Ceramic slurry for coating lithium ion battery separator and preparation method of separator containing ceramic slurry

A lithium-ion battery, ceramic slurry technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high water content of ceramic separators, high storage conditions, and long baking process cycles, and achieve shortened Baking time, simple mixing process, and the effect of improving battery cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

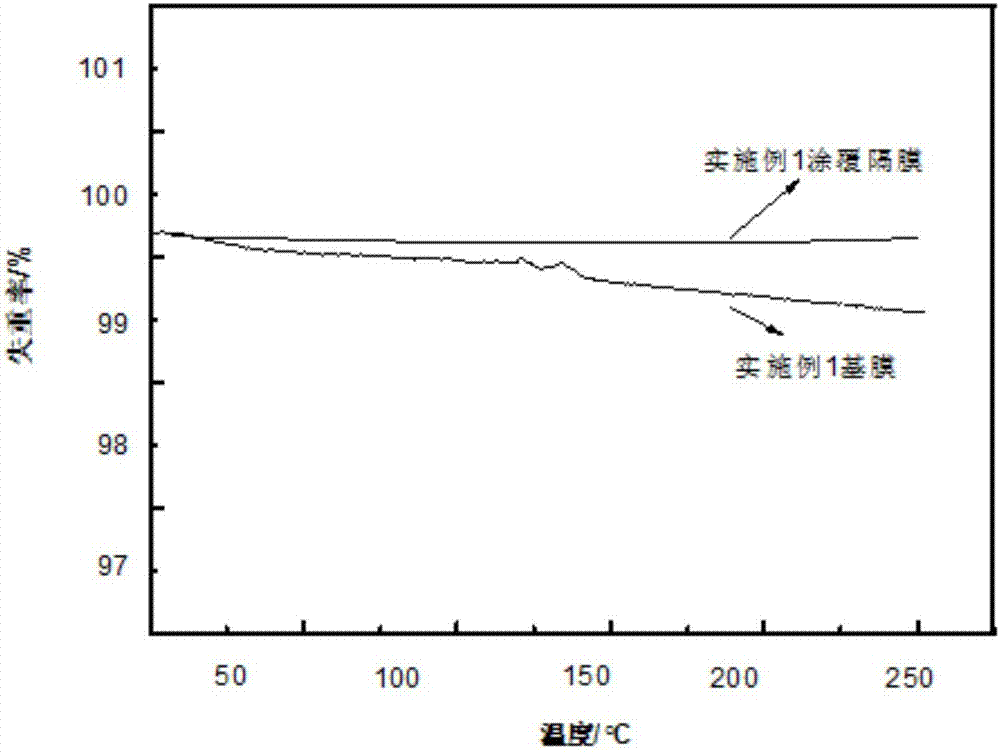

Embodiment 1

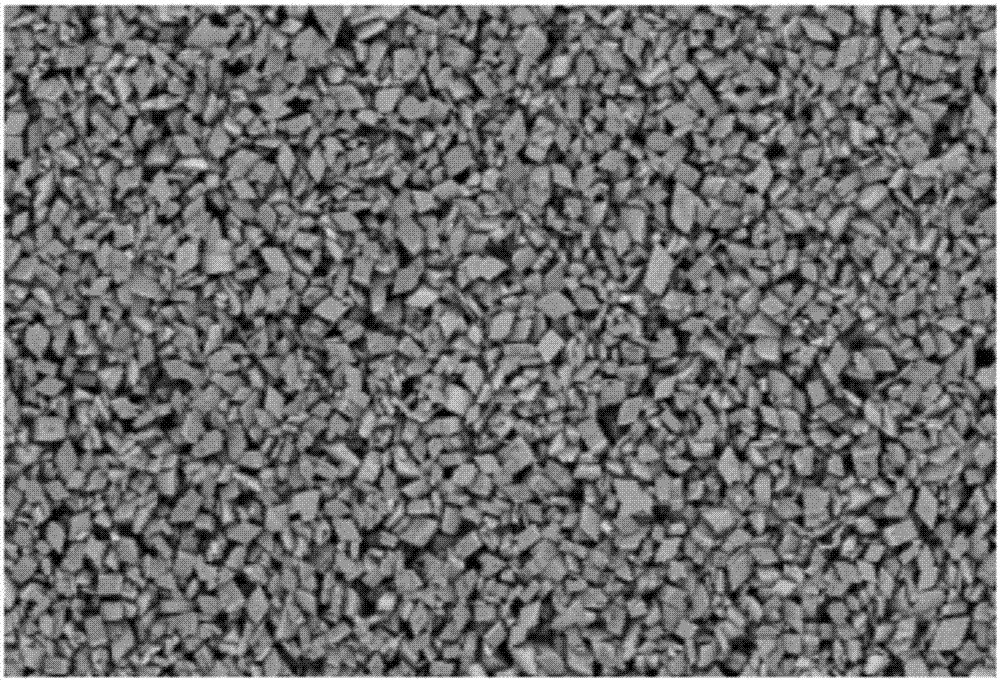

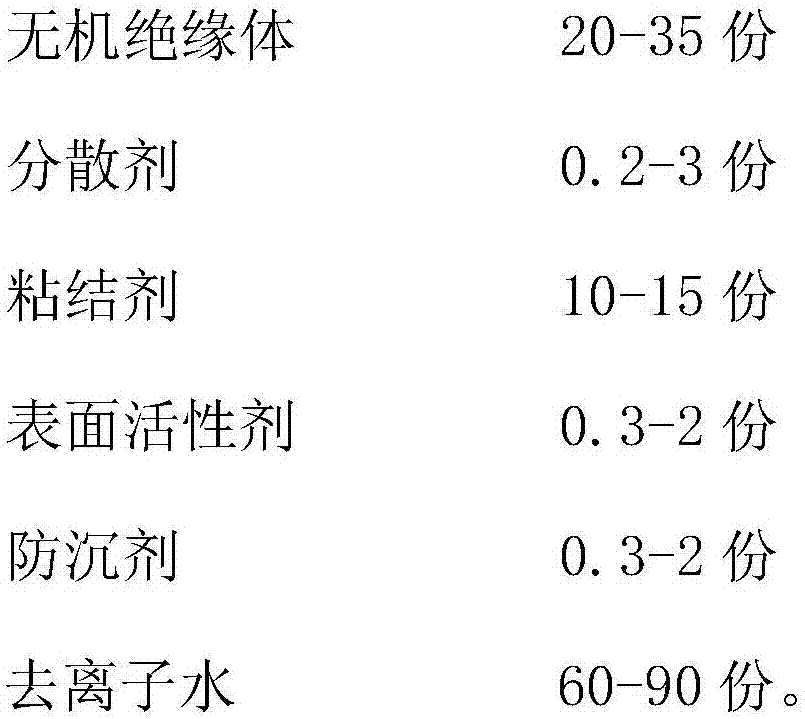

[0028] Add 20 parts of boehmite, 0.2 parts of polyacrylic acid ammonium salt copolymer solution, 0.5 parts of synthetic layered silicate solution and 60 parts of deionized water into the disperser, control the temperature of the disperser to 25°C, and the power to 1800W. After 3 hours, add 10 parts of water-based polypropionic acid modified resin to the disperser, 0.3 part of polyether modified silicone surfactant, keep the temperature of the disperser at 25°C, and the power at 600W, and continue to disperse for 1 hour. A 200-mesh sieve was used to obtain a ceramic slurry. Use a coating machine to control the coating thickness to 4 μm, evenly coat the slurry on the surface of the PE base film, and then dry it to obtain a lithium-ion battery separator. Control the speed of the coating machine to 40 m / min, and the oven temperature to 65 °C .

Embodiment 2

[0030] Add 32 parts of boehmite, 3 parts of polyvinyl alcohol solution, 0.3 parts of hydroxymethylcellulose sodium solution and 70 parts of deionized water into the disperser, control the temperature of the disperser at 20°C, and the power of 2000W, and disperse for 4 hours , then add 13 parts of water-based acrylonitrile multi-polymer copolymer, 1 part of water-based non-ionic fluorocarbon surfactant, keep the temperature of the disperser at 20°C, and the power of 500W, continue to disperse for 2 hours and pass through a 200-mesh screen to obtain a ceramic slurry material. Use a coating machine to control the coating thickness to 2 μm, evenly coat the ceramic slurry on the surface of the PP / PE base film, and then dry it to obtain a lithium-ion battery separator. Control the speed of the coating machine to 15 m / min, and the oven temperature is 60°C.

Embodiment 3

[0032] Add 35 parts of boehmite, 3 parts of polyvinylpyrrolidone solution, 2 parts of sodium hydroxymethylcellulose solution and 90 parts of deionized water into the disperser, control the temperature of the disperser at 30°C, and the power of 1500W, and disperse for 5 hours , and then add 15 parts of water-based polyvinyl alcohol, 2 parts of water-based nonionic fluorocarbon surfactant, keep the temperature of the disperser at 30°C, and the power of 300W, and continue to disperse for 3 hours through a 200-mesh sieve to obtain a ceramic slurry. Use a coating machine to control the coating thickness to 1 μm, evenly coat the ceramic slurry on the surface of the PP base film, and then dry it to obtain a lithium-ion battery ceramic diaphragm. Control the speed of the coating machine to 60 m / min, and the oven temperature is 75°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com