Application of micron shell powder as fortifier for early strength of cement

A technology of early strength and shell powder, applied in the field of building materials, can solve the problems of reduced structural durability, low early strength, concrete damage, etc., and achieve the effects of improving early strength, convenient acquisition, and simple mixing process

Inactive Publication Date: 2013-05-01

DALIAN MARITIME UNIVERSITY

View PDF1 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide the application of micron shell powder as cement early strength enhancer, develop a kind of preparation method that can improve cement early strength by utilizing micron shell powder, thereby solve the problem of concrete caused by the low early strength of ordinary cement-based materials. Early damage, resulting in reduced structural durability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

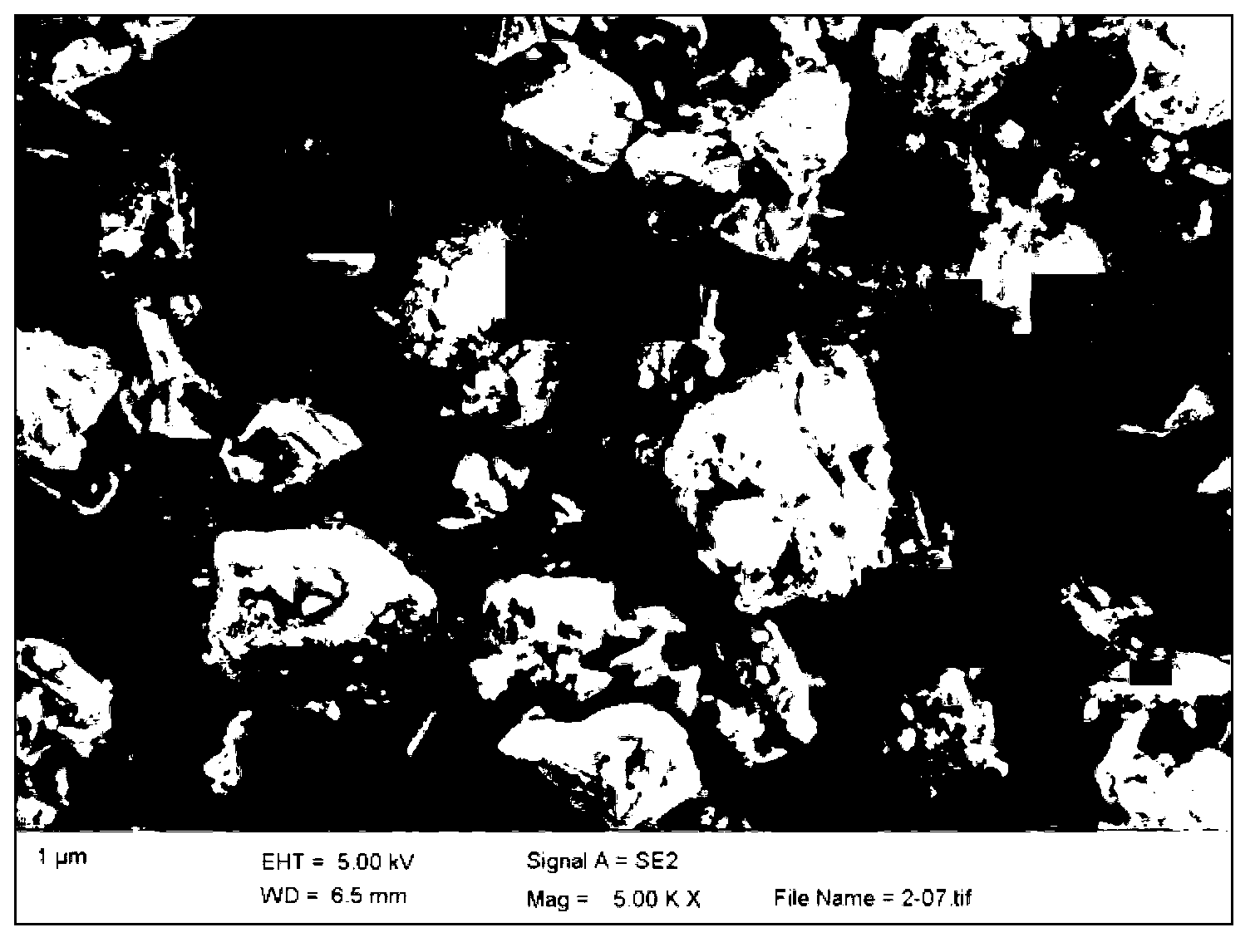

[0024] The used micron shell powder of the present invention, its particle diameter is 1~3 micron, figure 1 The microscopic morphology of the micron shell powder is given. In the experiment, the DS-5510DTH ultrasonic cleaning machine is used to disperse the micron shell powder ultrasonically, and the power is 300W.

[0025] (1) See Table 1 for the mix ratio of ordinary cement specimens and micron shell powder cement specimens.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

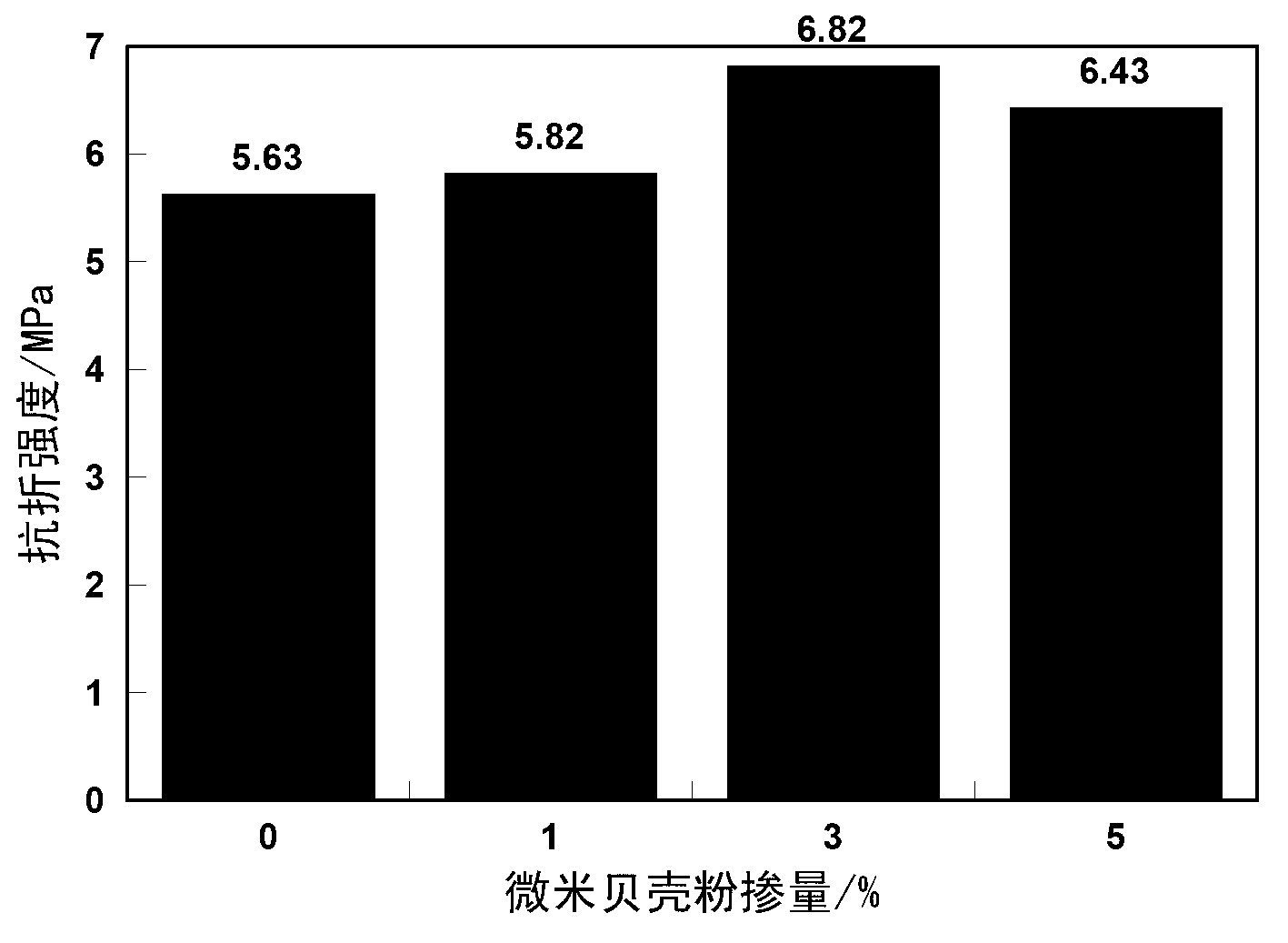

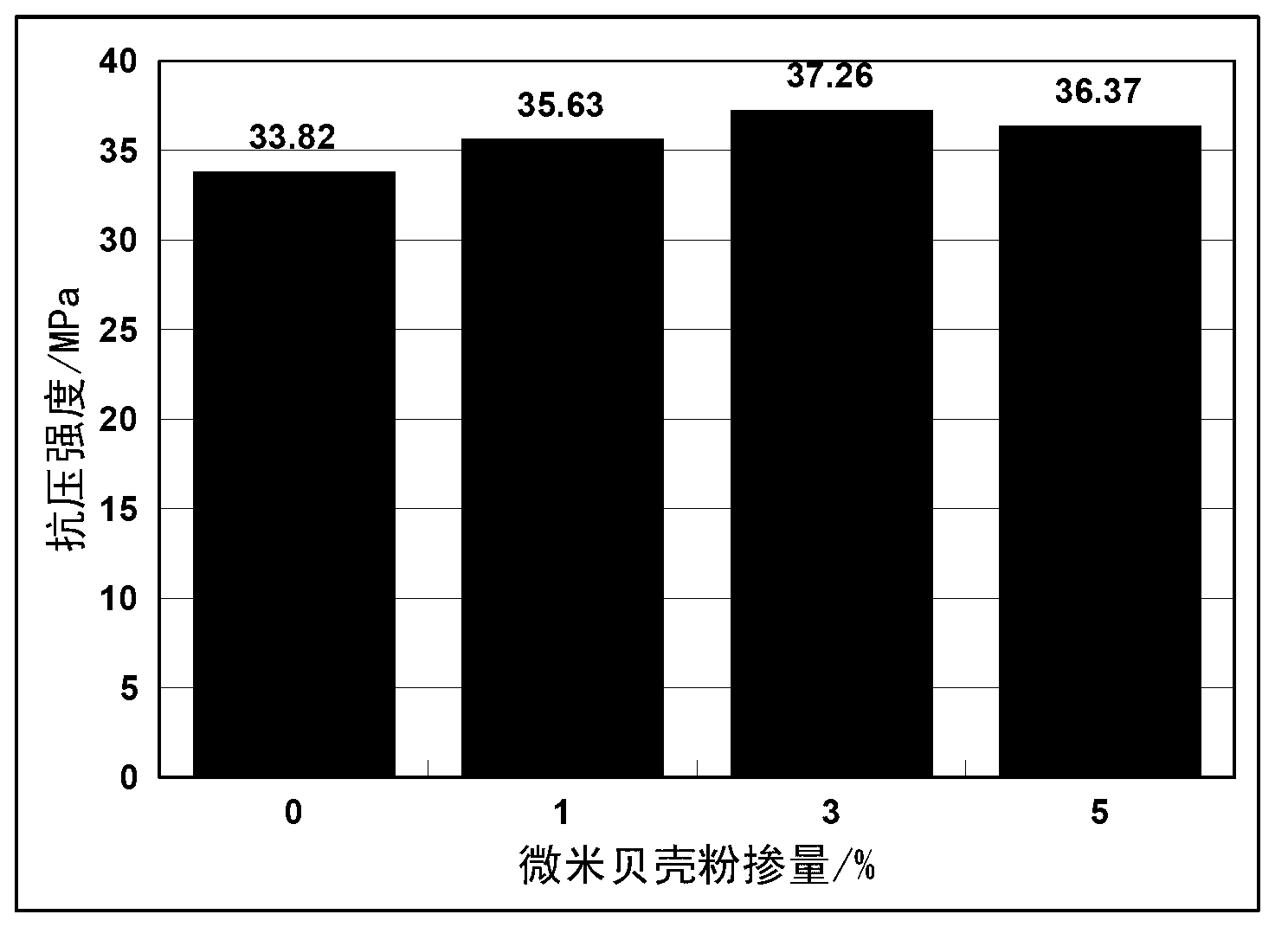

The invention relates to an application of micron shell powder as a fortifier for early strength of cement, and belongs to the field of building materials. The micron shell powder serves as a modifier for improving the early strength of the cement, so that the problem that the structural durability is reduced caused by early damages of concrete due to the fact that the early strength of an ordinary cement-based material is low is solved.

Description

technical field [0001] The invention relates to the application of micron shell powder as an early strength enhancer of cement, belonging to the field of building materials. Background technique [0002] Cement-based materials are widely used in infrastructure such as houses, bridges, and coastal dams. However, with the development of economic construction, higher requirements are placed on the performance of cement-based materials; The erosion of harmful substances will inevitably lead to the degradation of the performance of cement-based materials, resulting in initial damage to the structure, which directly affects the durability of the structure. How to improve the early performance (mechanical properties, durability) of cement-based materials is of great significance to improve the durability of concrete structures, and related research has gradually attracted the attention of civil engineering circles at home and abroad. [0003] Micron-sized shell powder is an inorga...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B22/10

Inventor 范颖芳张世义

Owner DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com