3) are respectively arranged above the foreign matter removing part and a shelling part (6) is arranged below the foreign matter removing part. On the other hand, air classification parts (8) are arranged in parallel in the chase and adjacent to the exhaust fan and a rice milling part (9) is arranged below the air classification part and a pair of shelling rollers (6a,6b) are vertically erected and the milled rice is thrown out along the horizontal direction and an angle change plate (31) and an upper transfer tube (10) for throwing the milled rice to the air classification part using the energy of the thrown-out milled rice are arranged at the milled rice discharge side of the shelling part.

Owner:SATAKE CORP

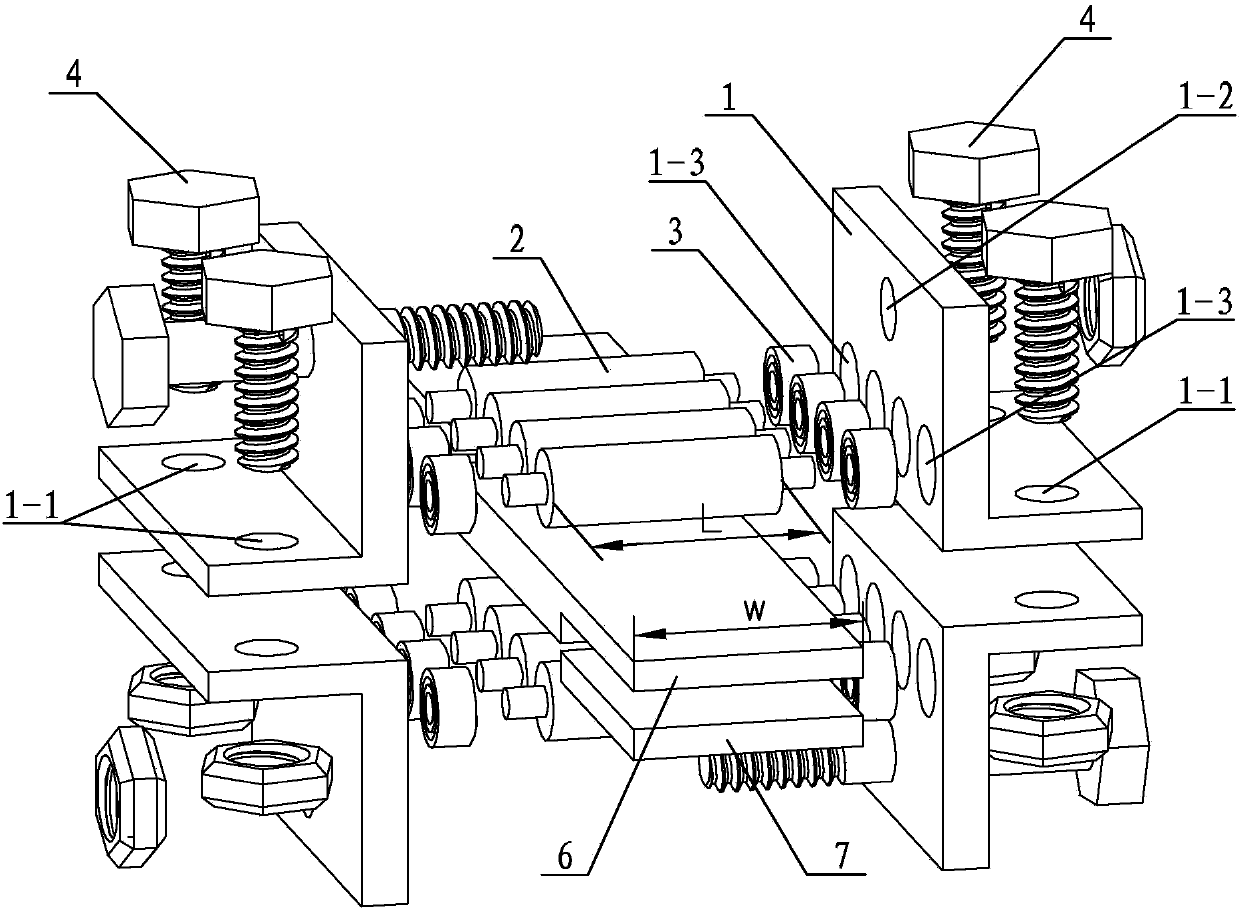

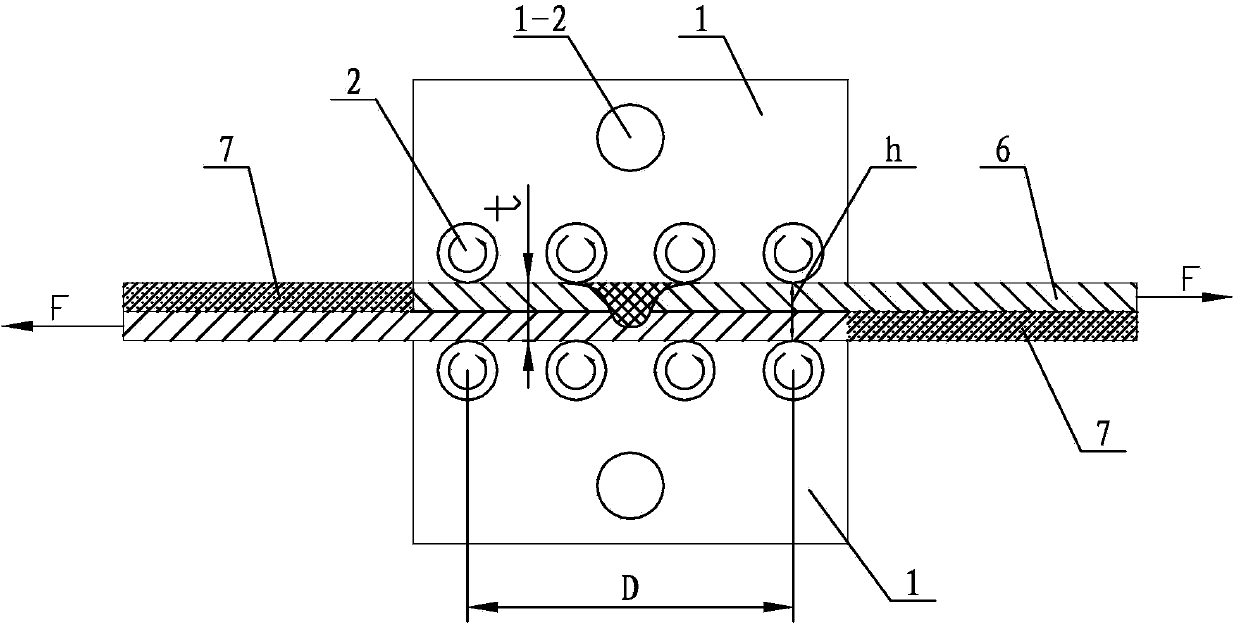

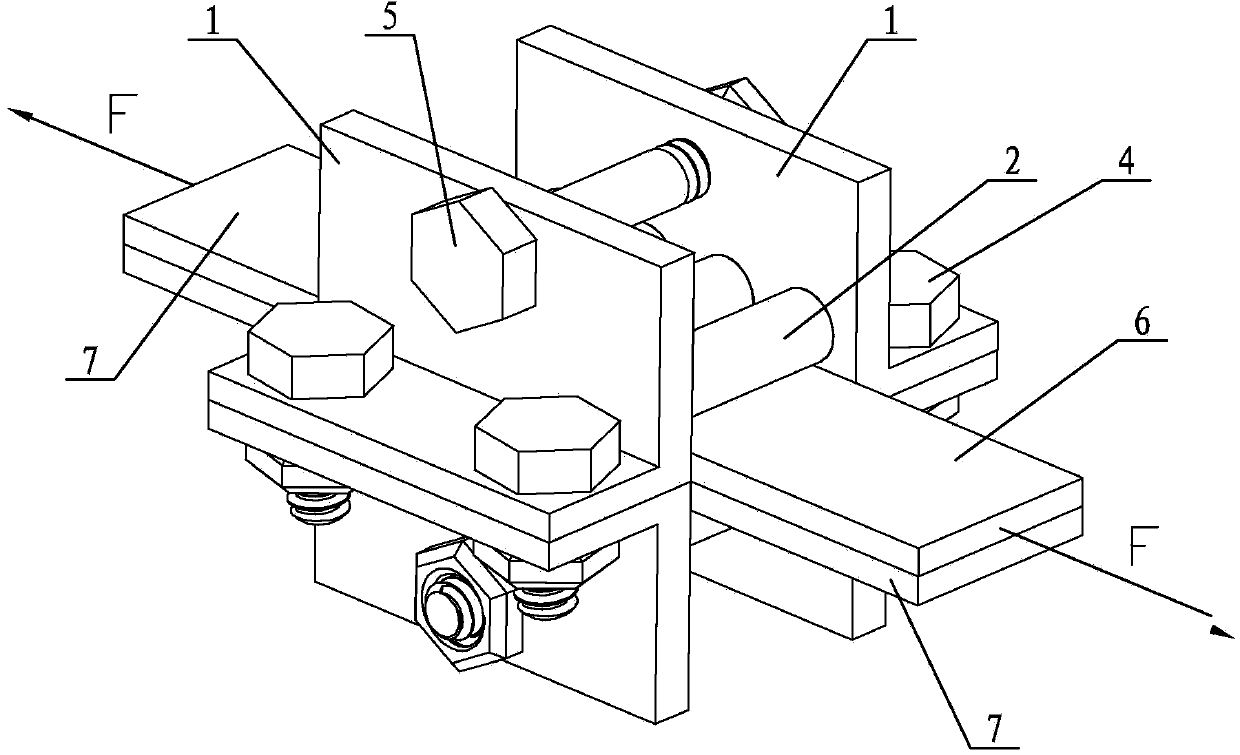

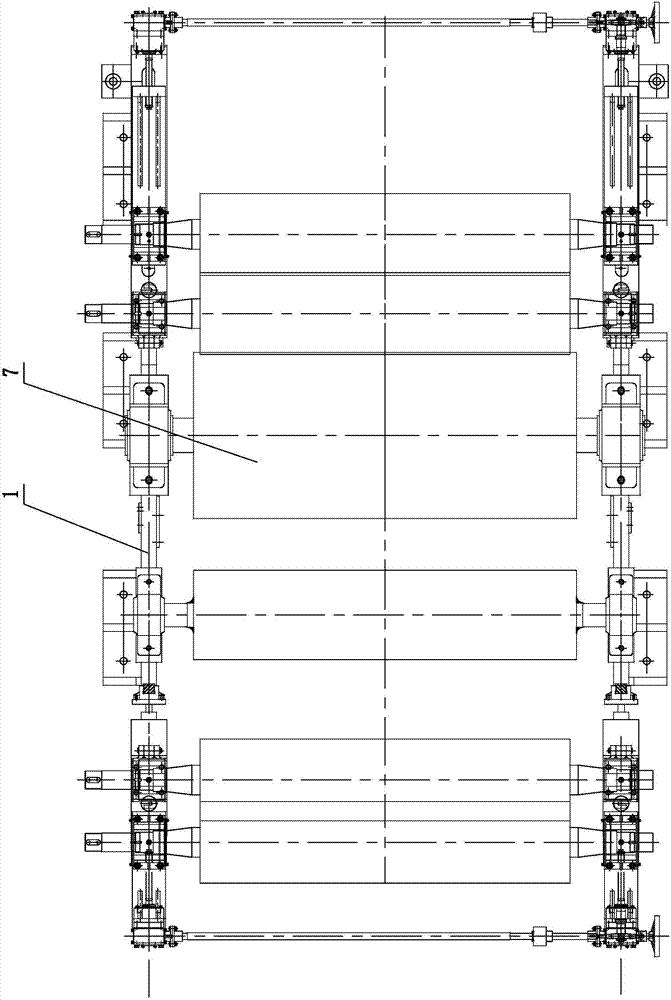

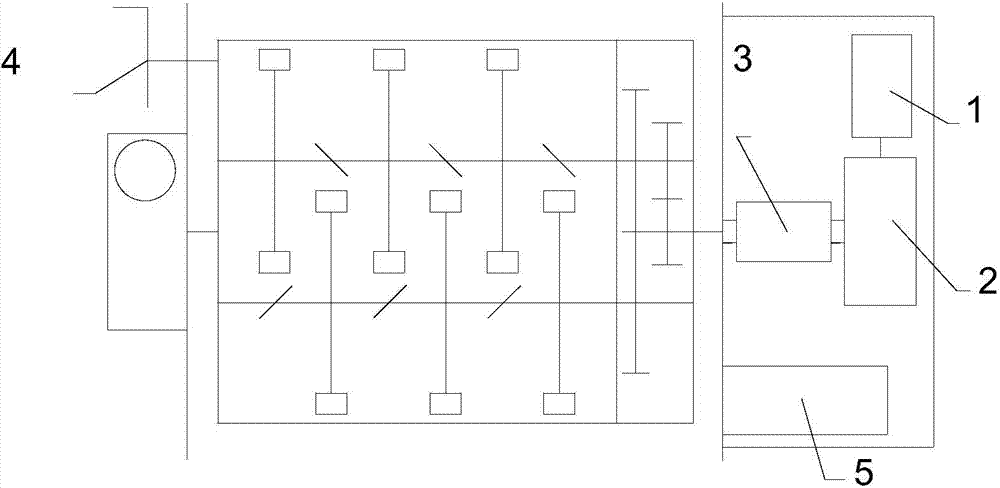

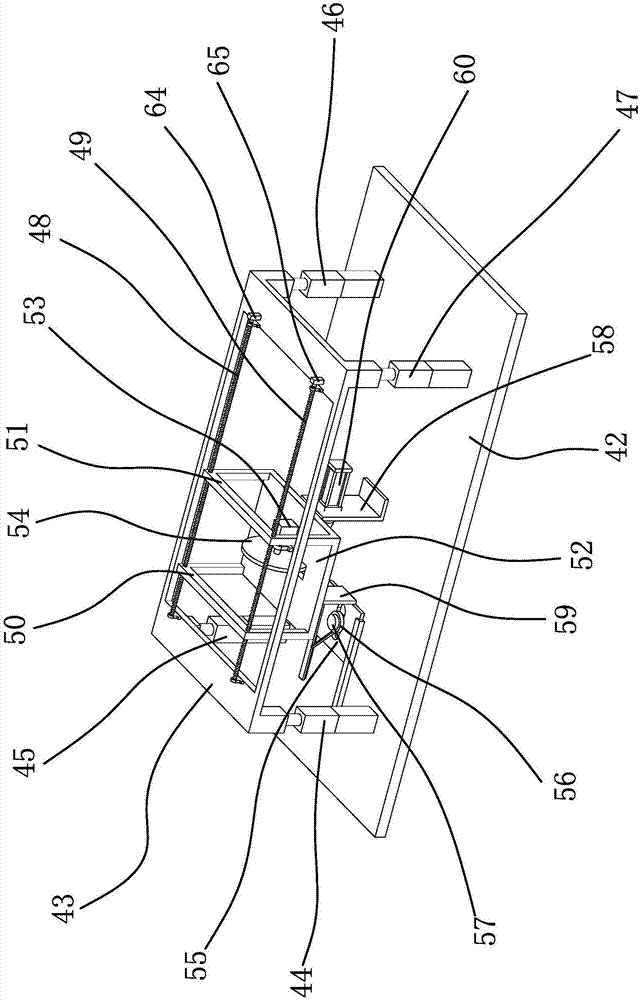

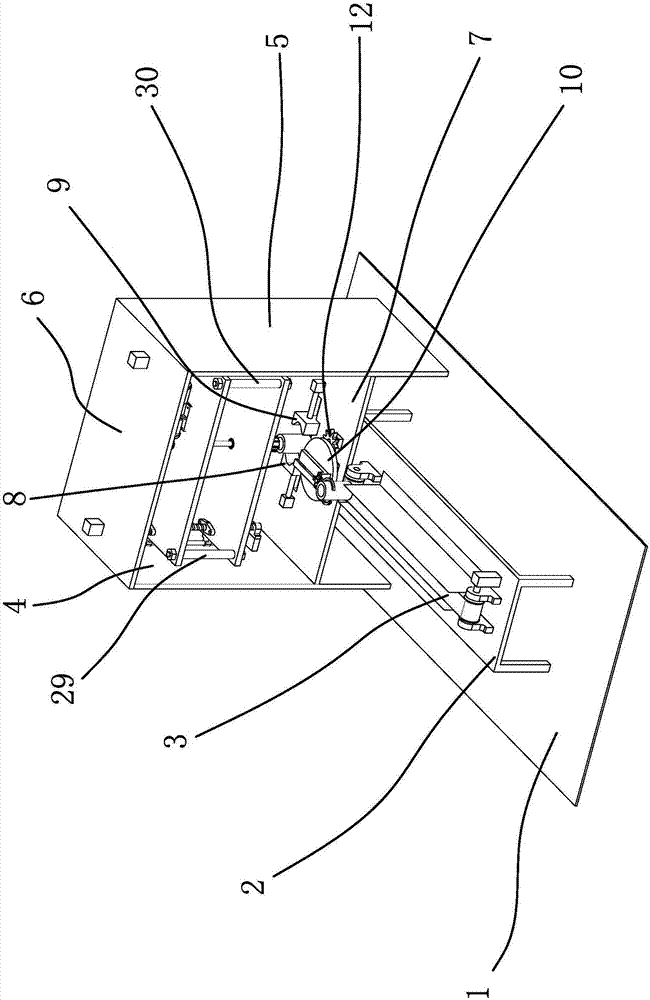

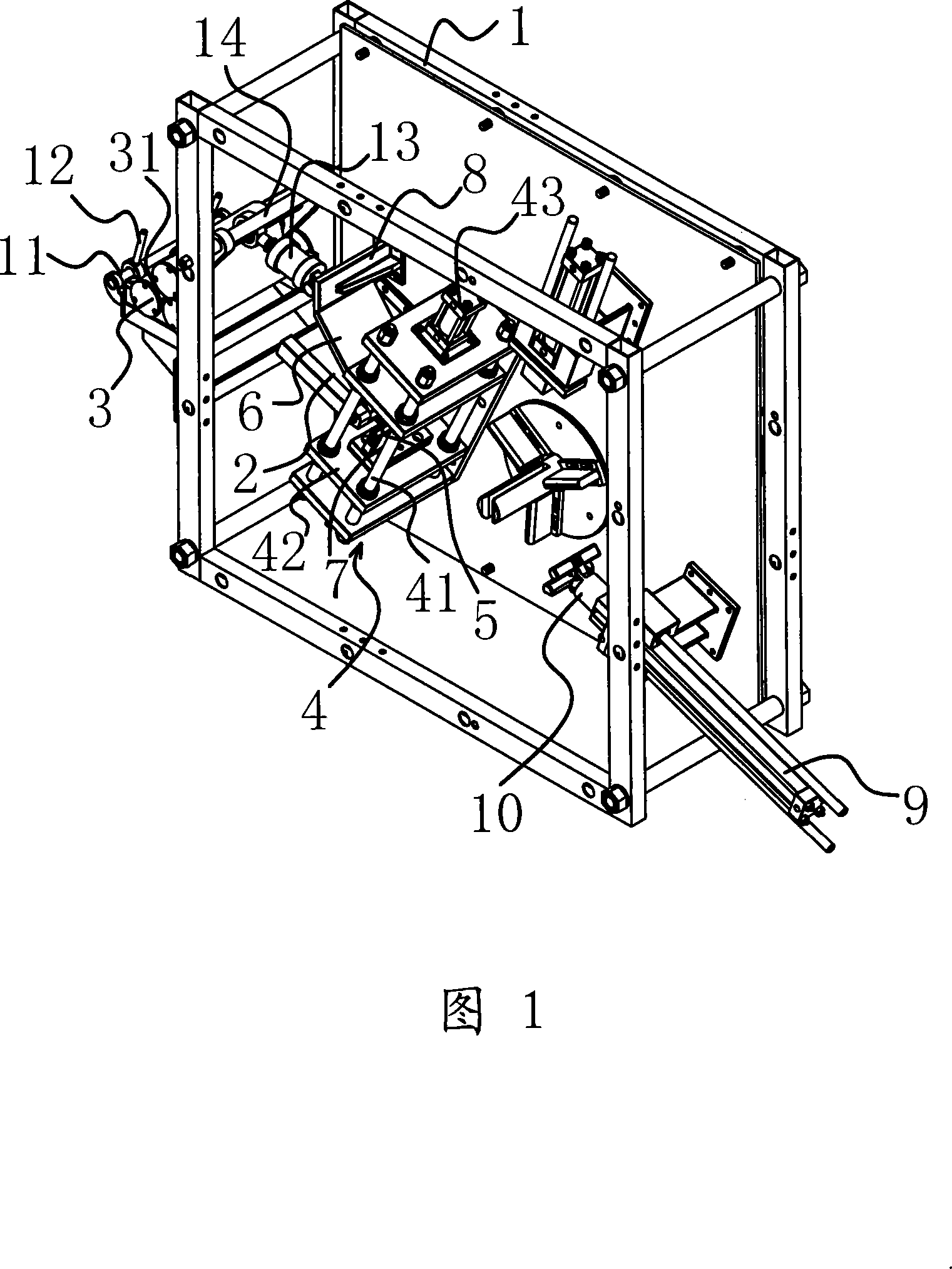

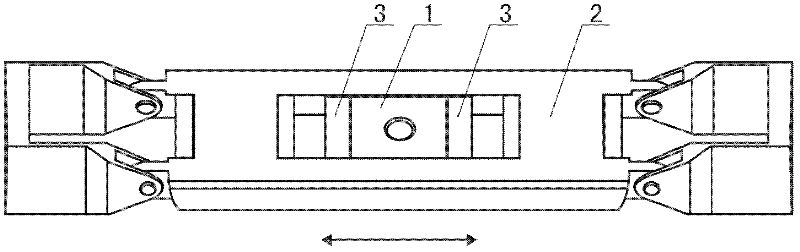

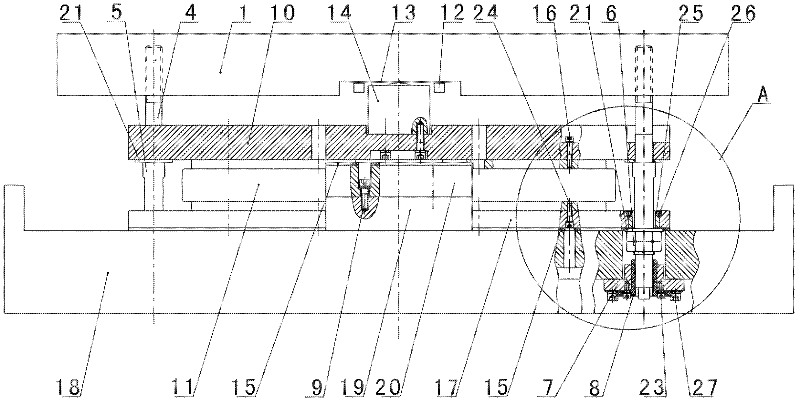

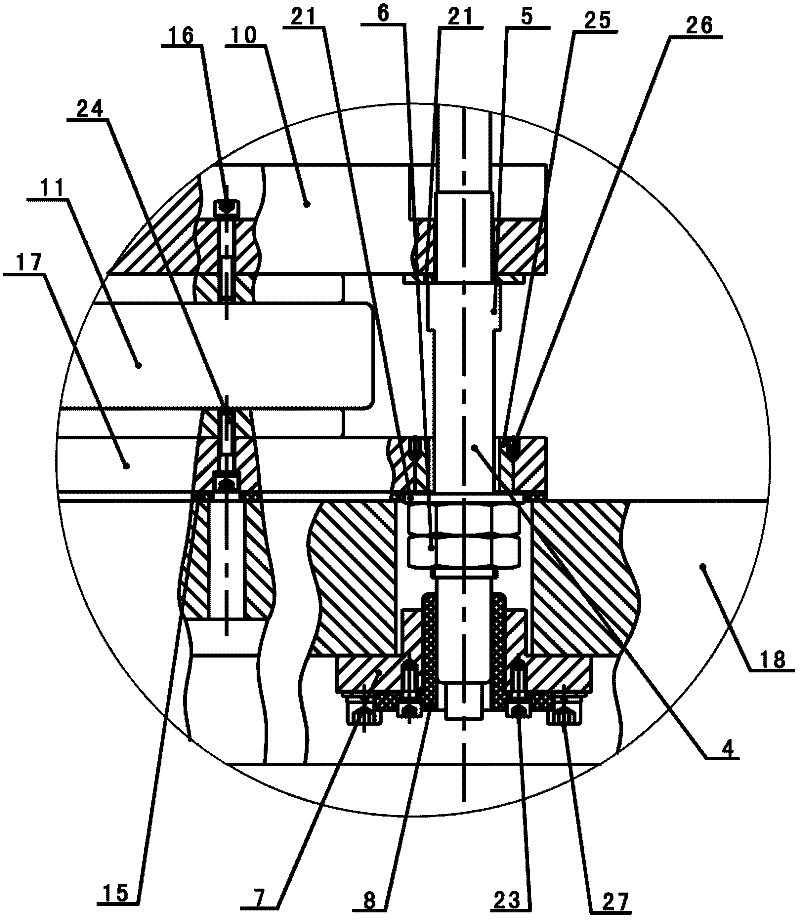

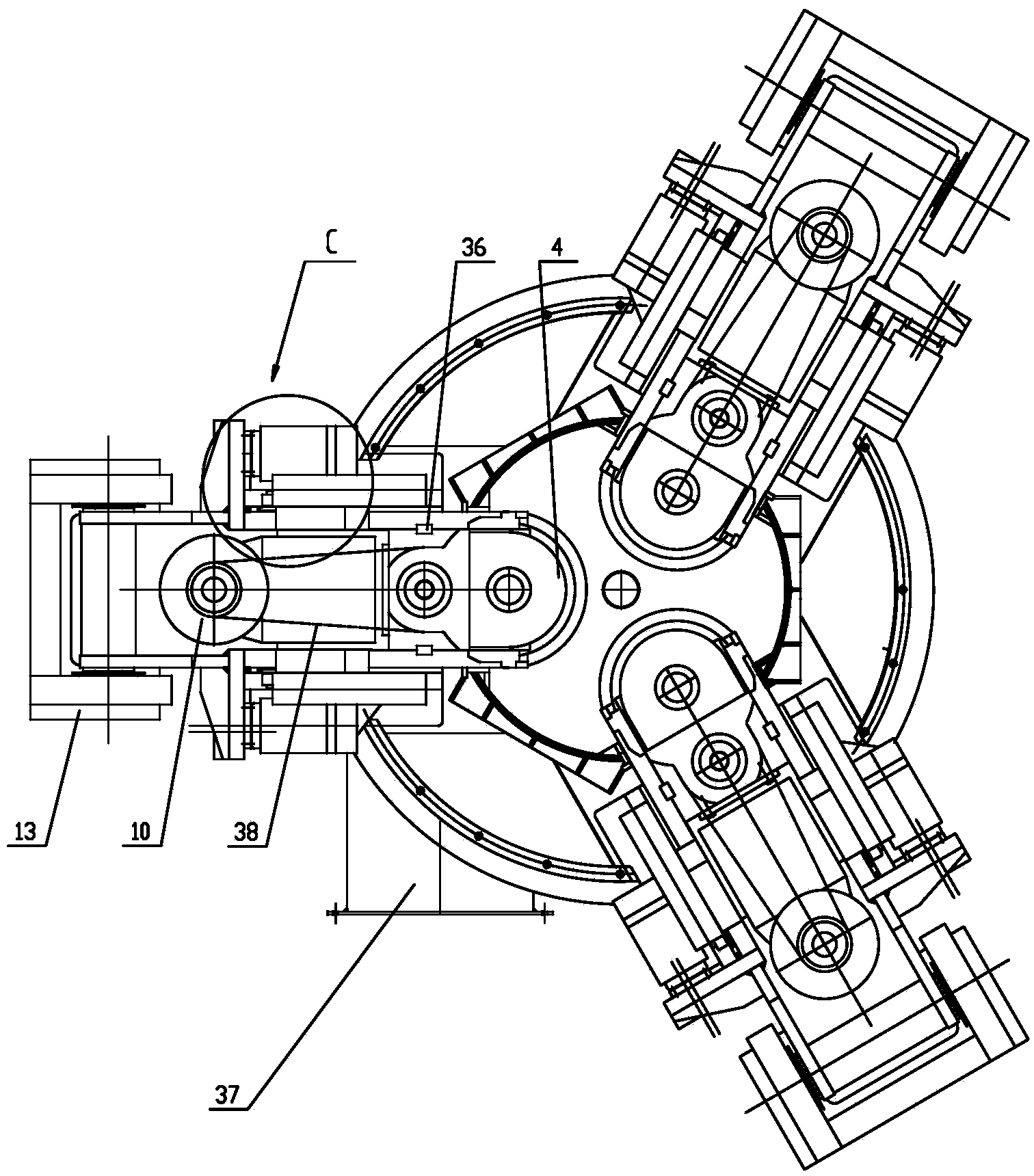

Fixture and method for measuring maximum tensile and shearing force of lap joint of friction stir welding

ActiveCN103592181AGuaranteed pure tensile shear failureEliminate additional bending momentsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesFriction weldingLap joint

The invention provides a fixture and a method for measuring the maximum tensile and shearing force of a lap joint of friction stir welding to overcome the problem that additional bending moment influences measurement results of the maximum tensile and shearing force of a lap joint of friction stir welding in a traditional tensile and shearing test. According to the fixture, four bearing installing holes are arranged along a same horizontal line; eight rollers are arranged in two layers, each layer consisting of four parallely arranged rollers; the end parts of each roller is mounted in a corresponding bearing installing hole through a positioning bearing. The method comprises the following steps: 1, allowing the distance between axle centers of two rollers located at two outermost sides of each layer of rollers to be 10 to 20 times thickness of the lap part of a test piece for tensile and shearing testing; 2, placing the test piece for tensile and shearing testing between the upper layer of rollers and the lower layer of rollers; and 3, clamping the assembled test piece for tensile and shearing testing, the fixture and cushion blocks on a tensile and shearing testing machine, carrying out tensile and shearing testing on the test piece for tensile and shearing testing at a loading speed of 0.5 to 1.5 mm / min and recording a maximum tensile and shearing test load F. The fixture and the method provided by the invention are used for measuring the maximum tensile and shearing force of the lap joint of friction stir welding.

Owner:HARBIN INST OF TECH

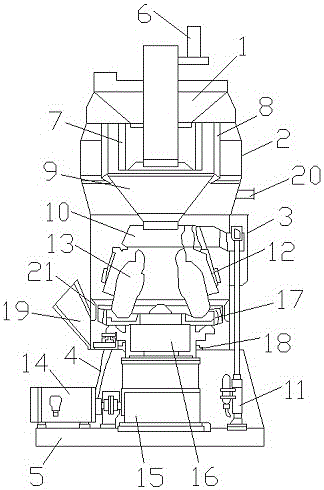

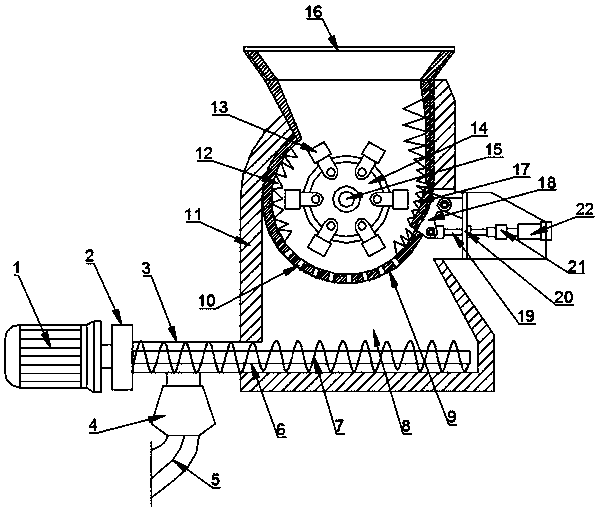

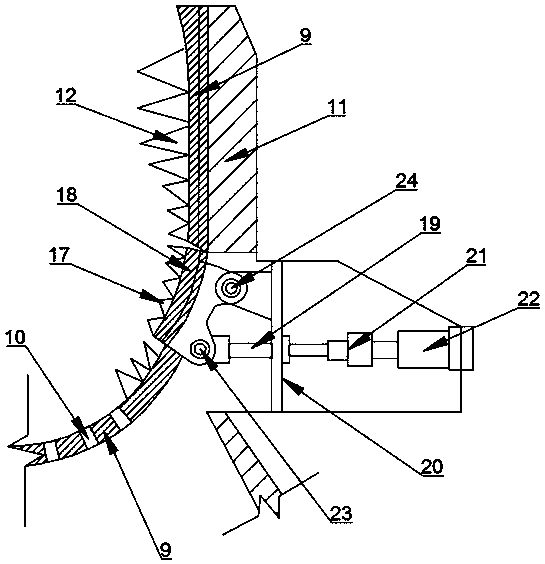

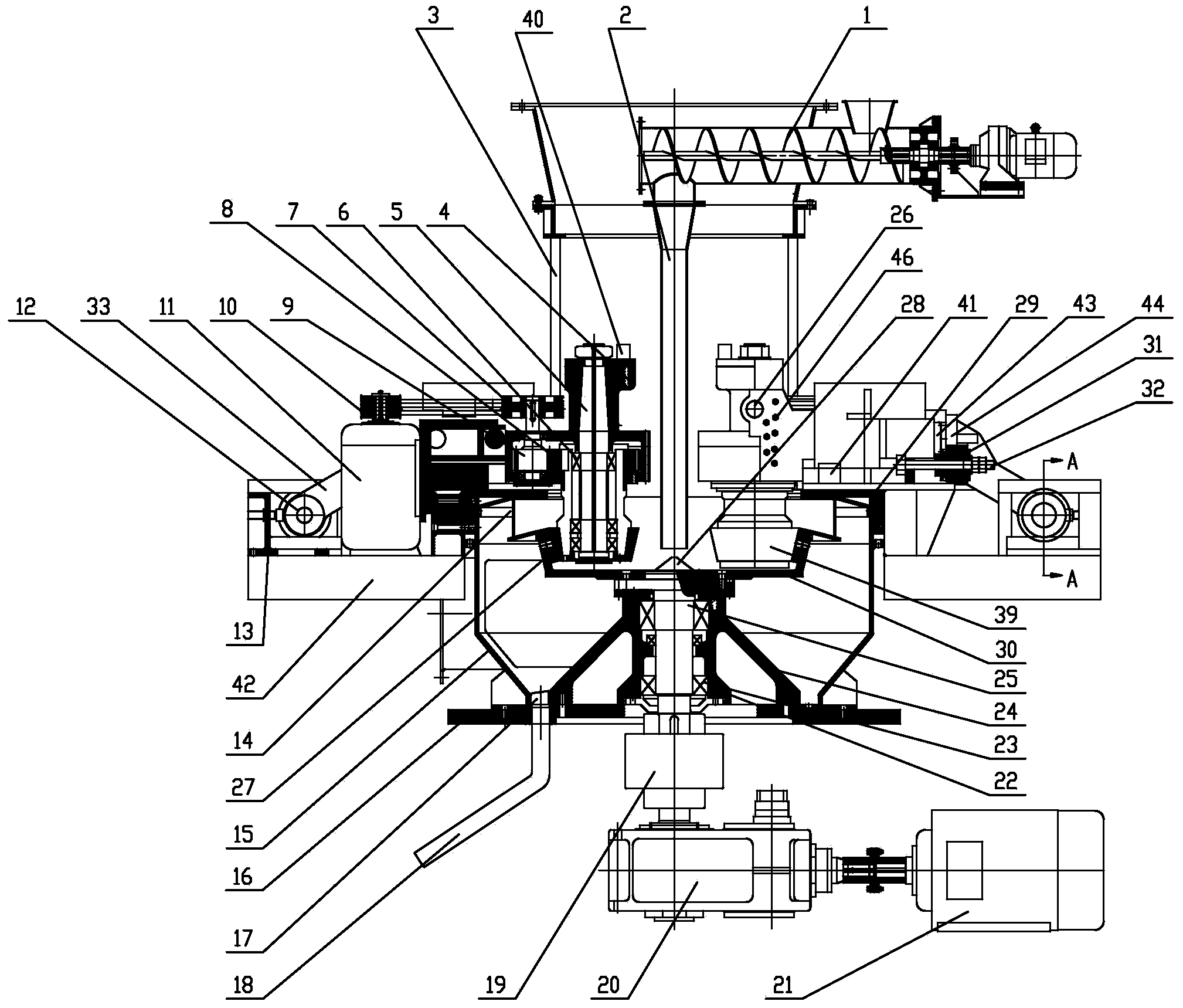

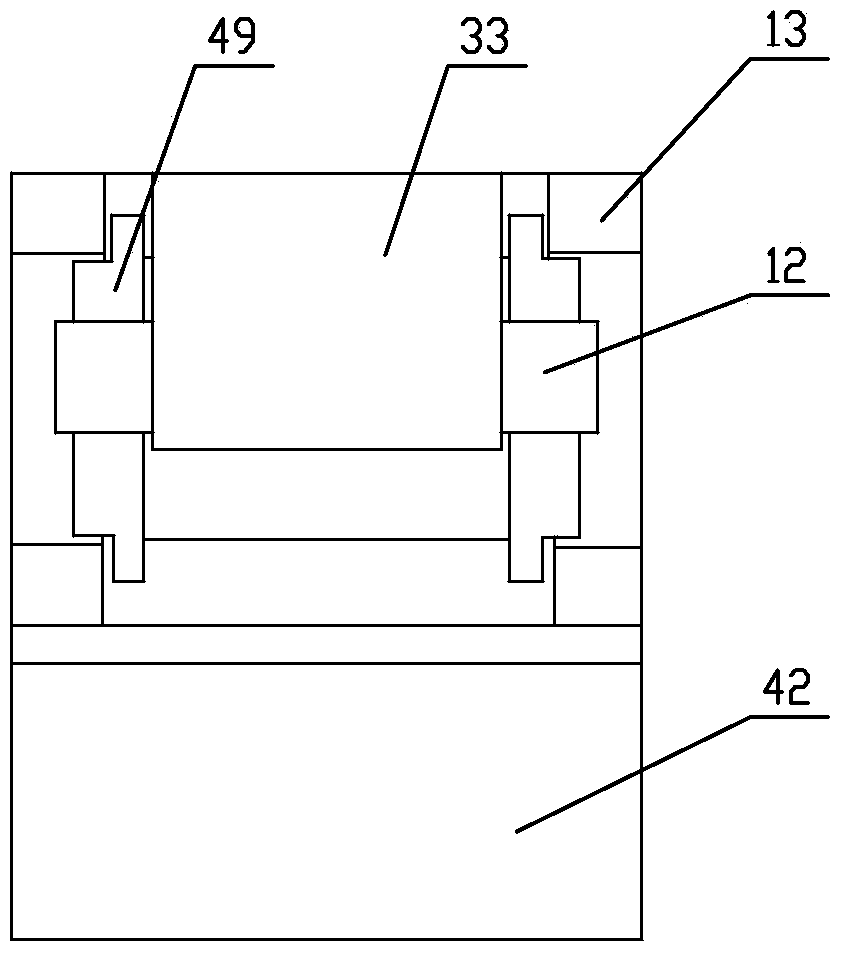

Coal mill for boiler

The invention discloses a coal mill for a boiler. The coal mill comprises a distributor, a dynamic separator, an upper frame body, a lower frame body and a base which are sequentially arranged from top to bottom, wherein a driving motor is arranged on the distributor; the distributor is in transmission connection with the driving motor; a rotary blade and a stationary blade are arranged in the dynamic separator; a refeed coal scuttle is arranged at the lower part of the dynamic separator; a loading rack and a pull rod are arranged below the refeed coal scuttle; the pull rod is arranged on one side of the loading rack; the loading rack is fixedly connected with the base through the pull rod; two grinding rollers are arranged on the inner side of a swinging and adjusting device; a motor is arranged on one side of the lower frame body; a speed reducer is arranged in the lower frame body. The coal mill for the boiler is compact in structure, stable in running, high in service efficiency and convenient to operate, can discharge dust during grinding to reduce pollution, and allows the diameter of ground coal powder to be adjusted.

Owner:WUXI YICHEN MOLD TECH

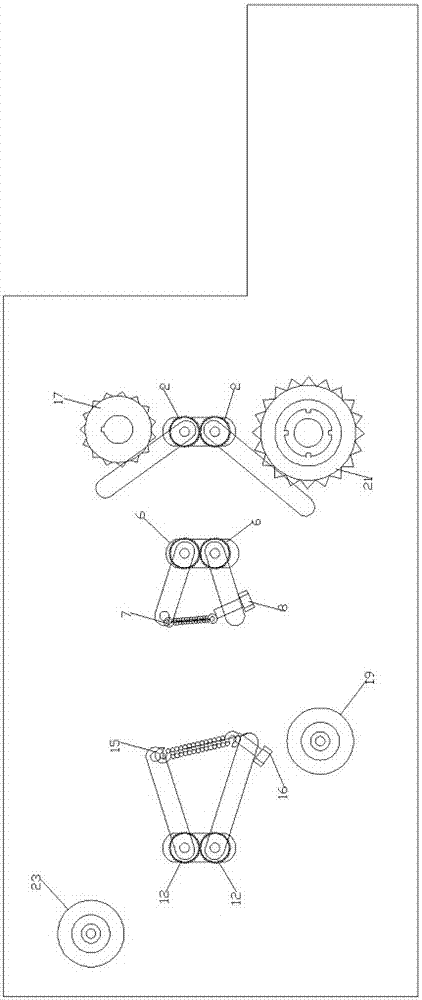

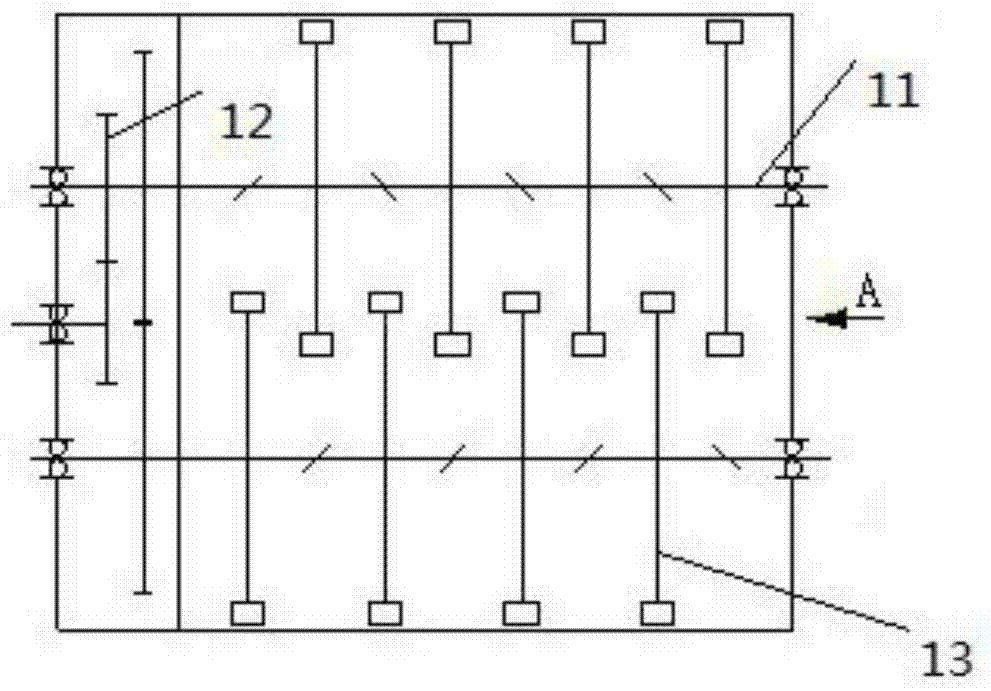

Instant shellfish hairbrush scrubbing machine

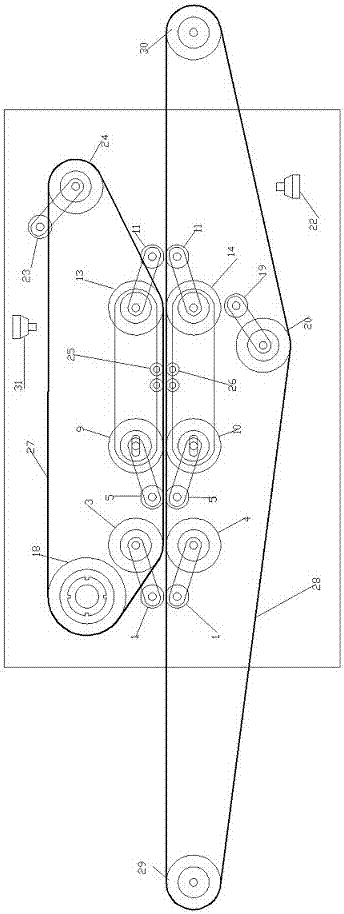

The invention relates to the field of production and processing, in particular to an instant shellfish hairbrush scrubbing machine, comprising multiple bearings, clamps and upper and lower groups of conveyor belts with hairbrushes, wherein the two groups of conveyor belts are not synchronous in speed; a chain wheel and an idler wheel for supporting the hairbrush conveyor belts form a conveying mechanism, the hairbrush conveyor belts are arranged in the conveying mechanism in a sleeving way to drive material transmission, and the upper and lower hairbrush conveyor belts are not synchronous in speed, so as to realize mutual scrubbing action; a first group of clamps are used for tightly pressing fed materials; a second group of clamps are used for enabling the materials to be in a center position and to be sufficiently scrubbed; the tensity of a spring is adjusted by adjusting a screw cap, so as to further adjust a gap between the hairbrush conveyor belts. The instant shellfish hairbrush scrubbing machine has the advantages of novel structure, high production efficiency and the like.

Owner:青岛天鼎信息科技有限公司

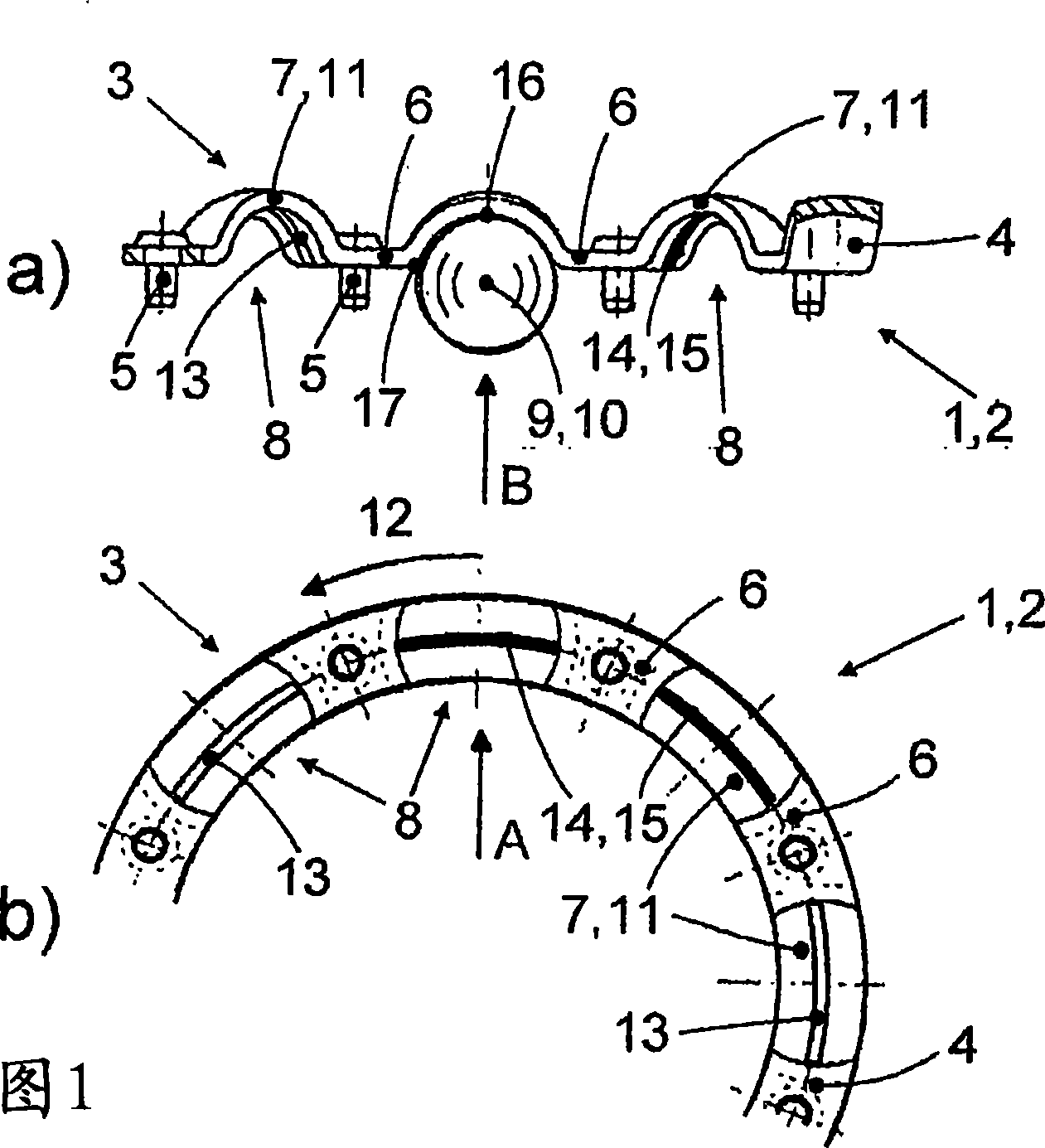

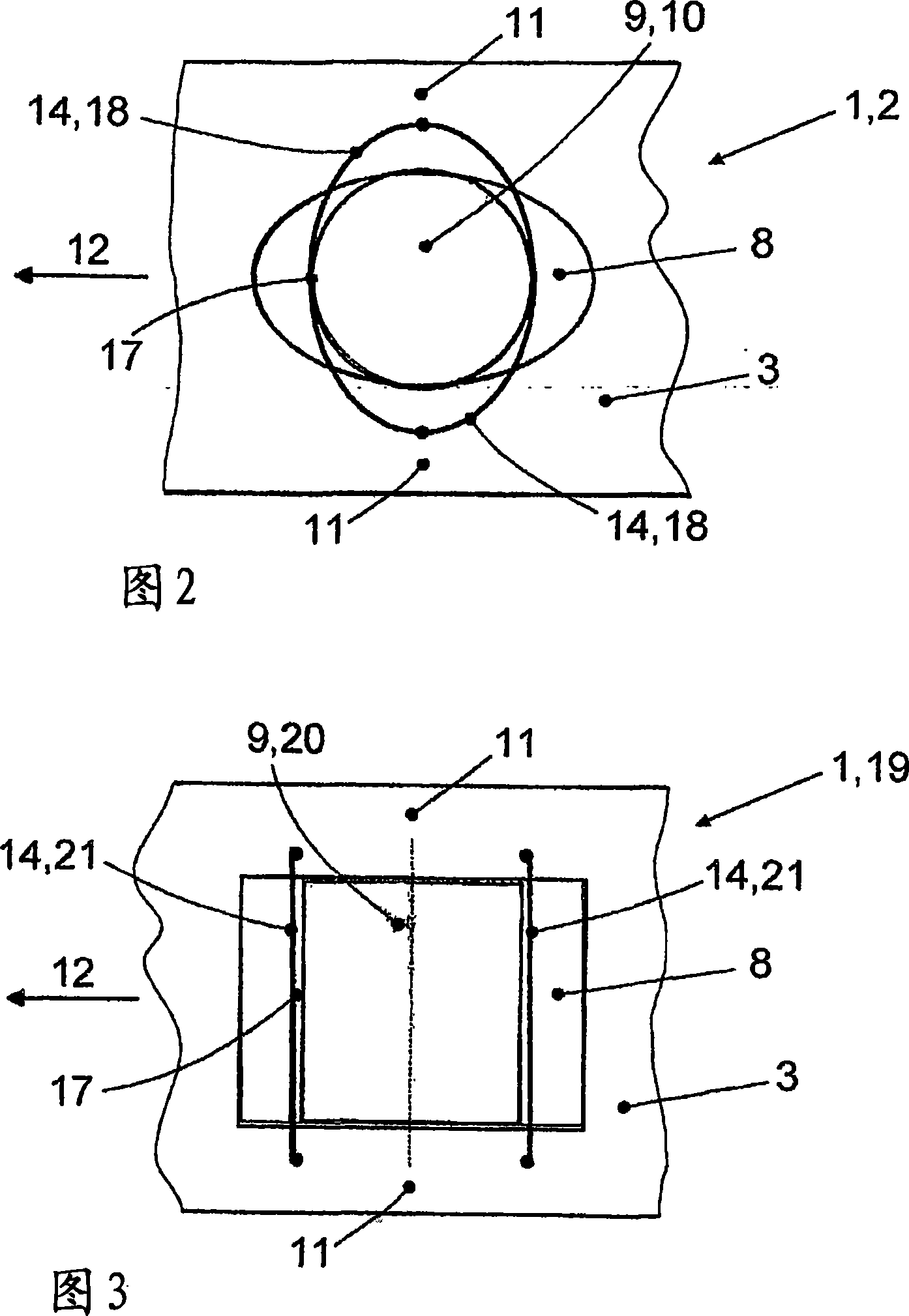

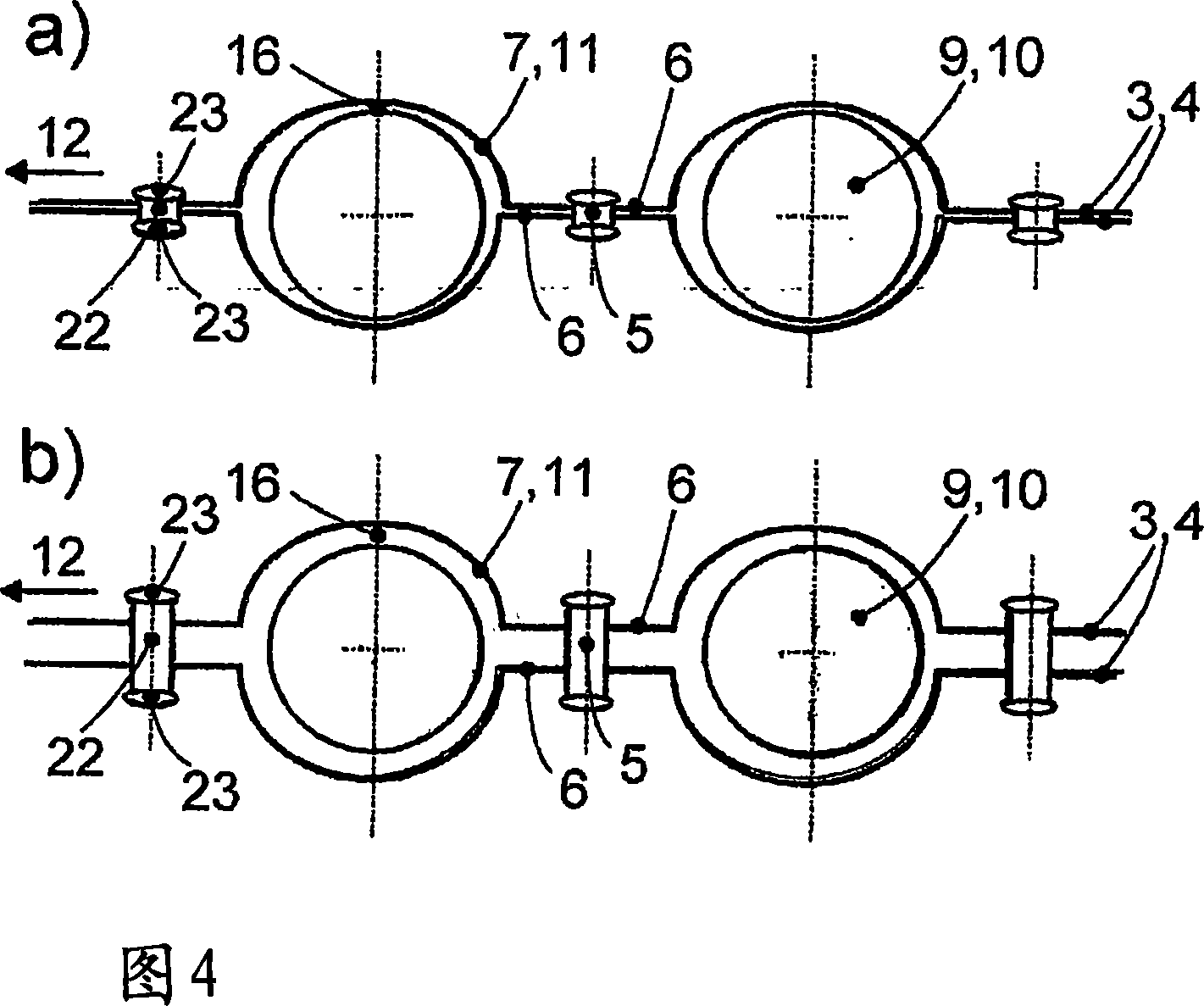

Combustion turbine with axial relative movel guide unit

InactiveCN1381670AAdjust the clearanceChange gapLeakage preventionGas turbine plantsCombustionEngineering

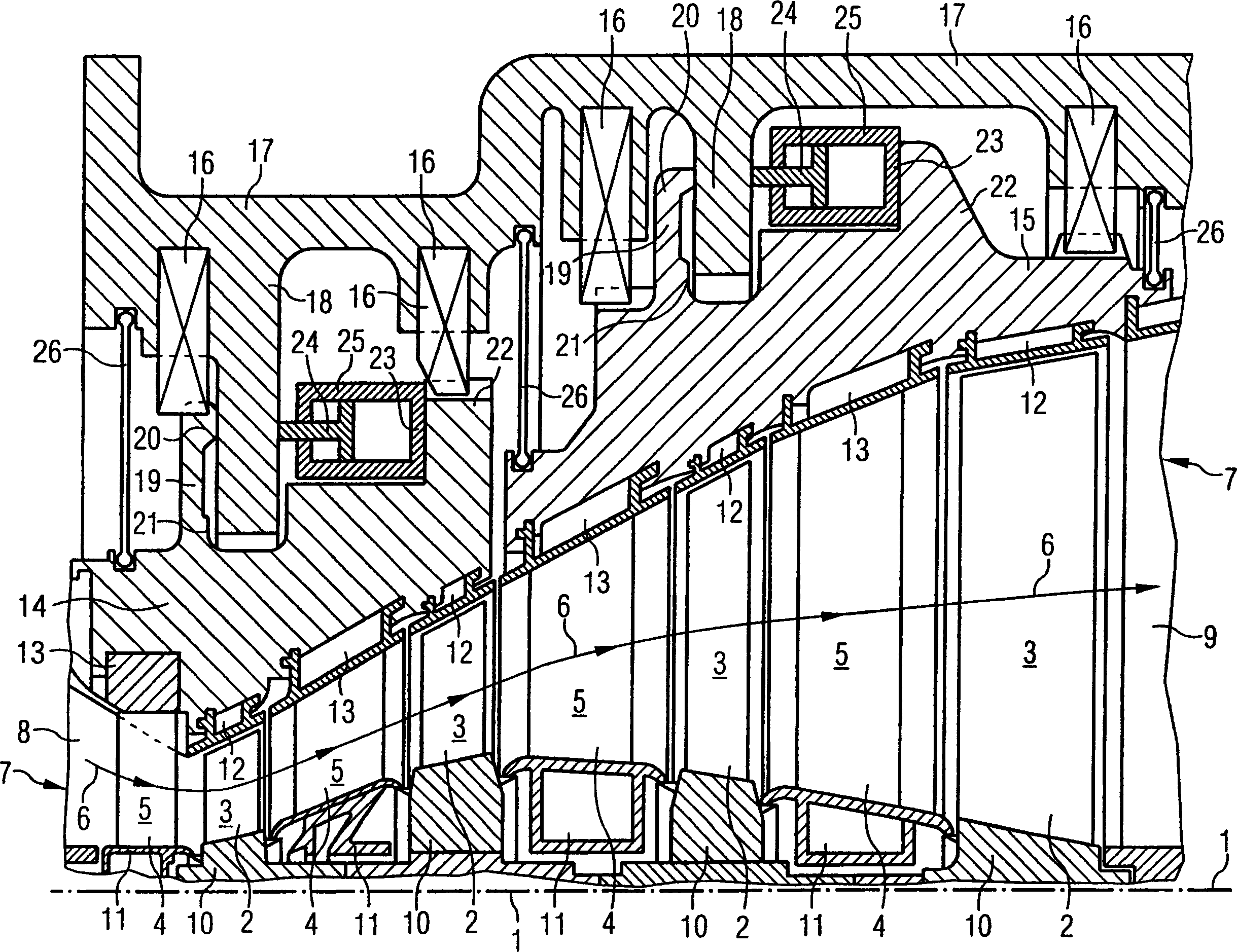

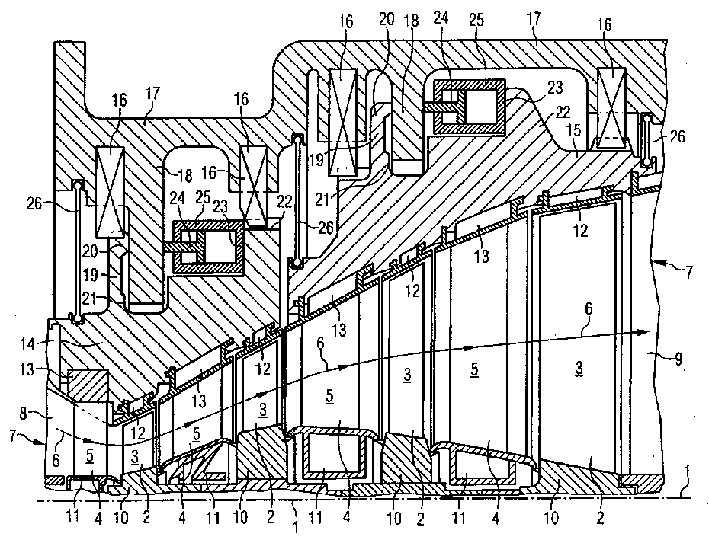

In order to balance different thermal expansions caused by thermal instability, the gas turbine of the present invention has a relatively movable guide part (14 / 15) in the axial direction, which surrounds a funnel-shaped gas channel (7) from the outside. In order to obtain an optimum working blade tip clearance, the invention proposes that at least one funnel-shaped guide part (14 / 15) can be moved axially controlled by a motor. By means of this axial movement, and due to the funnel-shaped configuration of the guide part, the width of the gap between the tips of the rotor blades can be varied.

Owner:SIEMENS AG

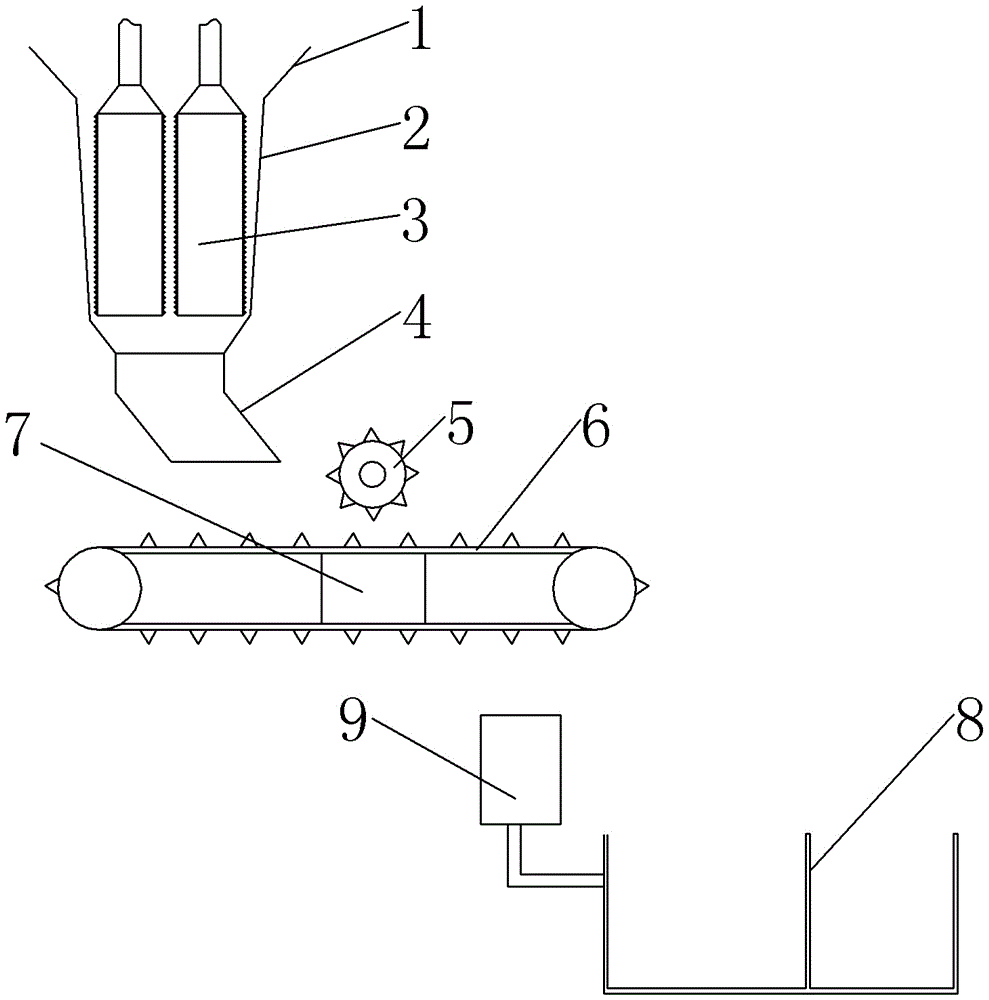

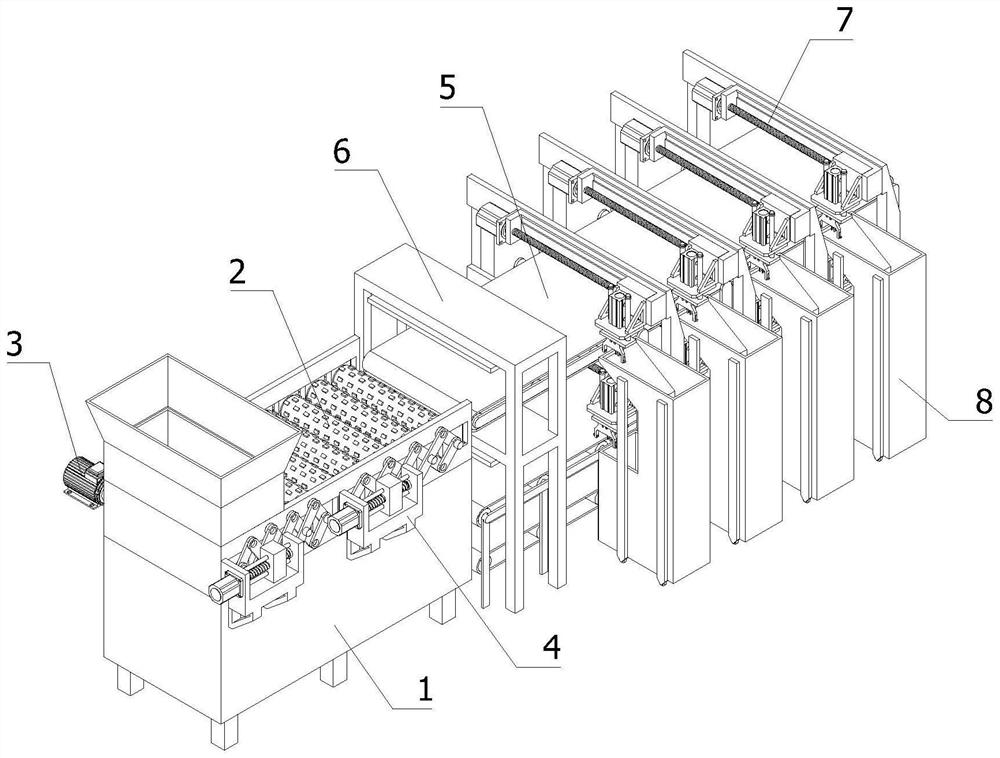

Mechanical equipment for processing walnut powder

The invention discloses mechanical equipment for processing walnut powder. The mechanical equipment for processing walnut powder comprises a frame, wherein an accumulating chamber is inverted-cone-shaped, the taper of the accommodating chamber is 1:7-8, shell breaking rolls which are connected with a motor and a driving shaft are suspended in the accommodating chamber, and are two rolls which are distributed at intervals, the bottom of the accommodating chamber communicates with a discharging channel, the discharging channel is inclined rightwards, spines are uniformly distributed on an additional roll, the additional roll is mounted between the discharging channel and a conveying belt, a supporting frame is arranged between two belt pulleys, a storage tank is arranged below the conveying belt and comprises a front tank for storing walnut kernels and a rear tank for storing walnut shells, the front tank and the rear tank are separated from each other by a partition, a fan is mounted on the outer wall of the left side of the front tank, and air blown out from the fan is horizontally rightward. By the mechanical equipment for processing the walnut powder, shells can be broken fully, time and labor are saved, efficiency is high, and walnut shell breaking costs are greatly reduced; and the mechanical equipment has great promotion effect on development of the industry.

Owner:贵州天和农业发展有限公司

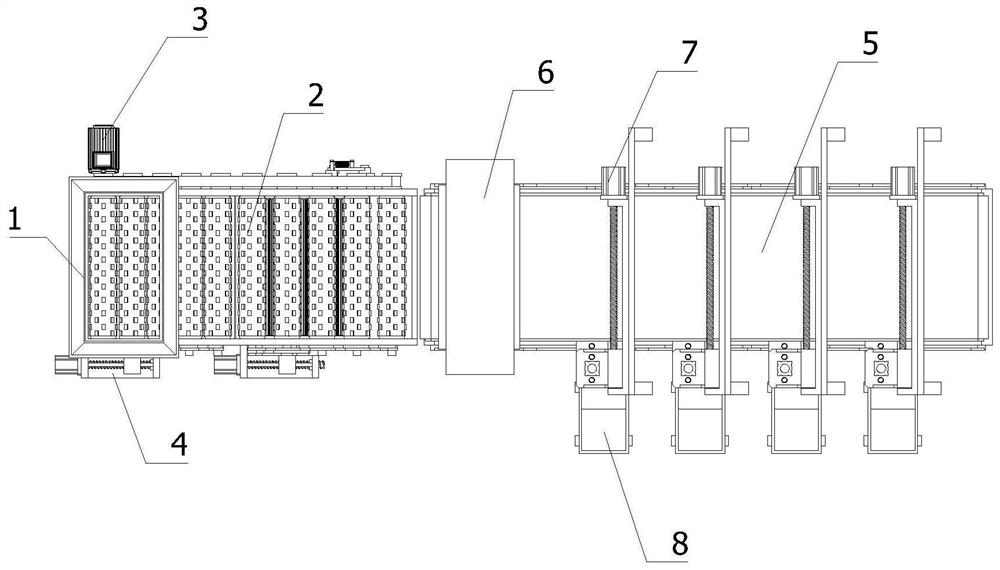

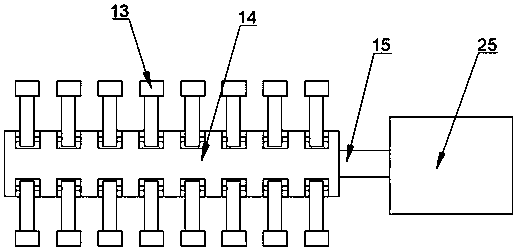

Automatic sorting equipment

PendingCN114160451ASolve technical problems of sortingFacilitate strippingSievingScreeningWorking environmentProcess engineering

The invention relates to the related field of coal mining, in particular to automatic sorting equipment which comprises a grading box, grading rollers, a driving assembly, an adjusting assembly, a conveying belt, an identifying assembly and a collecting assembly.The automatic sorting equipment comprises the grading box, the grading rollers, a driving assembly, an adjusting assembly, a conveying belt, an identifying assembly and a collecting assembly.Firstly, raw coal is poured into the grading box, and the size of a gap between every two adjacent grading rollers is adjusted through the adjusting assembly; raw coal is graded one by one according to the size of the gaps between the grading rollers, then all the grading rollers are driven by the driving assembly to rotate, the raw coal which does not fall off from the gaps between the grading rollers moves in the length direction of the grading box, and the graded raw coal finally falls onto the conveying belt. According to the coal gangue sorting device, coal gangue in raw coal is recognized through the recognition assembly on the conveying belt, then the recognized coal gangue is clamped through the material moving mechanism and moved out of the conveying belt, and the technical problems that when the coal gangue is sorted in a manual mode, labor intensity is large, the working environment is severe, and efficiency is low are solved.

Owner:李扬

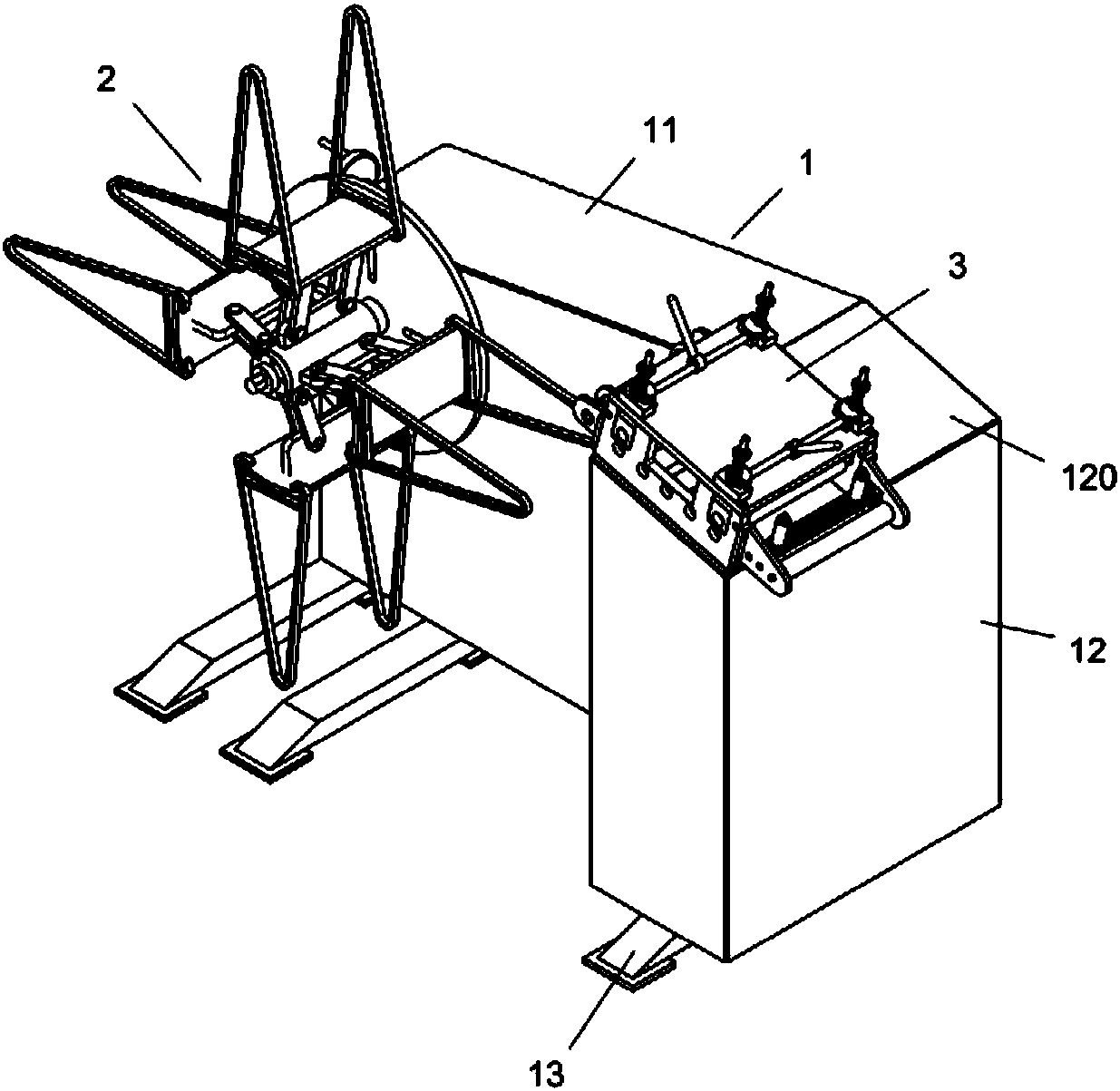

Cloth winding device of textile dyeing and cloth-collecting equipment

InactiveCN108423472AAvoid offsetAdjust the clearanceTextile treatment carriersWebs handlingEngineeringCentrifugal force

The invention discloses a cloth winding device of textile dyeing and cloth-collecting equipment, the device comprises a machine box, wherein a cloth guiding device and a cloth winding device are arranged at the upper part of the machine box sequentially, a cloth guiding driving mechanism and a cloth winding driving mechanism are arranged in the machine box, the cloth guiding driving mechanism drives the cloth guiding device to operate, and the cloth winding driving mechanism drives the cloth winding device to operate. According to the cloth winding device of the textile dyeing and cloth-collecting equipment, the cloth guiding device and the cloth winding device are arranged, the cloth guiding device can be used for guiding incoming cloth, the cloth winding device is in an automatic tension-type winding structure, a center shaft can be driven to rotate by a driving mechanism, further a swing rod at the upper part of the center shaft is driven to swing, the swing rod will drive an arc-shaped cloth winding plate to expand outwards under the action of centrifugal force, further a paper tube with which the upper part of the cloth winding plate is sleeved is tensioned, automatic cloth winding is realized, when the center shaft stops rotating, the swing rod drives the arc-shaped cloth winding plate to retract, and accordingly, the paper tube is released.

Owner:苏州默声熙达设备科技有限公司

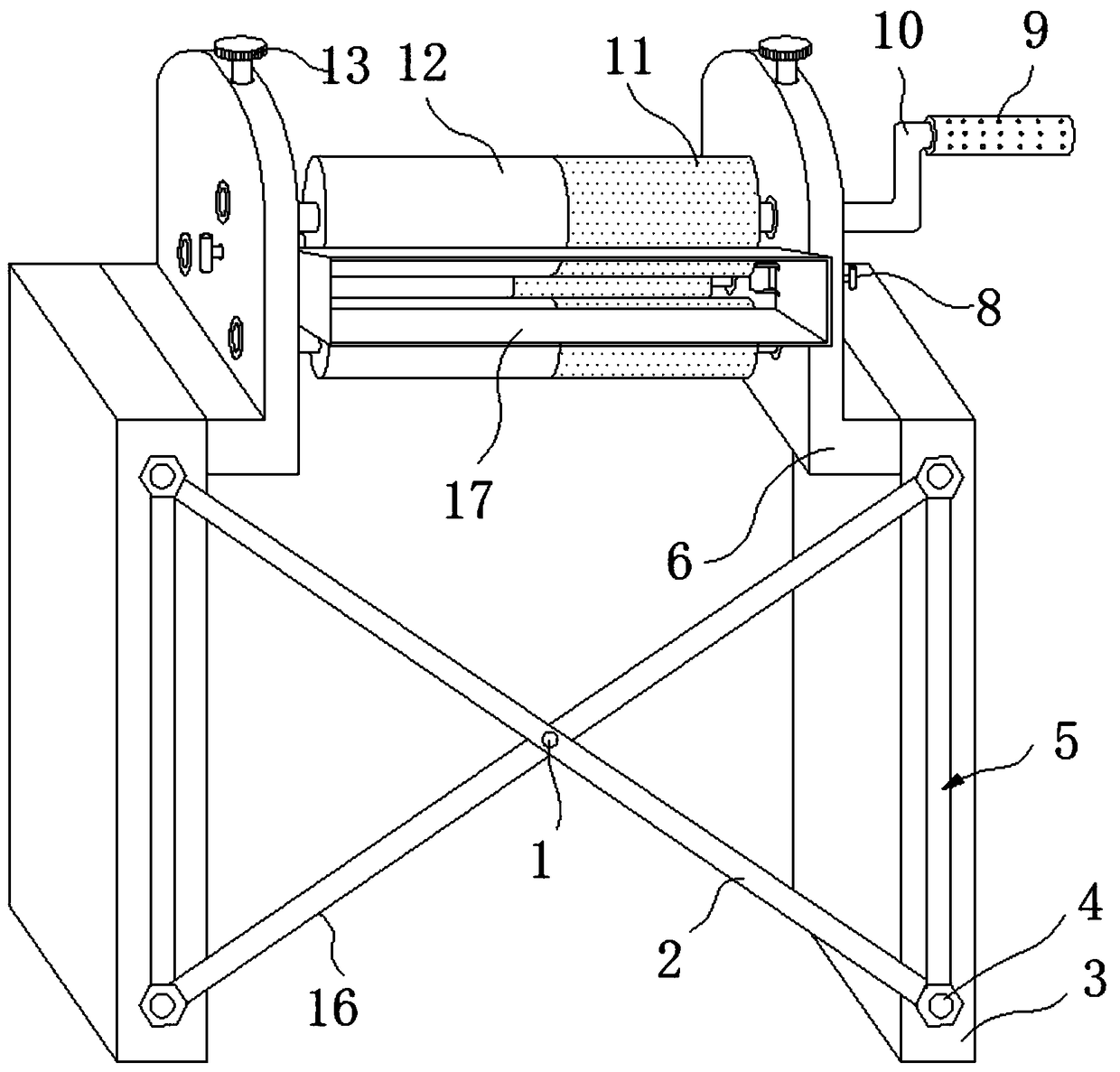

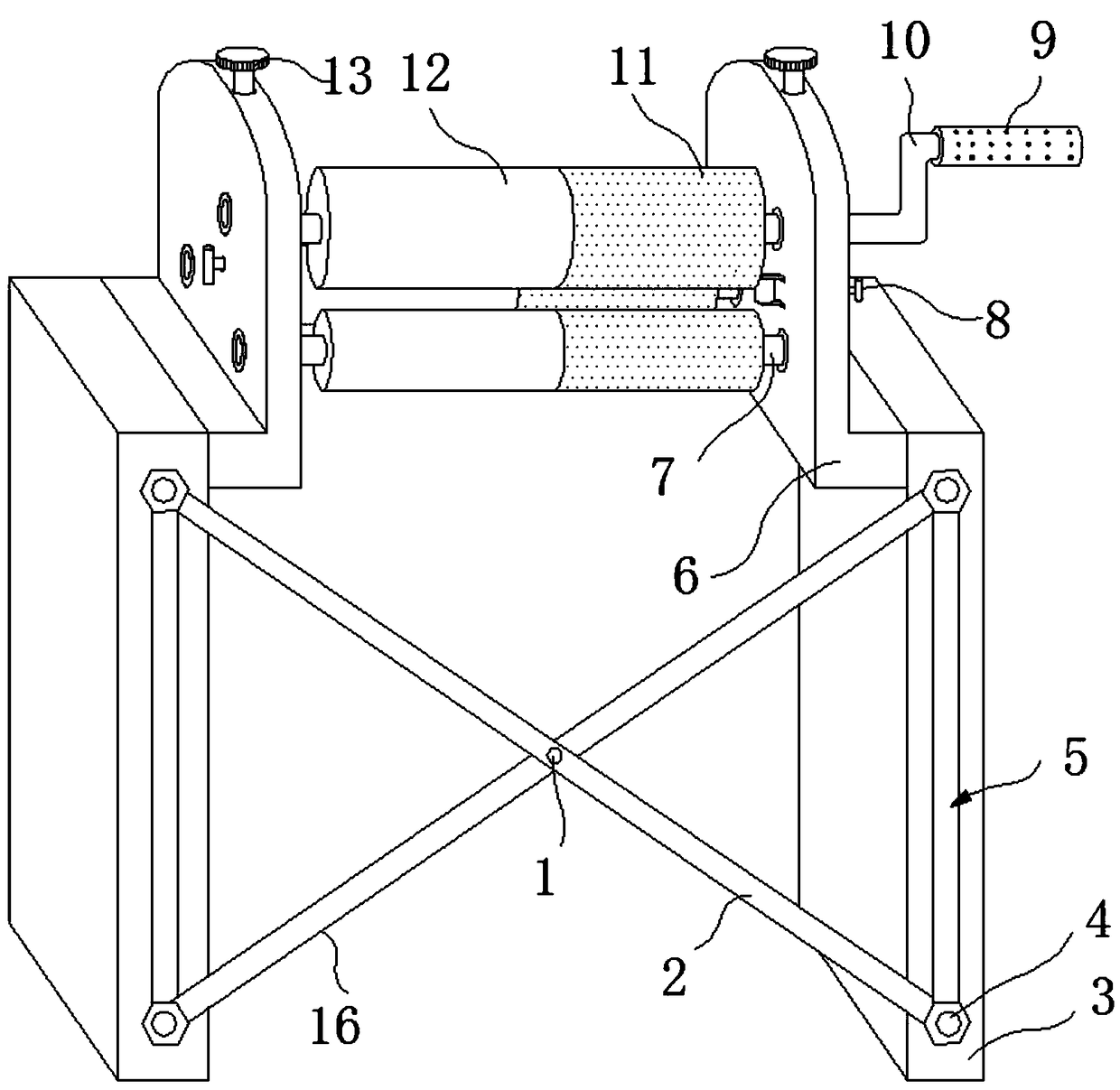

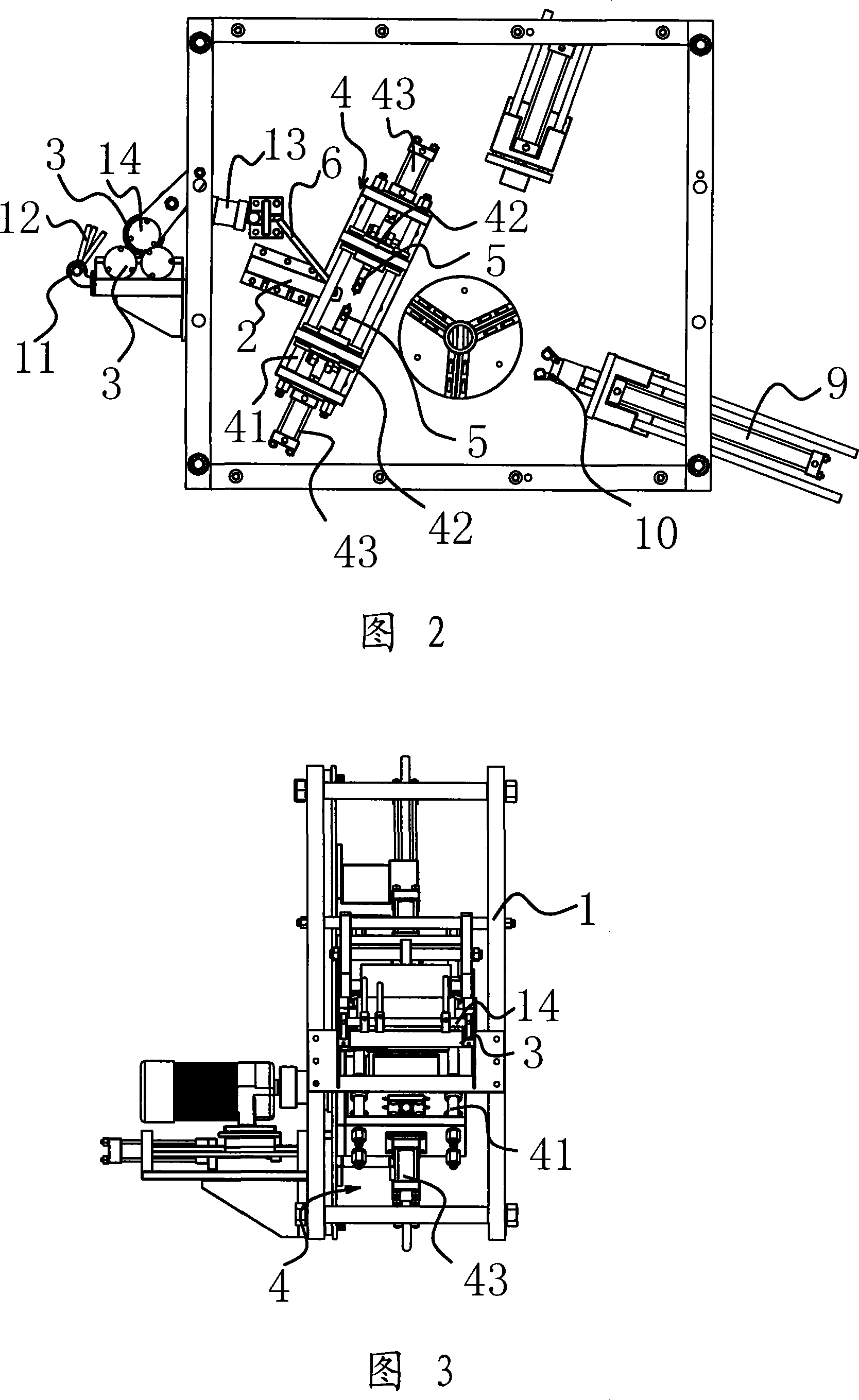

Main machine of bottom-coating roller coater

InactiveCN104324843ACompact structureAdjust the clearanceLiquid surface applicatorsCoatingsSurface mountingSurface coating

The invention relates to a main machine of a bottom-coating roller coater. The main machine comprises a surface coating mechanism and a back surface coating mechanism, and is characterized in that the back surface coating mechanism comprises a back coating regulating mechanism and a back coating roller support, wherein a second linear guide track is transversely arranged between the back coating regulating mechanism and the back coating roller support, a second slide block is arranged on the second linear guide track, and the second slide block is fixed on a back coating strip material roller support; the surface coating mechanism comprises a surface coating support, a third slide block is arranged at the bottom of the surface coating support, the third slide block is matched with a third linear guide track which is horizontally arranged on a frame of the roller coater, a fourth linear guide track is mounted on the upper surface of the surface coating support, a fourth slide block is arranged on the fourth linear guide track, and the fourth slide block is fixed at the bottom of a surface coating roller support; and a fifth linear guide track is mounted on the upper surface of the surface coating roller support, a fifth slide block is arranged on the fifth linear guide track, and the fifth slide block is fixed at the bottom of a surface coating strip material roller support. The main machine provided by the invention is compact in structure and can conveniently and reasonably regulate the gap between rollers so as to ensure the service life of equipment.

Owner:WUXI Z&C GENERAL MACHINERY & ELECTRICAL

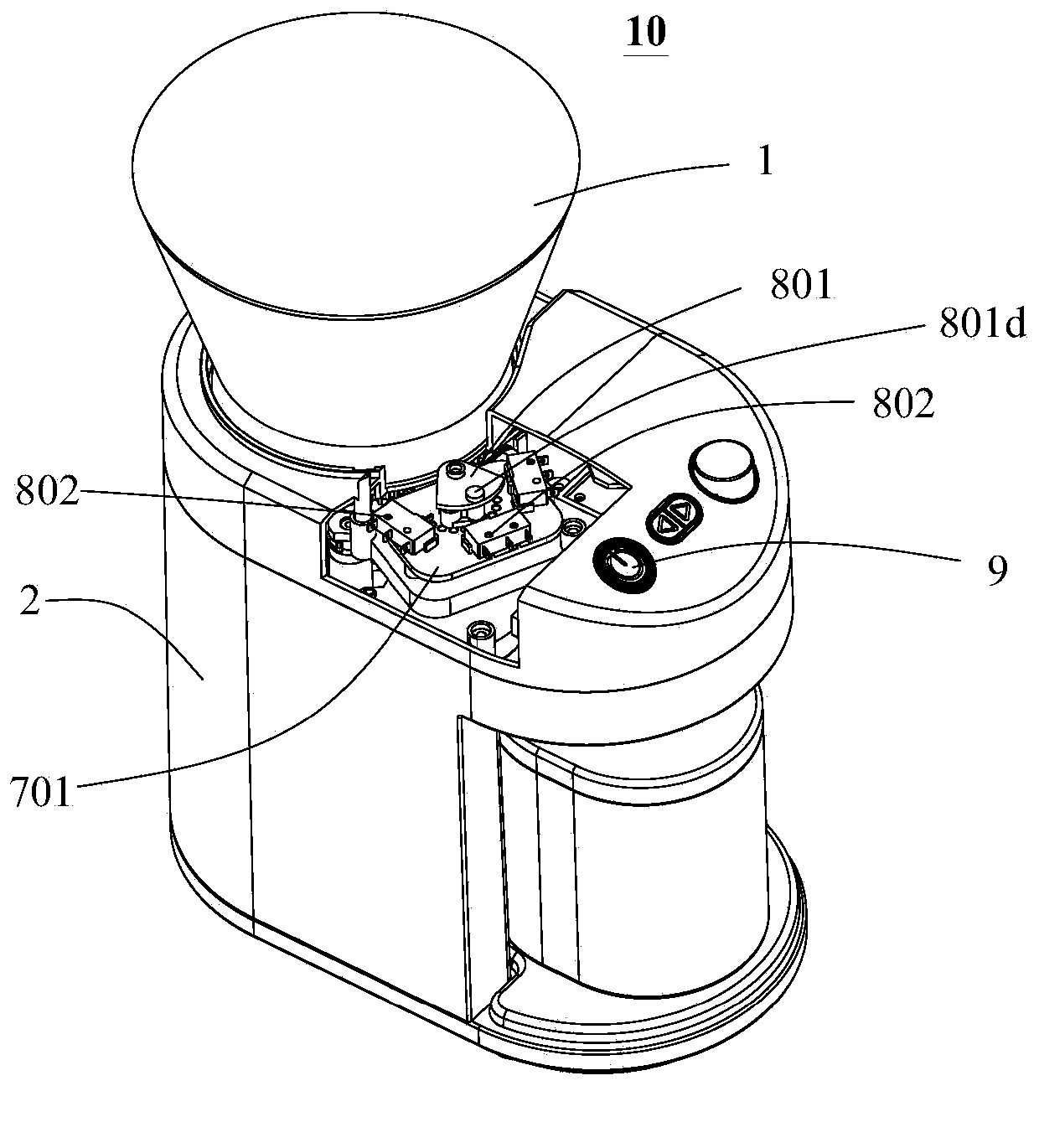

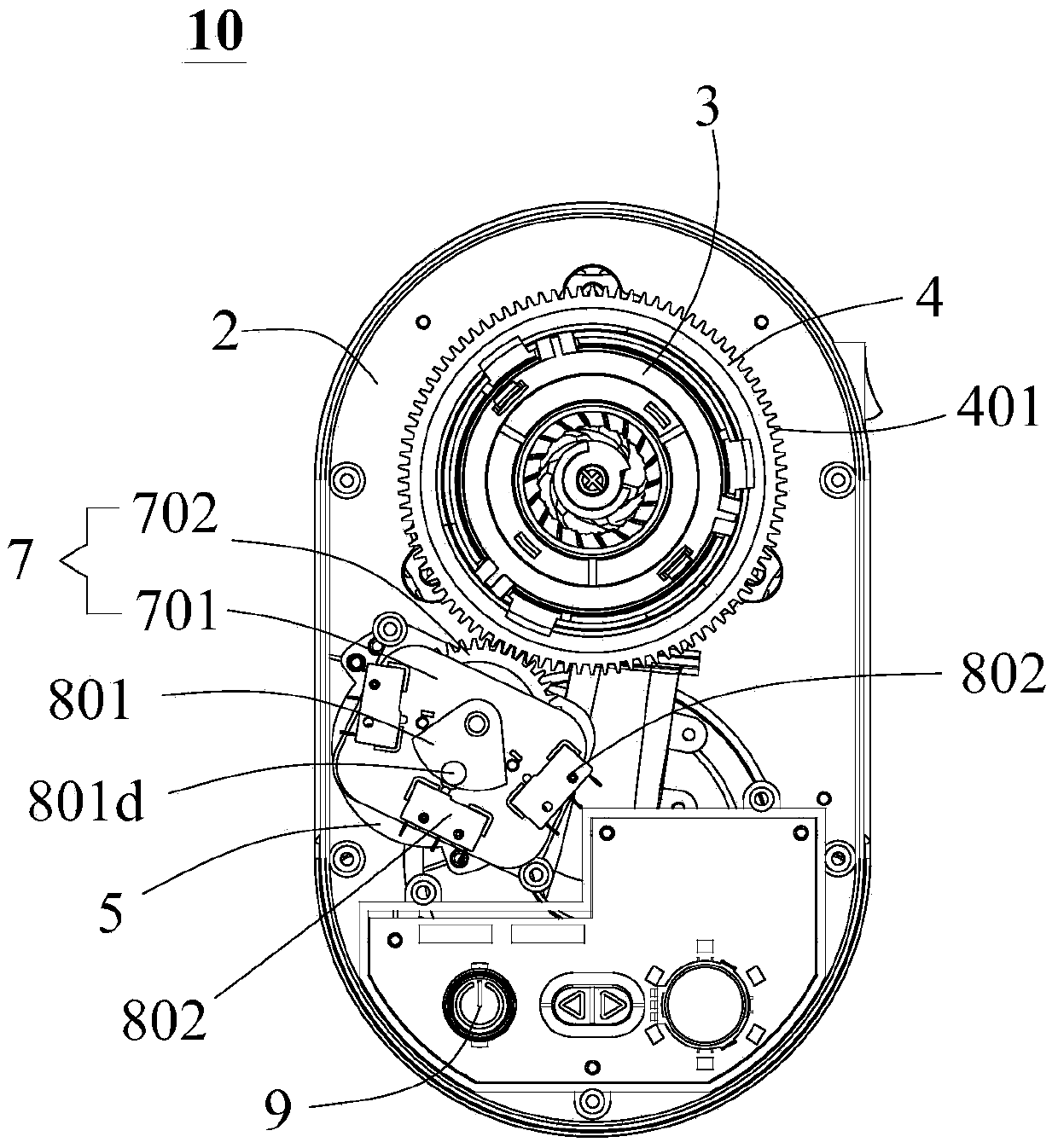

Powder grinding device

ActiveCN104172946AEasy to useControl rotation angleCoffee millsSpice millsEngineeringElectric control

The invention relates to a powder grinding device which comprises a main body, an abrasive wheel assembly arranged in the main body, a rotary adjusting ring arranged on the abrasive wheel assembly and used for adjusting crudeness and fineness of powder ground by the abrasive wheel assembly, a power source arranged on the main body and used for promoting rotation of the rotary adjusting ring, and an angle controller arranged on the main body and used for controlling the rotation angle of the rotary adjusting ring. According to the powder grinding device, the crudeness and fineness of the ground powder are adjusted by the adoption of an electric control mode, so that the use of the powder grinding device is simple, and the level in people's heart is improved.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

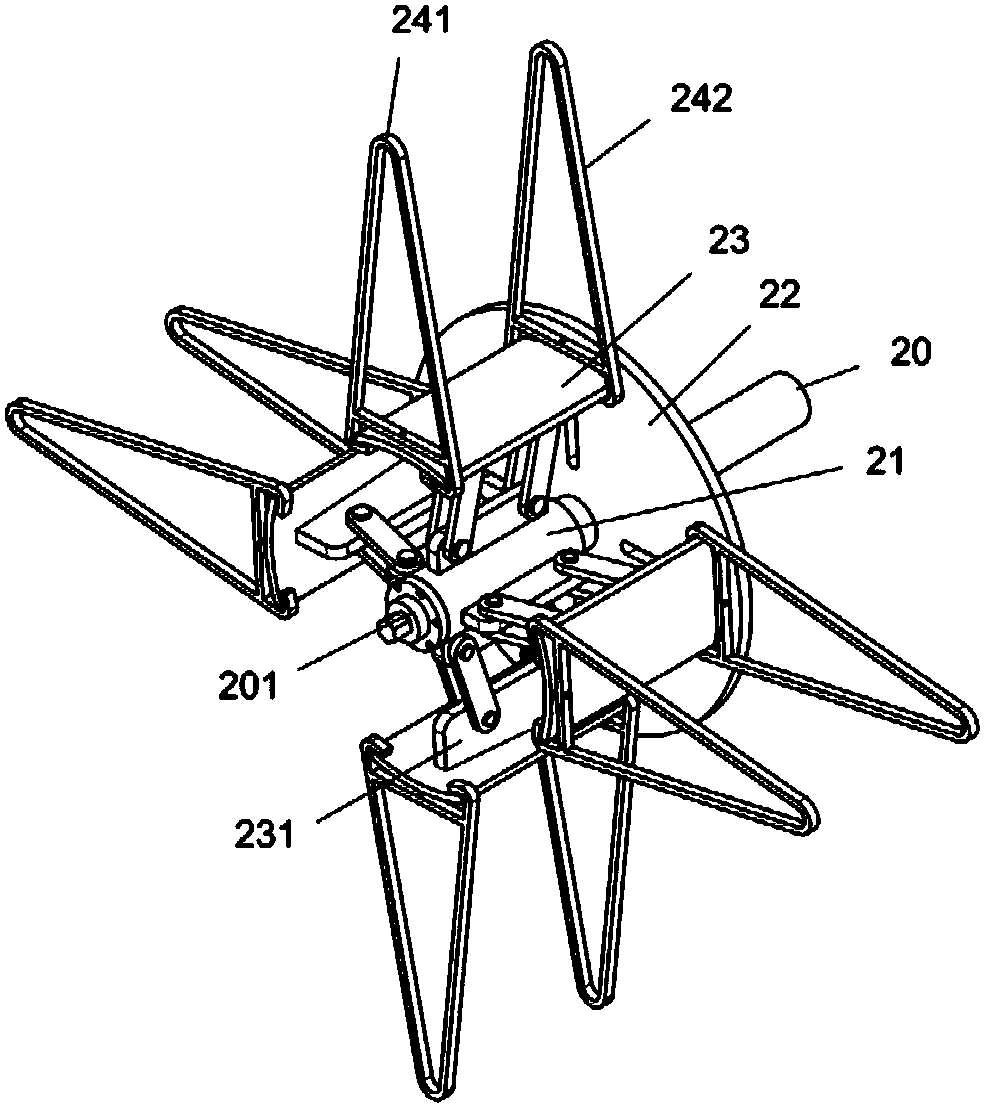

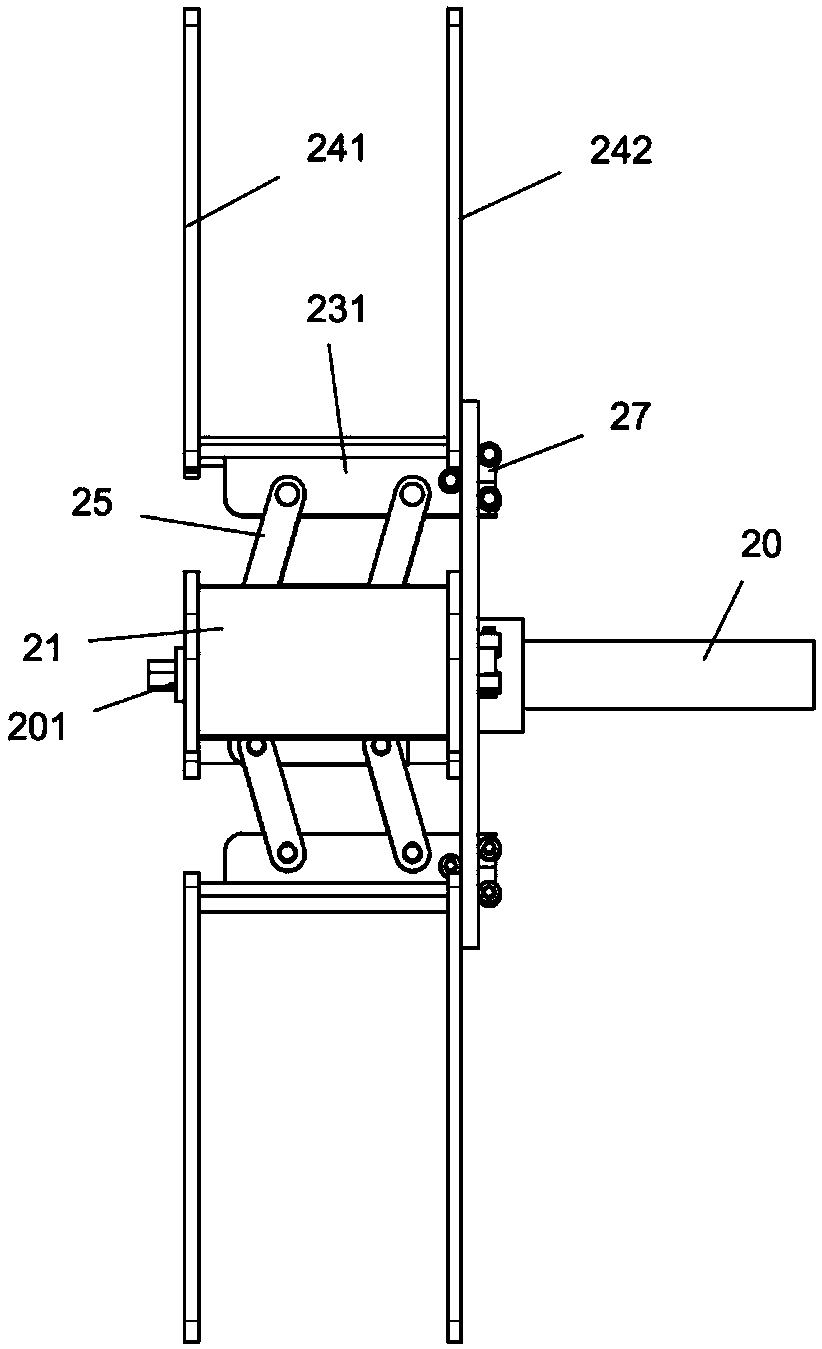

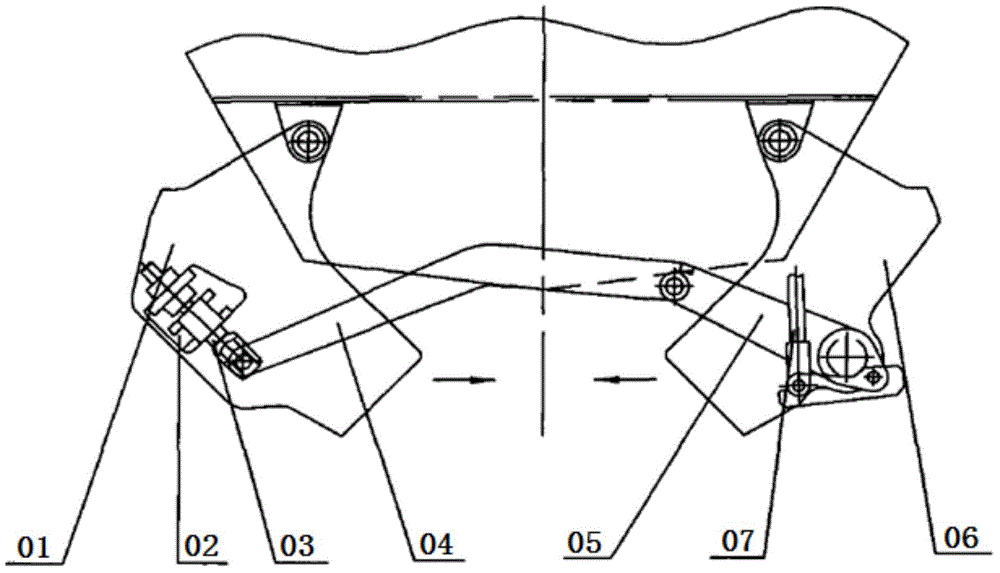

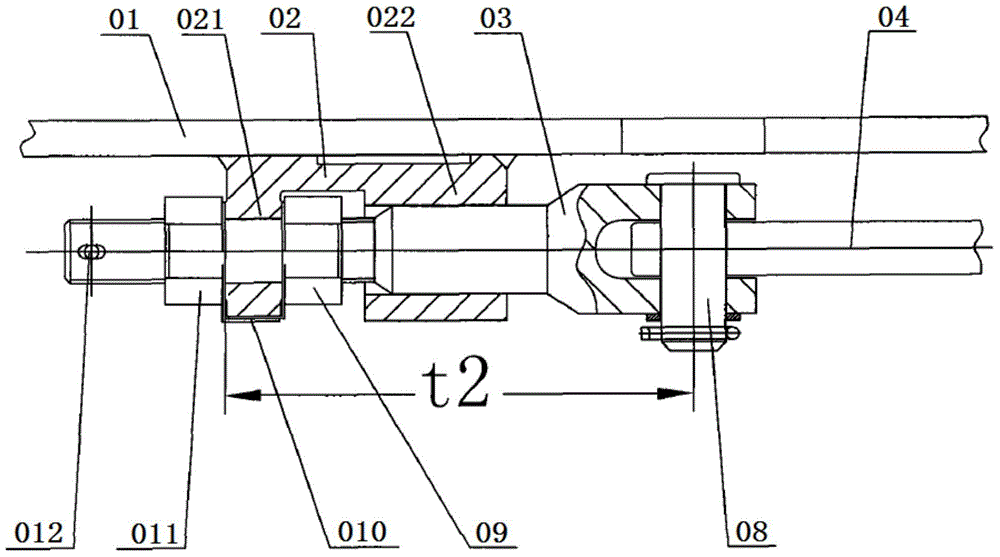

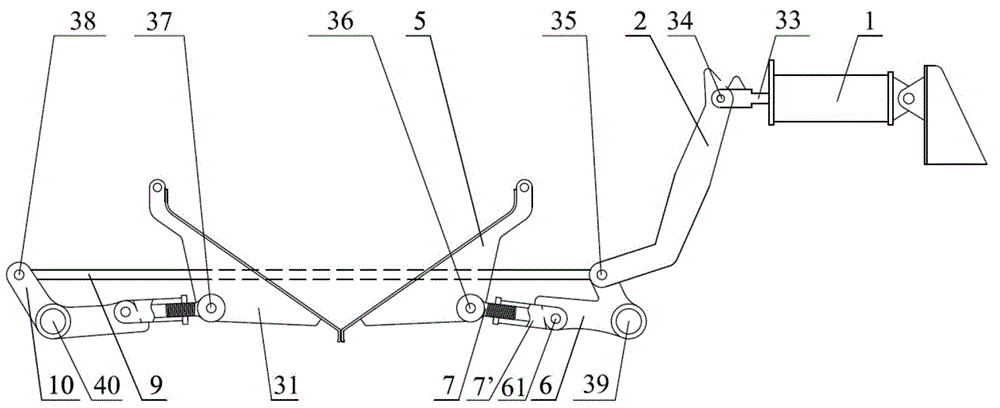

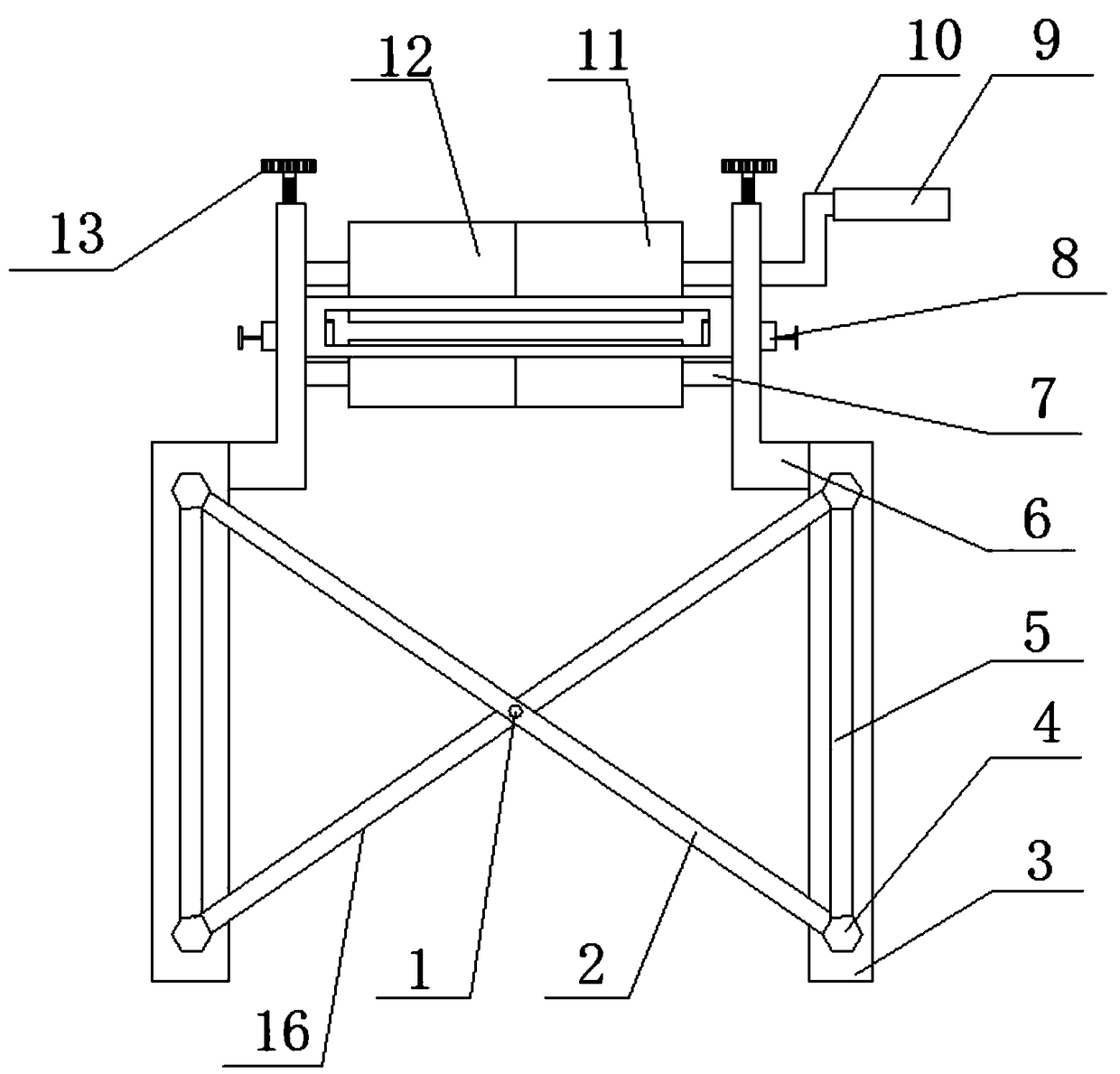

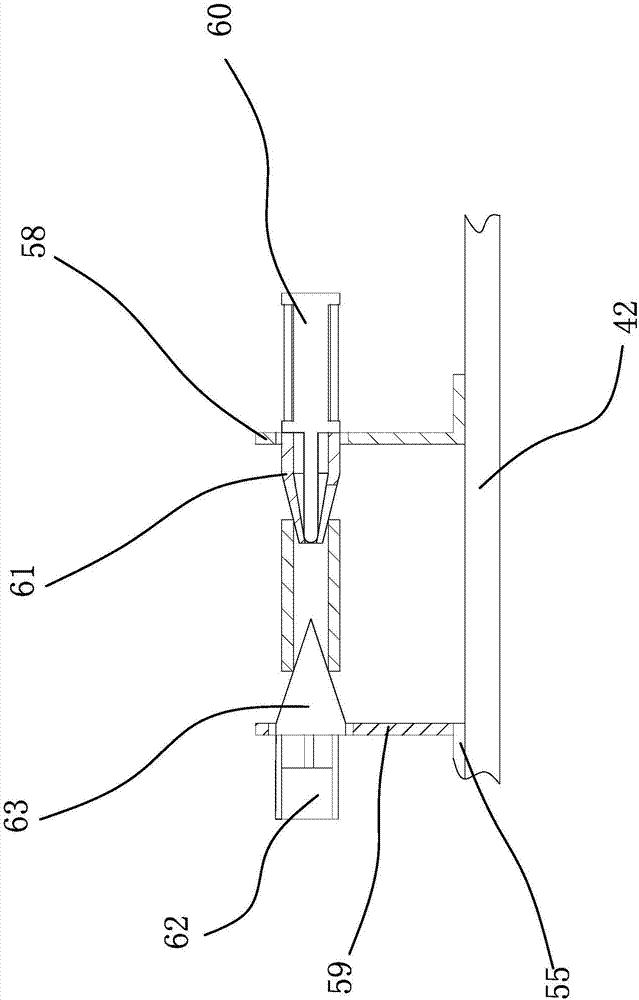

Bottom door clearance adjustment mechanism and hopper car

ActiveCN104875757ASimple control systemAdjust the clearanceHopper carsControl systemAgricultural engineering

The invention discloses a bottom door clearance adjustment mechanism and a hopper car and belongs to the technical field of hopper cars for railways. The bottom door clearance adjustment mechanism comprises a telescopic type driving component and a connecting rod type drive mechanism, wherein the connecting rod type drive mechanism comprises a first connecting rod, a second connecting rod and a plurality of telescopic type third connecting rods, the first connecting rod and the second connecting rod are hinged, a free end of the telescopic driving component is hinged to the free end of the first connecting rod, and the second connecting rod is hinged with a first side bottom door and a second side bottom door of each bottom door through the telescopic type third connecting rods respectively. The hopper car is provided with the bottom door clearance adjustment mechanism. According to the bottom door clearance adjustment mechanism and the hopper car, a plurality of bottom doors are controlled to be opened or closed simultaneously by the connecting rod type drive mechanism on the basis of only one telescopic type driving component, and the control system is simple; clearance adjustment of two side bottom doors of each bottom door can be achieved.

Owner:CRRC YANGTZE CO LTD

Three-roller symmetric type plate rolling machine

The invention relates to the field of cold working equipment and particularly relates to a three-roller symmetric type plate rolling machine. The three-roller symmetric type plate rolling machine comprises a screw, a first support, a side plate, a nut, a sliding groove, vertical plates, roller shafts, a limiting structure, a handle, a limiting block, a pulley, a ferrule, a dowel, an anti-slip sleeve, a crank, first press rollers, second press rollers, a locking nut, a bearing, a locating block, a second support, a feeding plate and a stop block. The sliding groove is arranged in the side plate, the sliding groove is in rotating connection with the first support and the second support through the nut, the two vertical plates are arranged at the top end of the side plate and symmetrically distributed, the three roller shafts are in rotating connection with the vertical plates through the bearing, one ends of the roller shafts are connected with the vertical plates, the ferrule is in rotating connection with the pulley through the dowel, and rolled materials can be guided by the pulley. The roller shafts are driven to rotate by rocking the crank with the hand, so that the coiling of the plate materials is facilitated. By arranging the first press rollers and the second press rollers on the roller shafts in a sleeving manner, the coiling of different plate materials is facilitated.

Owner:江苏中泰绿色建筑科技有限公司

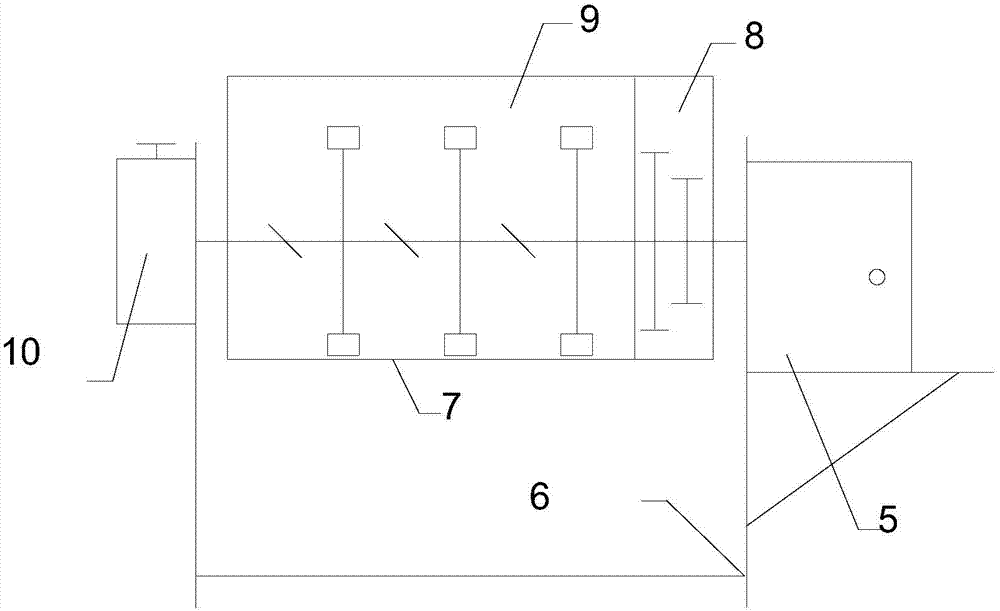

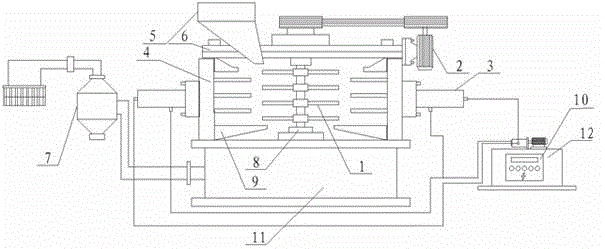

Concrete workability testing device and concrete workability testing method

The invention relates to a testing device, and particularly relates to a concrete workability testing device and a concrete workability testing method. The concrete workability testing device comprises a rack, and a mixing cylinder body fixed on the rack, wherein power equipment and a discharging device are arranged at two sides of the mixing cylinder body; a gear transmission box and a mixing cylinder are arranged in the mixing cylinder body, mixing shafts are arranged in the mixing cylinder, mixing arms are fixedly arranged on each group of mixing shafts, blades are fixedly arranged on the mixing arms; the mixing shafts are connected with the gear transmission box; the power equipment comprises a motor, the motor is connected with an electric cabinet and a speed reducing box respectively, and a torque velocity sensor is connected with the speed reducing box and the mixing shafts. According to the concrete workability testing device, a power parameter in a mixing process is obtained by virtue of the torque velocity sensor, further the concrete workability is obtained, and the quality of a finished material is accurately reflected; the rotating speed of the motor is regulated, and further the mixing speed is controlled, the concrete workability in a mixing process is dynamically monitored, and the real-time change of the concrete workability in the mixing process is relatively systematically and completely obtained.

Owner:CHANGAN UNIV

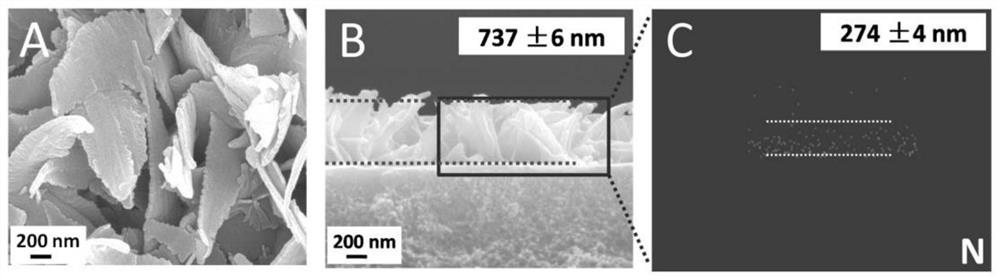

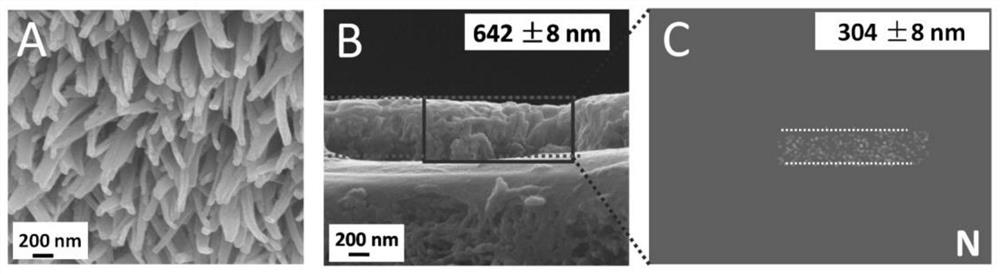

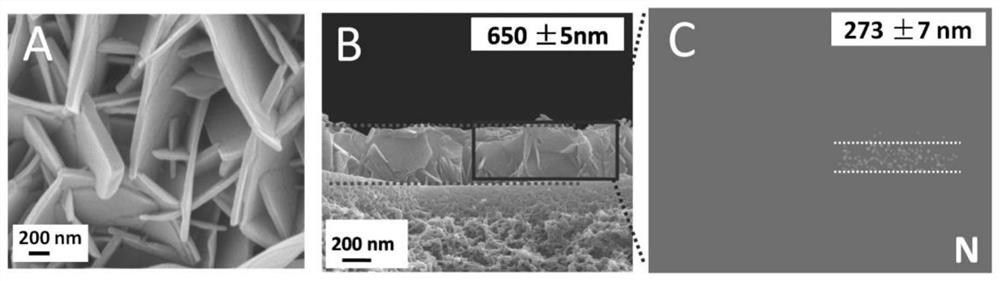

Mixed matrix membrane with high-selectivity gas channel and preparation method

ActiveCN111744375AAddressing the Effects of Gas Separation PerformanceImprove permeabilitySemi-permeable membranesGas treatmentHydrophilic polymersPolysulfone membrane

The invention discloses a mixed matrix membrane with a high-selectivity gas channel and a preparation method and belongs to the technical field of membrane separation. The preparation method comprisesthe following steps of: coating the surface of polysulfone with polydimethylsiloxane and polyvinyl alcohol to prepare a hydrophilic modified polysulfone membrane; applying a low-temperature solid-phase synthesis method to synthesize metal compound hydrophobic filler particles in situ on the surface of the obtained hydrophilic modified polysulfone membrane by utilizing metal salt and ligand so asto obtain a hydrophobic HMP / MPSf membrane; and finally, coating the surface of the hydrophobic HMP / MPSf membrane with the hydrophilic polymer polyvinylamine for interface self-assembly, and then drying to obtain the mixed matrix membrane with the high-selectivity gas channel. The CO2 permeation rate of the mixed matrix membrane with the high-selectivity gas channel is 1800-3400 GPU; the CO2 permeation coefficient of the mixed matrix membrane is 490-995Barrer; and the CO2 / N2 selectivity of the mixed matrix membrane is preferably 65-70. The mixed matrix membrane is particularly suitable for separation of mixed gas containing carbon dioxide.

Owner:中恒新材料科技(山东)有限责任公司

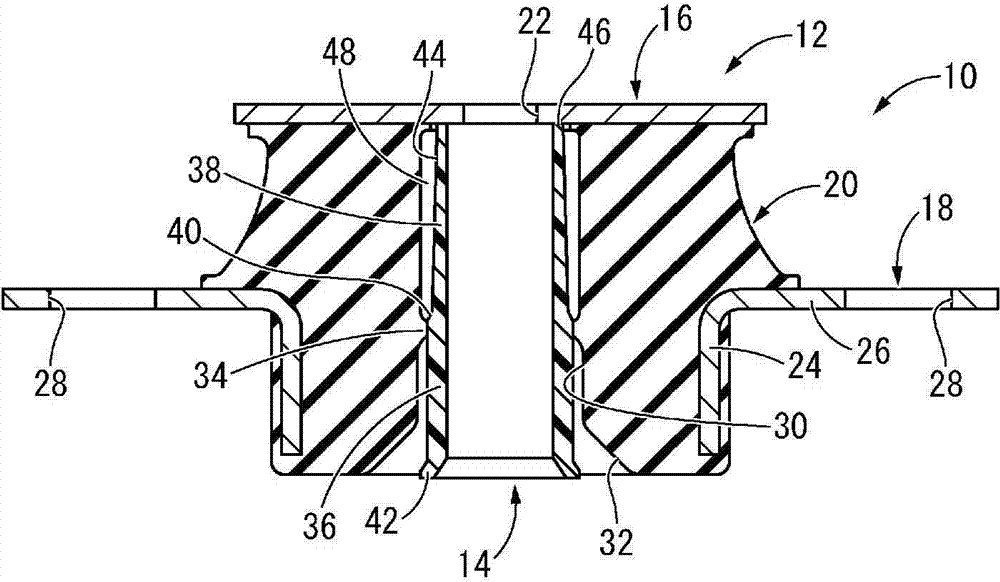

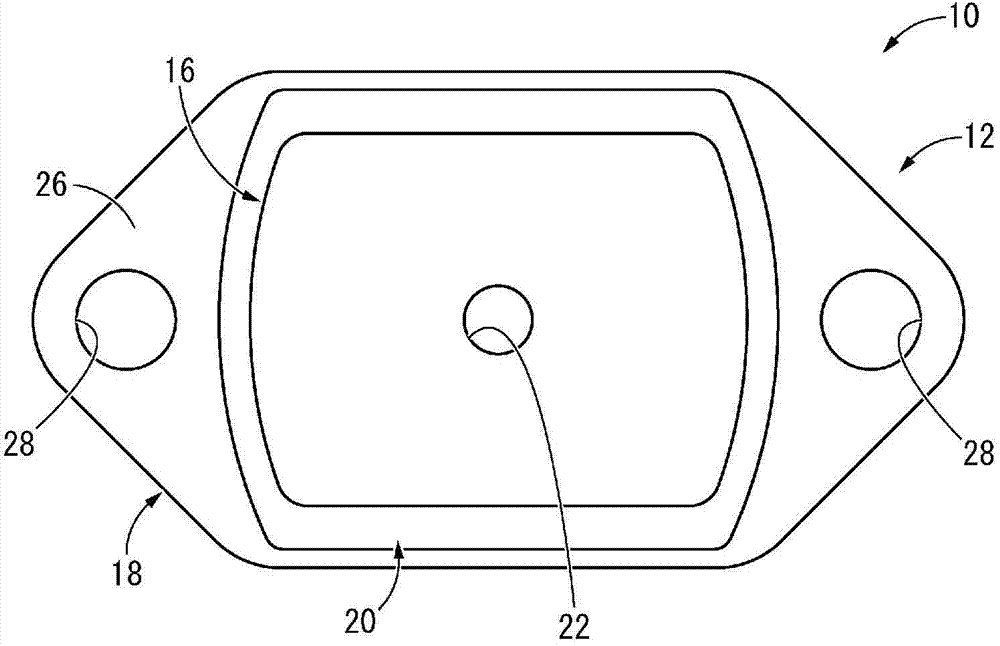

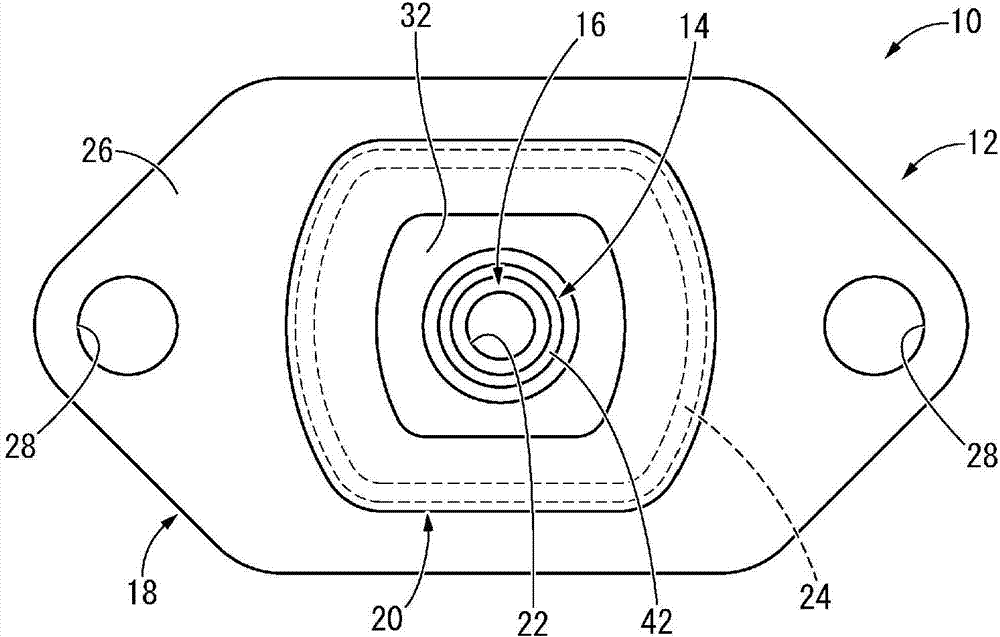

Vibration damping device

ActiveCN104736879AAdjust the clearanceThe dynamic stiffness constant decreasesSpringsNon-rotating vibration suppressionElastomerEngineering

Provided is a vibration damping device having a novel structure, the vibration damping device being configured so that a separate sleeve is held by a main rubber elastic body before the vibration damping device is mounted to a member to which the vibration damping device is to be connected in a vibration damping manner, and so that the vibration damping device has soft spring characteristics obtained by preventing the main rubber elastic body from having high dynamic spring characteristics in a state in which the vibration damping device is mounted to the member. A vibration damping device (10) is configured in such a manner that a first mounting member (16) and a second mounting member (18) are secured to a cylindrical main rubber elastic body (20) and in such a manner that an axial load acts between the first mounting member (16) and the second mounting member (18) while the vibration damping device (10) is in a mounted state. A separate sleeve (14) is inserted and disposed in the main rubber elastic body (20) in a non-secured manner. A rubber-side contact section (34) which is provided on the inner peripheral surface of the main rubber elastic body (20) and a sleeve-side contact section (36) which is provided on the outer peripheral surface of the separate sleeve (14) are pressed against each other, and as a result, the separate sleeve (14) is held by the main rubber elastic body (20). In the mounted state, the rubber-side contact section (34) and the sleeve-side contact section (36) are axially displaced relative to each other, and as a result, a retaining force acting between the main rubber elastic body (20) and the separate sleeve (14) is reduced.

Owner:SUMITOMO RIKO CO LTD

Efficient garbage crushing equipment

InactiveCN105728126AImprove working environmentGood environmental effectGrain treatmentsLow speedEngineering

The invention discloses efficient garbage crushing equipment which comprises a machine body. A main shaft is rotatably mounted in the machine body, and crushing blades extending outwards are evenly distributed on the circumferential face of the main shaft. Adjusting toothed plates of an annular structure are arranged outside the main shaft and fixed to the machine body in the mode that the adjusting toothed plates can stretch to the center and retract through oil cylinders. Crushing blades are evenly distributed on the inner wall of each adjusting toothed plate. A feed hopper is mounted at the top end of the machine body, materials needing to be processed enter the machine body from the feed hopper, the main shaft rotates at a low speed under the action of a main motor, and the main motor is fixedly mounted outside the machine body. A discharging cavity is formed in the bottom of the machine body, the side wall of the discharging cavity communicates with a pipeline, and the far end of the pipeline is connected with a dust collecting device.

Owner:XIAN ALL SAFE SCI & TECH

Dust removal air duct polishing method

PendingCN107414613AAchieve circumferential polishingAchieve clampingEdge grinding machinesRevolution surface grinding machinesPolishingDust control

The invention provides a dust removal air duct polishing method, and belongs to the technical field of machinery. The dust removal air duct polishing method is characterized by comprising the following steps that firstly, a prepared dust removal air duct is clamped to an outer wall polishing machine, a polishing disc is started, the outer wall of the dust removal air duct is polished to remove burrs, and outer wall polishing lasts for 8-12 min; secondly, the dust removal air duct obtained after the outer wall is polished is placed in a conveying device; thirdly, the dust removal air duct is conveyed to a transfer mechanism through a conveying belt on the conveying device and transferred to the position between a first clamping block and a second clamping block through a mechanical arm on the transferring mechanism to be clamped; fourthly, an inner wall polishing machine is started, a polishing brush is rotated, the position relation between the polishing brush and the dust removal air duct is adjusted, the inner wall of the dust removal air duct is polished, and inner wall polishing lasts for 3-5 min; fifthly, inner wall polishing of the dust removal air duct is completed, and the dust removal air duct is conveyed out. The method has the advantage of being capable of polishing the dust removal air duct more conveniently.

Owner:ZHEJIANG JIEYU ENVIRONMENTAL PROTECTION EQUIPCO

Crusher capable of conveniently adjusting crushing size

InactiveCN108311221AAdjust the clearanceAdjust particle sizeGrain treatmentsArchitectural engineeringCrushed stone

The invention discloses a crusher capable of conveniently adjusting the crushing size. The crusher comprises a discharge pipe, a crushing cylinder, a crusher shell, fixed hammers, rotary hammers, a feed hopper, movable hammers and a movable block, wherein the crushing cylinder is arranged in the crusher shell, the multiple fixed hammers are welded to the inner wall of the crushing cylinder, the multiple rotary hammers are connected to the side wall of a crushing roller through pin shafts, the lower part of the outer side of the movable block is connected to a movable hinge base, the movable hinge base is fixed to the end part of a connecting rod, and the connecting rod penetrates through a through groove in a baffle plate and is connected to a telescopic rod of an electric cylinder througha connector. The crusher has the advantages that the rotary hammers and the fixed hammers are used for crushing stone which falls between the rotary hammers and the fixed hammers, the crushing effectis good, the movable block is driven to rotate inwards or outwards around a fixed hinging base through the telescopic rod of the electric cylinder, so that gaps between the movable hammers and the rotary hammers can be adjusted, the particle size of the crushed stone can be further adjusted, and the crusher is convenient and fast to use.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Automatic belt cutter

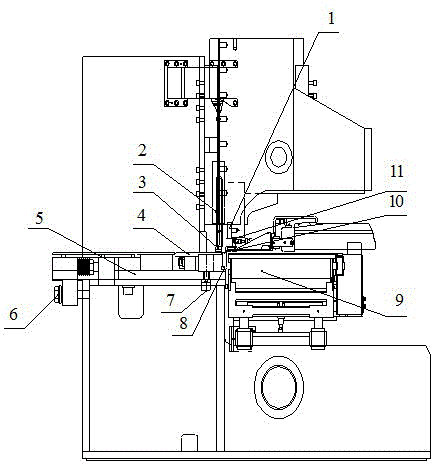

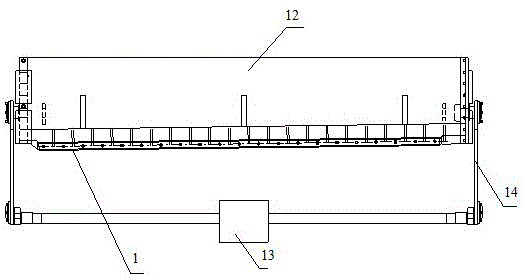

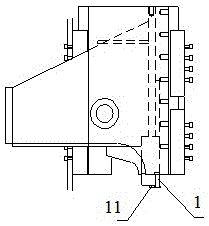

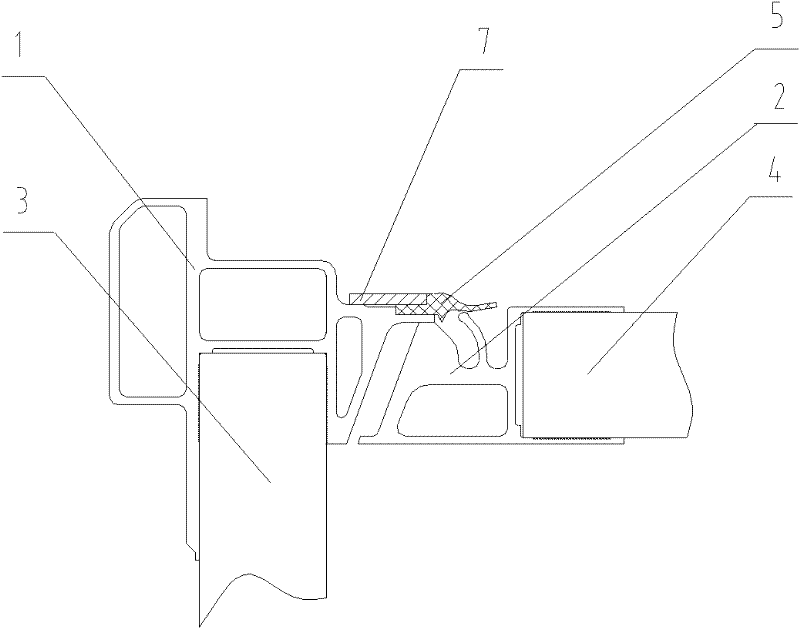

ActiveCN101134540AHigh degree of automationSimple structureMetal working apparatusArticle deliveryMechanical engineering

The present invention provides one kind of automatic belt cutting machine, and belongs to the field of mechanical technology. The automatic belt cutting machine includes one frame, one worktable on the frame, at least two parallel drums set on one side of the worktable to form one gap in between for the belt to pass through, one belt end grasping mechanism set on the other side of the worktable, and one belt cutting mechanism between the drums and the belt end grasping mechanism. The automatic belt cutting machine has the features of high efficiency and wide application range.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

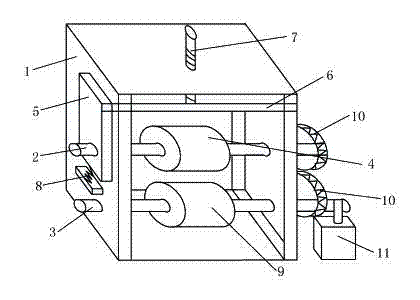

Wiredrawing machine

InactiveCN102826409AExtrude evenlySmooth entryFilament handlingElectric machineMechanical engineering

The invention belongs to the technical field of wiredrawing tools, and particularly relates to a wiredrawing machine. The invention discloses a wiredrawing machine, which comprises a frame body, wherein the frame body is provided with an upper shaft and a lower shaft; the upper shaft is provided with an upper roller; the two ends of the upper shaft are provided with slide pieces; the slide pieces are arranged on the frame body in a sliding way; the tops of the slide pieces are provided with pressure plates; the upper part of the frame body is provided with a pressure lever which can be used for extruding pressure plates; a spring is arranged between the bottom of each slide piece and the frame body; the lower shaft is provided with a lower roller; the upper shaft and the lower shaft are connected with each other through a gear; and the lower shaft is connected with a motor. Due to the adoption of the wiredrawing machine, external force can be applied in the extruding process of a cable or a rattan rope, so that an entire process is smoother.

Owner:徐铭耀

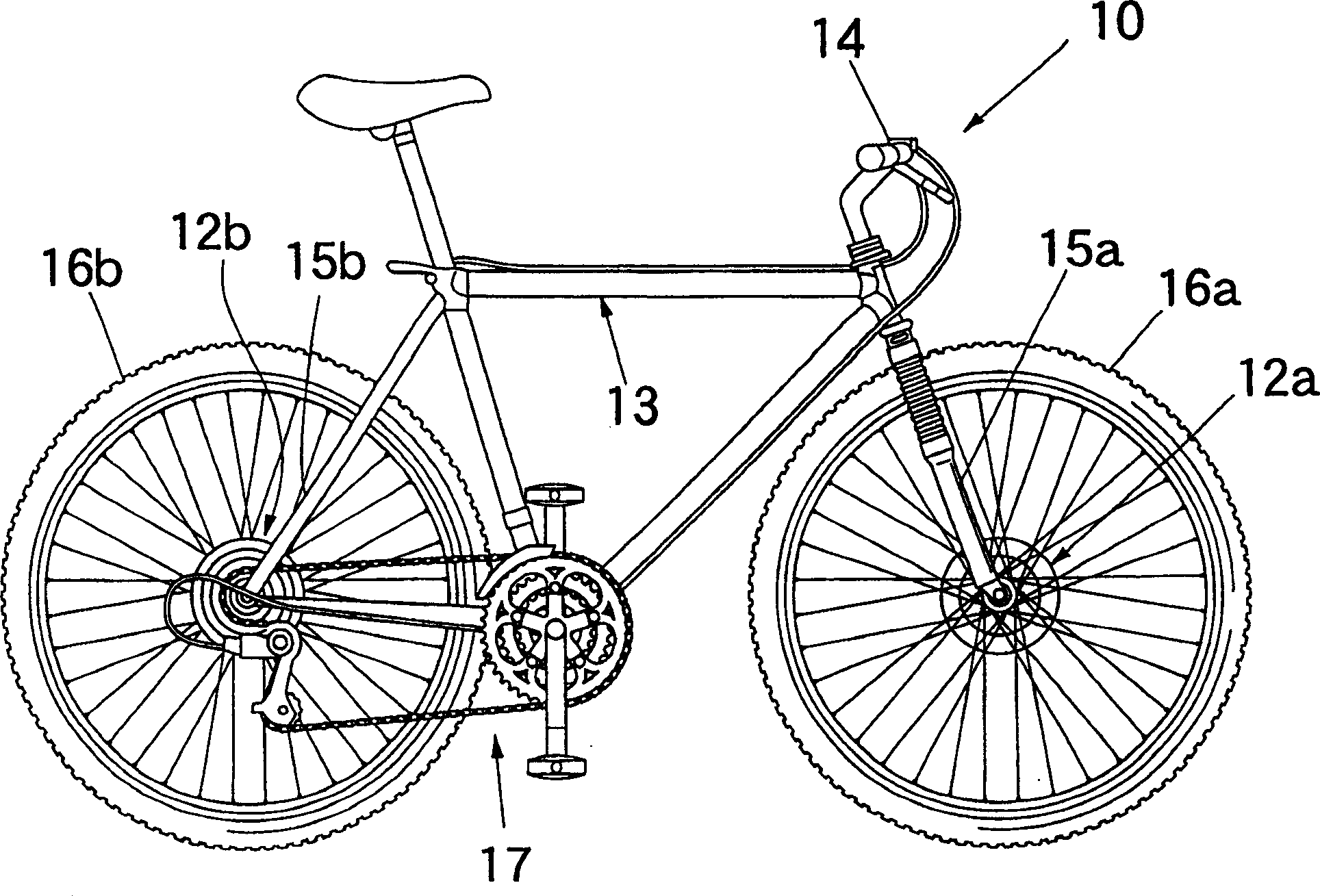

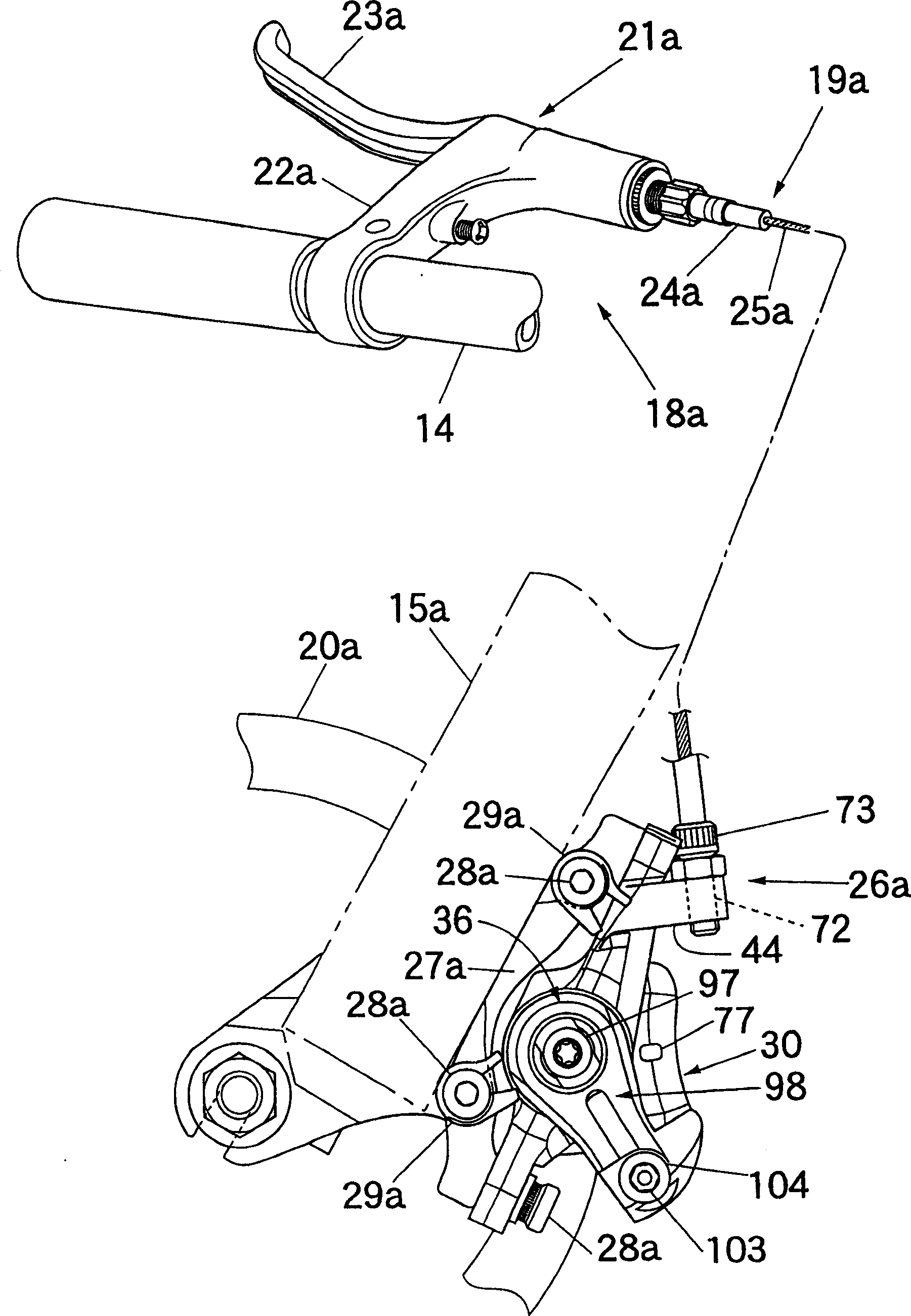

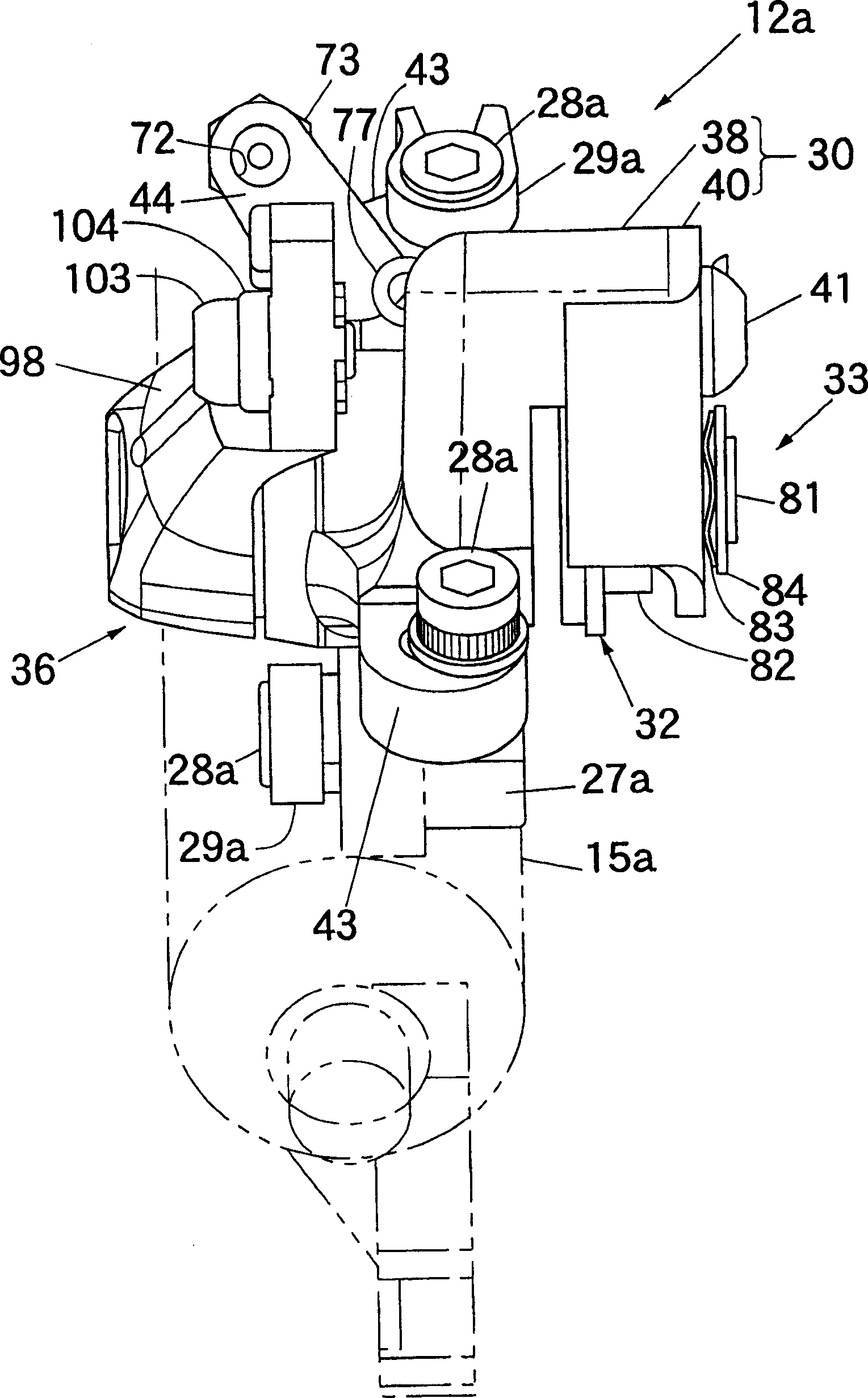

Disk brake for cable

InactiveCN1443678AAdjust the clearanceReduce weightAxially engaging brakesBrake actuating mechanismsAxial compressionEngineering

A bicycle cable disc brake is equipped with a disc brake pad adjustment mechanism to adjust the gap between the friction pads. Cable disc brakes have a first caliper housing portion that contains a cable actuating mechanism, and a second caliper housing portion that contains a disc brake pad adjustment mechanism. The disc brake pad adjustment mechanism consists of a caliper housing part, an adjustment shaft, an adjustment plate and an adjustment bias component. The adjustment shaft is movably connected to the caliper housing portion for rotation about the longitudinal axis of the adjustment shaft. The adjustment plate is connected to the adjustment shaft for axial movement along the longitudinal axis of the adjustment shaft as the adjustment shaft rotates relative to the caliper housing portion. The adjustment biasing member is operably disposed between the caliper housing portion and the adjustment shaft and is arranged to axially force the adjustment shaft against the caliper housing portion. The adjustment shaft and caliper housing portion are configured with indexing means to selectively maintain the adjustment shaft in a predetermined angular position relative to the caliper housing portion along the longitudinal axis of the adjustment shaft.

Owner:SHIMANO INC

Vibration isolation system of vibrating centrifuge

InactiveCN102652930ASmall dynamic stiffness and natural frequencyImprove static stiffnessCentrifugesAir springEngineering

The invention discloses a vibration isolation system of a vibrating centrifuge. The vibration isolation system comprises a vibration isolation device, wherein the vibration isolation device comprises a guide rod, the axial direction of the guide rod is taken as the up-and-down direction, the upper end of the guide rod is connected with a rotating arm support of the vibrating centrifuge, the lower end of the guide rod sequentially penetrates through an upper-layer rigid plate, a middle-layer rigid plate and a lower-layer rigid plate, a linear bearing is connected with a regulating block, the regulating block is mounted on the lower-layer rigid plate, the lower end of the guide rod penetrates through the linear bearing, the two ends of the lower-layer rigid plate are respectively connected with the inner side of a support of a rotating arm system of the vibrating centrifuge, a force sensor is positioned between the rotating arm support and the upper-layer rigid plate, and an air spring is positioned between the upper-layer rigid plate and the middle-layer rigid plate. By adopting the structure that the air spring cooperates with the rigid plates, the imbalance force of the support of the rotating arm system relative to the rotating arm support is buffered and the vibration isolation purpose can be achieved. The vibration isolation system disclosed by the invention has the advantages of small dynamic rigidity, small inherent frequency, great static rigidity, good vibration isolation performance and capabilities of isolating vibration waves with higher frequency and bearing greater imbalance force.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

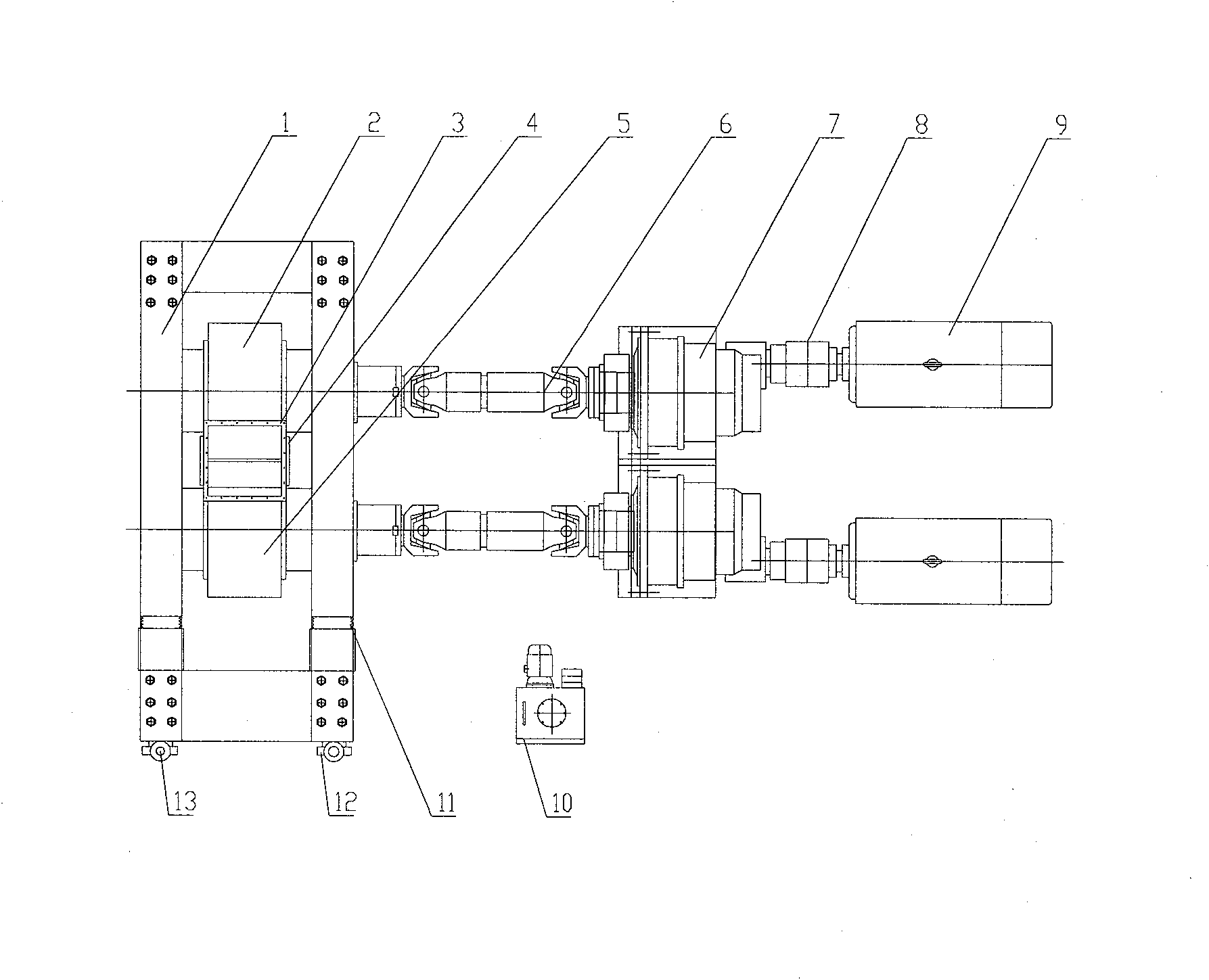

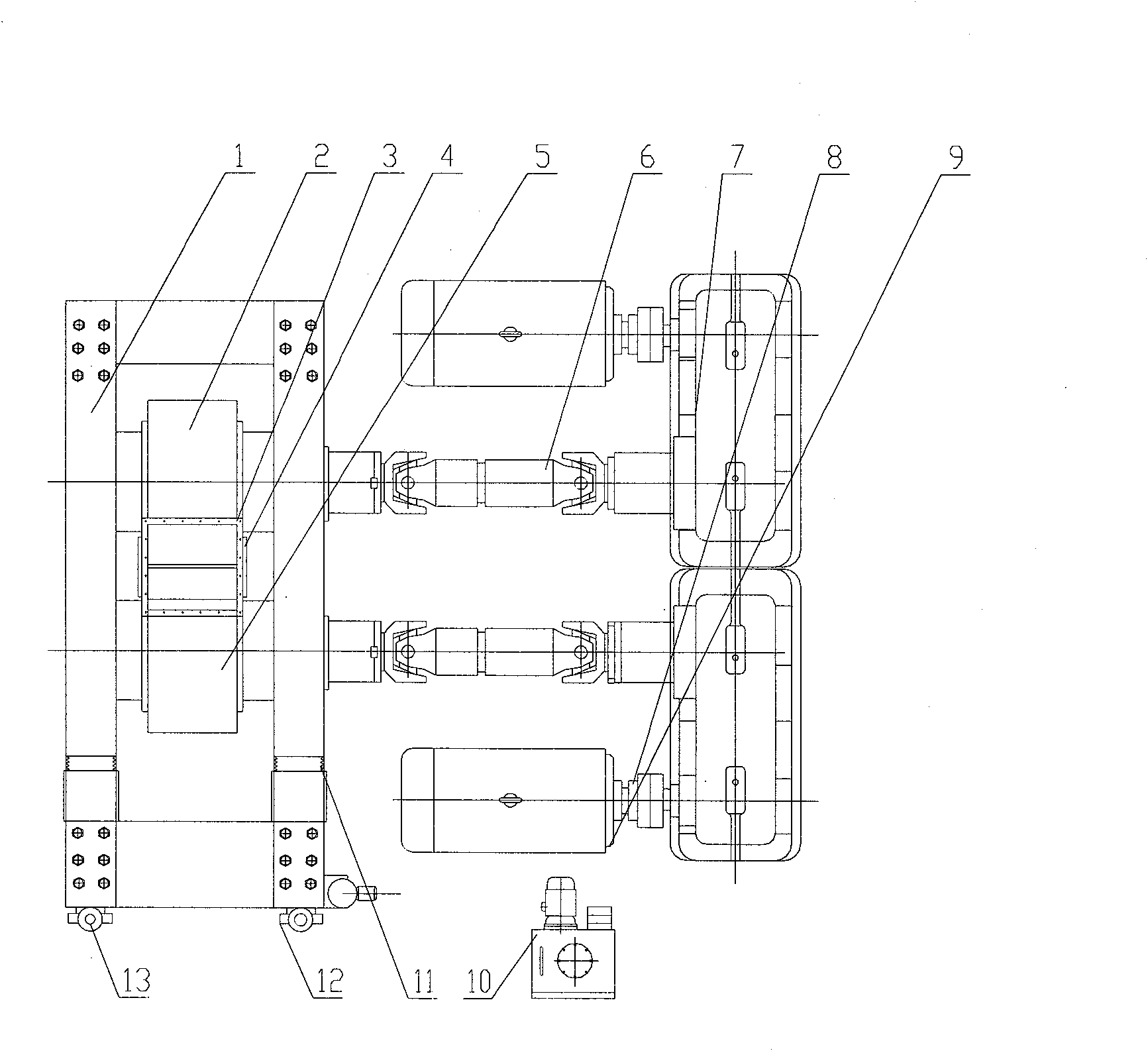

High-pressure roller mill for metal ore

ActiveCN101596473AIncrease production capacityReduce power consumptionGrain treatmentsControl systemElectric machinery

The invention belongs to equipment for pulverizing a metal ore rock material, which consists of a stander, high-pressure rollers, a universal transmission shaft, a retarder, a feeding adjustment device, a hydraulic control system, an electric control system and other main parts. Two sets of high-pressure roller devices are horizontally arranged on the stander in parallel; a driving mode of the equipment comprises that: a motor is connected with the high-pressure rollers through the retarder and the universal transmission shaft; each set of the high-pressure roller is provided with each independent drive device, wherein one set of the high-pressure roller is fixed; the other set of the high-pressure roller can slide in the horizontal direction; one side of a movable roller is provided with a pressure application hydro-cylinder; and two sides of the end face of the high-pressure roller are provided with self-adaptive floating side baffles. The pulverization equipment is high-efficiency, energy-saving and consumption-reducing and has remarkable economic benefit.

Owner:中钢天源安徽智能装备股份有限公司

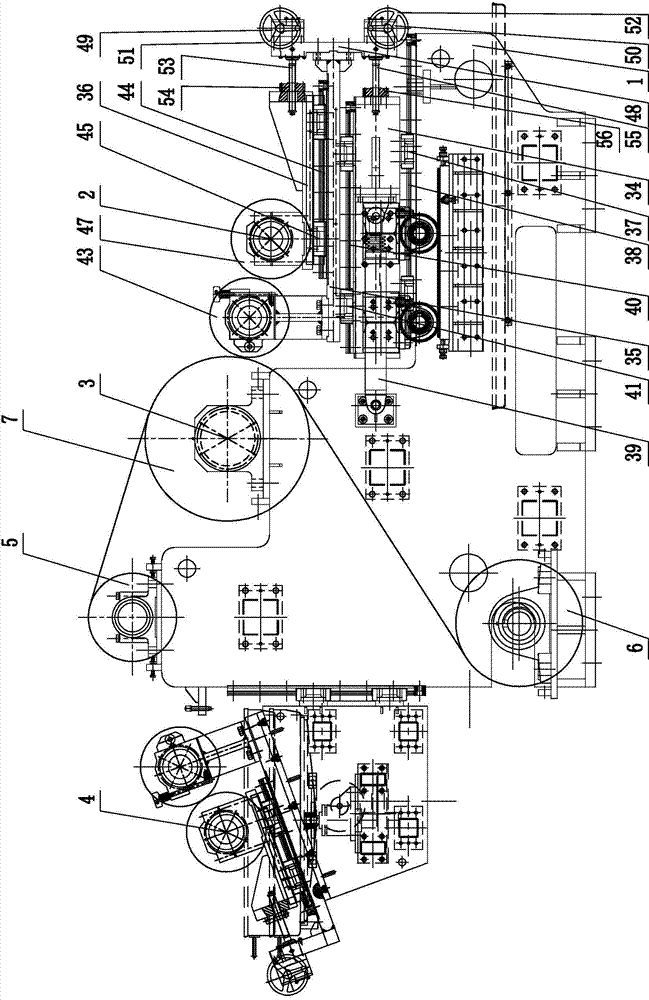

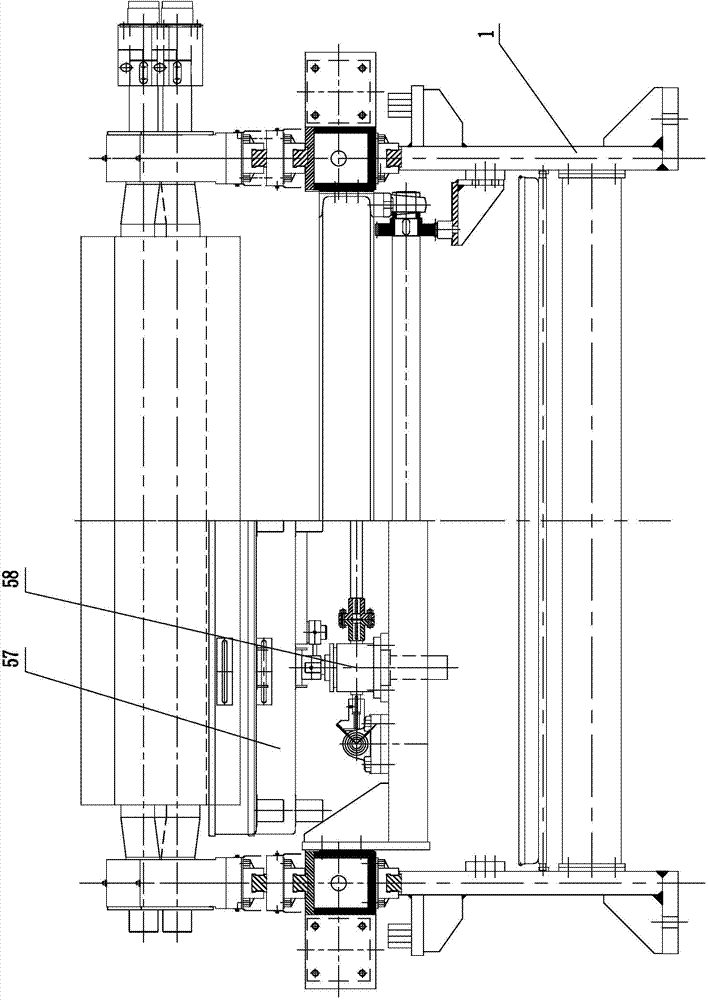

Wire cord fabric cutting-off device and technology thereof

The invention discloses a wire cord fabric cutting-off device and a technology thereof. The cutting-off device comprises a cutting mechanism including an upper cutter and a lower cutter, a turning plate material lifting mechanism, a material pressing mechanism, a conveying belt mechanism and a clamp fixed length mechanism. The cutting mechanism including the upper cutter and the lower cutter comprises an upper cutter rack, the upper cutter mounted on the upper cutter rack, an upper cutter driving mechanism used for driving the upper cutter rack to move up and down, a rack body, a movable workbench, the lower cutter mounted on the movable workbench and an overall cutter adjusting mechanism. The turning plate material lifting mechanism comprises a turning plate and a turning plate linear driving mechanism. The clamp fixed length mechanism comprises a clamp support, a clamp mechanism, a longitudinal movement system and a transverse movement system. According to the wire cord fabric cutting-off device and the technology thereof, the turning plate material lifting mechanism and the material pressing mechanism clamp the wire cord fabric end and is lifted up from a lower cutter opening, the clamp fixed length mechanism clamps the wire cord fabric end for fixed-length and fixed-angle operation, the length and the angle of wide materials can be accurately determined, the materials tend not to be bonded on the upper cutter, the cut materials can accurately fall onto the conveying belt mechanism to be fed into a connector device, and thus the connector precision can be improved.

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG +1

Improving agent for soil of saline and alkaline lands and preparation method of improving agent

InactiveCN108218488ATurn waste into treasureSuitable for growthAgriculture tools and machinesBio-organic fraction processingFertilizerWater content

The invention discloses an improving agent for soil of saline and alkaline lands. The improving agent is prepared from the following components in parts by weight: 40-60 parts of phosphorus gypsum, 15-30 parts of black soil, 5-8 parts of ageratina adenophora, 3-5 parts of iris japonica thunb, 5-8 parts of pine needle, 1-2 parts of hydrochloric acid, 3-6 parts of acetic acid and 3-6 parts of oil cake. A preparation method comprises the following steps: (1) taking the phosphorus gypsum, drying, crushing and sieving to obtain phosphorus gypsum powder for later use; (2) taking the black soil, drying, crushing and sieving to obtain black soil powder for later use; (3) respectively crushing and sieving the other components and ingredients, adding the hydrochloric acid and the acetic acid and mixing, then adding 1-3 parts of raw glucoamylase and 15-20 parts of water, stirring and fermenting; (4) adding the phosphorus gypsum powder and the black soil powder into a fermented mixture, stirring and controlling the water content of the mixture to be 15%-20%. The improving agent disclosed by the invention has the beneficial effects that the problem of failure to realize utilization of large-batch phosphorus gypsum as a fertilizer ingredient in the prior art can be solved; meanwhile, prepared fertilizer has the effects of reducing the salinity and the alkalinity of the soil and improving thefertility of the soil so as to be suitable for growth of crops.

Owner:贵州贵和隆科技研发有限公司

Sealing device between vertical wallboards of shelter

The invention discloses a sealing device between vertical wallboards of a shelter. The sealing device comprises a vertical section, a horizontal section and a sealing member, wherein the vertical section and the horizontal section are respectively matched with the vertical wallboards and horizontal wallboards; the sealing member is fixedly connected with the vertical section through a batten and is a strip-shaped sealing member made of elastic materials with uniform cross sections and is matched with the vertical section; an installation part fixedly connected with the vertical section is arranged at one end of the cross section of the sealing member, and a strip-shaped deformable sealing strip is arranged at the other end of the cross section; a slot connected with the vertical wallboards is arranged on the vertical section, and a limiting part and a step are arranged in the direction of a vertical slot; the horizontal section is provided with another slot; a limiting surface is arranged along the opposite direction of the slot; and a sealing part closely matched with the strip-shaped sealing strip is arranged between the limiting surface and the slot. Because the deformable sealing strip design is arranged on the cross section of the sealing member, even if a larger gap generated in the installation process can be compensated, and the sealing property of the sealing device is not influenced.

Owner:KF MOBILE SYST

Hydraulically-loaded dual-power pulverizer

ActiveCN103801430AConstant pressureImprove running stabilityGrain treatmentsEngineeringMechanical engineering

The invention discloses a hydraulically-loaded dual-power pulverizer which comprises a body, a large pulverizing disc arranged in the body, a pulverizing disc power device for driving the large pulverizing disc, and pulverizing head bodies matched with the large pulverizing disc, wherein the pulverizing head bodies are arranged on saddles. The pulverizer also comprises a pulverizing head power mechanism for driving the pulverizing head bodies, a charging device arranged on the upper part of the body, and an air inlet system and an overflow recovery device which are arranged at the bottom of the body, wherein the front ends of swinging arm bodies are rigidly connected with the pulverizing head bodies through pin shafts, screws and fixing keys; pulverizing head rollers are pressed to the inner side of the steep wall of the outer edge of the large pulverizing disc under the action of hydraulic devices; the tail ends of the swinging arm bodies are connected with a tail frame through rotating wheel shafts, so that the swinging arm bodies can rotate around the rotating wheel shafts, respectively; lubricating oil circulation systems are used for pulverizing head spindles. The whole pulverizer can stably run, and is slight in vibration, easy to maintain and high in efficiency.

Owner:HAIAN TIANPENG MACHINERY MFG

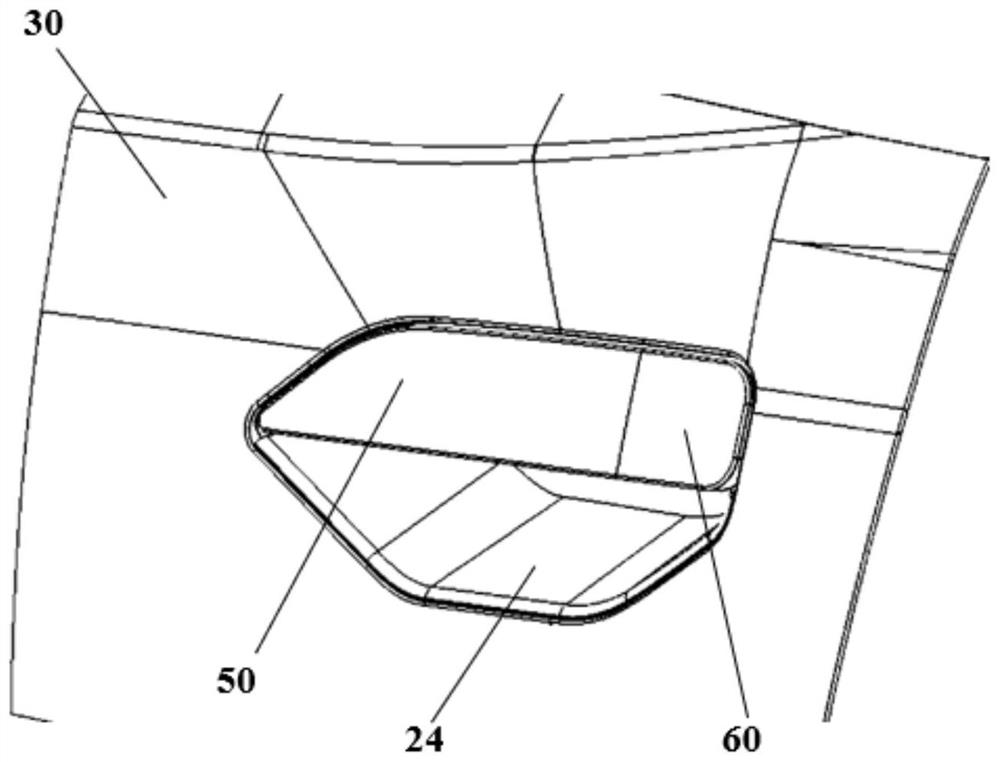

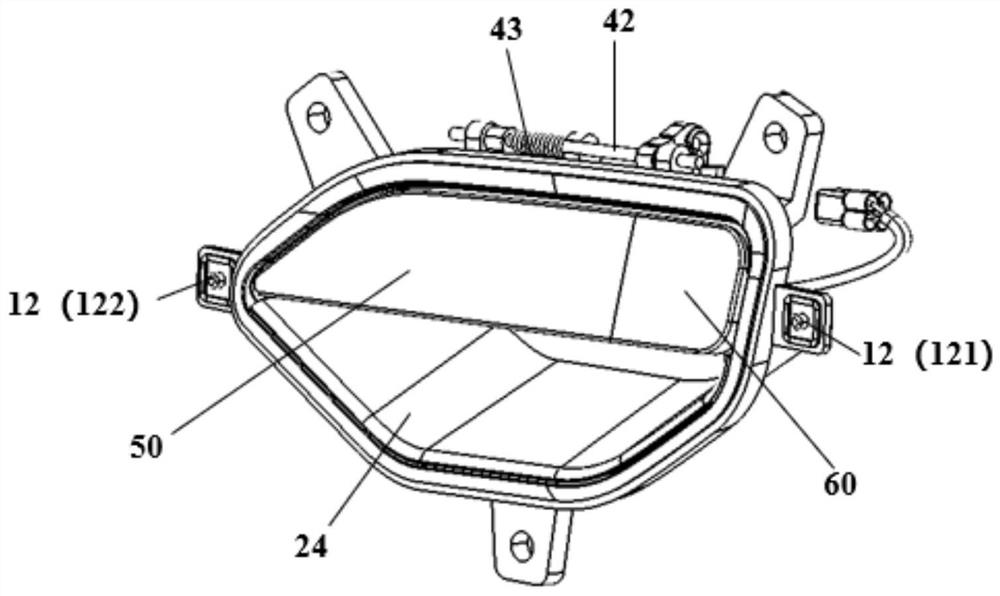

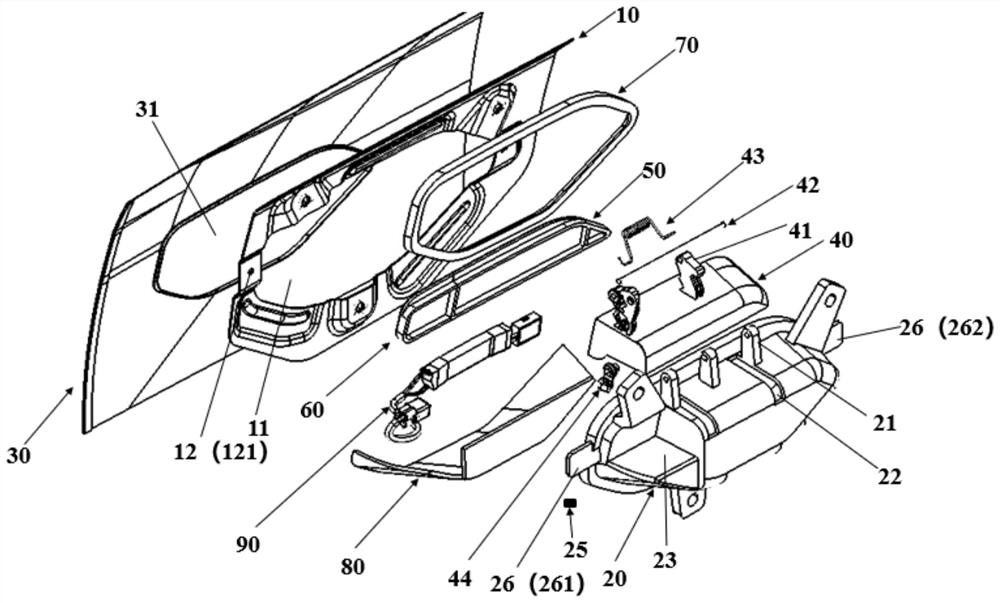

Vehicle door handle assembly for vehicle and vehicle door

The invention provides a vehicle door handle assembly for a vehicle and a vehicle door, and relates to the technical field of interior and exterior of the vehicle. The vehicle door handle assembly comprises a mounting reinforcing plate and a handle base, the mounting reinforcing plate is fixedly connected with an exterior panel, and the mounting reinforcing plate is provided with at least one via hole and a second mounting hole corresponding to a first mounting hole; the handle base is provided with an inwards-sunken operation space and at least one pin corresponding to the at least one via hole; and the at least one pin penetrates through the at least one corresponding via hole to fix the handle base to the mounting reinforcing plate, so that the operation space of the handle base faces the outside of the vehicle and is exposed out of the first mounting hole and the second mounting hole. The vehicle door handle assembly can adjust the gap and flushness.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

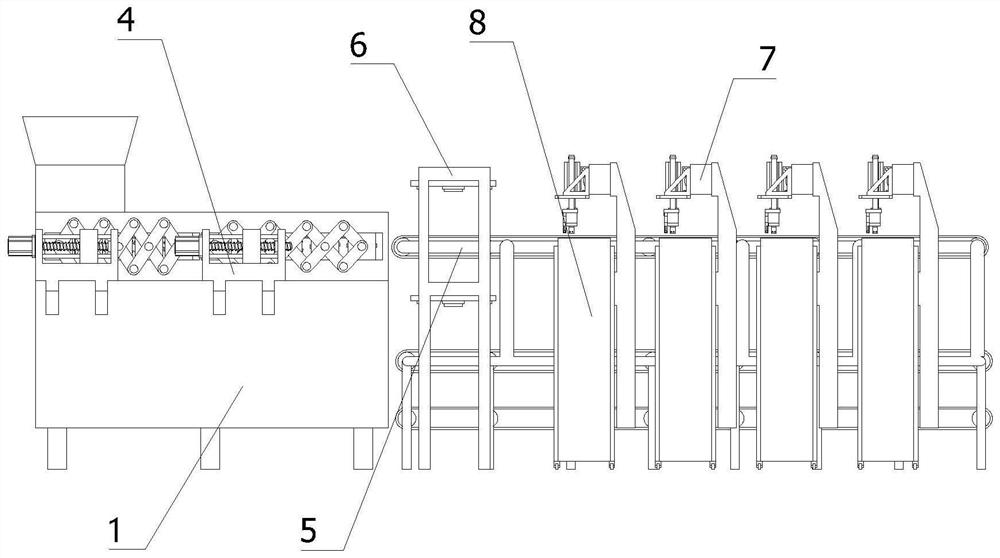

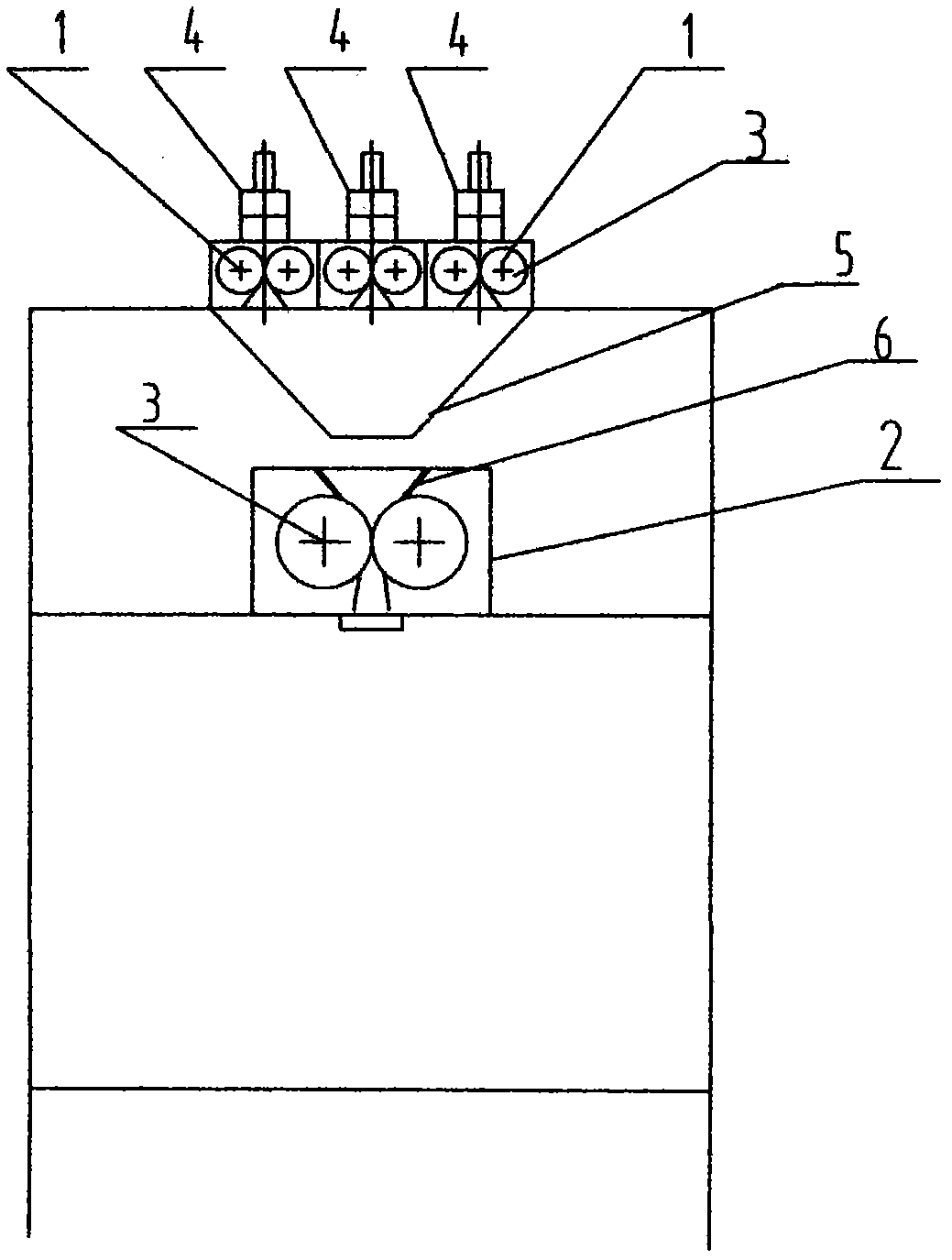

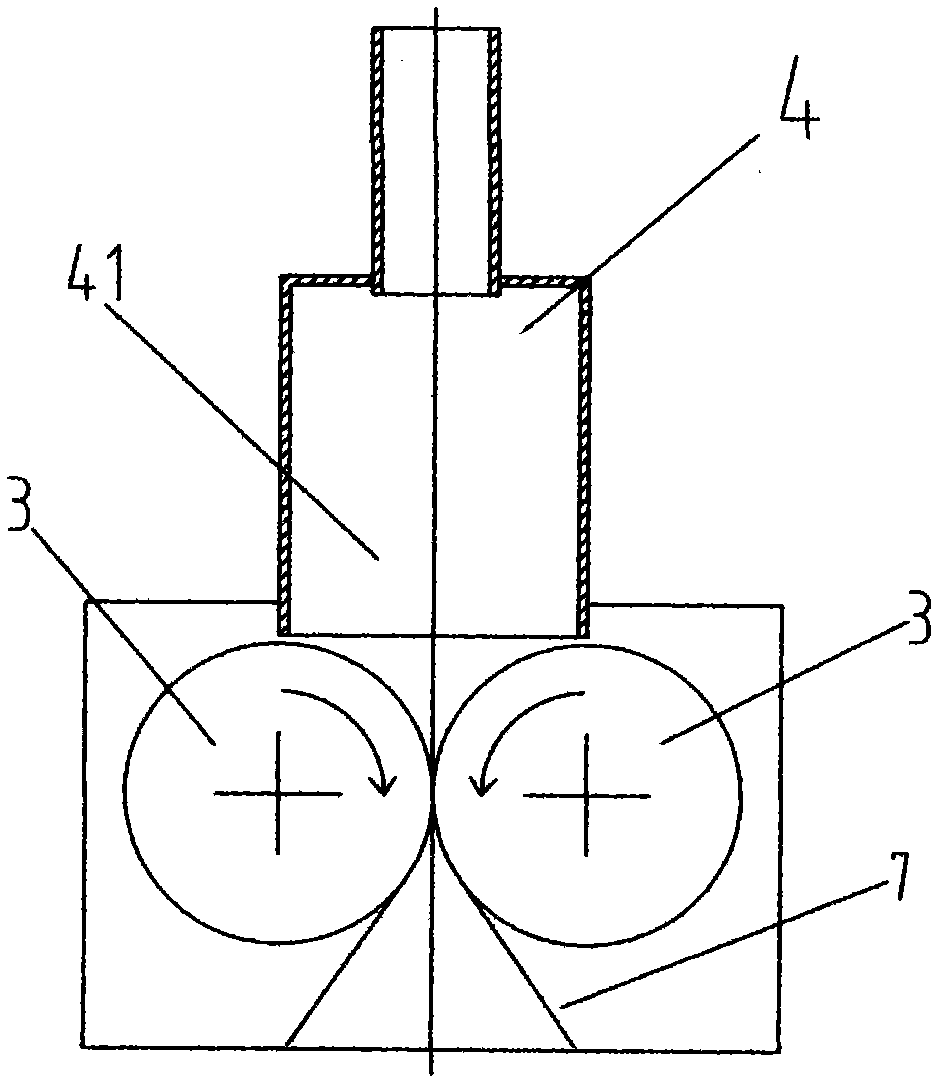

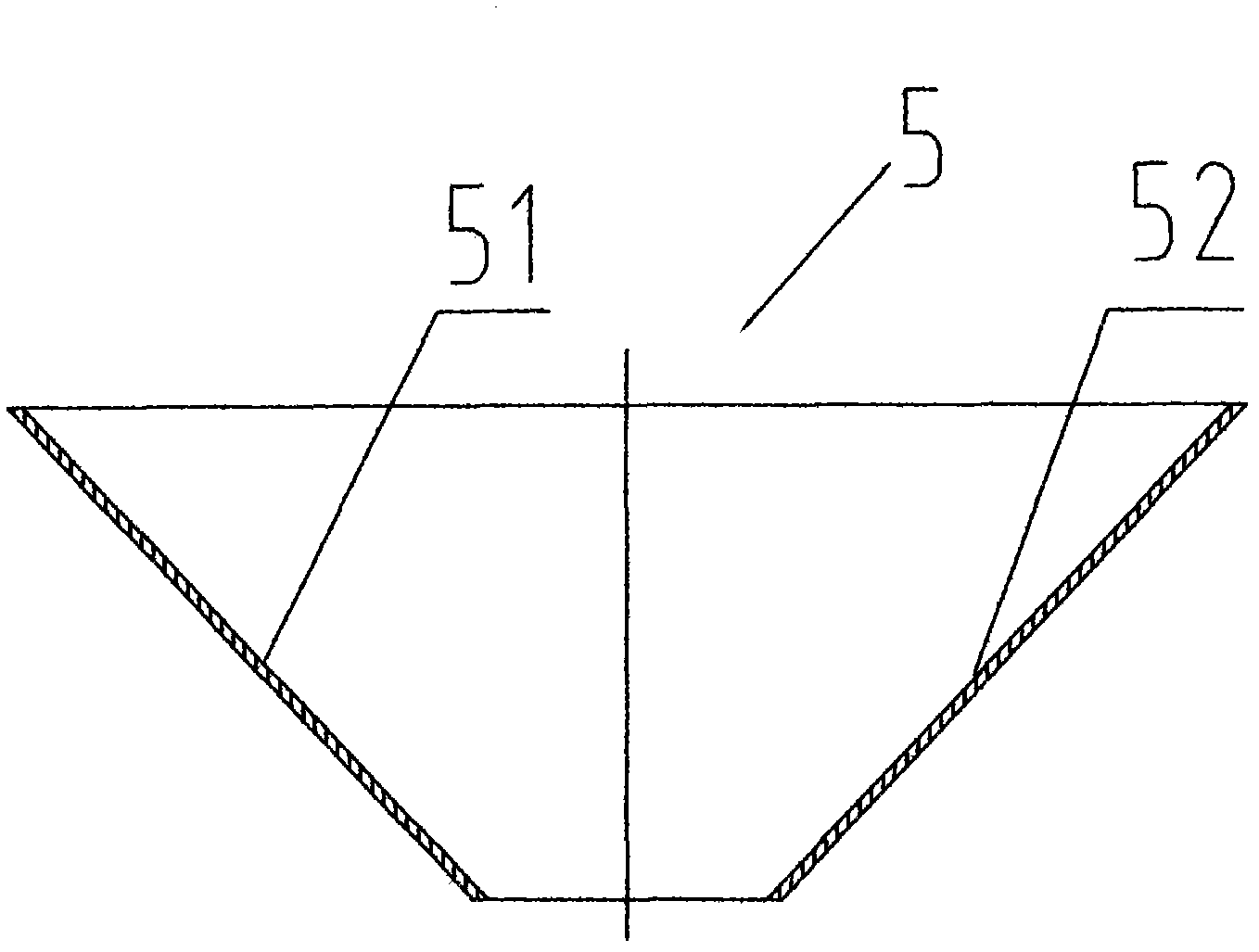

Ceramic pulverizing, crushing and mixing mechanism

The invention provides a ceramic pulverizing, crushing and mixing mechanism, relates to a pulverizing device for producing ceramics, and particularly relates to a crushing and mixing device for producing nature-imitated stone and ceramics with various textures. The mechanism comprises a plurality of crushing mechanisms and a mixing and stirring mechanism, each of the crushing mechanisms and the mixing and stirring mechanism consists of a pair of parallel rolling shafts, an adjustable clearance is arranged between each pair of rolling shafts, the mixing and stirring mechanism is located below the crushing mechanisms, and a supply mechanism is disposed on each crushing mechanism, is a hopper with a discharge opening, and is used for continuously uniformly feeding on the corresponding crushing mechanism. The crushing mechanisms and the mixing and stirring mechanism are operated by a computer controller in a centralized manner, pulverizing, crushing and mixing procedures are greatly simplified, manual operation is reduced, production efficiency is greatly improved, the ceramic pulverizing, crushing and mixing mechanism is controlled by a computer to realize quantitative color-separation supply, color mixing, crushing and spreading, and realizes quantification and color matching for appearances of ceramic wall and floor tiles.

Owner:黎贤饶

Roller bearing with a window cage with positioning elements in the bearing pockets for altering the pocket play by means of temperature-dependent change in shape of the positioning elements for exampl

InactiveCN101171433AGood damping propertiesImprove running stabilityRolling contact bearingsShaftsShape changeRolling-element bearing

Owner:SCHAEFFLER KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com