Instant shellfish hairbrush scrubbing machine

The technology of scrubbing machine and brush is applied in the field of instant shellfish brush scrubbing machine, which can solve the problems of reducing production efficiency, damaging the original taste of instant food, etc., and achieves the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

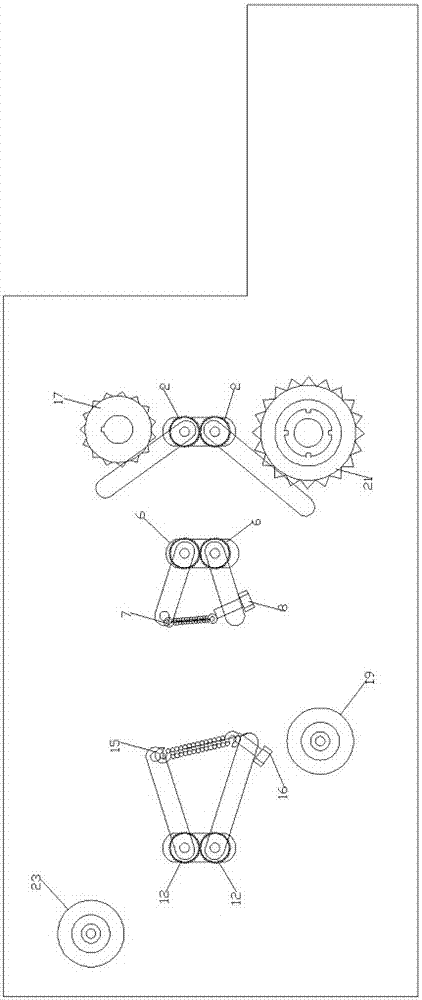

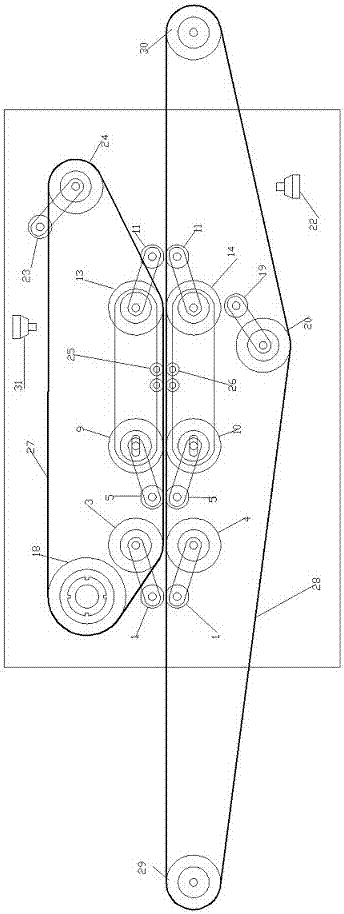

Method used

Image

Examples

Embodiment Construction

[0012] The material is placed on the lower brush conveyor belt (28) from the fourth roller (29), and the material is driven forward by the lower brush conveyor belt (28). When the material runs to the sixth roller (3) and the seventh roller (4), it is squeezed by the sixth roller (3) and the seventh roller (4), and the position is centered, and then the upper brush conveyor belt ( 27), the lower brush conveyor belt (28) squeezes, because the speed of the upper brush conveyor belt (27) and the lower brush conveyor belt (28) are not synchronized, at this time, the material starts to be scrubbed. The material is conveyed to the eighth roller (9), the ninth roller (10), the eighth roller (9), the ninth roller (10), the tenth roller (13), the eleventh roller (14), the first When pressing roller (25) and second pressing roller (26), be squeezed, realize further washing by rubbing with the hands.

[0013] By adjusting the angle of the third roller (24), the tension of the upper brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com