a stirring device

A stirring device and stirring shaft technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve problems such as material mixing, achieve uniform mixing, zero residue, and ensure rapidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

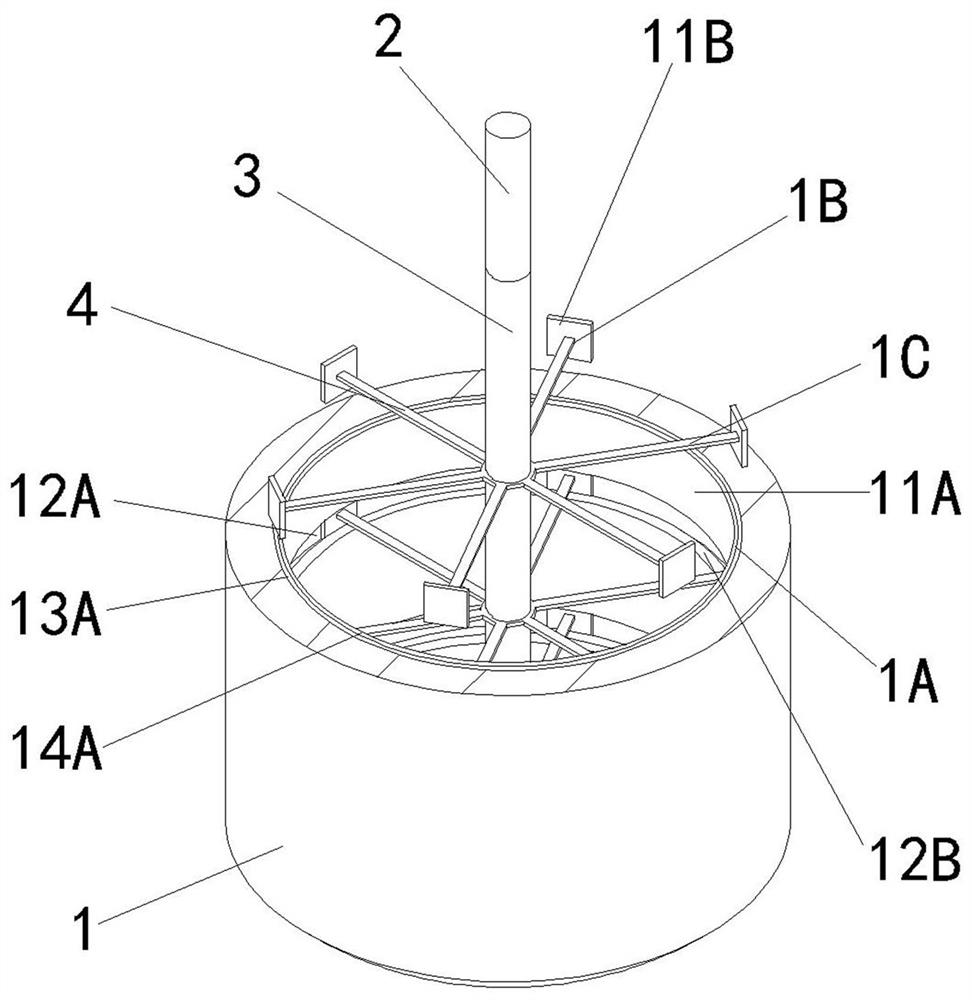

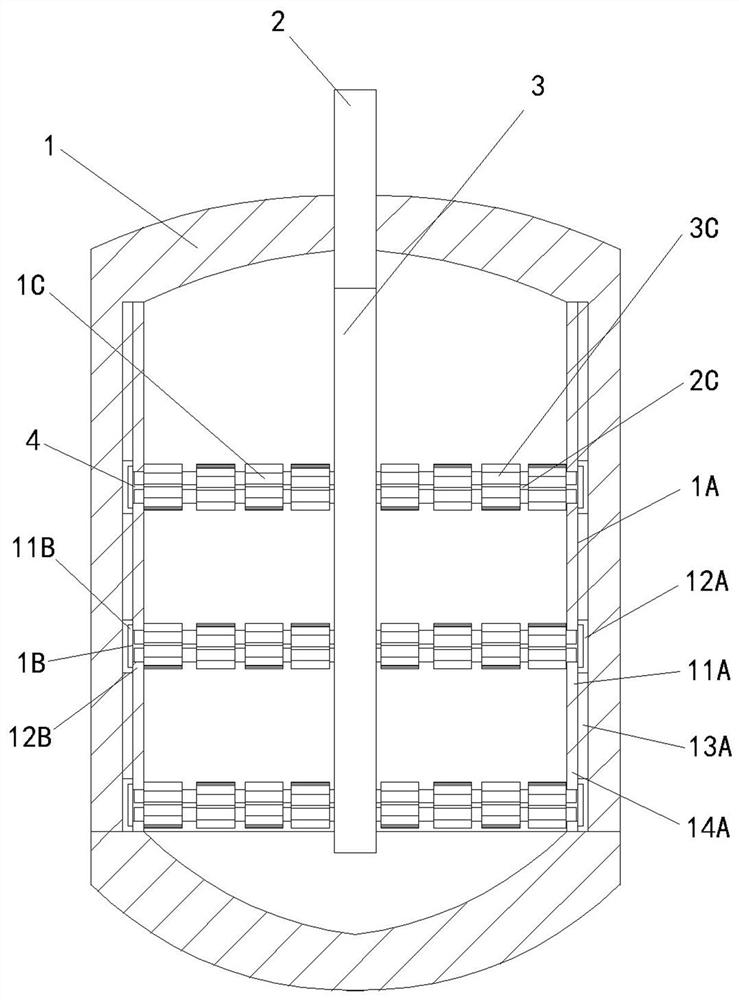

[0027] Embodiment 1, a kind of stirring device, comprises reactor body 1 and the rotating shaft 2 that extends into reactor body 1, and reactor body 1 is a tank shape, and upper and lower bottom surface is a spherical surface that protrudes outwards, and lower bottom surface can be Opening and closing downwards, a rotating shaft 2 with a motor extending into the interior of the reactor body 1 is provided in the middle of the upper ground, and the stirring shaft 3 is fixedly connected to the rotating shaft 2, and the stirring shaft 3 extends to the junction of the lower bottom surface and the cylinder body. , three stirring units 4 parallel to the horizontal plane are screwed on the stirring shaft 3, and the ends of the stirring units 4 extend into the inner surface of the reactor body 1 and move in the reactor body 1, and each stirring unit 4 includes six horizontal screws The stirring blade 1C connected to the stirring shaft 3.

[0028] The stirring blade 1C includes a base b...

Embodiment 2

[0034] Embodiment 2, a limiting structure is provided between the end of the base body 2C and the inner ring channel 12A. The limiting structure includes a limiting piece welded to the end of the base body 2C and a limiting edge matched with the limiting piece. The anti-residue smooth layer 14A constitutes the limiting edge .

[0035] The stirring unit 3 welded to the rotating shaft protrudes from the reactor from the inside to the outside to connect with the motor, and then installs a temperature-regulating medium jacket layer 13A in the reactor body 1, and installs an anti-residue smooth layer between the temperature-regulating medium jacket layers 13A 14A, and then fixedly cover the anti-residue smooth layer 14A on the temperature-regulating medium jacket layer 13A, the anti-residue smooth layer 14A leaves the above-mentioned limited edge, and finally close the lower bottom surface for stirring operation. All the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com