Ceramic pulverizing, crushing and mixing mechanism

A technology of ceramic powder and crushing mechanism, which is applied in the direction of grain processing, etc., can solve the problems of large workload and production cost, easy wear of needle rollers and rollers, and bulky volume, so as to simplify the process of crushing and mixing and improve production efficiency , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

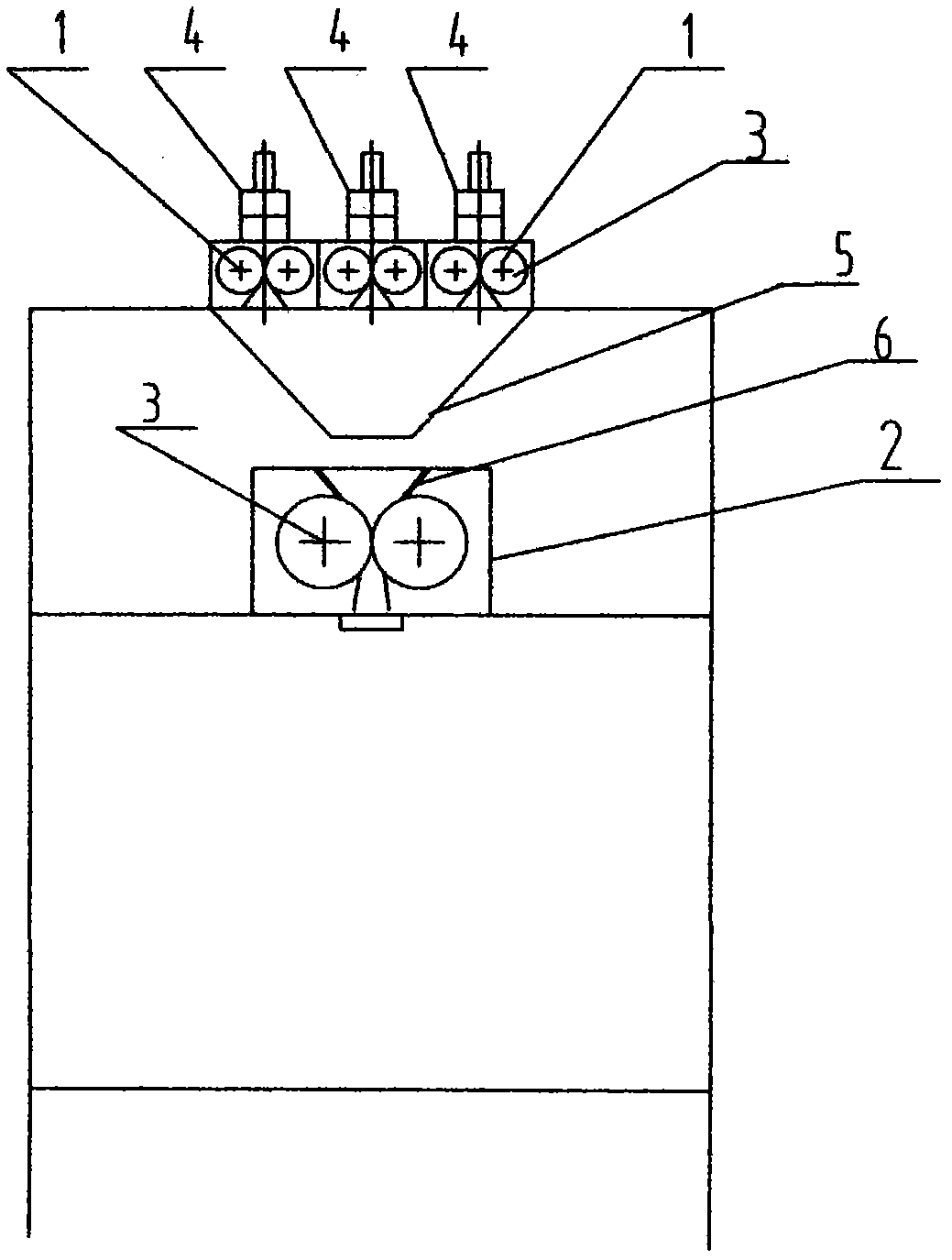

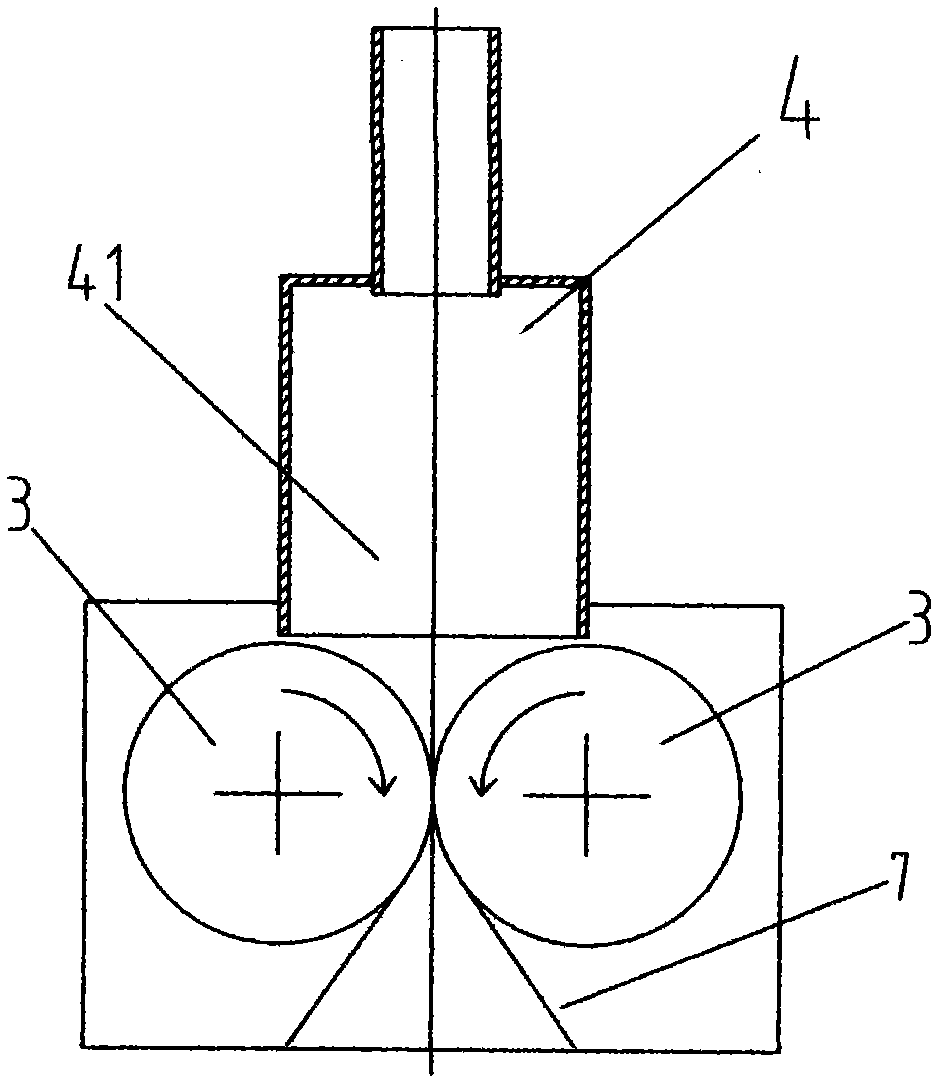

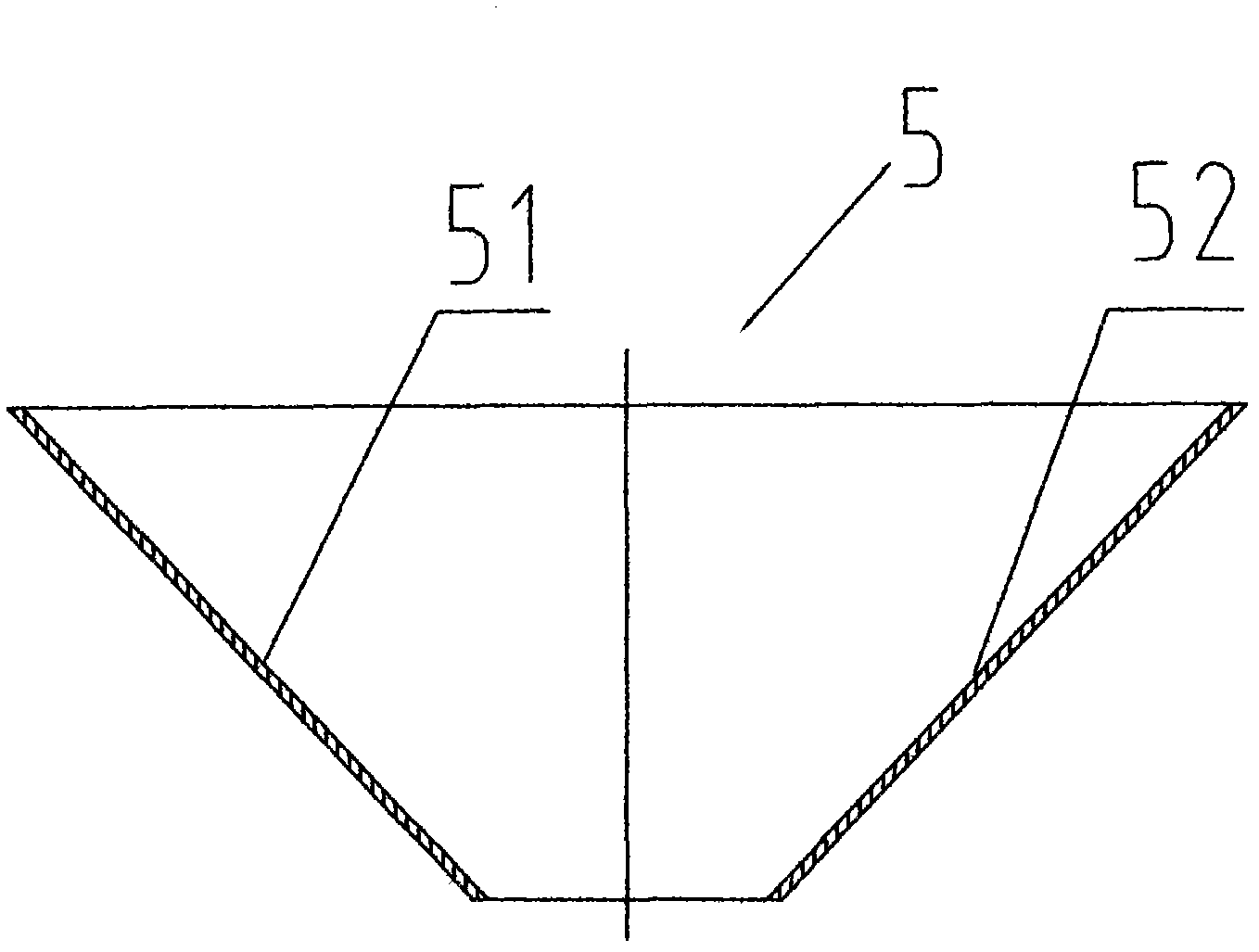

[0022] Such as figure 1 A ceramic powder crushing mechanism shown in Fig. 5 includes a plurality of crushing mechanisms 1 and a mixing and crushing mechanism 2, and the crushing mechanism 1 and the mixing and crushing mechanism 2 are composed of a pair of parallel Composed of rollers 3, each pair of parallel rollers 3 is two unequal speed rotating shafts, the two rollers are driven by the same motor, gear-related speed change and relatively reverse operation (that is, in each pair of rollers 3, one roller Turn quickly, the other roller turns slowly and in the opposite direction, as in figure 2 As shown), there is an adjustable gap between the parallel rollers 3, which can be used with conventional technology, and will not be described in detail here. The mixing and crushing mechanism is located below the crushing mechanism 1, and a feeding mechanism 4 is arranged on the crushing mechanism 1. The feeding mechanism 4 is a funnel with a feeding opening 41, and the size of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com