A high-quality synthetic rubber manufacturing process and its auxiliary tools

A production process and synthetic rubber technology, applied in the field of high-quality synthetic rubber production process and its auxiliary tools, can solve the problems of poor tensile effect, poor tear strength and mechanical properties, and achieve fast heating speed and improved tear resistance. good crack strength and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

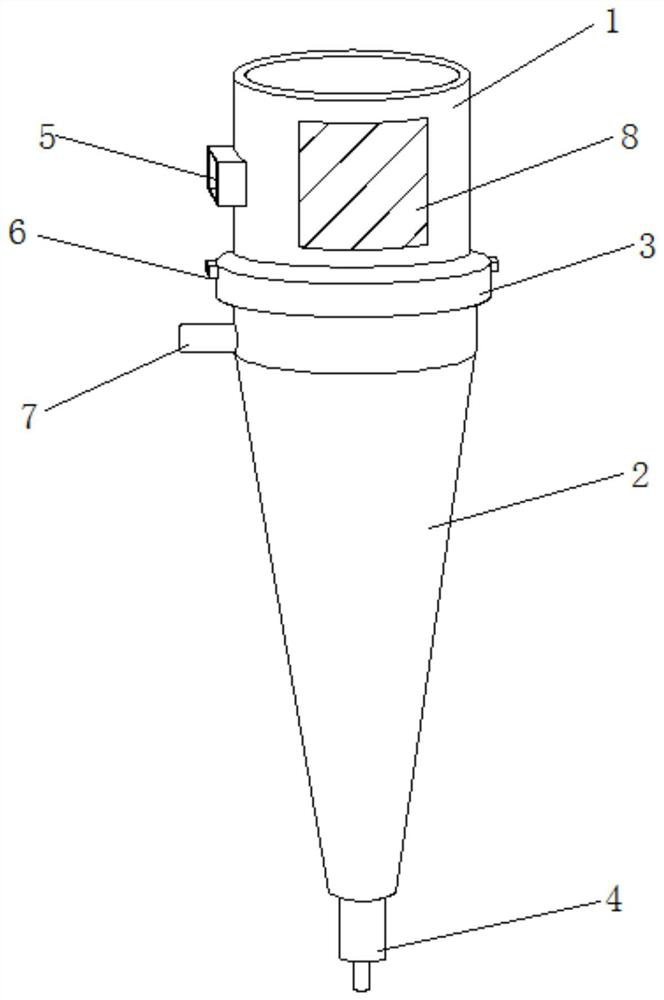

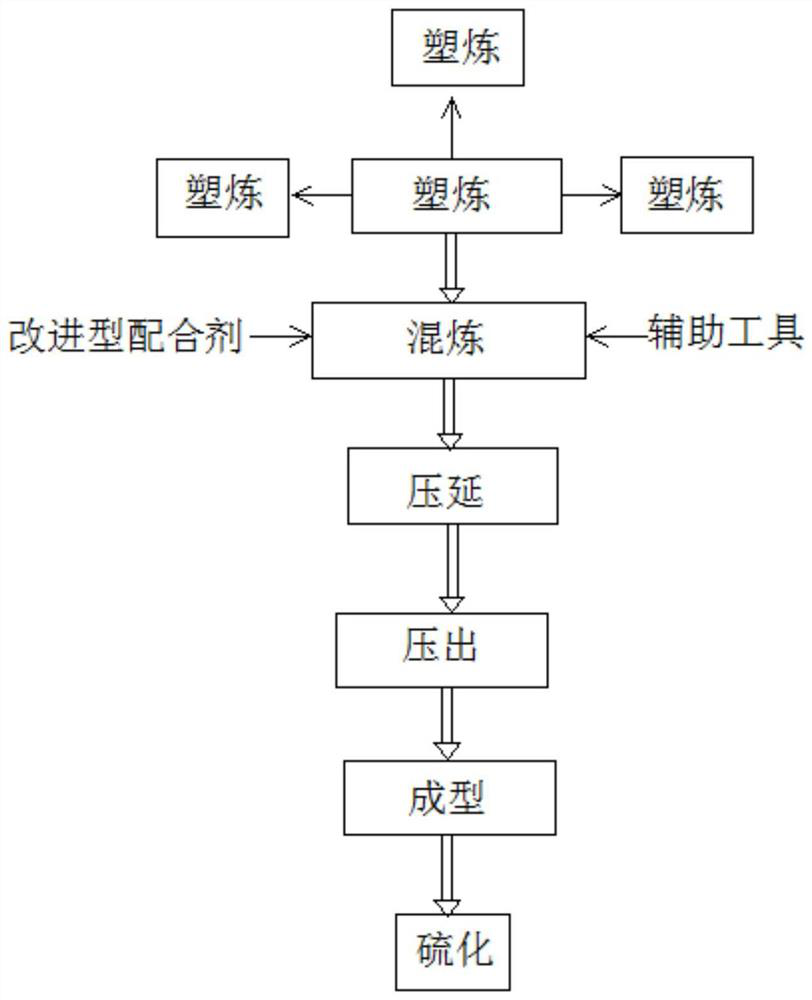

[0038] see figure 2 , a high-quality synthetic rubber, including raw rubber to be treated, its production process includes mastication, mixing, calendering, extrusion, molding and vulcanization, mastication includes rubber drying, rubber cutting and rubber breaking, and mixing includes improving Type compounding agents and auxiliary tools, improved compounding agents include fillers, reinforcing agents, accelerators, vulcanizing agents, anti-aging agents and anti-scorch agents, please refer to figure 1, the auxiliary tool includes the first-stage mixing cylinder 1, the second-stage mixing cylinder 2 and the mixing discharge head 4, the mixing discharge head 4 is fixedly connected to the lower end of the second-stage mixing cylinder 2, and the first-stage mixing cylinder 1 is arranged on the second The upper end of the stage mixing cylinder 2, the side end of the first stage mixing cylinder 1 is excavated with the first feed port, and the first feed port is connected with the ...

Embodiment 2

[0050] Ethylene, chloroprene, isobutylene and acrylonitrile are mixed according to the ratio of 1:3:6:2. The filler of this ratio is added from the third feeding pipe 6, and the heating speed is fast, which can also be greatly improved. Improve the tensile effect of synthetic rubber; the reinforcing agent formed by mixing and polymerizing diisocyanate compounds and polyethers in a ratio of 3:4 should be fed from the third feeding pipe 6 and the second feeding pipe 7 respectively. Putting it in at intervals of three minutes before and after can greatly improve the tear strength of synthetic rubber;

Embodiment 3

[0052] Ethylene, chloroprene, isobutylene and acrylonitrile are mixed according to the ratio of 2:4:7:3. The filler of this ratio is added from the third feeding pipe 6, and the heating speed is fast, which can also be greatly improved. Improve the tensile effect of synthetic rubber; the reinforcing agent formed by mixing and polymerizing diisocyanate compounds and polyethers in a ratio of 3:4 should be fed from the third feeding pipe 6 and the second feeding pipe 7 respectively. Putting it in at intervals of three minutes before and after can greatly improve the tear strength of synthetic rubber;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com