Patents

Literature

92results about How to "Simple mixing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

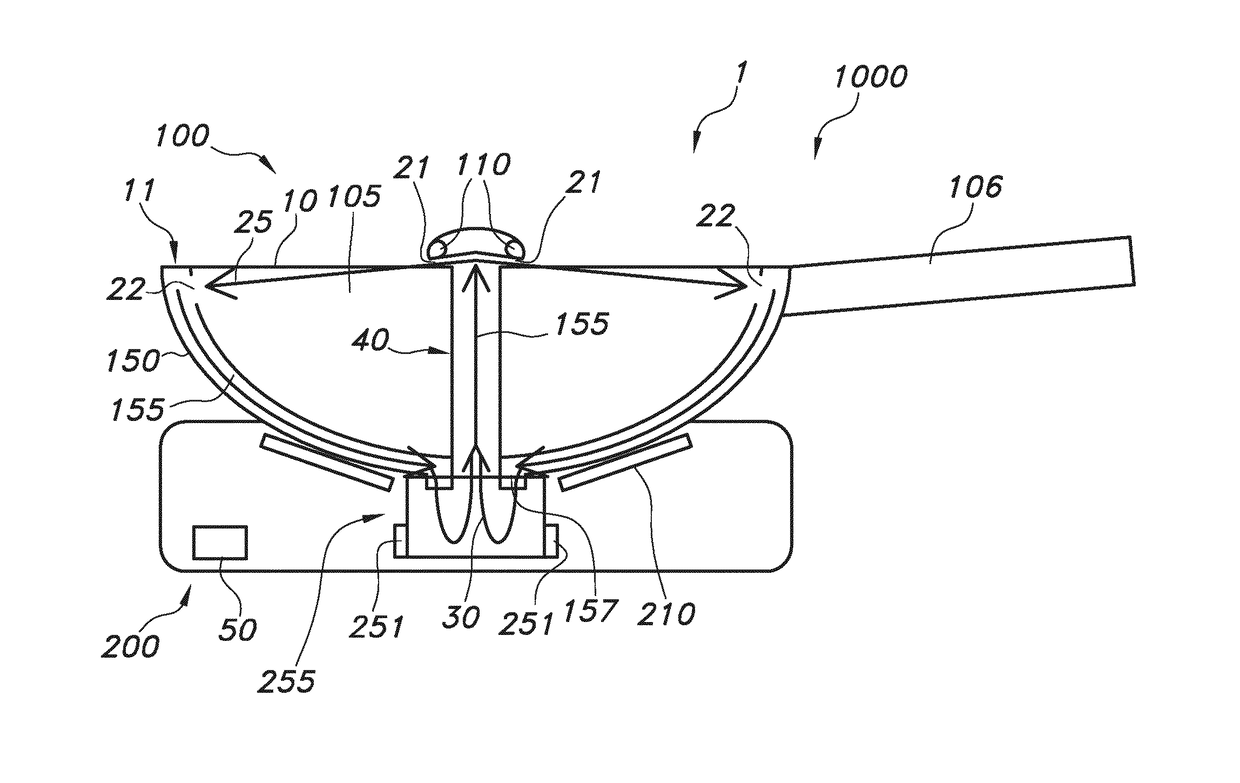

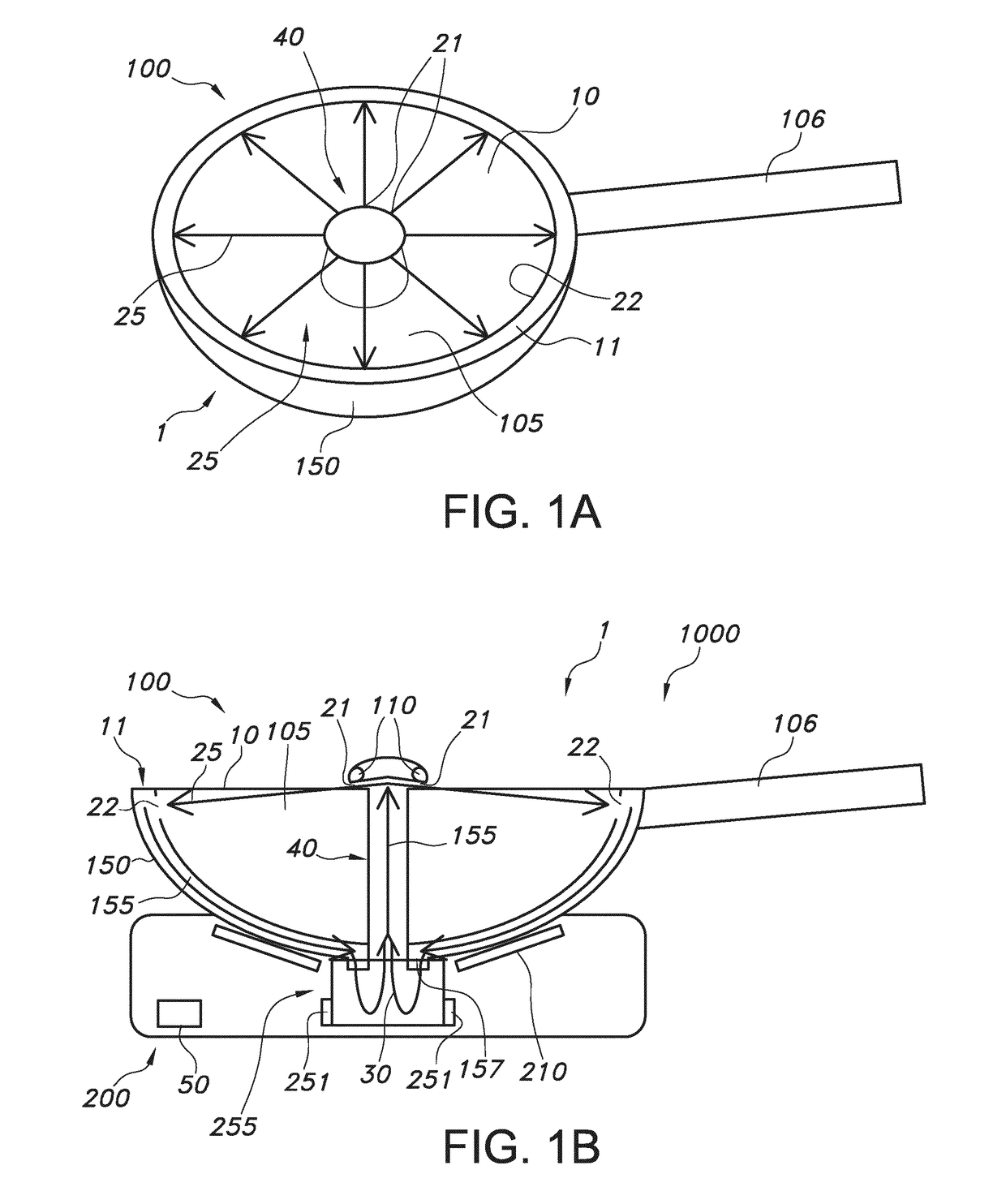

Smokeless air blade wok

InactiveUS20170367514A1Reduce escapeImprove efficiencyFood scienceCooking vessel constructionsEngineeringFood preparation

The invention provides a food preparation vessel (100) comprising a main inlet (10) for introduction of a food material into the food preparation vessel (100), wherein the food preparation vessel (100) comprises a gas flow generator outlet (21) and a gas flow receiver inlet (22), wherein the gas flow generator outlet (21) is configured to provide a gas flow (25) in the direction of the gas flow receiver inlet (22) and having a component parallel to the main inlet (10) when the gas flow generator outlet (21) is functionally coupled with a gas flow generator in operation.

Owner:KONINKLJIJKE PHILIPS NV

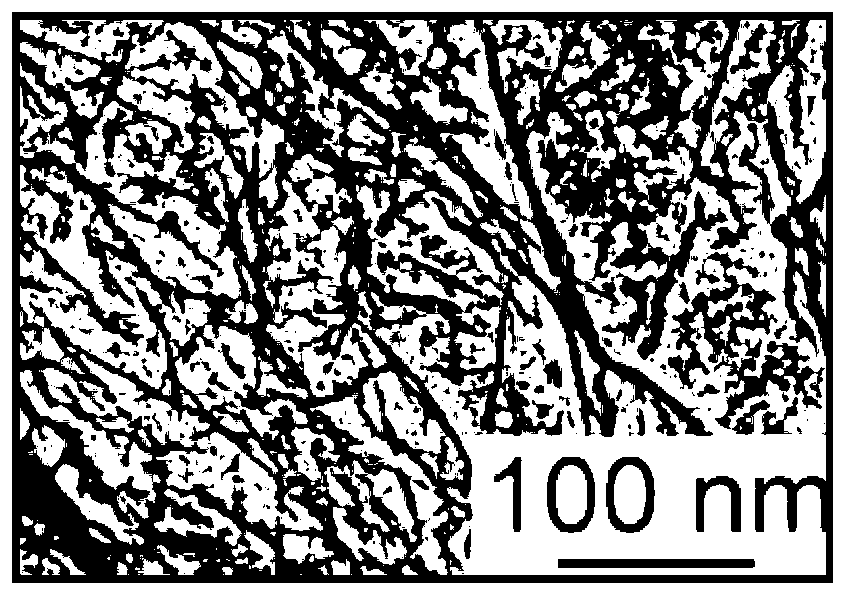

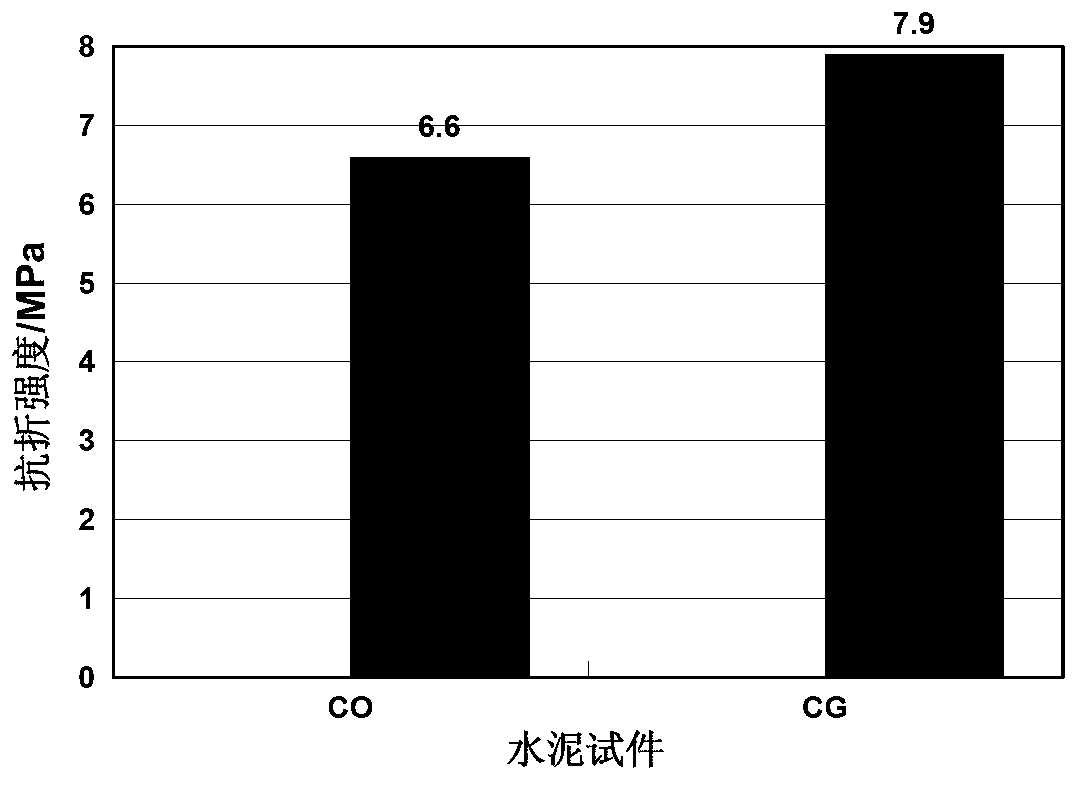

Application of graphene oxide as reinforcing agent of cement early strength

The invention relates to an application of graphene oxide as a reinforcing agent of a cement early strength, and belongs to the field of building materials. The invention provides the application of graphene oxide as the reinforcing agent of the cement early strength. Graphene oxide is nanoscale high polymer material, and not only can fill small gaps among cement particles, so that a microstructure of the cement is dense and flat, and also graphene oxide has high surface activity, so that a hydration process of the cement can be promoted, and the mechanical property of the cement is effectively improved.

Owner:DALIAN MARITIME UNIVERSITY

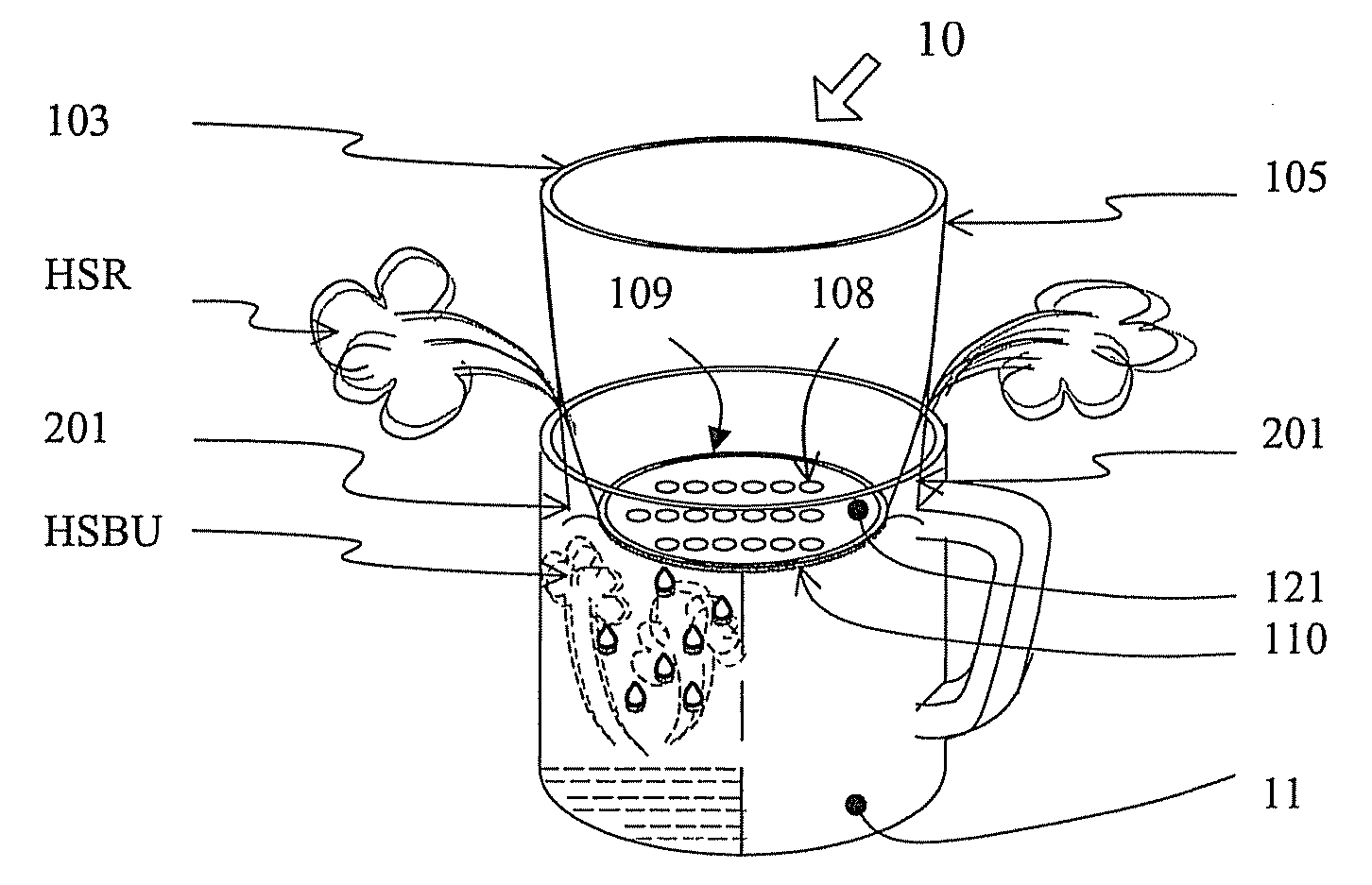

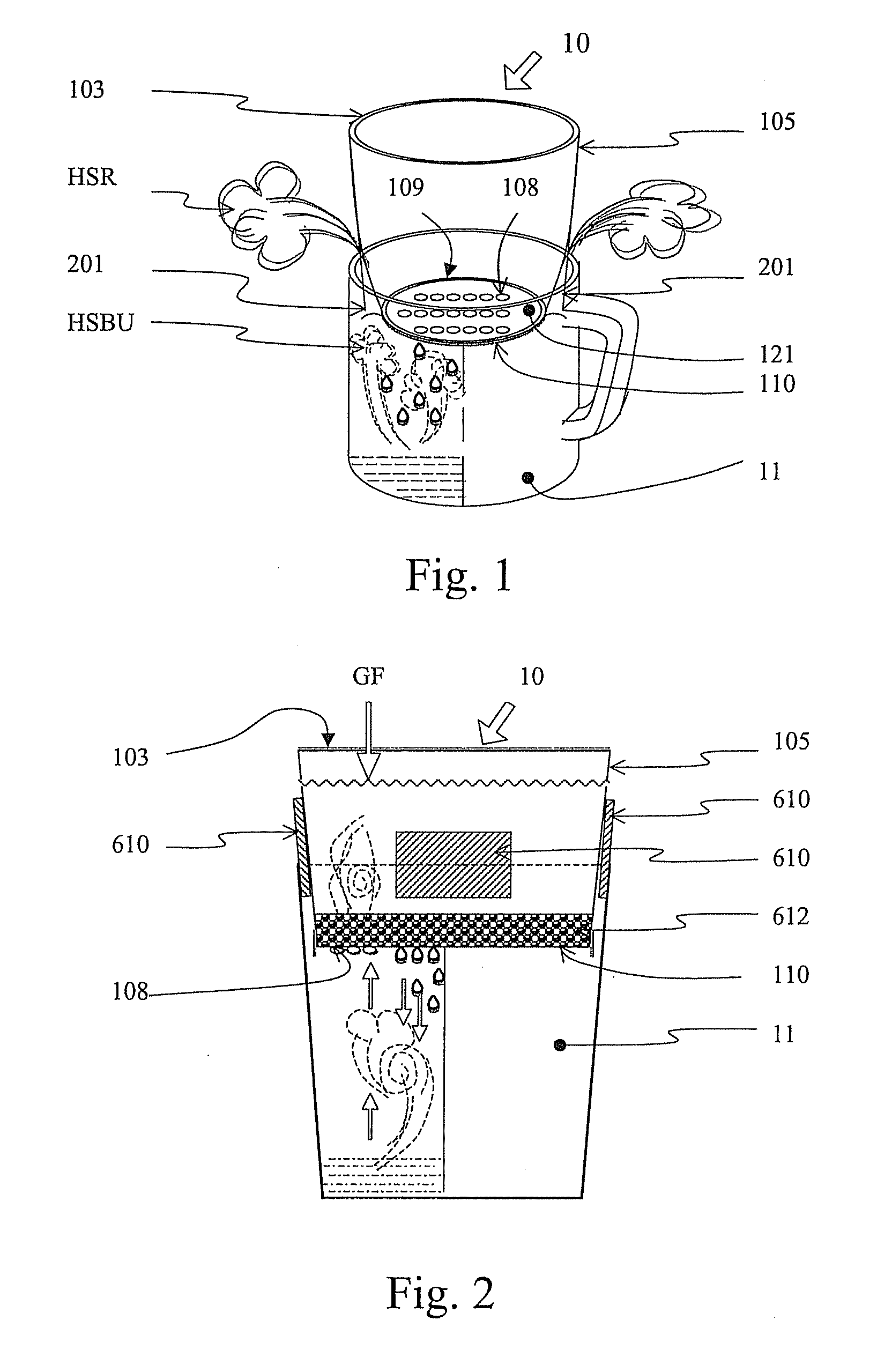

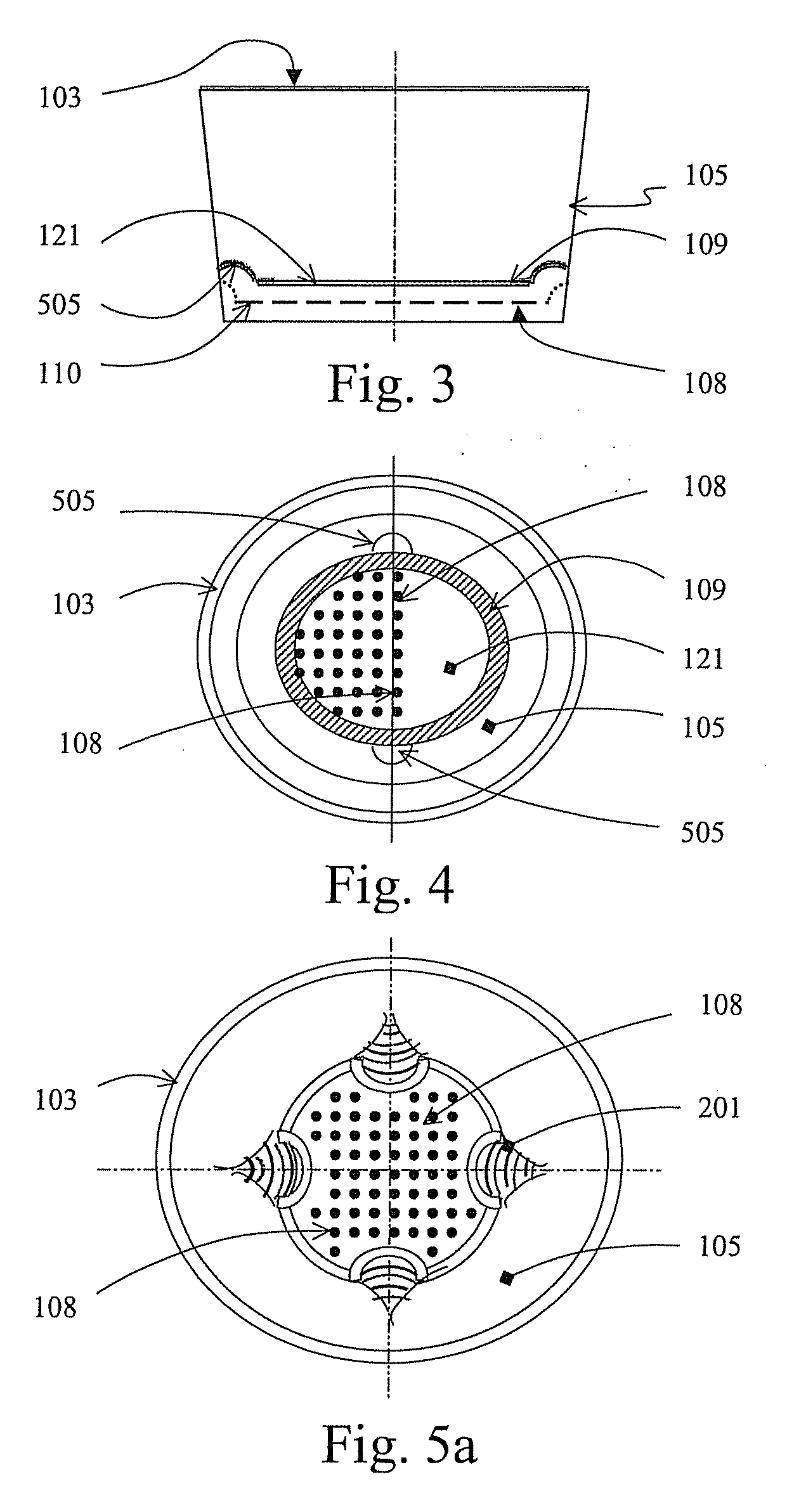

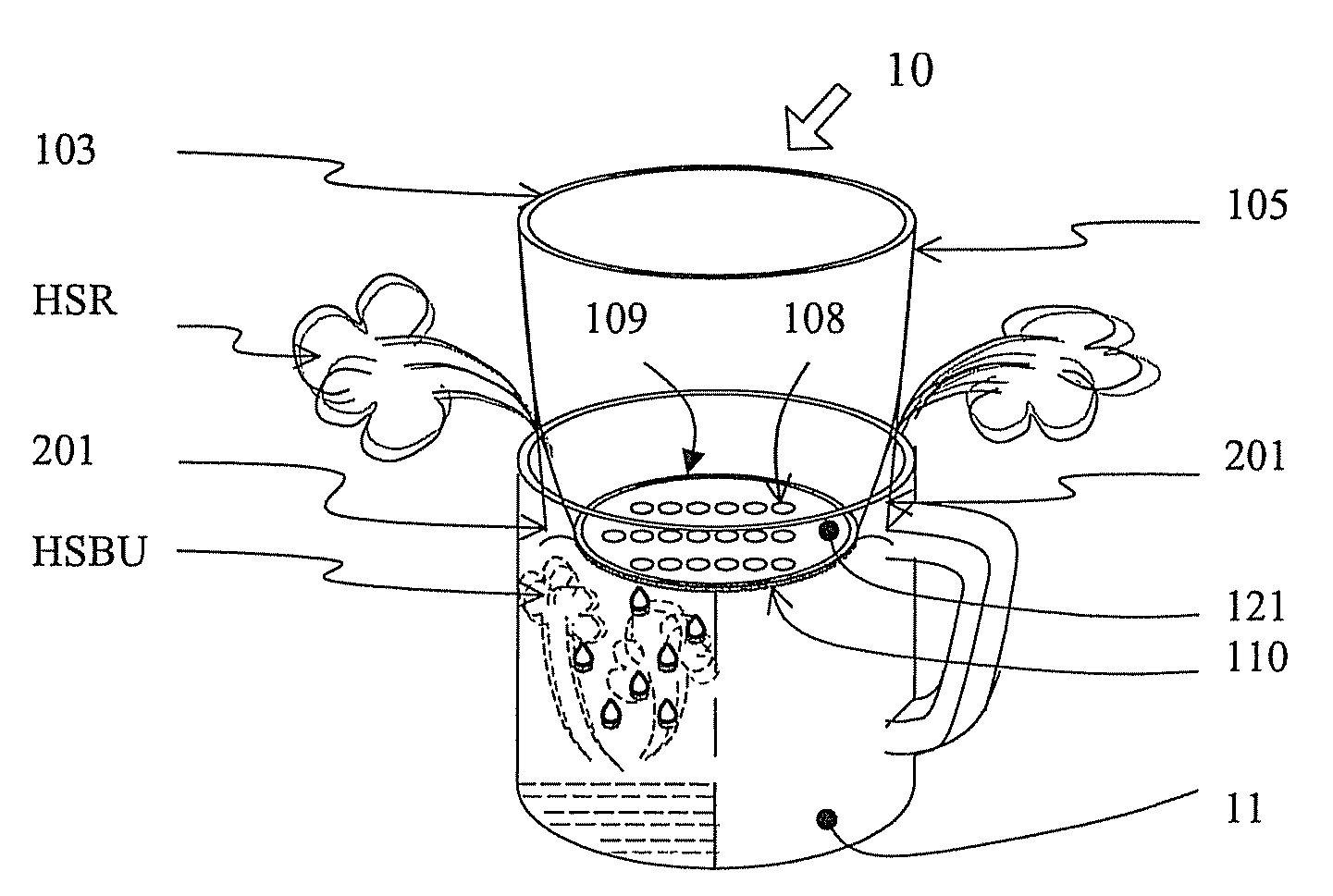

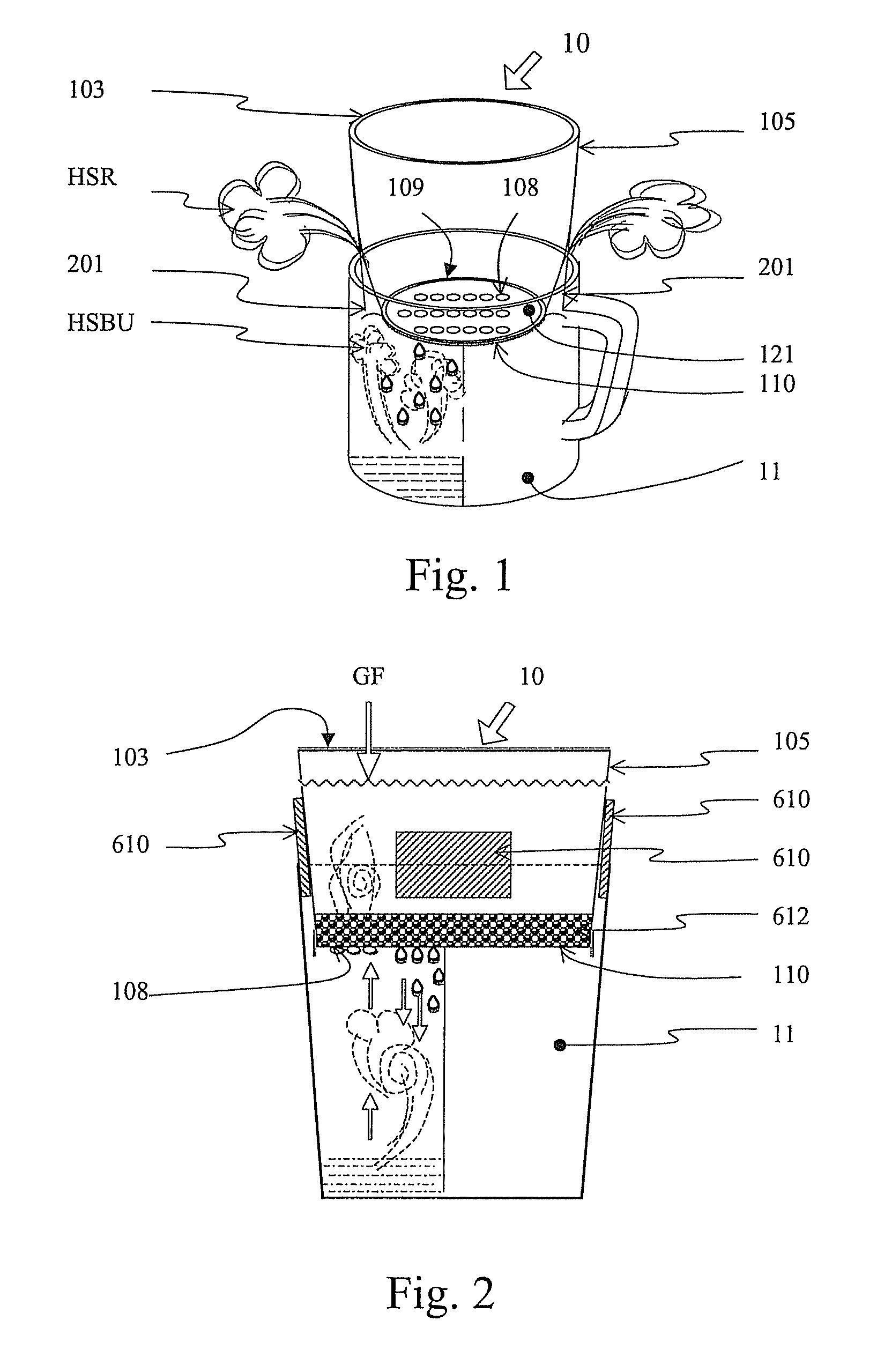

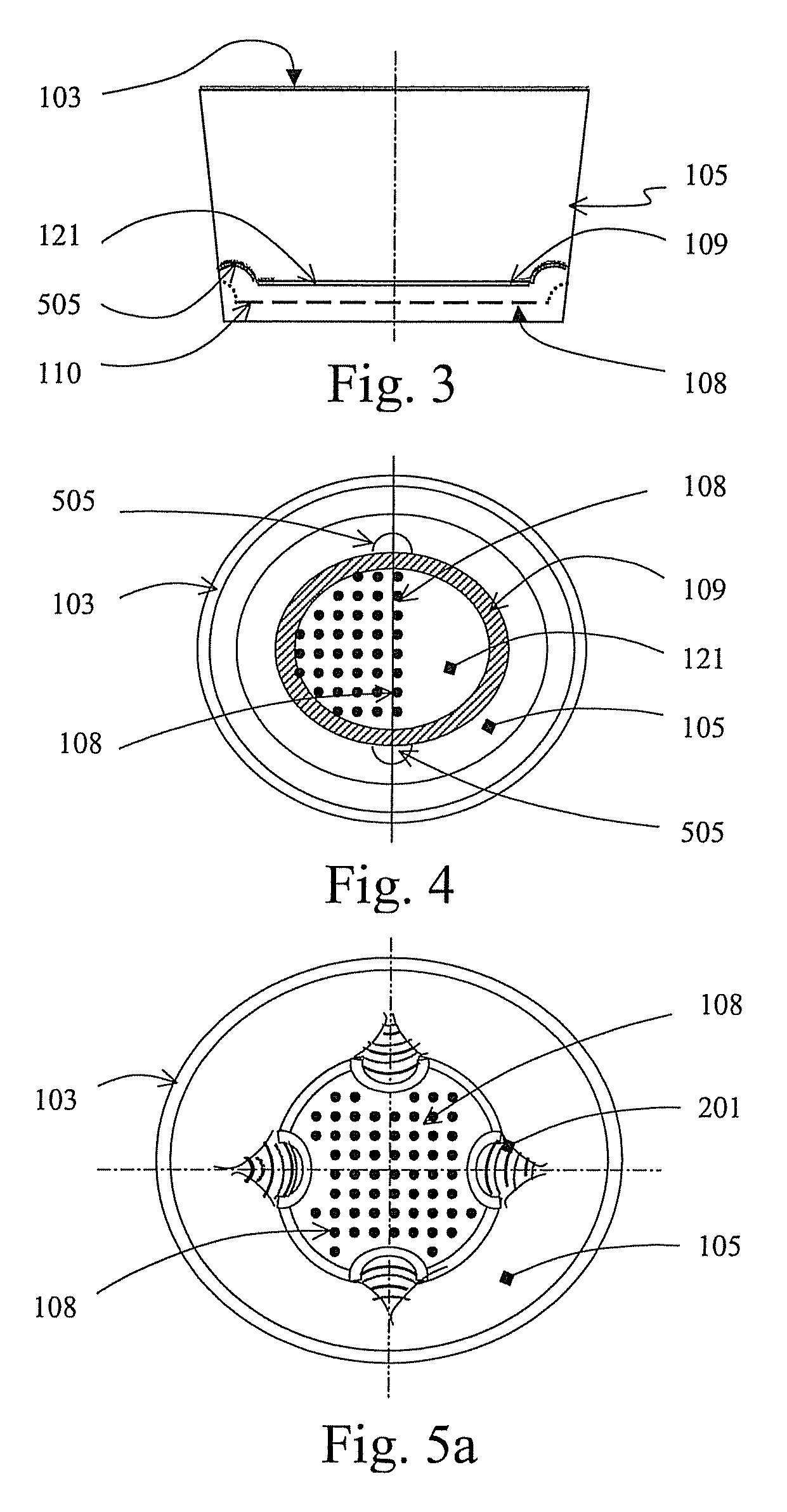

Instant extraction cup

The invention relates to a disposable infusion product for making a beverage including a filter cup composed of a water permeable material and having on the base of the cup a plurality of perforations as a time control mechanism for flow of liquid. The invention also relates to a method of preparing an individual serving of a solid beverage flavorant, such as coffee or tea being immersed in the filter cup. The assembly includes four concave vents being set on the lower part of the outer side wall of the filter cup to provide relief for hot steam build up that occurs and which could slow down the drip down process when two cups are telescopically engaged in a liquid receiving container. A supporting sit-on-ring telescopically engages above the liquid receiving container.

Owner:TJEN EDDY

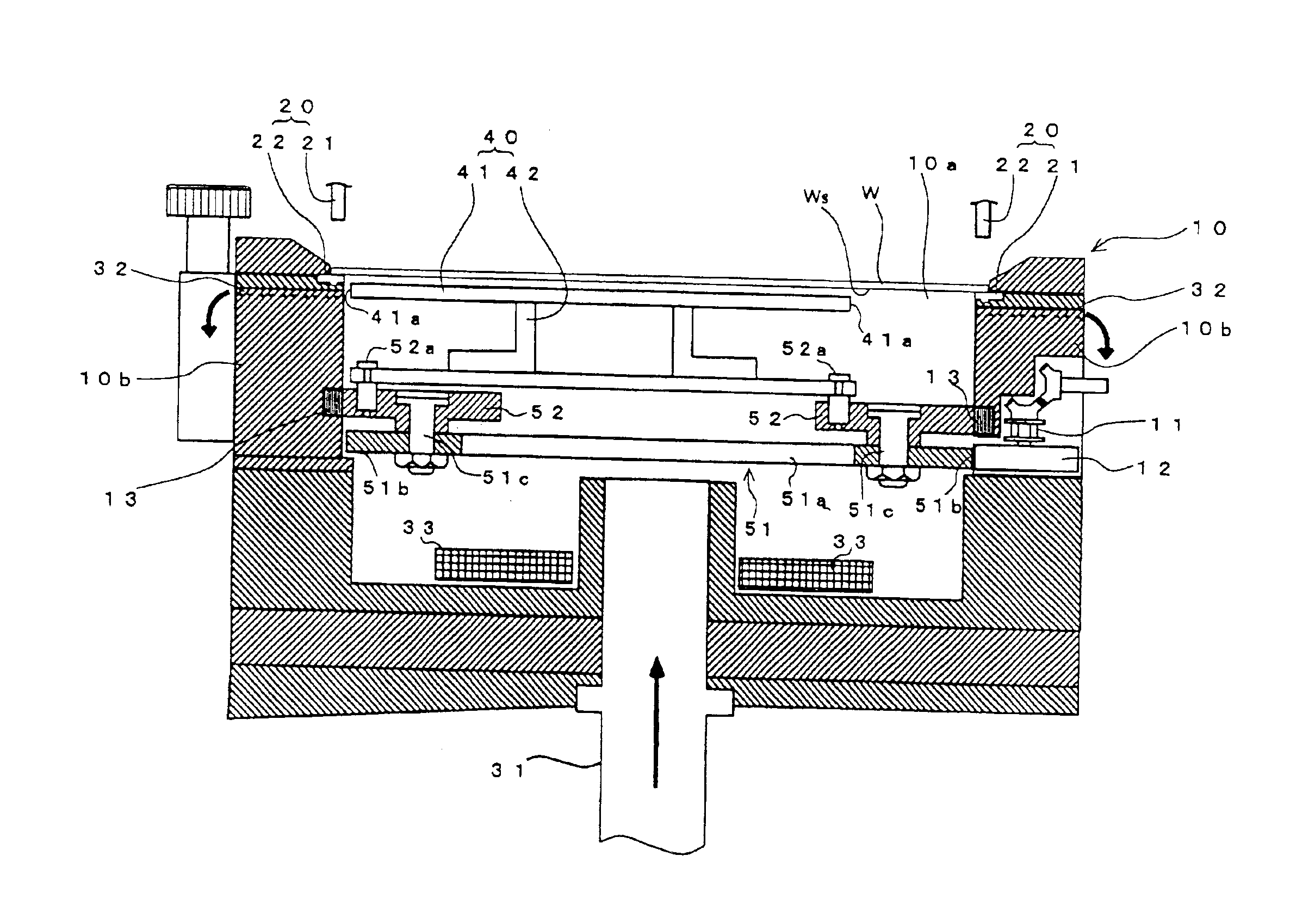

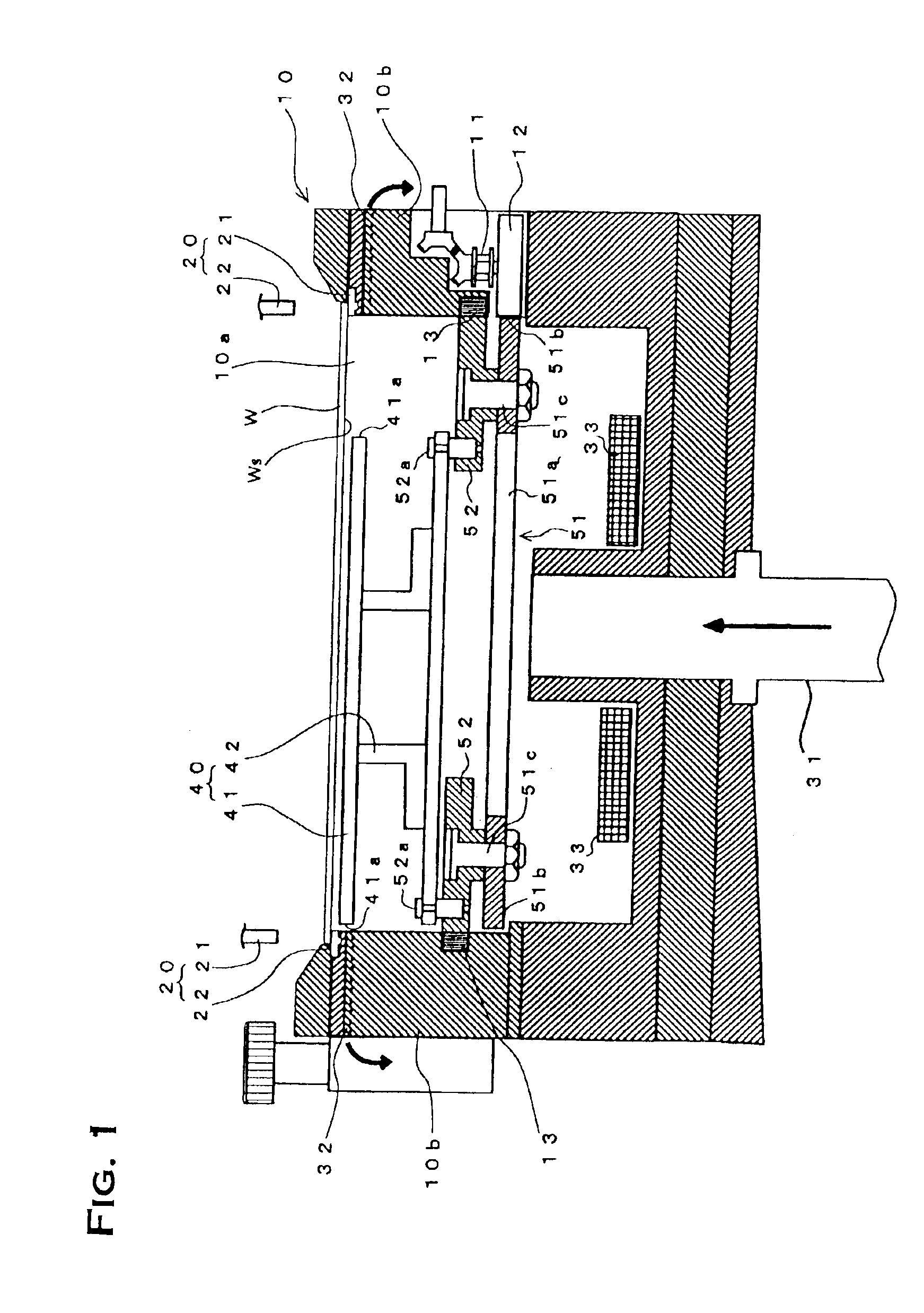

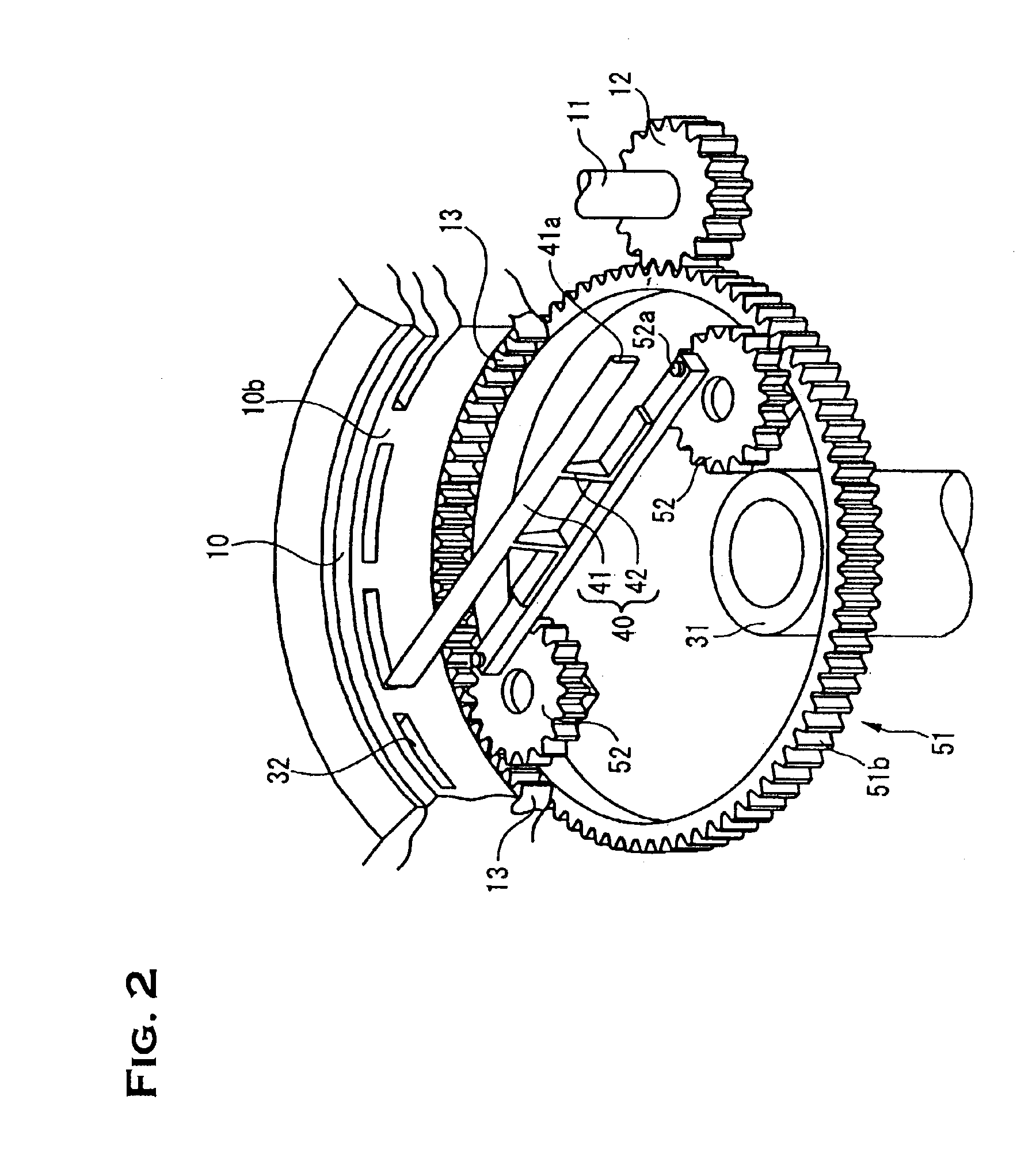

Plating apparatus for wafer

A plating apparatus is provided to allow the whole area of a target plating surface of a wafer to be subjected to more uniform plating treatment and moreover enables a target plating surface of a wider area to be subjected to positive and uniform plating treatment. In the plating apparatus which has a stirring bar within a plating tank and which performs plating treatment of a target plating surface of the wafer while stirring a plating solution near the target plating surface of the wafer by moving the stirring bar, the stirring bar is rotated while being oscillated in a motion plane substantially parallel to the target plating surface of the wafer. By this operation, the occurrence of an eddy flow of the plating solution is suppressed during stirring and it becomes possible to positively carry out more uniform plating treatment of a wider region.

Owner:ELECTROPLATING ENGINEERS OF JAPAN LTD

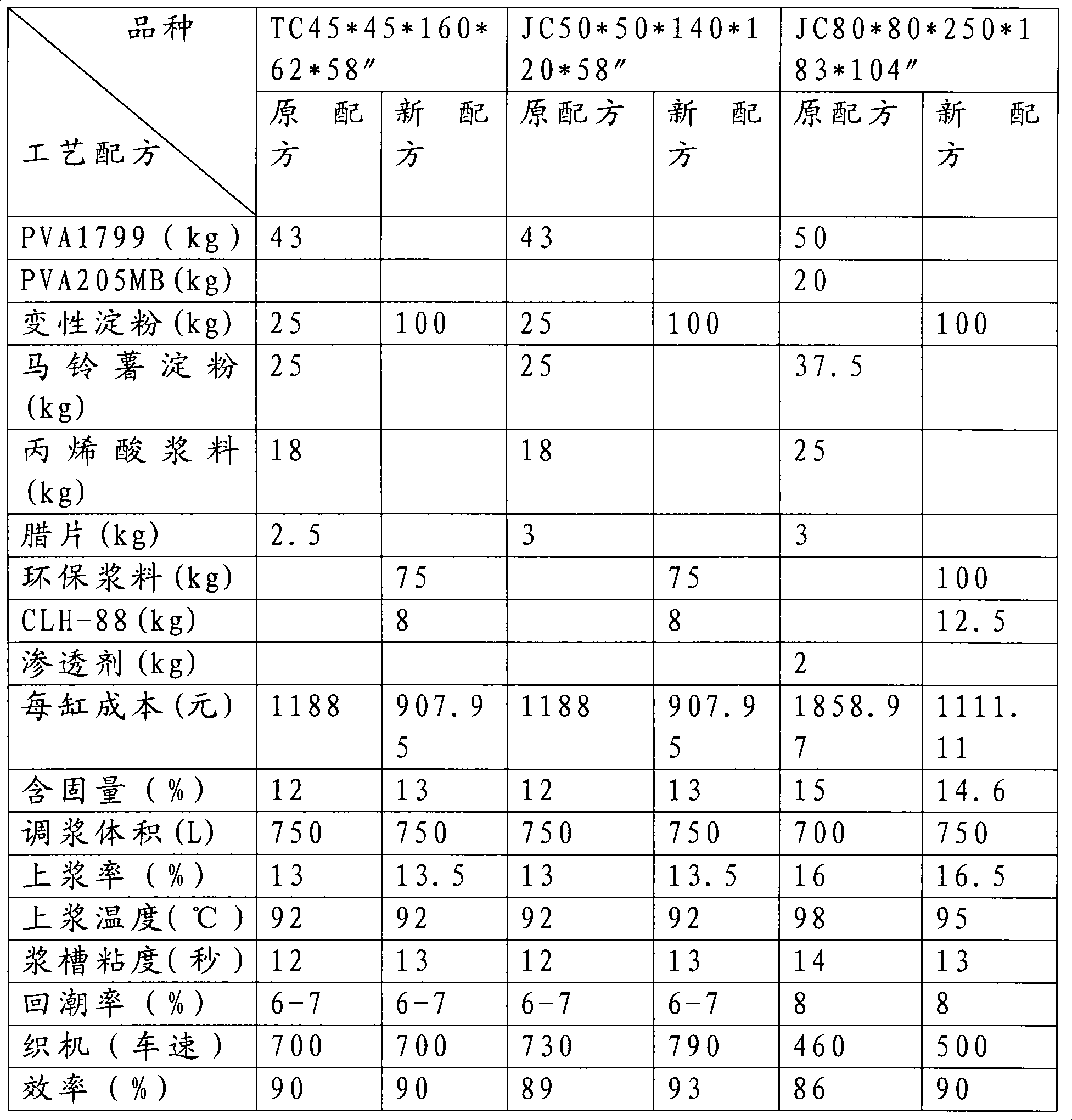

Textile slurry composition replacing for polyvinyl alcohol and preparing method thereof

The invention provides an environment-friendly textile size composition which has simple process and convenient use, and substitutes for polyvinyl alcohol, and a preparation method thereof, which aim at the current status that the sizing of the prior textile fiber warp can not be independent from PVA size and the disadvantages of the prior size. The size composition is prepared by mixing an ultrafine particle inorganic material which accounts for 1 to 10 percent of the total weight, polyacrylic acid size which accounts for 10 to 40 percent of the total weight, and water for the balance. The size composition is matched with modified starch size, can fully substitute for the PVA size during the sizing process of yarns such as pure cotton, polyester cotton, hemp, artificial cotton, and tenel, and meet the manufacturing requirement of high-difficulty varieties.

Owner:青岛常力恒工贸有限公司

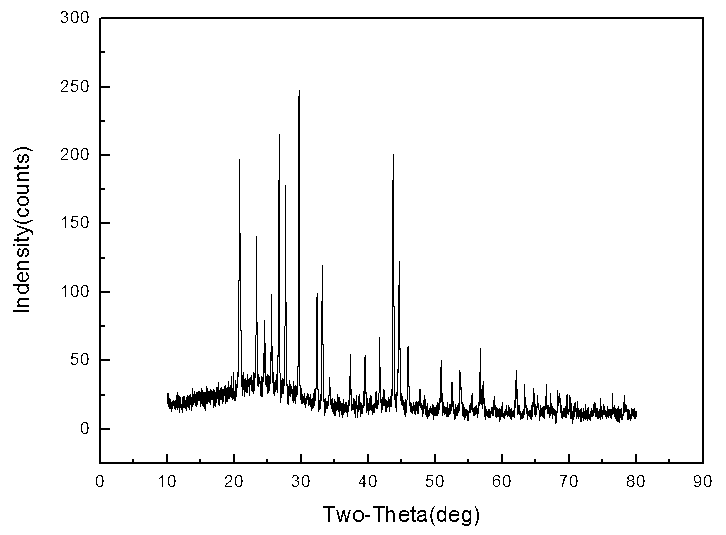

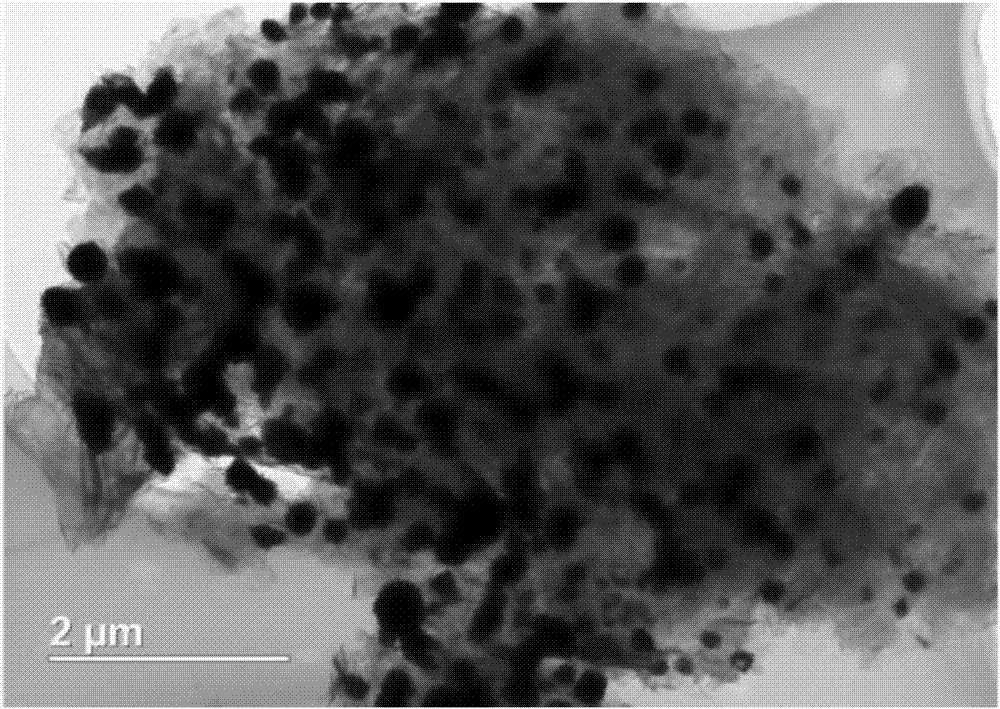

Lead/carbon composite for storage battery and preparation method of lead/carbon composite material

ActiveCN103137955AIncrease the proportionAvoid uneven mixingCell electrodesCarbon compositesCharge current

The invention discloses a lead / carbon composite for a storage battery. The lead / carbon composite is prepared from the following raw materials in percent by weight: 85-99.9 percent of lead-salt solution and 0.1-15 percent of conductive carbon material, wherein the lead salt solution is prepared from a soluble lead salt and deionized water, and the mol concentration of the lead salt solution is 0.1-0.8M. The invention also discloses a preparation method of the lead / carbon composite for the storage battery. The lead / carbon composite is substantially a conductive carbon material modified by lead oxide. Lead has the characteristics of low resistivity, high plasticity and high hydrogen evolution overpotential. The characteristics of the lead ensure that the hydrogen evolution overpotential of the carbon material after modified by PbO in a lead-acid battery is remarkably increased; and meanwhile the charging current occupied by partial hydrogen evolution reaction in a charging process is reduced, and the charging efficiency is increased.

Owner:SHENZHEN CENT POWER TECH

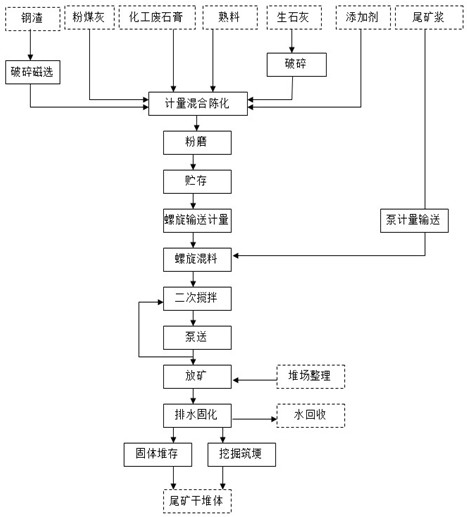

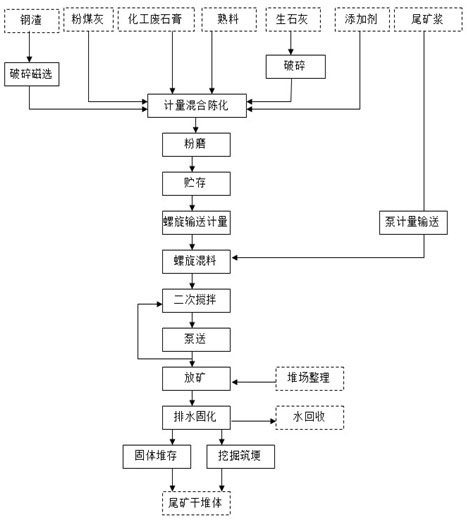

Curing and dry-piling method of iron tailings

The invention relates to a curing and dry-piling method of iron tailings, belonging to the technical field of mine safety. The curing and dry-piling method comprises the following steps of: adding a curing agent and a chemical additive produced by adopting steel slag, chemical waste gypsum, clinker, coal ash and quick lime in tailing pulp, and synchronously realizing precipitation, water drainage and curing and pile-up by secondary mixing and stirring. Compared with the prior art, the curing and dry-piling method has the advantages of simple technical process, low cost, small occupied area and high safety, and is a new method for safe pile-up of the iron tailings.

Owner:KUNMING UNIV OF SCI & TECH +1

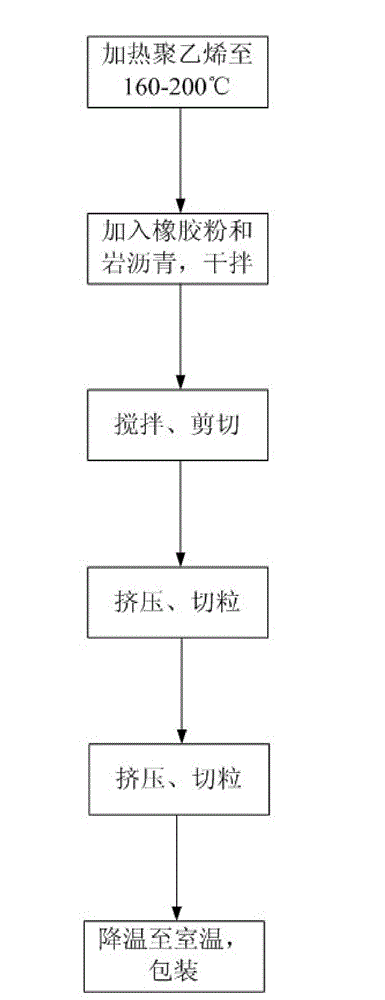

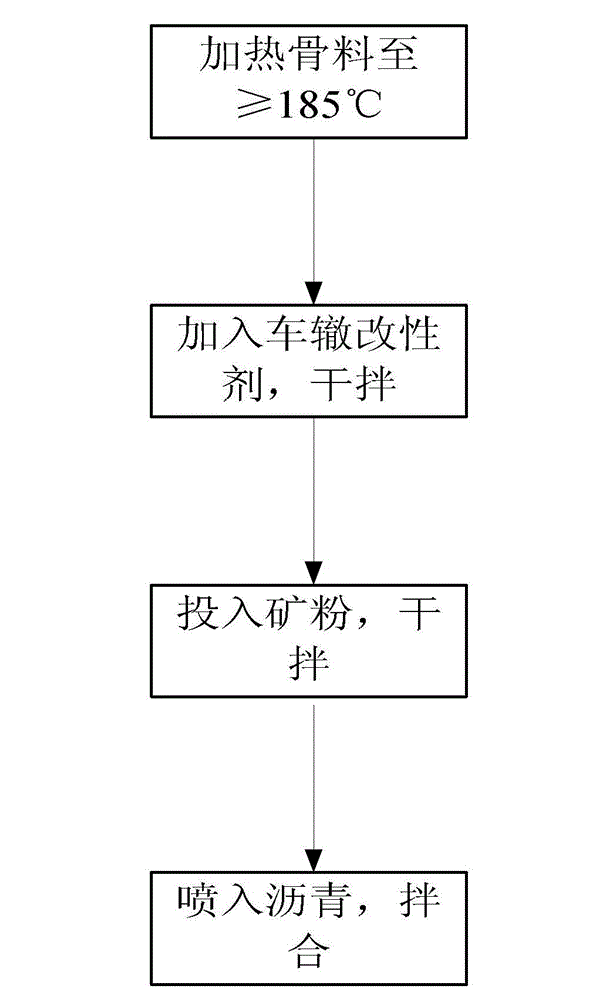

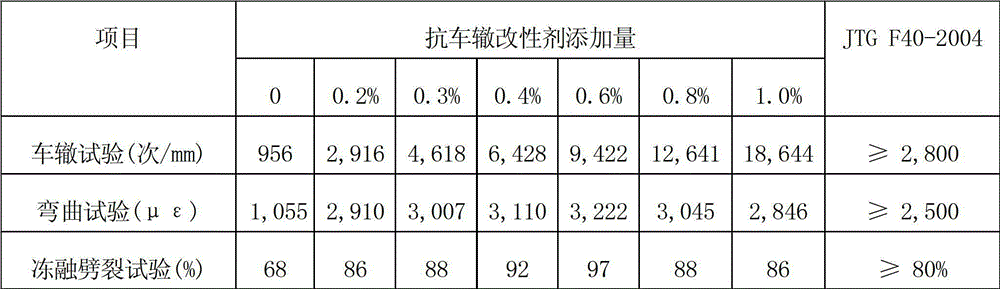

Anti-rutting modifying agent used for asphalt pavement and asphalt mixture containing anti-rutting modifying agent

ActiveCN103059587ASolve technical problemsRealize repeated recyclingBuilding insulationsPolymer scienceEngineering

The invention relates to an anti-rutting modifying agent. The anti-rutting modifying agent comprises (a) high-density low-pressure polyethylene, (b) rubber powder and (c) rock asphalt. The anti-rutting modifying agent is good in low-temperature cracking resistance, high in bonding strength, high in water damage resistance, good in non-deformability, low in cost, simple in preparation technology, convenient to operate and convenient to add in asphalt mixture.

Owner:北京中交路通科技发展有限公司

Glass fiber screen cloth immersing glue solution for grinding wheel reinforcement and initial rinsing method

InactiveCN101139172ASolve the problem that is easy to cause scrap rateReduce pollutionHydrometerFiberglass mesh

The present invention discloses a glass fiber mesh fabric dip solution for reinforcement of grinding wheel and the dipping method, which belongs to the field of composite materials; wherein the dip solution is formed by mixing the industrial alcohol with the liquid phenolic resin, the solid content of which is larger than or equal to 65 percent. The mixing ratio between the liquid phenolic resin against the industrial alcohol ranges from 1:0.15 to 0.20. The presoaking method is realized by utilizing the conventional dipping machine and the specific operating steps are that the glass fiber mesh fabrics are delivered into a dipping groove through a fabric transportation drum and a fabric storage roller so as to be dipped by the dip solution arranged in the dipping groove; then the dipped glass fiber mesh fabrics go into the rubber pressing by a dandy roll and then are fed into an oven to be pre-cured; the dipped glass fiber mesh fabrics are pulled out by a traction device and are trimmed and rolled up after passing through a buffering fabric storage roller and a deviation-correcting device. Two kinds of raw materials are selected as the raw materials of the present invention, thus simplifying the confection process of the present invention; the hydrometer is used to measure and adjust the proportion of the dip solution, thus resulting in that the gum chicle content is effectively controlled and the quality of products is stable; the volatile quantity is lowered from originally 5 percent to 1.5 percent. The glass fiber mesh fabric dip solution for reinforcement of grinding wheel causes few contaminations to the environment, has low cost and is easy to be popularized and put into use.

Owner:北京玻钢院复合材料有限公司

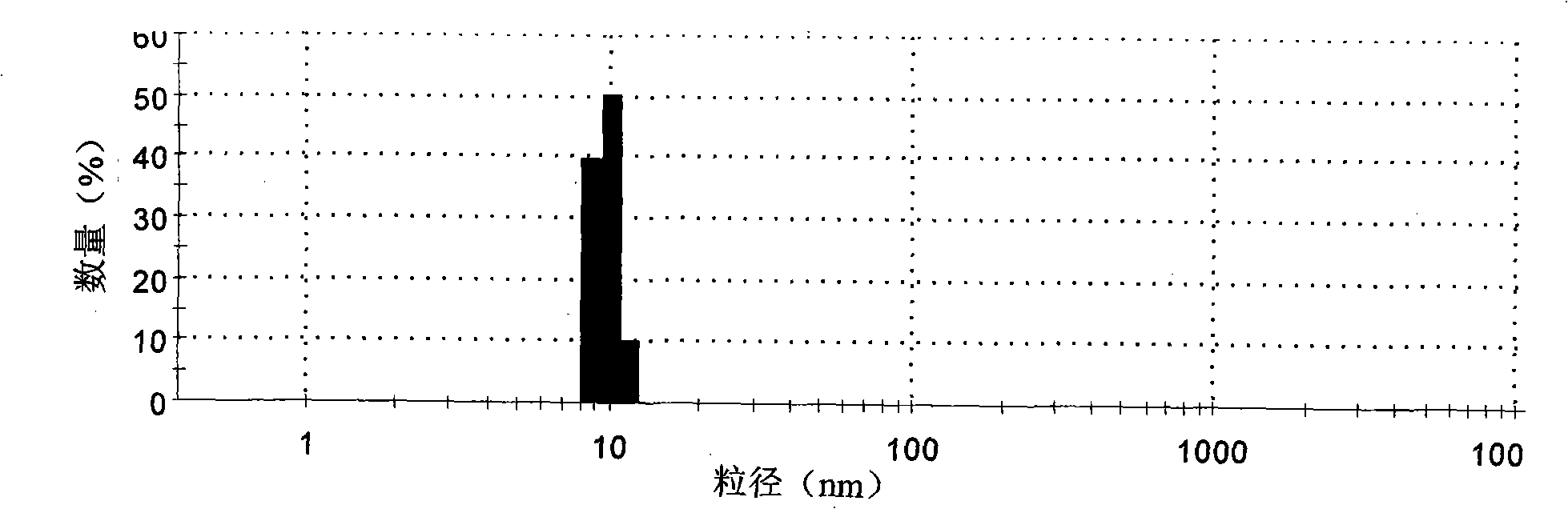

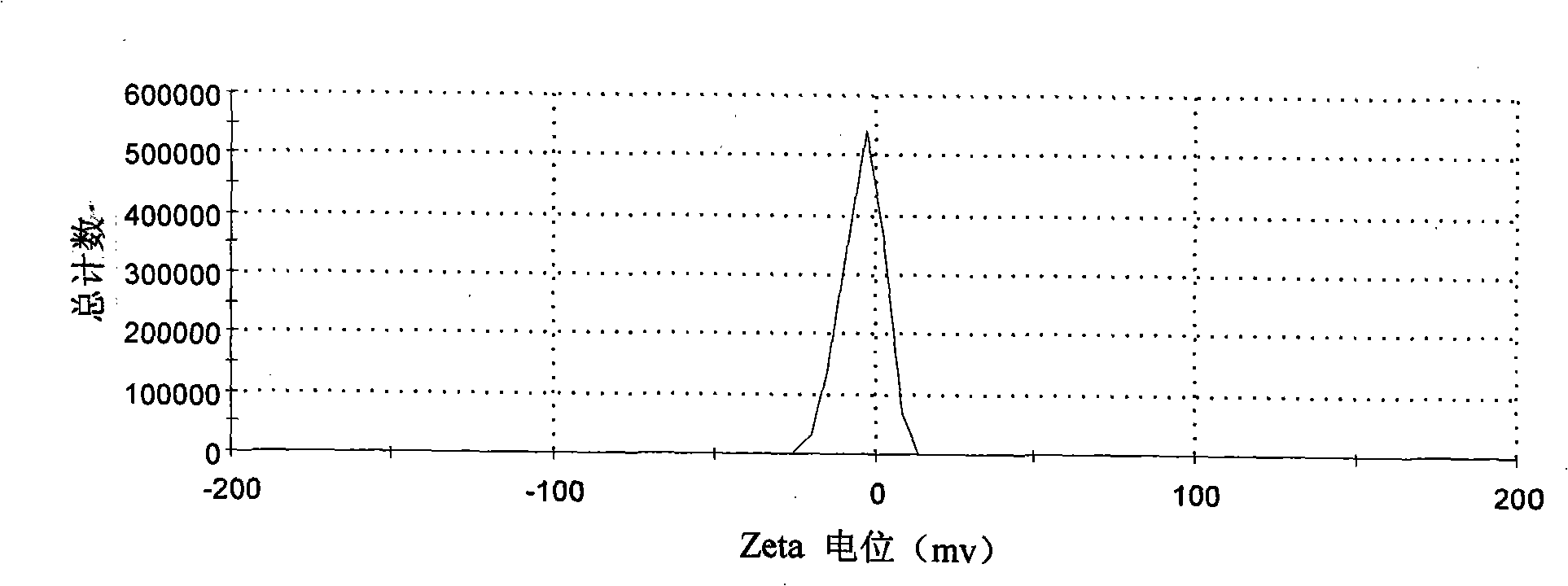

Icariin microemulsion and preparation method thereof

InactiveCN101513388ASimple mixing processIncreased penetration through the cell layerOrganic active ingredientsSkeletal disorderBULK ACTIVE INGREDIENTMethyl oleate

The invention relates to an icariin microemulsion which takes icariin as active ingredient; the icariin is dissolved in oil and then added with emulsifying agent, assistant emulsifier and water to prepare microemulsion with the micro emulsion grain diameter of 10-100nm, wherein, the oil can be one or more in oleic acid, ethyl oleate, isopropyl myristate or castor oil; the icariin microemulsion has the components with the mass percent: 0.66-6.02% of saturated solution of oil of icariin, 10-50% of emulsifying agent, 10-38% of assistant emulsifier and the balance water, Hank's balanced salt solution (HBSS), PBS buffer solution or normal saline. The icariin microemulsion can be kept clear, transparent, stable and uniform when being placed at room temperature for a year, thus good stability is verified evidently. The experiments of cells and animals prove that the icariin microemulsion can strengthen the icariin to penetrate cell layers, promote the medicine to be ingested and absorbed and enhance the healing effect of the medicine. The invention also discloses a preparation method of the icariin microemulsion.

Owner:贾晓斌

Method for remedying heavy metal polluted soil by inducing calcium carbonate precipitation through microorganisms

ActiveCN111672900AWide variety of sourcesTake advantage ofContaminated soil reclamationMicroorganismSoil science

The invention discloses a method for remedying heavy metal polluted soil by inducing calcium carbonate precipitation through microorganisms, and belongs to the technical field of geotechnical engineering. The method comprises the following steps: step 1, preparing a bacterial liquid and a cementing liquid; step 2, detecting the concentration of heavy metal pollutants in a suspected contaminated site; step 3, remedying the heavy metal polluted soil; and step 4, detecting the remedying effect. A slurry mixing mode is adopted, the cementing liquid, the bacterial liquid and the heavy metal pollutants can be in full contact, the operation is easy, the cost is low, the remediation uniformity is good, secondary pollution is avoided, and remedied soil can serve as a roadbed filler.

Owner:HEFEI UNIV OF TECH

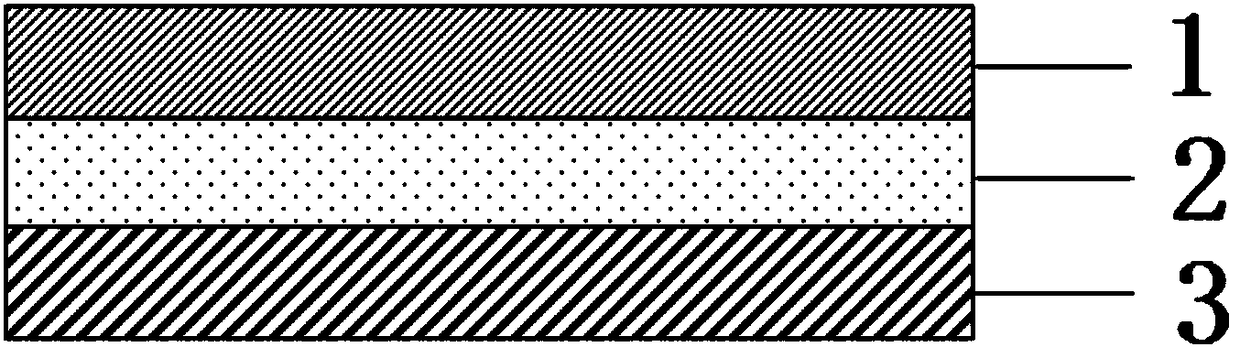

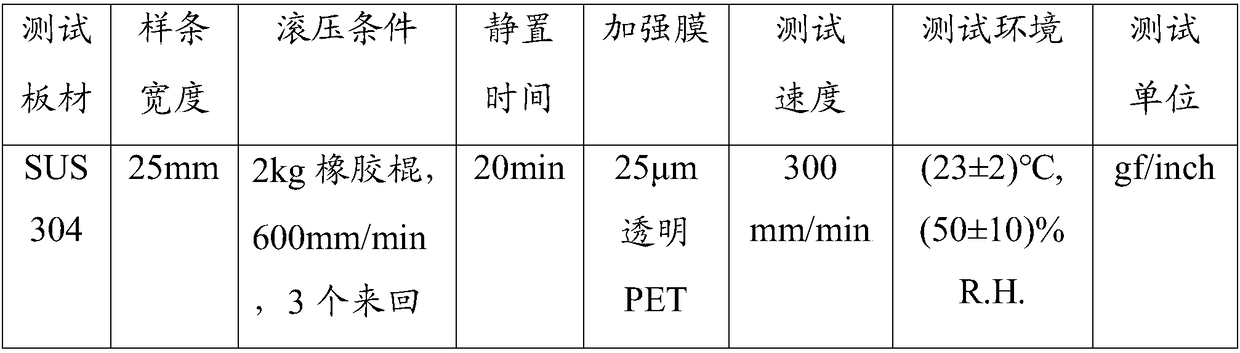

Single-side fire-retardant adhesive tape and preparation method thereof

InactiveCN108329857AOvercoming high mobilityOvercoming problems such as poor construction effectNon-macromolecular adhesive additivesFilm/foil adhesivesHigh volume manufacturingSolvent

The invention belongs to the technical field of an adhesive tape in an electronic product, and particularly relates to a single-side fire-retardant adhesive tape and a preparation method thereof. Thesingle-side fire-retardant adhesive tape comprises a substrate layer, a bonding agent layer and a release material layer, wherein the bonding agent layer is arranged on the surface of the substrate layer; the release material layer is arranged on the surface of the bonding agent layer; the bonding agent layer is prepared from raw materials of polyacrylate, curing agents, a first fire-retardant agent, a second fire-retardant agent and a solvent; the first fire-retardant agent is solid at normal temperature; the second fire-retardant agent is liquid at normal temperature. The preparation methodcomprises the steps of adhesive mixing, coating, composite reeling and curing. Compared with the prior art, the single-side fire-retardant adhesive tape has the following advantages that the bonding agent layer comprises two kinds of phosphorous fire-retardant agents; low smoke and low toxicity are realized; the phosphorous content is high; a good fire-retardant effect is achieved. The technical scheme provided by the invention is applicable to the adhesive tape finished product with high fire-retardant grade requirements; the adhesive mixing process is simple; the goal can be achieved by a general coating process; the characteristics of mass production and stable production are realized.

Owner:DWELL PHOTOELECTRIC MATERIAL SUZHOU

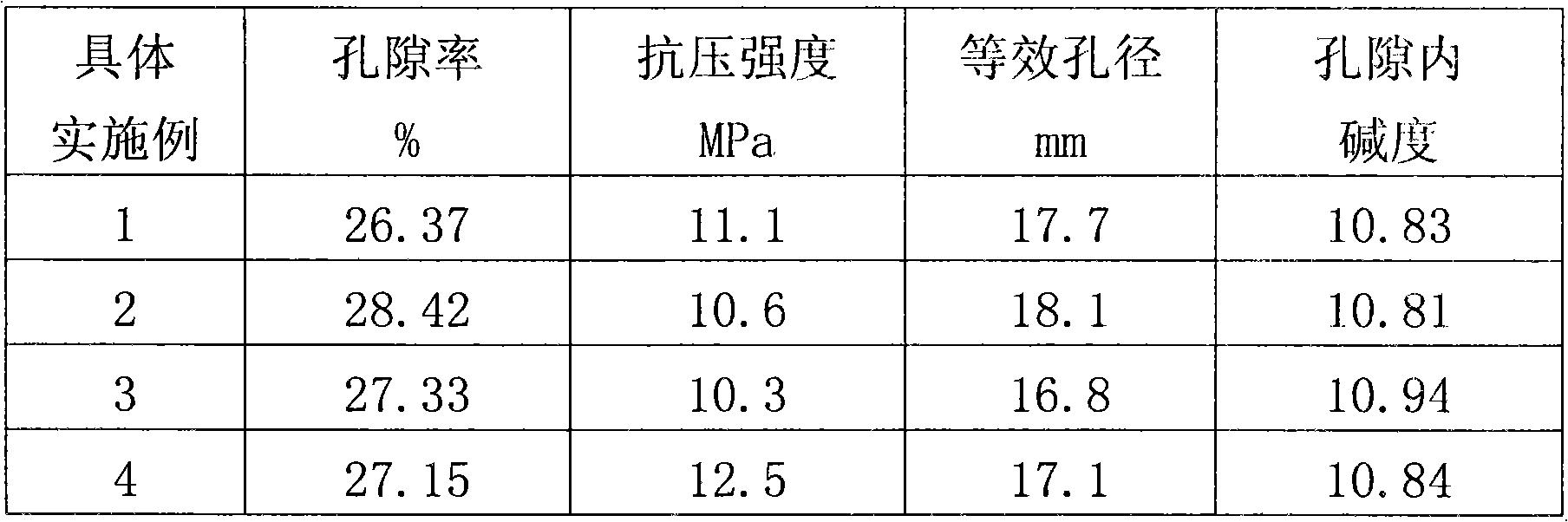

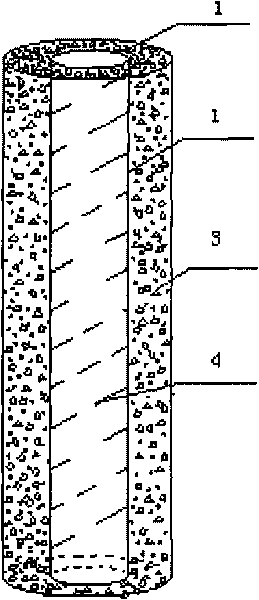

Preparation method of ecological embankment type porous concrete special for plant growing

InactiveCN102079105ASimple mixing processSimple molding processCeramic shaping apparatusVegetationPorosity

The invention discloses a preparation method of ecological embankment type porous concrete special for plant growing. The preparation method comprises the following steps of: adding premixing water into crushed stones and stirring to ensure that the surfaces of the crushed stones are moistened; adding cement and mineral waste residues or fly ash, and stirring the mixture for 15 to 45 seconds to ensure that a layer of cement grout shell is wrapped on the surfaces of the crushed stones; adding remaining mixing water for stirring, and continuously stirring the mixture for 1 to 10 minutes to obtain a mixed material, wherein the ratio of the water to the cement to the crushed stones is (0.29-0.39):1:(4-7), the used amount of the mineral waste residues or the fly ash is 10 to 30 percent of that of the weight of the cement; performing layer-by-layer pressing and gentle oscillation for moulding; and finally, covering the mixture by using a plastic film, and maintaining the mixture under a natural condition to obtain the ecological embankment type porous concrete. The materials adopted by the method are common, have wide sources and are simple in manufacturing; and the prepared porous concrete has high strength and high porosity, can be made into any shape as required, and can be applied to vegetation slope protections of roads and rivers as a base material for vegetation growth.

Owner:SOUTH CHINA UNIV OF TECH

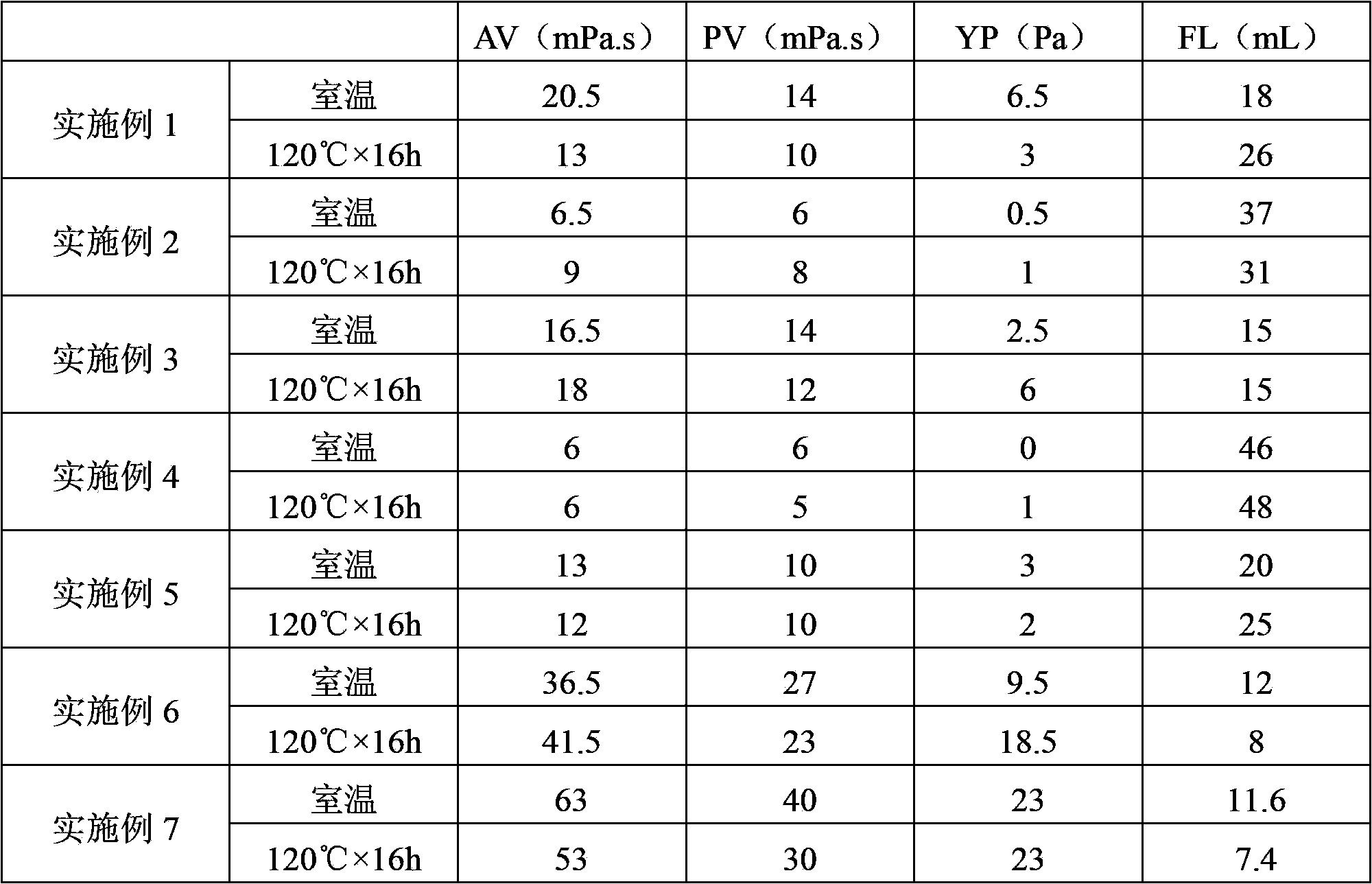

Solid-free drilling fluid

InactiveCN103509536ASimple system compositionSimple processing capacityDrilling compositionSalt resistanceFiltration

The invention provides solid-free drilling fluid. The solid-free drilling fluid comprises water and polymer swelling particles, and preferably, the solid-free drilling fluid also comprises alkali and / or salt. The solid-free drilling fluid provided by the invention can be formed by matching polymer swelling particles with different types, different swelling multiples and different particle sizes according to stratum requirements. The solid-free drilling fluid has the advantages of stable performance, high temperature resistance, high salt resistance, high rheological property, high lubricity and high filtration reducing property, and has simpler slurry matching and maintenance processes compared with conventional solid-free drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

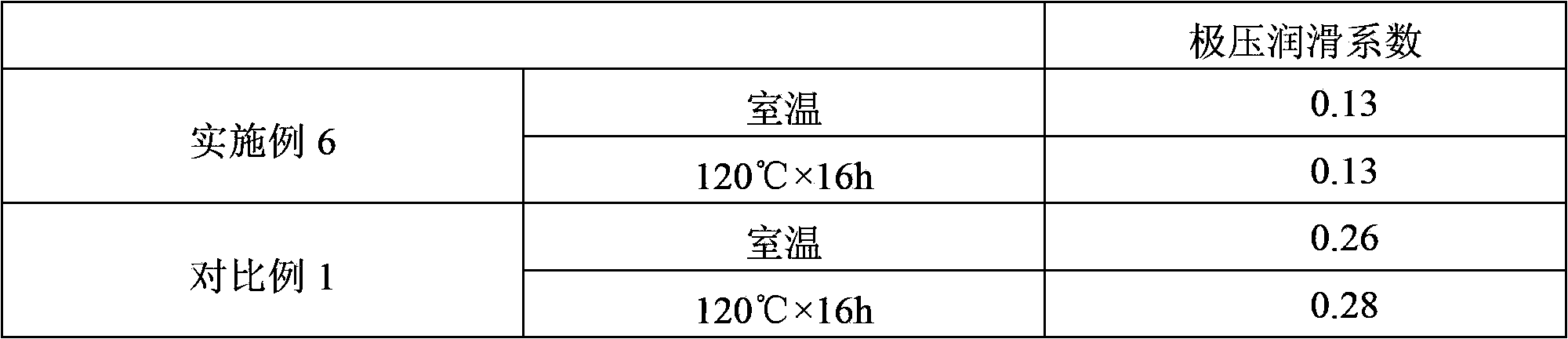

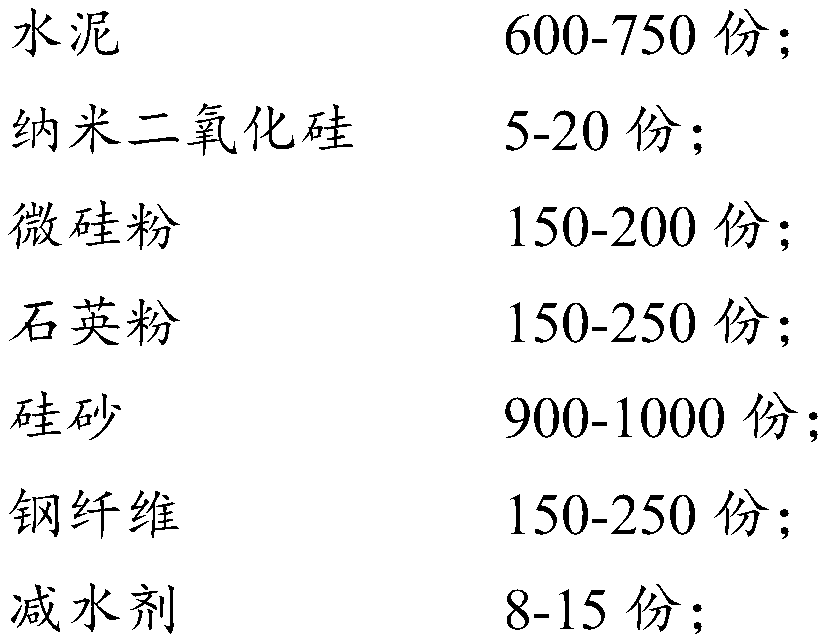

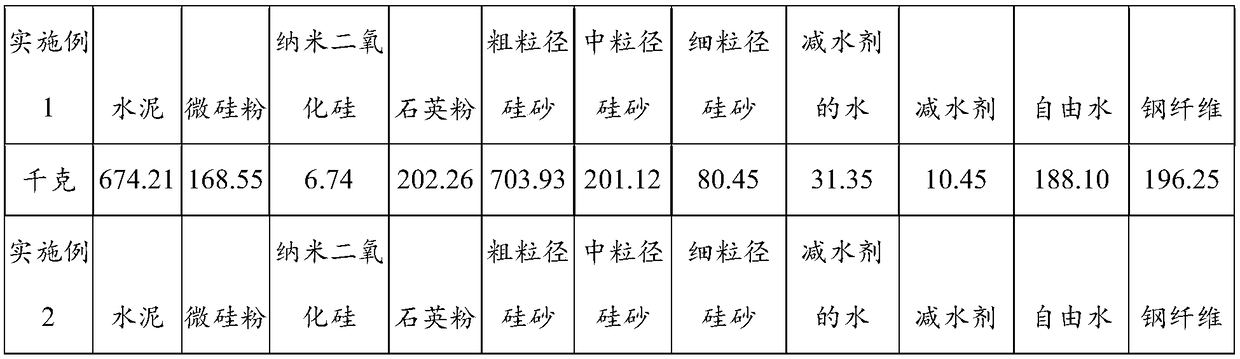

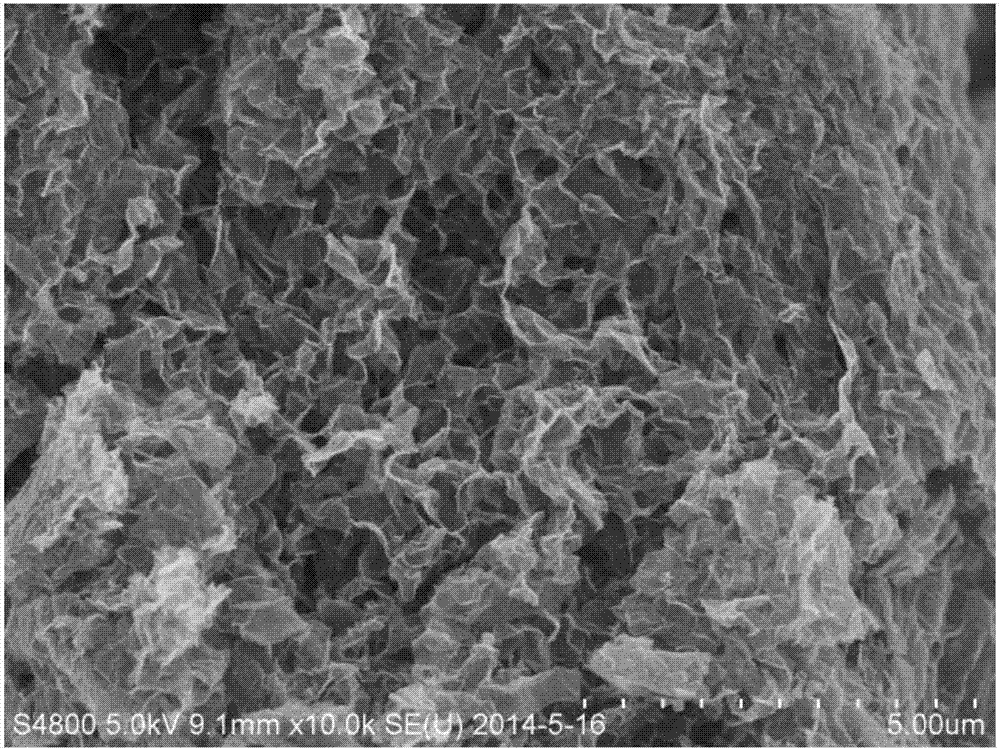

Ultra-high performance concrete slurry, ultra-high performance concrete and preparation method thereof

Belonging to the technical field of building materials, the invention in particular relates to an ultra-high performance concrete slurry, an ultra-high performance concrete and a preparation method thereof. The ultra-high performance concrete slurry comprises: cement, microsilica, nano silica, quartz powder, silica sand, steel fiber, a water reducing agent and water. According to the theory of theclosest packing, the adding proportion of each material is calculated, and trial mix experiments are carried out repeatedly, thus researching and developing the ultra-high performance concrete with the characteristics of minimum raw material variety, simple mixing process and maintenance technology, and the best mechanical properties.

Owner:GUANGDONG UNIV OF TECH

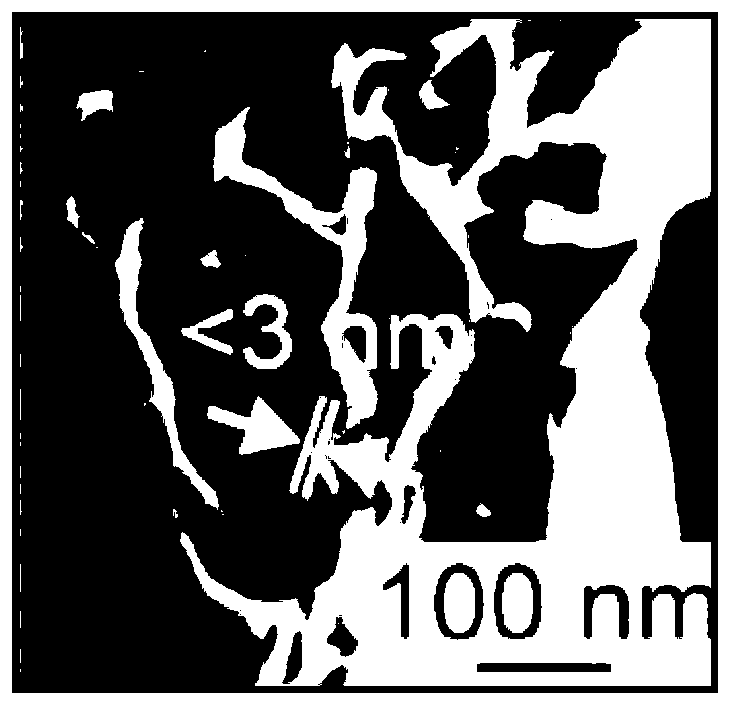

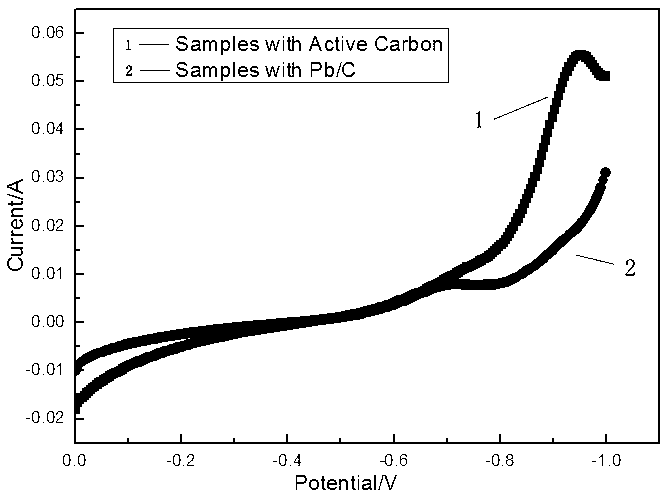

Lead-carbon super battery anode material and preparation method thereof

The invention provides a lead-carbon super battery anode material which is a graphene / Pb nano composite material. The lead-carbon super battery anode material is prepared by mixing a lead salt solution with a graphite oxide solution, carrying out hydrothermal reaction, and then carrying out macro body freeze drying and burning. The lead-carbon super battery anode material is prepared from 91 to 99.5 percent of lead and 0.5 to 9 percent of graphene. The lead salt solution is prepared by dissolving soluble lead salt into deionized water; the soluble lead salt is one or several of lead-containing nitrate, acetate, carbonate, hydrochloride, sulfate and complex salt. The invention further provides a preparation method of the lead-carbon super battery anode material. The preparation method provided by the invention has the advantages of high efficiency, environmental friendliness, high uniformity and the like; the prepared lead-carbon super battery anode material is high in uniformity, high in stability and wide in application prospect.

Owner:江苏强劲新能源科技有限公司

Material mixing method of graphite negative electrode slurry

ActiveCN109904430ASmooth mixingReunion won't happenCell electrodesSecondary cellsGraphiteEquilibrium constant

The invention provides a material mixing method of graphite negative electrode slurry. The graphite negative electrode slurry comprises a first graphite material, a second graphite material and a third graphite material, wherein the average grain diameter of the first graphite material is d1, the average grain diameter of the second graphite material is d2, and the average grain diameter of the third graphite material is d3, wherein d1 is smaller than d2 which is smaller than d3, and d2 is equal to k*(d1+d3); k is equal to a*(c1+c3) / (c2+0.5), wherein a is an equilibrium constant, and a is greater than or equal to 1.1 and less than or equal to 1.3; c1, c2 and c3 represent percentages of the first graphite material, the second graphite material and the third graphite material; and c1+ c2 +c3is equal to 1, and c1+c2 is less than or equal to c3. The material mixing method comprises the following steps of carrying out mixing on the first graphite material, the second graphite material andthe third graphite material to obtain three slurry materials respectively, and then enabling the three slurry materials to be mixed according to a specific sequence to obtain the graphite negative electrode slurry with high dispersion degree. The graphite negative electrode slurry disclosed by the invention is high in graphite dispersion degree, free of agglomeration, free of sedimentation, high in storage stability, high in energy density and high in rate performance.

Owner:山东中信迪生电源有限公司

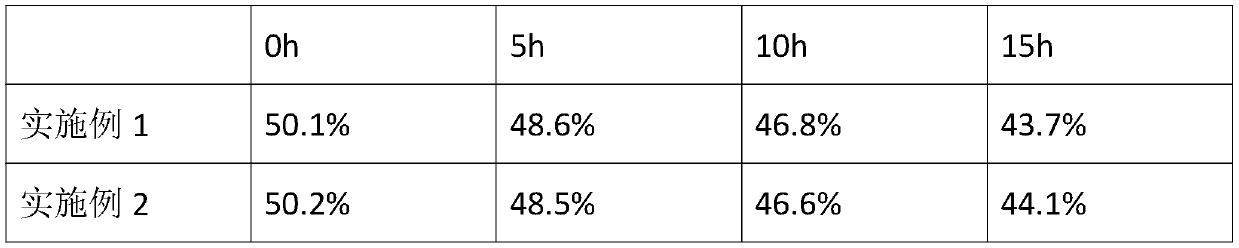

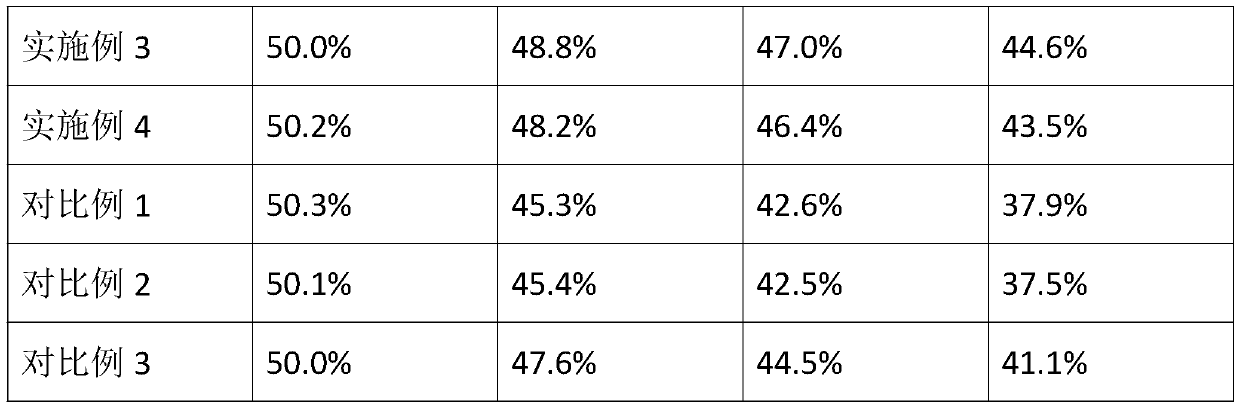

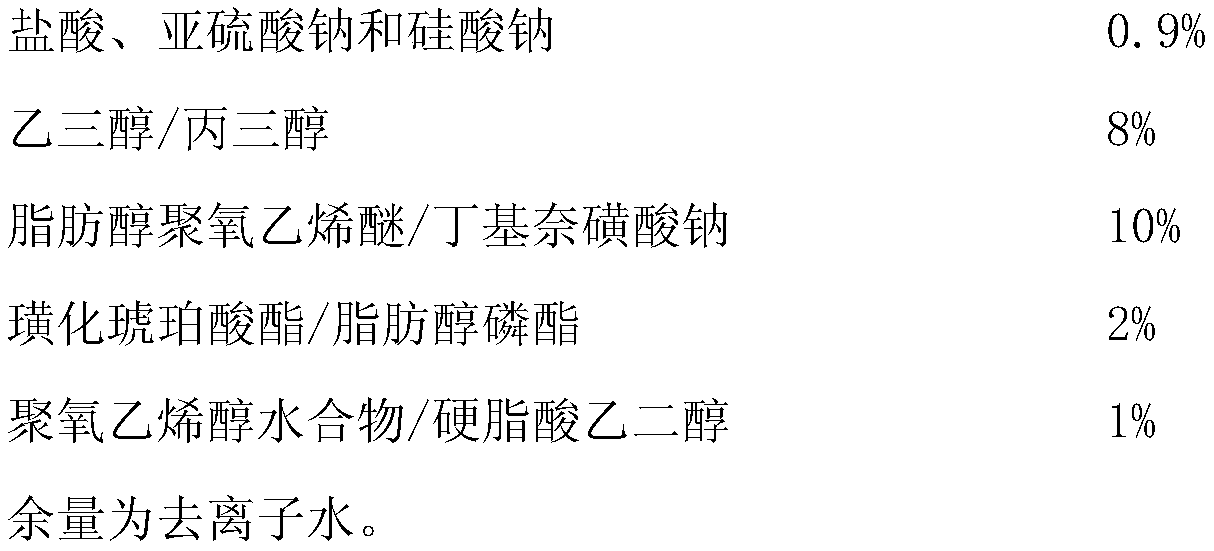

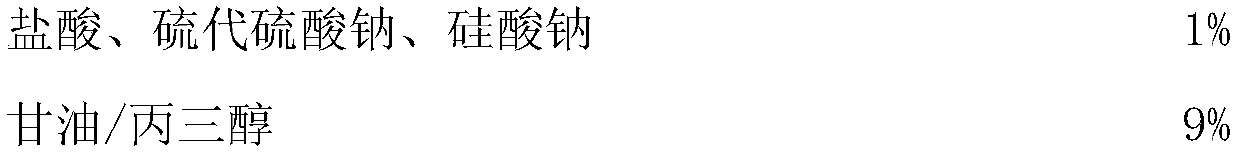

Environment-friendly sizing agent assistant, and preparation method and application of assistant

InactiveCN108004771ANo pollution in the processNot corrosiveDry-cleaning apparatus for textilesVegetal fibresPolyesterPolyvinyl alcohol

The invention discloses an environment-friendly sizing agent assistant, and a preparation method and an application of the assistant. The assistant is mainly applied to sizing of cellulose fibers or blend fibers and is characterized in that the sizing agent comprises 95-98% by mass of main material and 2-5% by mass of assistant, wherein the assistant is prepared from the following raw materials bymass percentage: 1-1.2% of starch viscosity reducer, 8-10% of plasticizer, 10-13% of wetting penetrant, 2-3% of soft smoothing agent, 1.5-2% of defoaming agent and the balance of deionized water. Theassistant is used for pure starch sizing and is applicable to the various cellulose fibers and the cotton-polyester blend fibers; no synthetic sizing agent is added; and PVA (polyvinyl alcohol)-freesizing is achieved in deed.

Owner:ZHEJIANG YUBO TEXTILE CO LTD

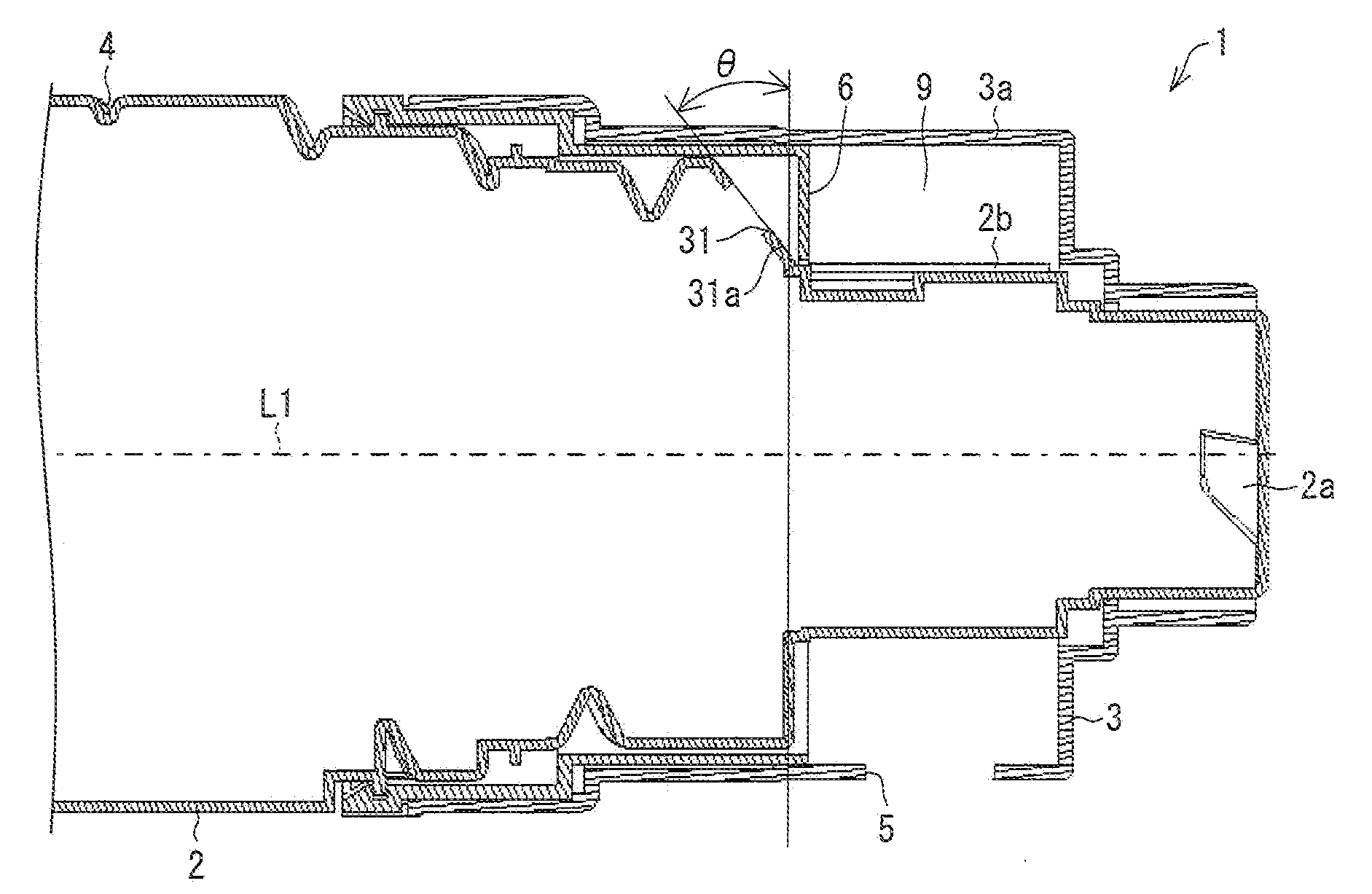

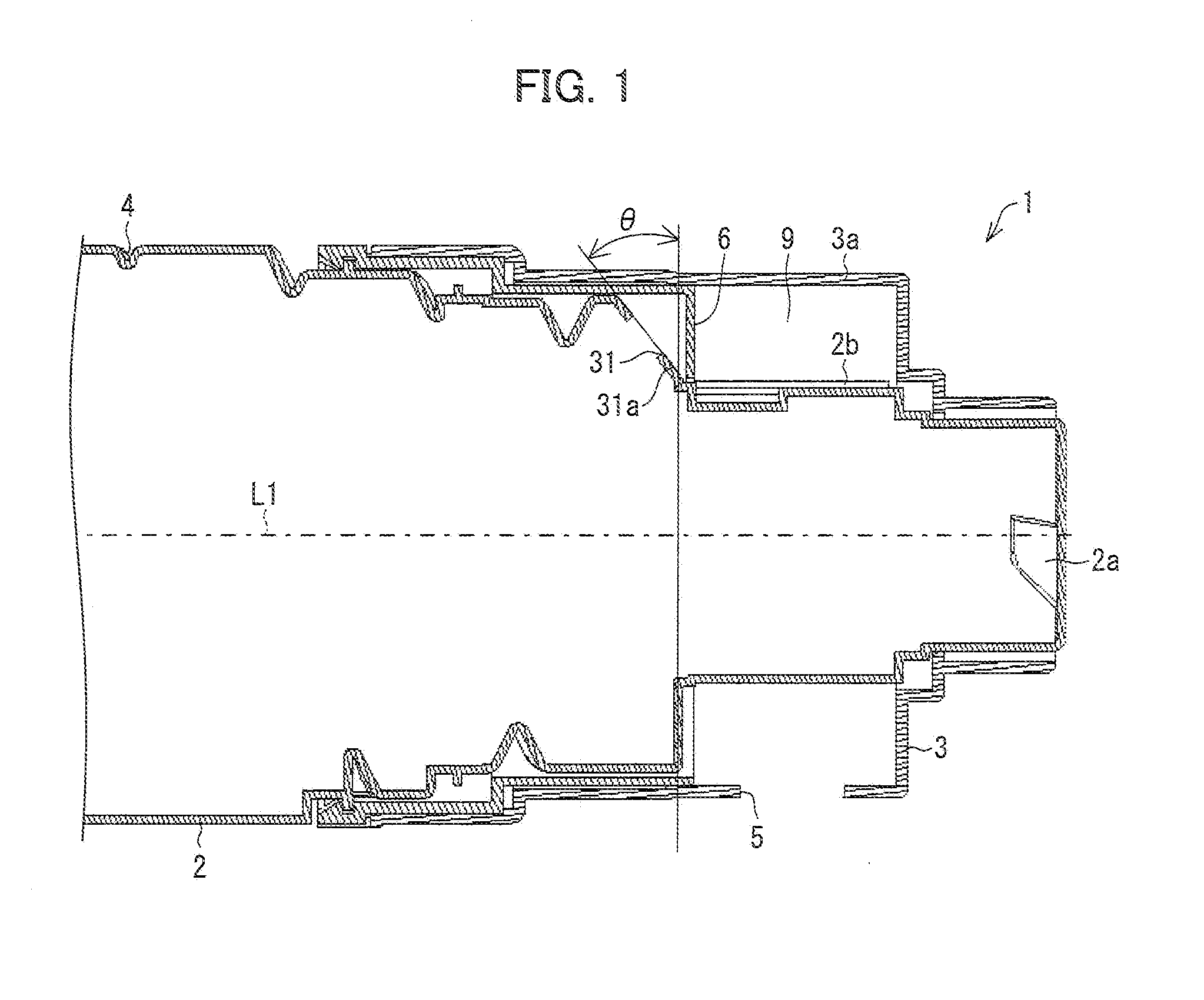

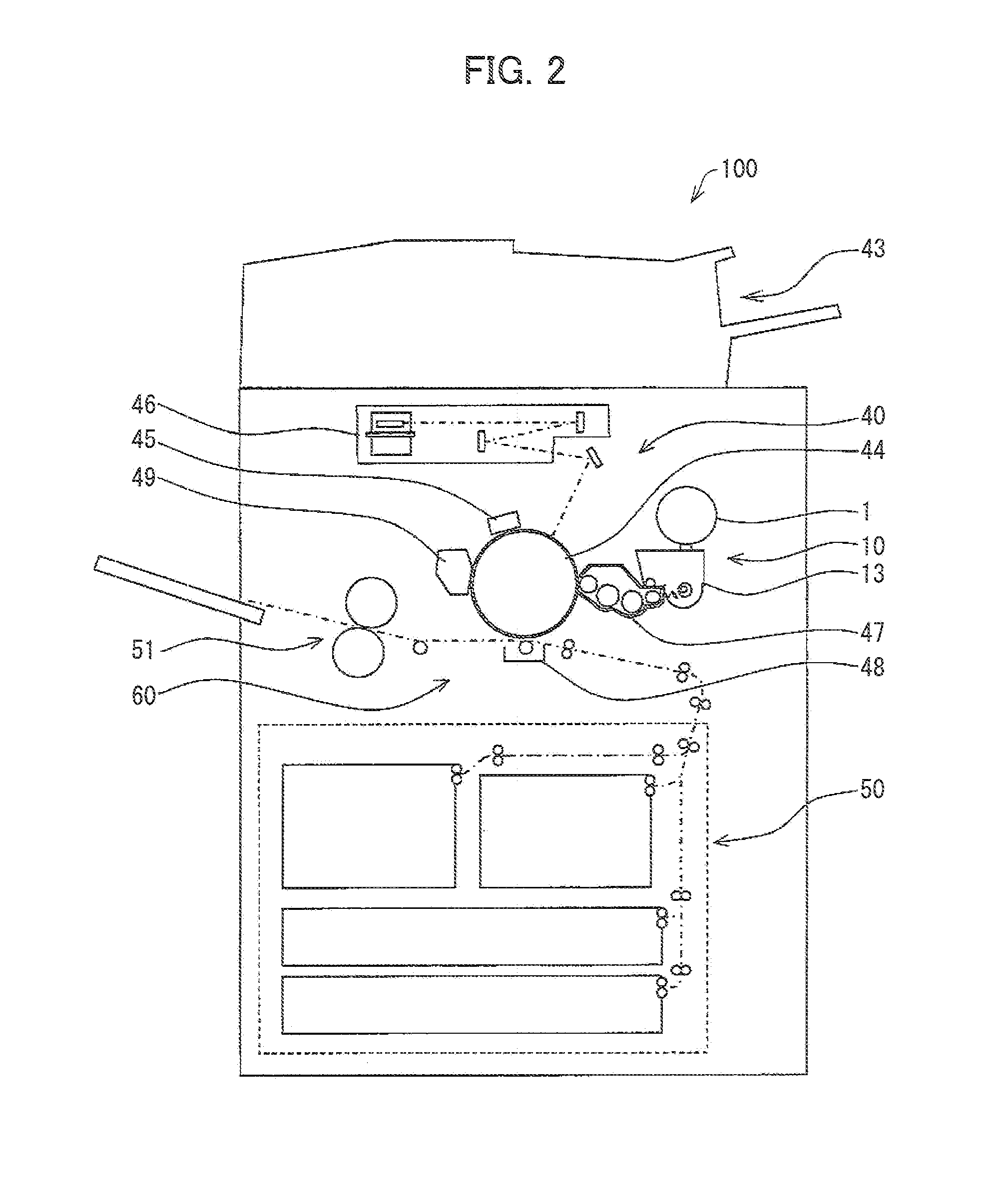

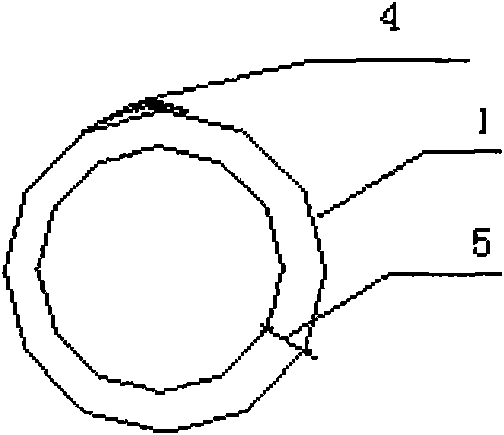

Developer container and image forming apparatus

ActiveUS20120183333A1Stir wellSpeed up the flowElectrographic process apparatusMechanical engineeringEngineering

A developer container 1 includes (i) a developer vessel 2, having a cylindrical shape, that carries and discharges toner contained therein through its first discharge opening 31 while the developer vessel 2 is being driven to rotate, and (ii) a developer supply section 3 which (a) supports the developer vessel 2 such that the developer vessel 2 can rotate, (b) temporarily stores the toner discharged from the first discharge opening 31, and (c) discharges the toner outside of the developer supply section 3 from a second discharge opening 5. The first discharge opening 31 is formed in an inclined surface 31a of an edge part of the developer vessel 2. The inclined surface 31a inclines, upstream of a direction in which the toner is carried along a shaft line L1, so as to be at angles with a surface perpendicular to the shaft line L1.

Owner:SHARP KK

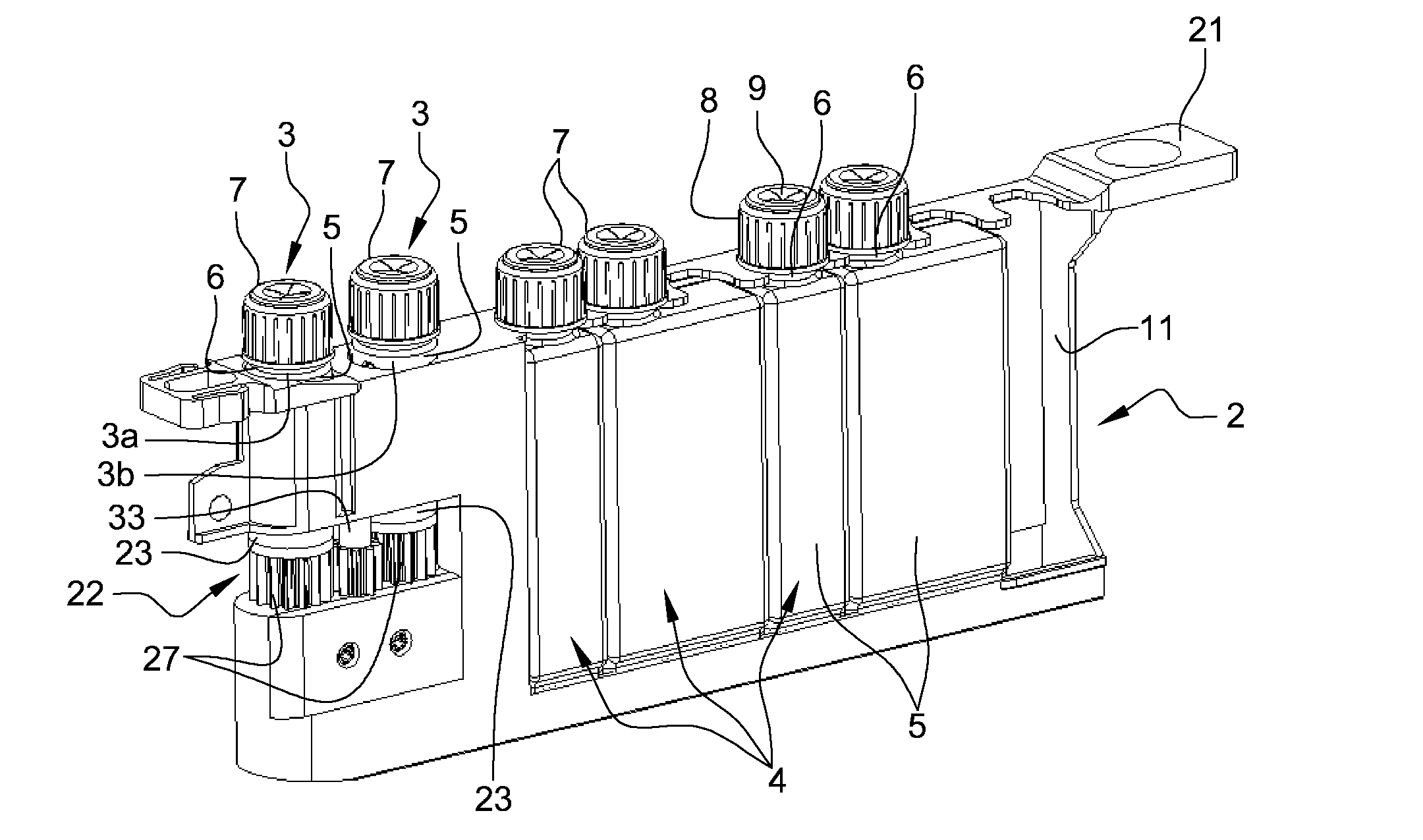

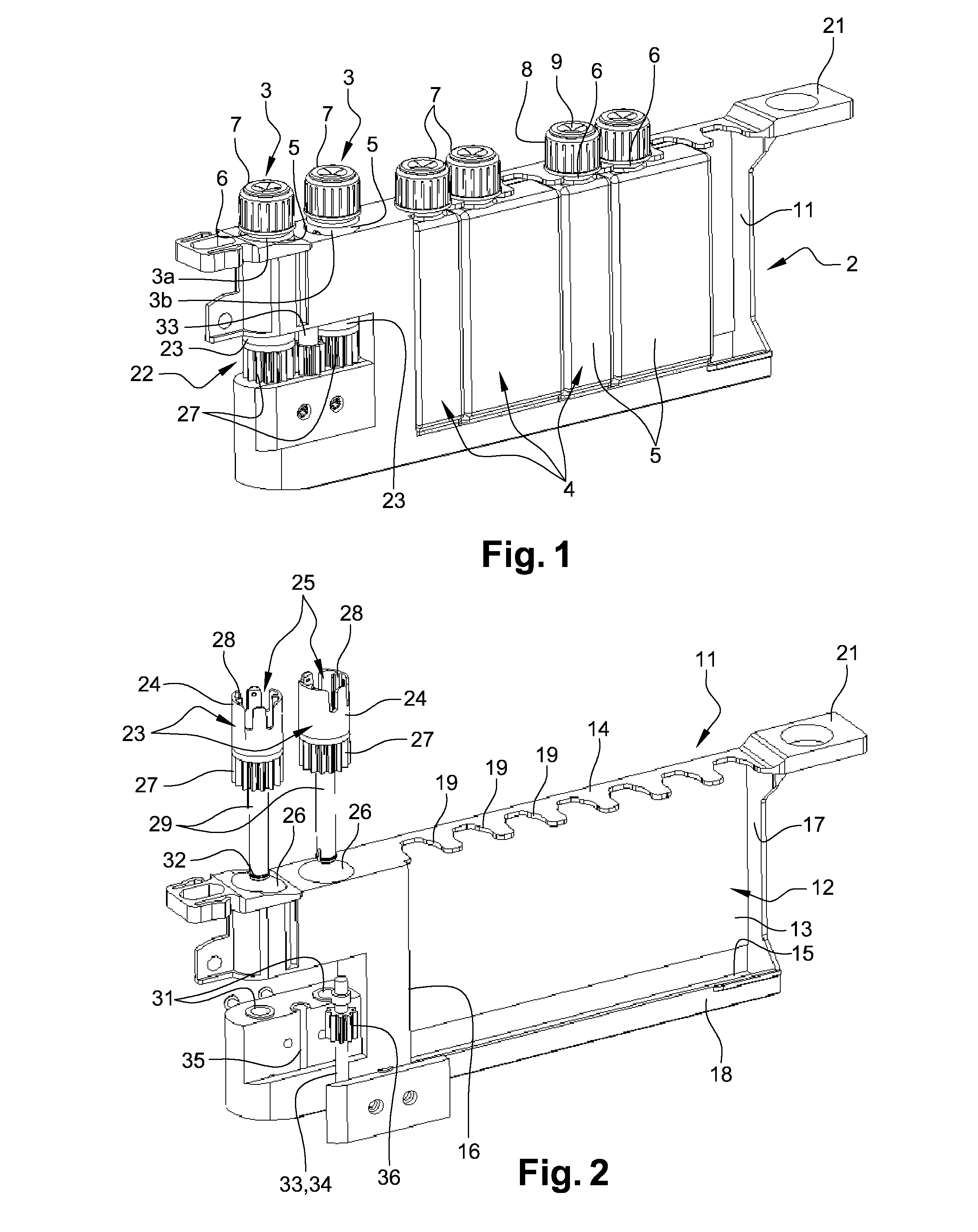

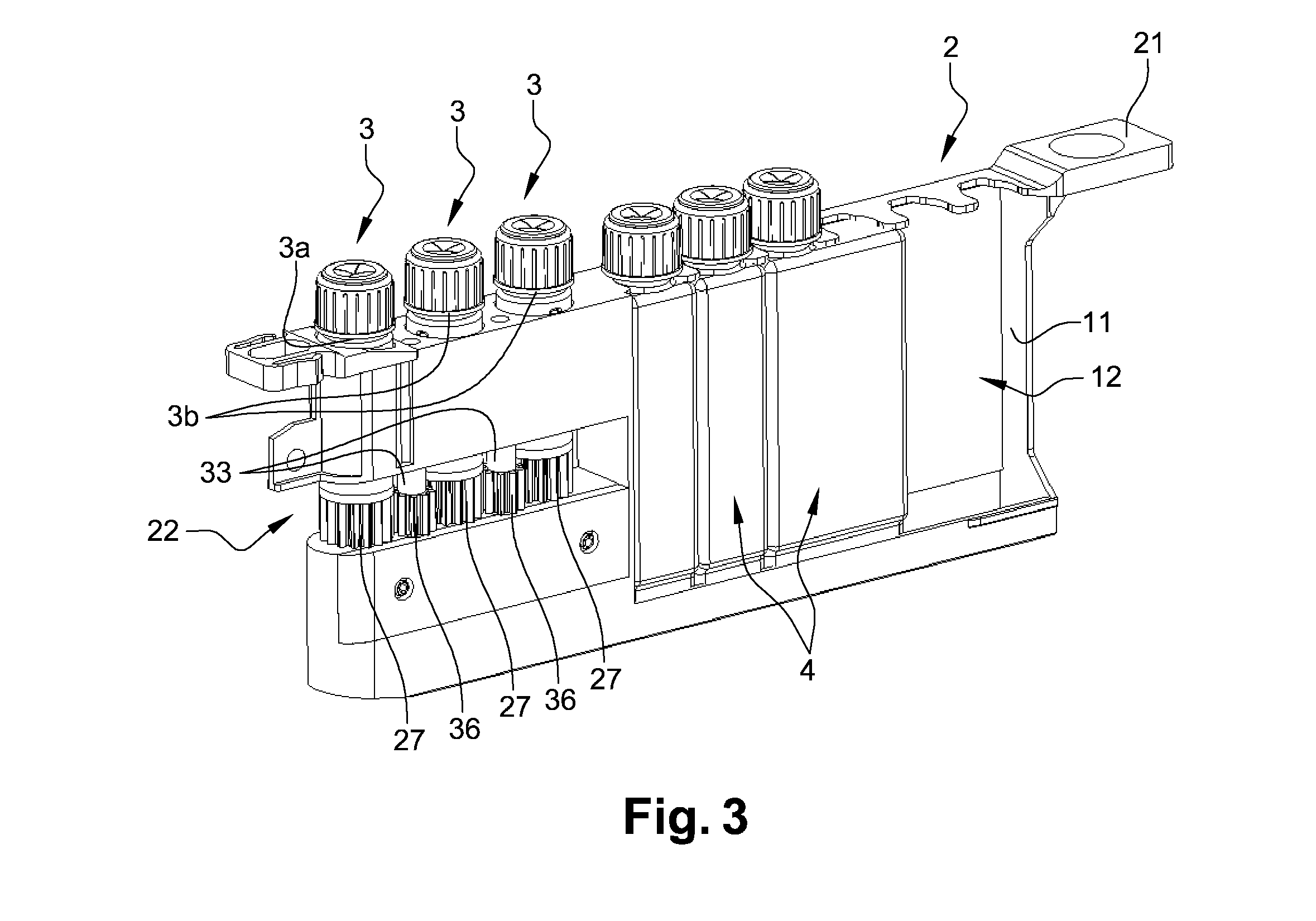

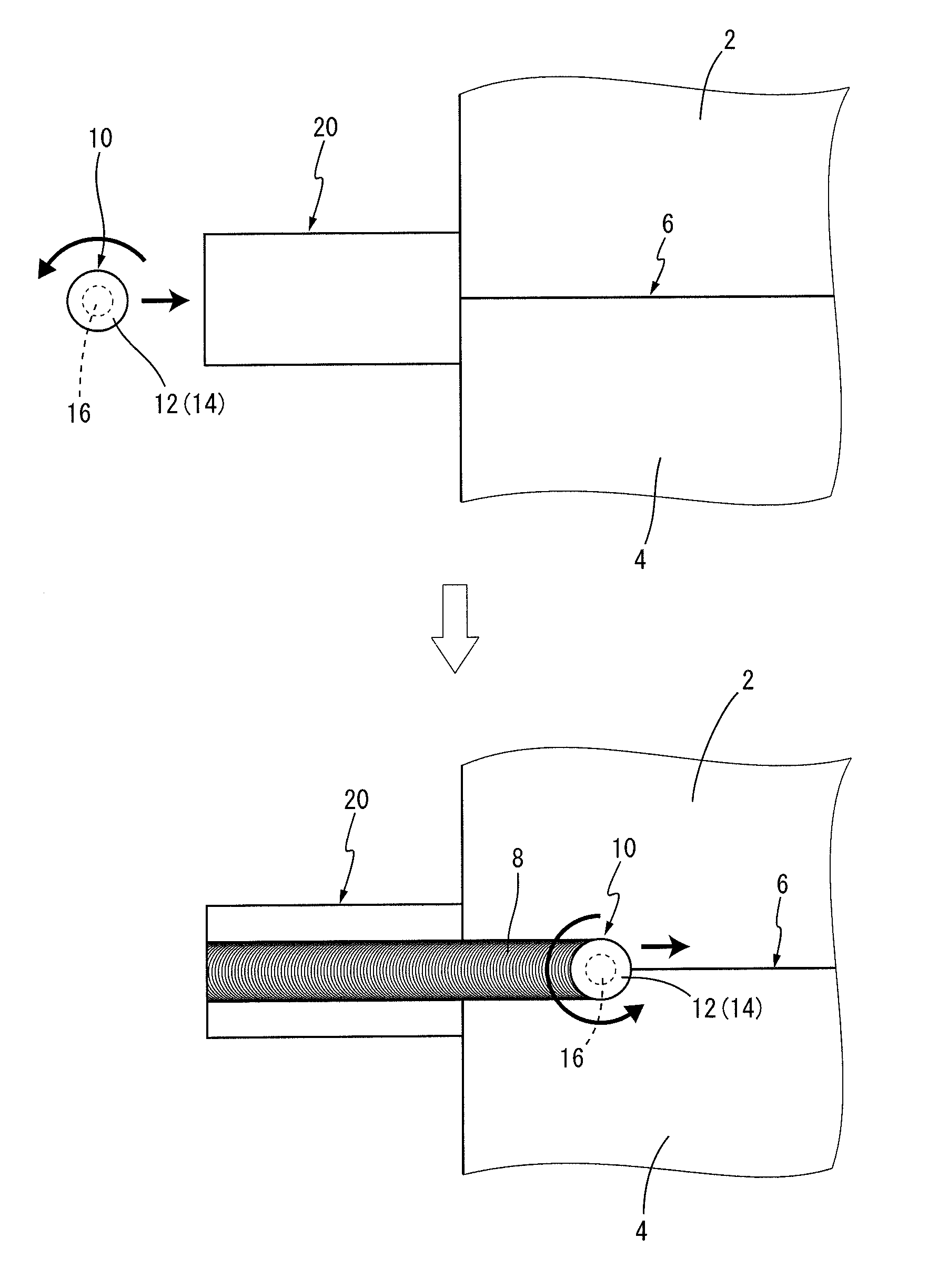

Analysis unit for analysis device

InactiveUS20150338429A1Simple mixing processIncrease the number ofRotating receptacle mixersTransportation and packagingElectrical and Electronics engineeringCoupling

This analysis unit (2) comprises a rack (11) suitable for receiving at least a first and a second container (3a, 3b), and an agitating device (22) suitable for mounting on the rack (11), the agitating device (22) being designed to drive at least the first container (3a) in rotation when the agitating device cooperates with a drive unit of an analysis device. The agitating device (22) comprises coupling means designed to rotationally couple at least the first and second containers (3a, 3b) held on the rack (11), the coupling means being configured to drive at least the second container (3b) in rotation when the first container (3a) is driven in rotation by the agitating device.

Owner:IMMUNODIAGNOSTIC SYST FRANCE

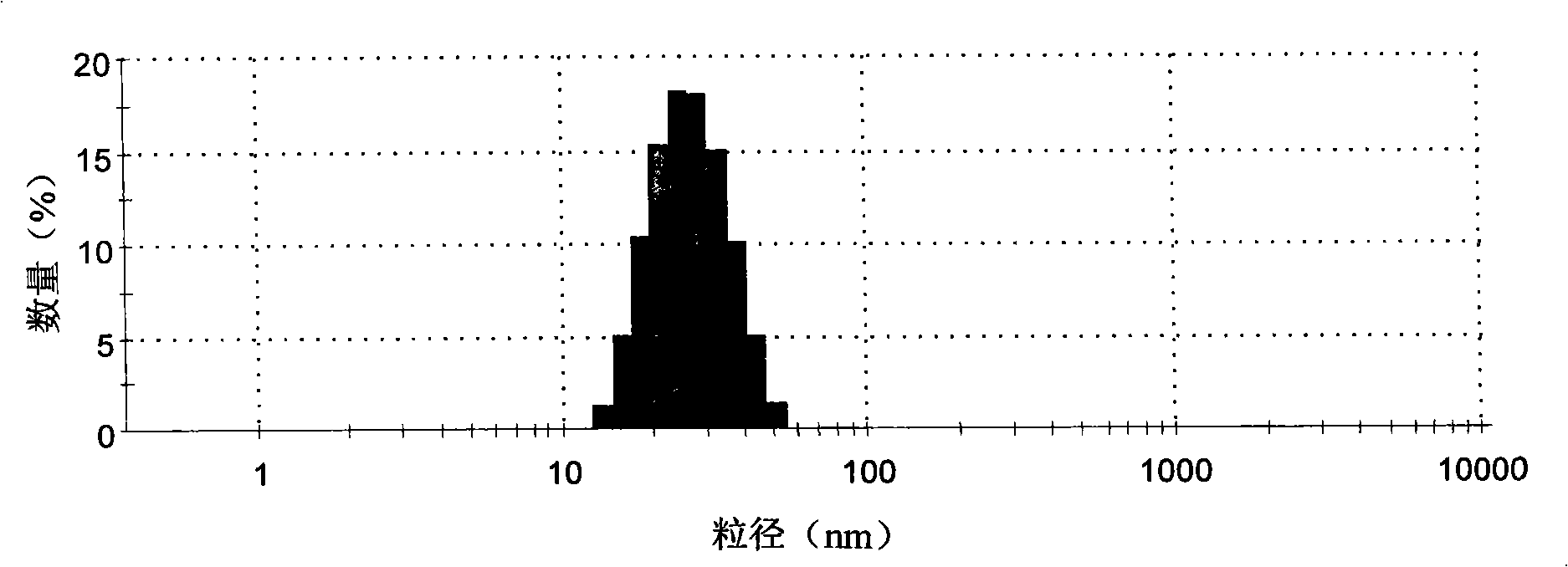

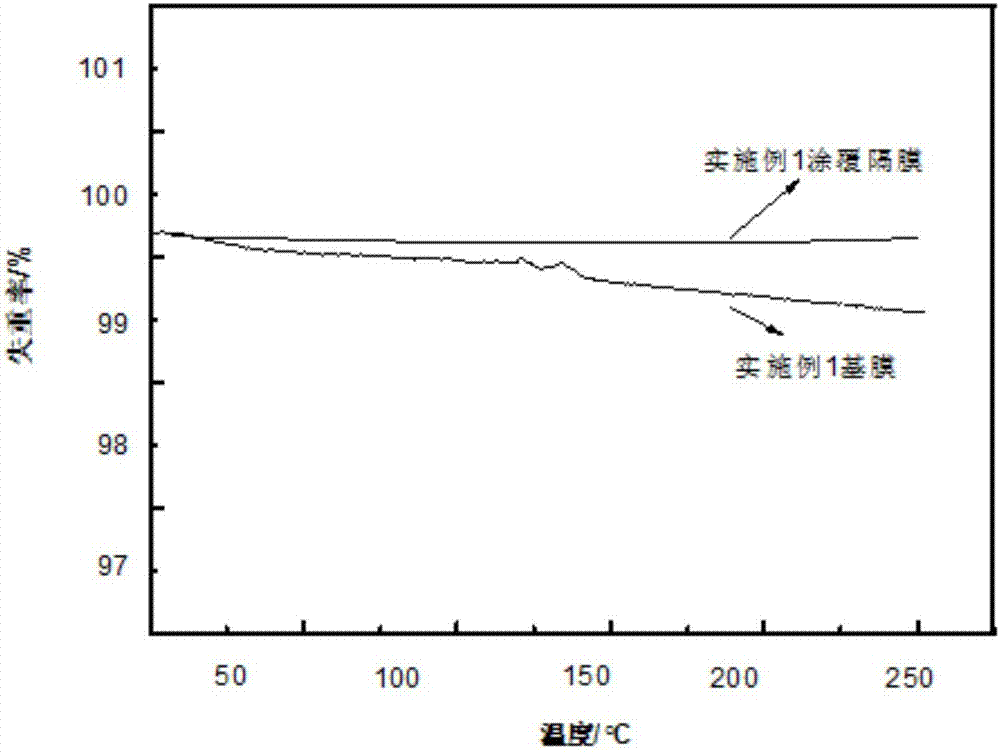

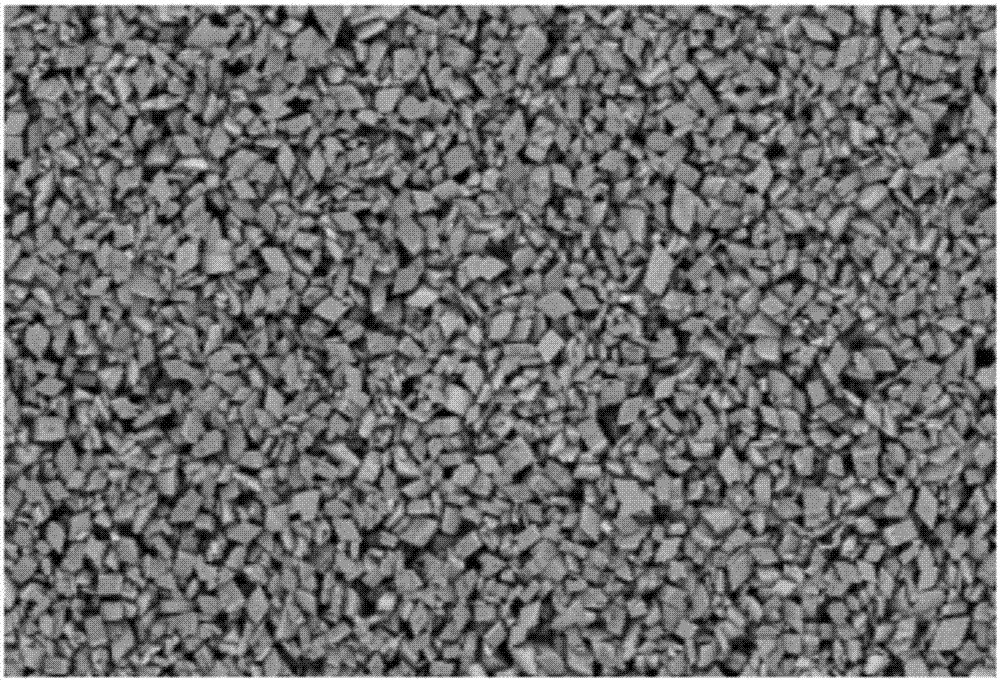

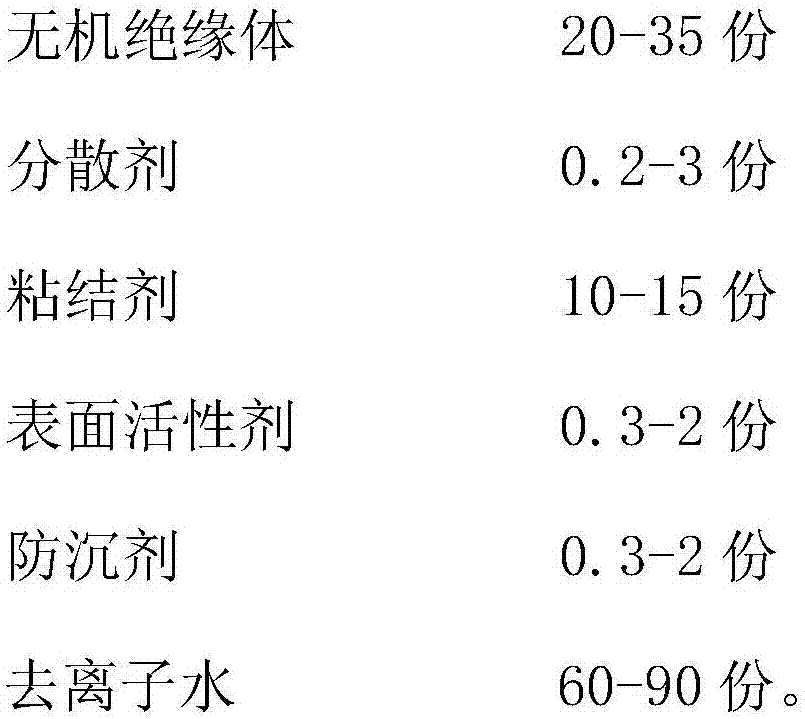

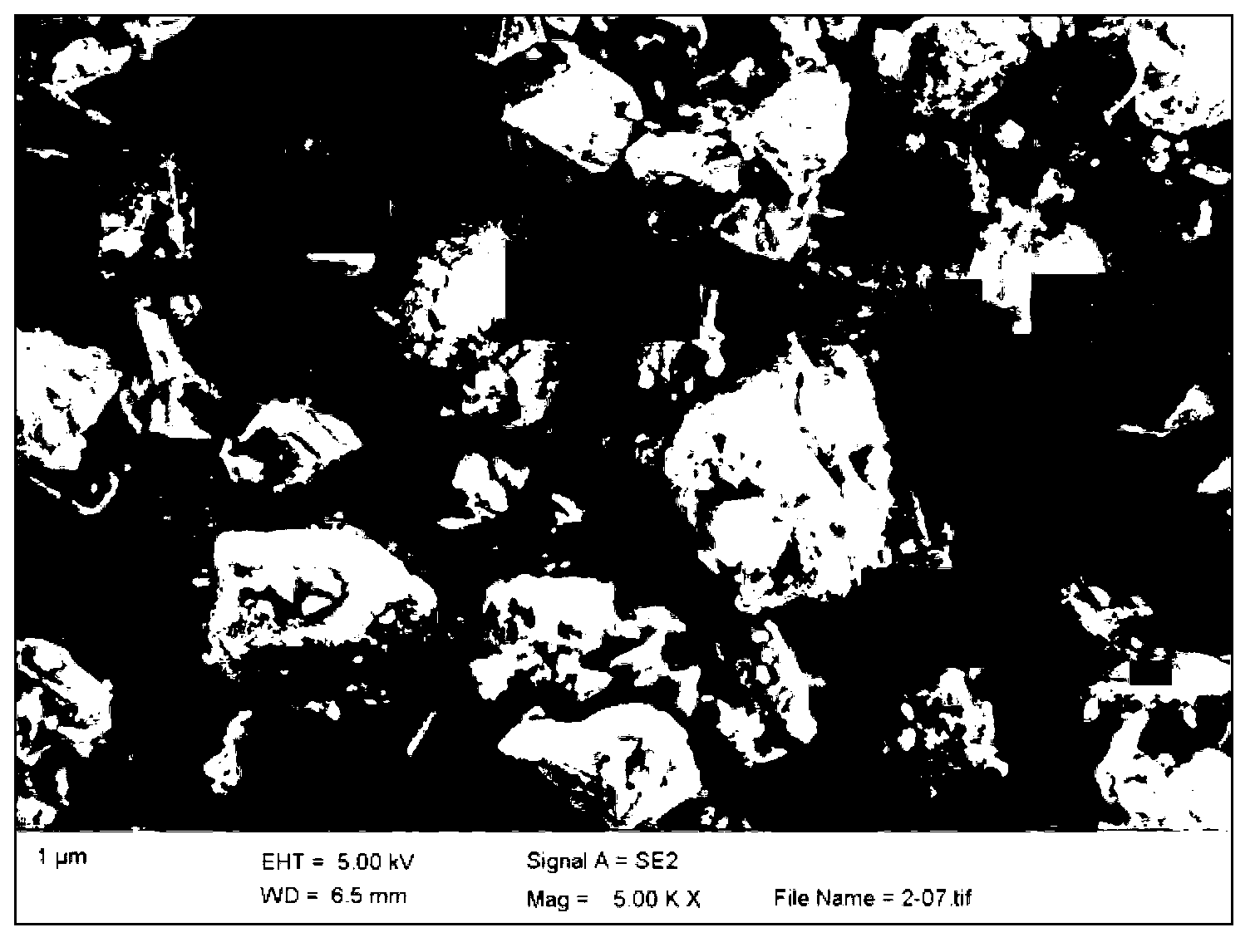

Ceramic slurry for coating lithium ion battery separator and preparation method of separator containing ceramic slurry

InactiveCN107394091AReduce pollutionThe mixing process is simpleCell component detailsSlurryHardness

The invention discloses ceramic slurry for coating a lithium ion battery separator and a preparation method of the separator containing the ceramic slurry. The ceramic slurry is prepared from 20 to 35 parts of an inorganic insulator, 0.2 to 3 parts of a dispersant, 10 to 15 parts of a binder, 0.3 to 2 parts of a surfactant, 0.3 to 2 parts of an anti-settling agent and 60 to 90 parts of deionized water. The preparation method is as follow: first adding the inorganic insulator, the dispersant, the anti-settling agent and the deionized water according to the ratio into a dispersion machine for high-speed dispersion for 3 to 5 hours, then adding the binder and the surfactant for dispersing at a low speed for 1-3 hours, sieving with a 200 mesh sieve to obtain the ceramic slurry, finally using a coating machine to evenly coat the surface of a separator base membrane with the ceramic slurry, and drying to obtain the ceramic separator. The ceramic slurry has the advantages of simple slurry mixing process and small hardness, and is beneficial to coating processing. Meanwhile, the coated ceramic separator has the advantages of low moisture content, facilitation in battery processing, reduction of thermal shrinkage of the separator base membrane, improvement of electrolyte wettability and improvement of battery cycle performance and the like.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method of modifying asphalt

InactiveCN101163750AReduce processing temperatureLow costPlastic recyclingBuilding insulationsPolymer scienceWaste rubber

A method for modifying bitumen with waste rubber powder, including a first step of mixing rubber powder with an aromatic oil in proportions of 98-60 % and 2-40 % respectively, and a second step of mixing the rubber powder from the first step with bitumen in proportions of 3-30 % and 97-70 % respectively, at a temperature of 140-200 DEG C and for a time of 5-40 minutes. The method is advantageous mainly in that the bitumen can be modified in a shorter time than with known methods, and in that the specifications of the modified bitumen can be controlled in such a way that it becomes commercially useful, thereby contributing to the solution of the environmental problem of too many tyres.

Owner:迪特尔·丹纳特

Ceramic slurry for photocuring and preparation method thereof

InactiveCN110128116AHigh solid contentImprove reaction efficiencyAdditive manufacturing apparatusPentaerythritolMetallurgy

The invention discloses ceramic slurry for photocuring and a preparation method thereof. By controlling the contents of the main ceramic slurry, a dispersing agent, a monomer and a photoinitiator, thehigh-solid-content ceramic slurry for photocuring is prepared; wherein the dispersing agent can enable the solid to be better dispersed in the liquid, so that the dispersion of the main ceramic slurry in the monomer is more uniform; the monomer is selected from a mixture of free radical type photosensitive resin and cationic type photosensitive resin with different functions and reaction efficiencies; wherein hexahydro-o-phthalic acid diglycidyl ether can make the finally prepared ceramic slurry for light curing not liable to deform, the 1,6-hexanediol diacrylate can make the viscosity of a monomer to be suitable for uniform dispersion of ceramic powder in the monomer and improves the solid phase content of the slurry; and dipentaerythritol hexaacrylate can improve the reaction efficiency; by selecting each substance in the monomer, the prepared ceramic slurry has high solid-phase content, high reaction efficiency and high printing precision.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

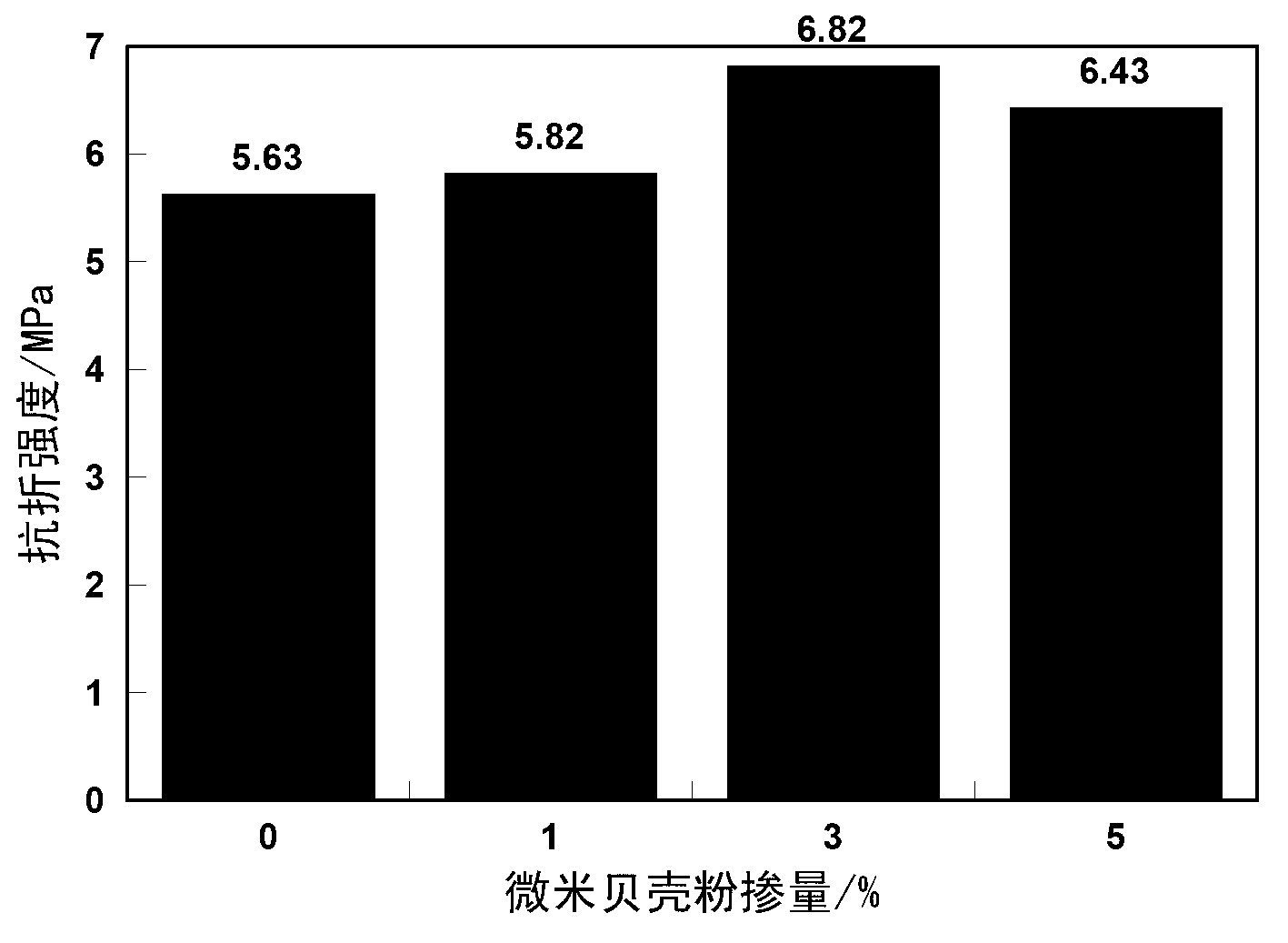

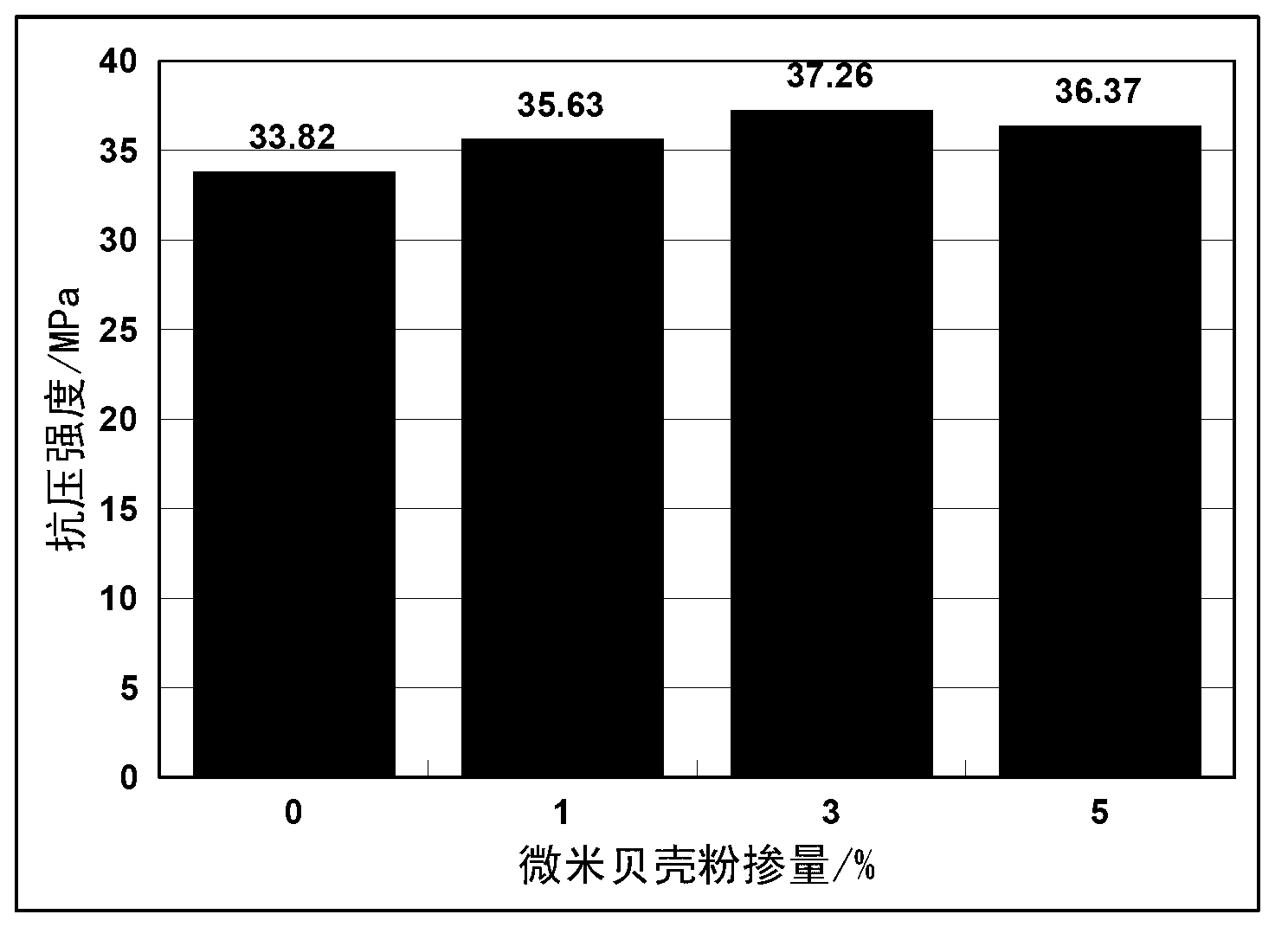

Application of micron shell powder as fortifier for early strength of cement

The invention relates to an application of micron shell powder as a fortifier for early strength of cement, and belongs to the field of building materials. The micron shell powder serves as a modifier for improving the early strength of the cement, so that the problem that the structural durability is reduced caused by early damages of concrete due to the fact that the early strength of an ordinary cement-based material is low is solved.

Owner:DALIAN MARITIME UNIVERSITY

Instant extraction cup

InactiveUS7856922B2Enough timeAvoid less flexibilityBeverage vesselsPackaging foodstuffsAdditive ingredientEngineering

Owner:TJEN EDDY

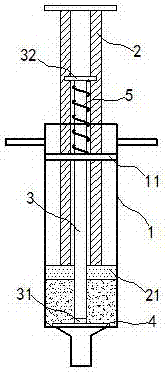

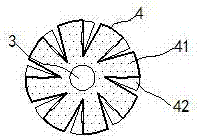

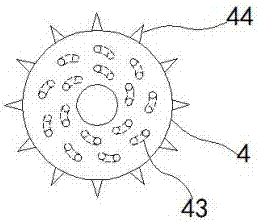

Injector easy in medicine dispensation

ActiveCN106955236ADoes not impede progressNormal injectionInfusion syringesPharmaceutical containersWorking pressureBiochemical engineering

The invention relates to an injector easy in medicine dispensation. The injector easy in medicine dispensation comprises a needle cylinder and a push rod; a piston plate is arranged at an end part of the push rod; the piston plate can perform airtight reciprocating sliding along the inner wall of the needle cylinder; a limiting plate is fixedly arranged on the inner wall of the needle cylinder; the push rod passes through the limiting plate and can perform reciprocating drawing relative to the limiting plate; a stirring rod is further arranged in the needle cylinder; the stirring rod is parallel with the push rod; a stirring sheet is arranged at one end, passing through the piston plate, of the stirring rod; a picking sheet is arranged at the other end, passing through the limiting plate, of the stirring rod; a tension spring is connected between the picking sheet and the limiting plate; the stirring rod and the piston plate maintain airtight connection; and the stirring rod can perform reciprocating drawing relative to the push rod. The injector is novel and unique in structure, and can effectively simplify the medicine dispensation flow and greatly improve medicine and injection efficiency; the injector reduces the work pressure of a medical worker, and effectively prevents medicine waste, medicine residue and pollution.

Owner:南阳市久康医疗器械有限公司

Preparation method of mixed positive electrode slurry based on lithium manganate material

ActiveCN109786714AIncrease areal densityIncrease energy densityCell electrodesSecondary cellsLithiumDispersity

The invention provides a preparation method of mixed positive electrode slurry based on a lithium manganate material. The mixed positive electrode slurry comprises an active material taking the lithium manganate material as a main material and lithium cobalt oxide as an auxiliary material; the lithium manganate accounts for 70-85wt% of the total amount of the active material; the lithium manganatecomprises first particles with the average particle size of R1 and second particles with the average particle size of R2; the mass ratio of the first particles to the second particles is a : b; and the average particle size R3 of the lithium cobalt oxide is between 0.7*(R1*a+R2*b) / (a+b) and 0.8*(R1*a+R2*b). The first particles, the second particles and the lithium cobalt oxide material are mixedand stirred separately, so that rapid and uniform mixing dispersion is realized, the dispersity and stability of the slurry are improved, and the stability of pole piece coating is improved.

Owner:陕西力创鑫电子科技有限公司

Construction process of floral tube dry filling piles

InactiveCN101713189AReduce labor intensityFew control parametersBulkheads/pilesResource utilizationWater table

The invention relates to a construction process of floral tube dry filling piles with obvious engineering effect, low economic cost, high technical content and high resource utilization by improving the inherent characteristics of cement, soil strata, materials and the like. The process comprises the following steps of: (1) pore-forming process: 1, using dry pore-forming process for pore-forming piles above underground water level; 2, positioning a pore opening machine and a drill for pore-forming piles below underground water level; drilling in at low stroke and high rotary speed with clean water; reaching a drilling-in depth; lifting to a pore opening at unified stroke and high rotary speed with clean water; drilling into a pore bottom at unified stroke and high rotary speed with clean water; rotating at high speed and filling with cement mortar; and lifting to the pore opening at high rotary speed and low stroke after cement mortar returns to the pore opening; moving the drill; (2) the process of installation and pile molding by filling: adopting the following steps for installing pile pores and filling dry cement above or below water level: installing floral tubes; correcting the pore position of the floral tubes; filling the dry cement; and filling the dry cement to an elevation required by the design.

Owner:HENAN UNIVERSITY

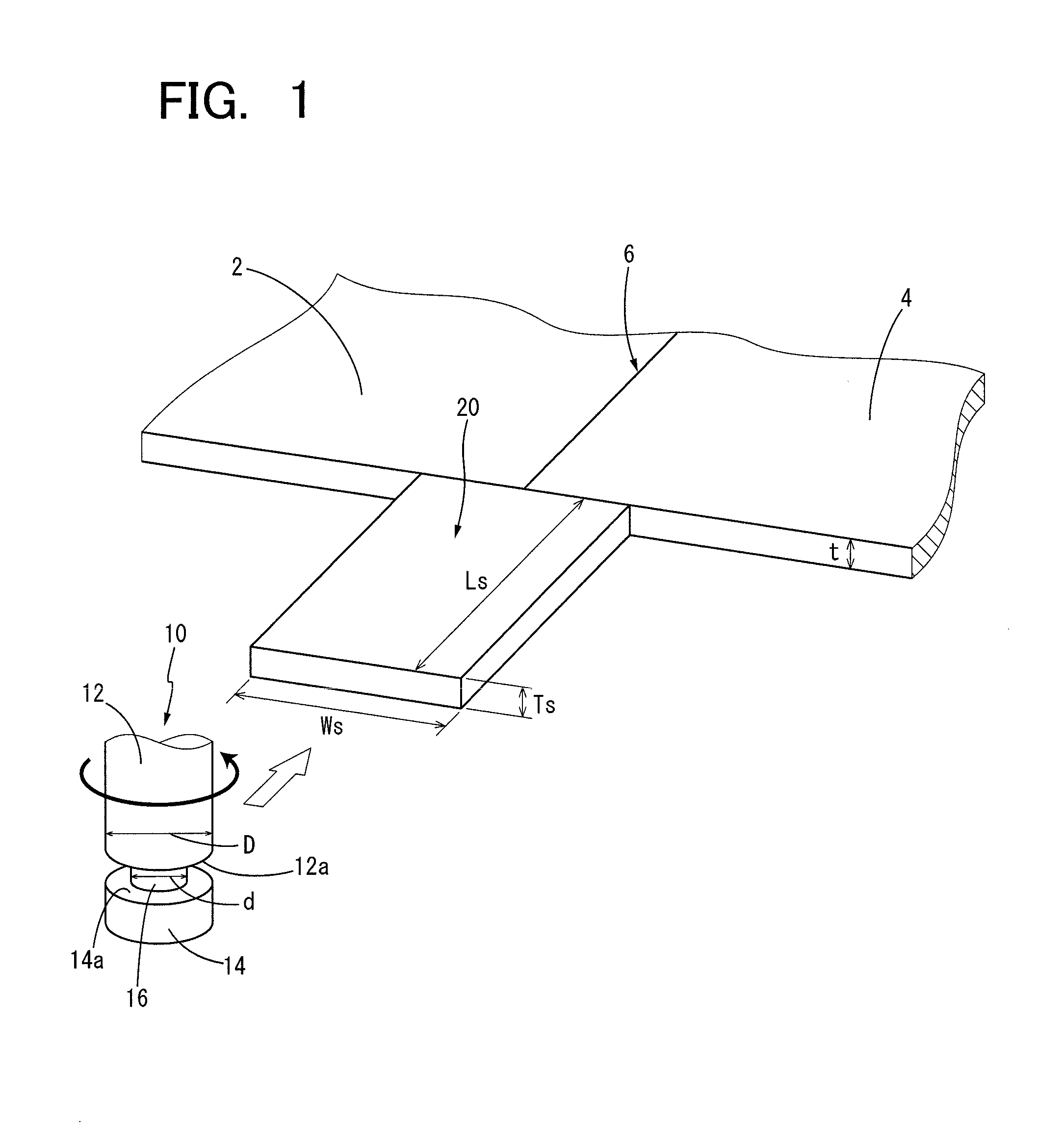

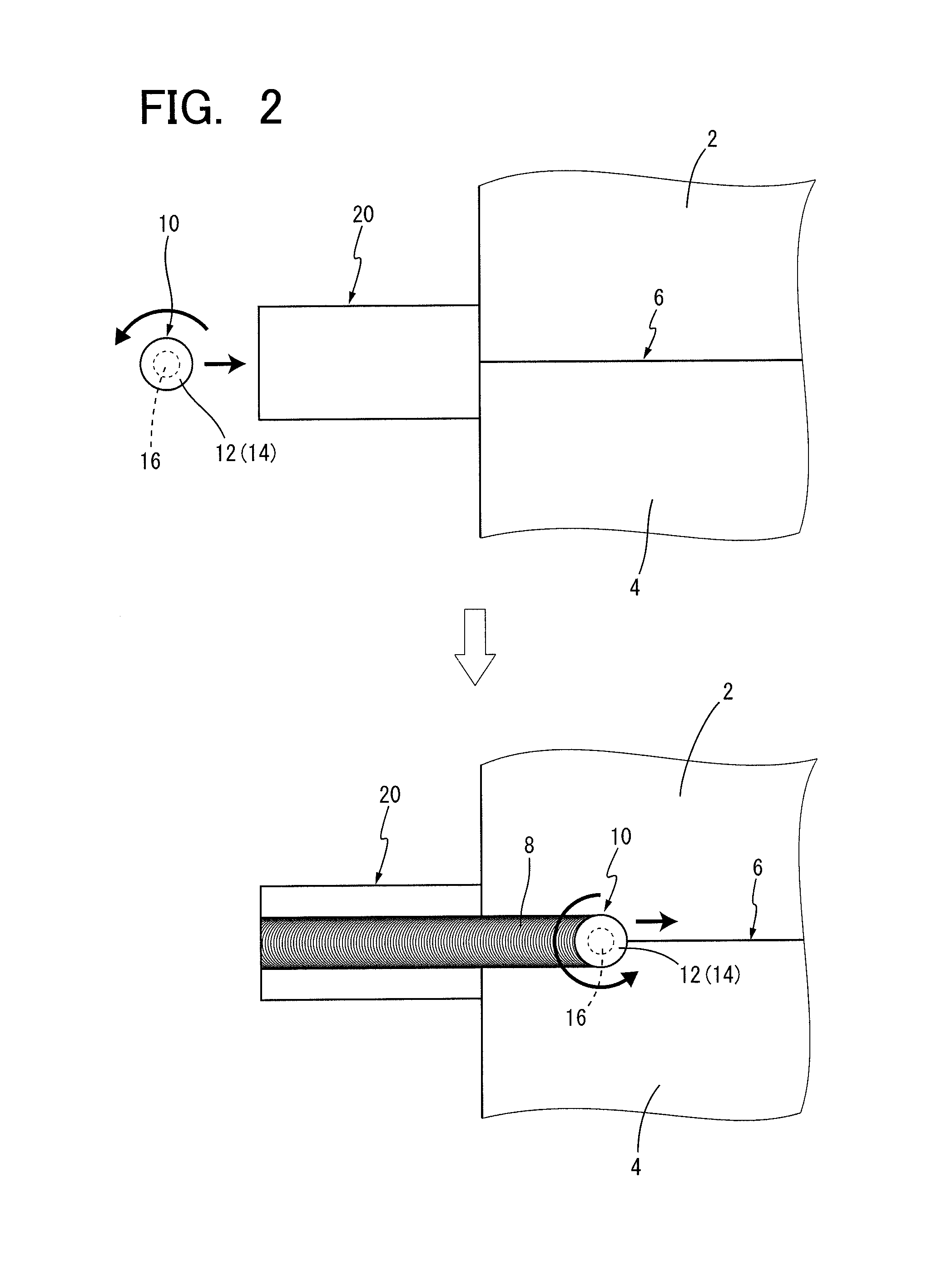

Friction stir welding method

ActiveUS20160151855A1Simple mixing processReadily forcedWelding/soldering/cutting articlesMetal working apparatusMaterials scienceFriction stir welding

A friction stir welding method which permits advantageous production of a product which has a sound welded area without joint defects, by joining together two members formed of the same material or respective different materials selected from a cast aluminum alloy and 2000 series, 4000 series, 5000 series and 7000 series aluminum alloys which are considered difficult to be joined together by the friction stir welding method. An initiation tab member formed of a 1000 series, 3000 series, 6000 series or 8000 series aluminum alloy is disposed in abutting contact with end faces of joining portions of first and second members (in an abutting part), on the side of initiation of the welding operation, and the friction stir welding operation is performed by moving a probe of a rotary tool through the initiation tab member into the joining portions of the two members.

Owner:FURUKAWA SKY ALUMINUM CORP

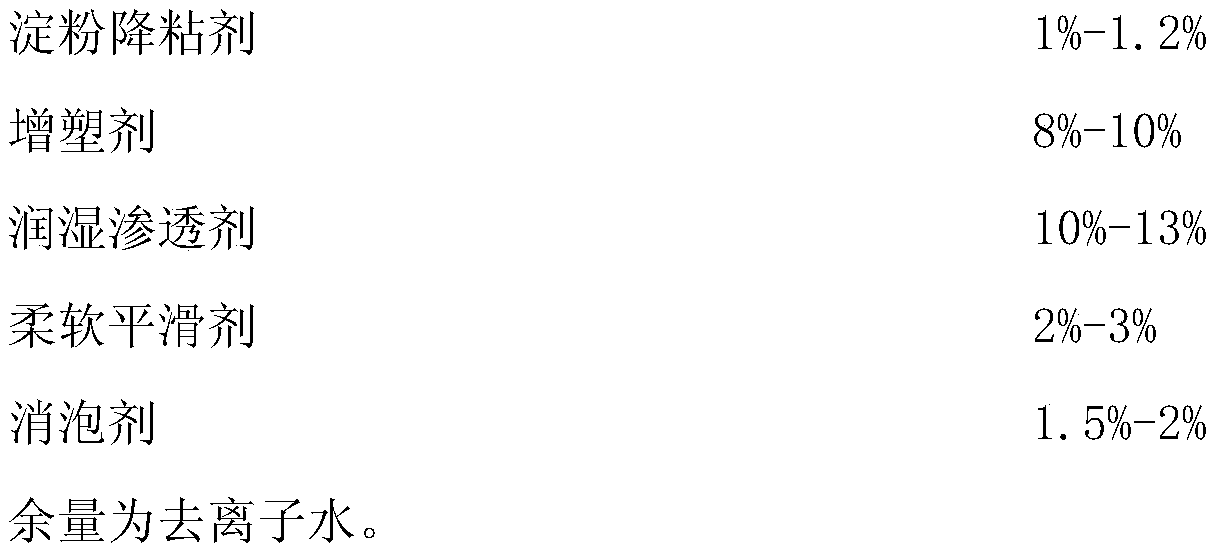

Compositions comprising (s)-2-amino-1-(4-chlorophenyl)-1-[4-(1h-pyrazol-4-yl)-phenyl]-ethanol as modulator of protein kinases

InactiveUS20110269808A1Improve securitySimple mixing processBiocideOrganic active ingredientsEnantiomerChemistry

The invention provides a composition comprising (S) 2-amino-1-(4-chloro-phenyl)-1-[4-(1H-pyrazol-4-yl)-phenyl]-ethanol, wherein the composition is either substantially free of (R) 2-amino-1-(4-chloro-phenyl)-1-[4-(1H-pyrazol-4-yl)-phenyl]-ethanol or the composition contains a mixture of the (S) and (R) enantiomers in which the (S) enantiomer predominates. Also provided are processes for the preparation of the (S) 2-amino-1-(4-chloro-phenyl)-1-[4-(1H-pyrazol-4-yl)-phenyl]-ethanok novel process intermediates and methods for making the novel process intermediates.

Owner:ASTEX THERAPEUTICS LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Compositions comprising (s)-2-amino-1-(4-chlorophenyl)-1-[4-(1h-pyrazol-4-yl)-phenyl]-ethanol as modulator of protein kinases Compositions comprising (s)-2-amino-1-(4-chlorophenyl)-1-[4-(1h-pyrazol-4-yl)-phenyl]-ethanol as modulator of protein kinases](https://images-eureka.patsnap.com/patent_img/5491ed3f-fe01-43ad-b144-1ce91a061e28/US20110269808A1-20111103-C00001.png)

![Compositions comprising (s)-2-amino-1-(4-chlorophenyl)-1-[4-(1h-pyrazol-4-yl)-phenyl]-ethanol as modulator of protein kinases Compositions comprising (s)-2-amino-1-(4-chlorophenyl)-1-[4-(1h-pyrazol-4-yl)-phenyl]-ethanol as modulator of protein kinases](https://images-eureka.patsnap.com/patent_img/5491ed3f-fe01-43ad-b144-1ce91a061e28/US20110269808A1-20111103-C00002.png)

![Compositions comprising (s)-2-amino-1-(4-chlorophenyl)-1-[4-(1h-pyrazol-4-yl)-phenyl]-ethanol as modulator of protein kinases Compositions comprising (s)-2-amino-1-(4-chlorophenyl)-1-[4-(1h-pyrazol-4-yl)-phenyl]-ethanol as modulator of protein kinases](https://images-eureka.patsnap.com/patent_img/5491ed3f-fe01-43ad-b144-1ce91a061e28/US20110269808A1-20111103-C00003.png)