Material mixing method of graphite negative electrode slurry

A graphite negative electrode and graphite material technology, applied to battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as obvious sedimentation, affect coating quality, and uneven dispersion, and achieve simple mixing process and easy operation , good coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

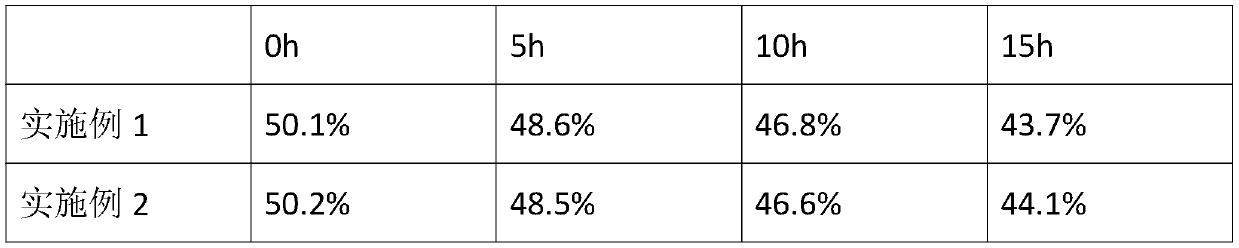

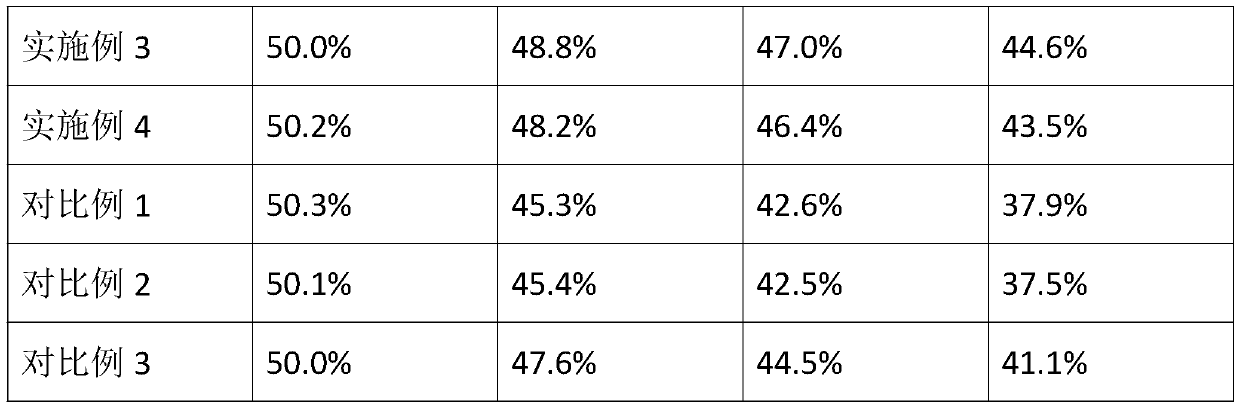

Examples

Embodiment 1

[0023] Provide the first graphite material, the second graphite material, the third graphite material, wherein the average particle diameter d1 of the first graphite material is 1 micron, the average particle diameter d2 of the second graphite material is 3 microns, and the third graphite material The average particle diameter d3 is 6 microns, the percentage content c1 of the first graphite material is 10%, the percentage content c2 of the second graphite material is 60%, and the percentage content c3 of the third graphite material is 30%;

[0024] 1), adding water into the first stirred tank, adding SBR, stirring for 4h; adding the three graphite materials into the first stirred tank according to the mass ratio, stirring for 6h, and then adding the first graphite material according to the mass ratio Added into the first stirred tank, stirred for 6h to obtain the first slurry;

[0025] 2), adding water into the second stirred tank, adding SBR, and stirring for 4h; according to...

Embodiment 2

[0028] A first graphite material, a second graphite material, and a third graphite material are provided, wherein the average particle diameter d1 of the first graphite material is 0.5 microns, the average particle diameter d2 of the second graphite material is 1.7 microns, and the third graphite material The average particle diameter d3 is 6.5 microns, the percentage content c1 of the first graphite material is 5%, the percentage content c2 of the second graphite material is 75%, and the percentage content c3 of the third graphite material is 20%;

[0029] 1), adding water into the first stirred tank, adding SBR, stirring for 4h; adding the three graphite materials into the first stirred tank according to the mass ratio, stirring for 6h, and then adding the first graphite material according to the mass ratio Added into the first stirred tank, stirred for 6h to obtain the first slurry;

[0030] 2), adding water into the second stirred tank, adding SBR, stirring for 4h; accordi...

Embodiment 3

[0033] Provide the first graphite material, the second graphite material, the third graphite material, wherein the average particle diameter d1 of the first graphite material is 1 micron, the average particle diameter d2 of the second graphite material is 2.1 microns, and the third graphite material The average particle diameter d3 is 6 microns, the percentage content c1 of the first graphite material is 10%, the percentage content c2 of the second graphite material is 70%, and the percentage content c3 of the third graphite material is 20%;

[0034] 1), adding water into the first stirred tank, adding SBR, stirring for 4h; adding the three graphite materials into the first stirred tank according to the mass ratio, stirring for 6h, and then adding the first graphite material according to the mass ratio Added into the first stirred tank, stirred for 6h to obtain the first slurry;

[0035] 2), adding water into the second stirred tank, adding SBR, stirring for 4h; according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com