Preparation method of ecological embankment type porous concrete special for plant growing

A porous concrete and ecological technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of complex calculation of raw material consumption, unable to meet the requirements of plant growth, unable to form uniform pores at the bottom of pores, etc., and achieve simple mixing and molding processes. , The effect of planting and greening is good, and the maintenance is simple and easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

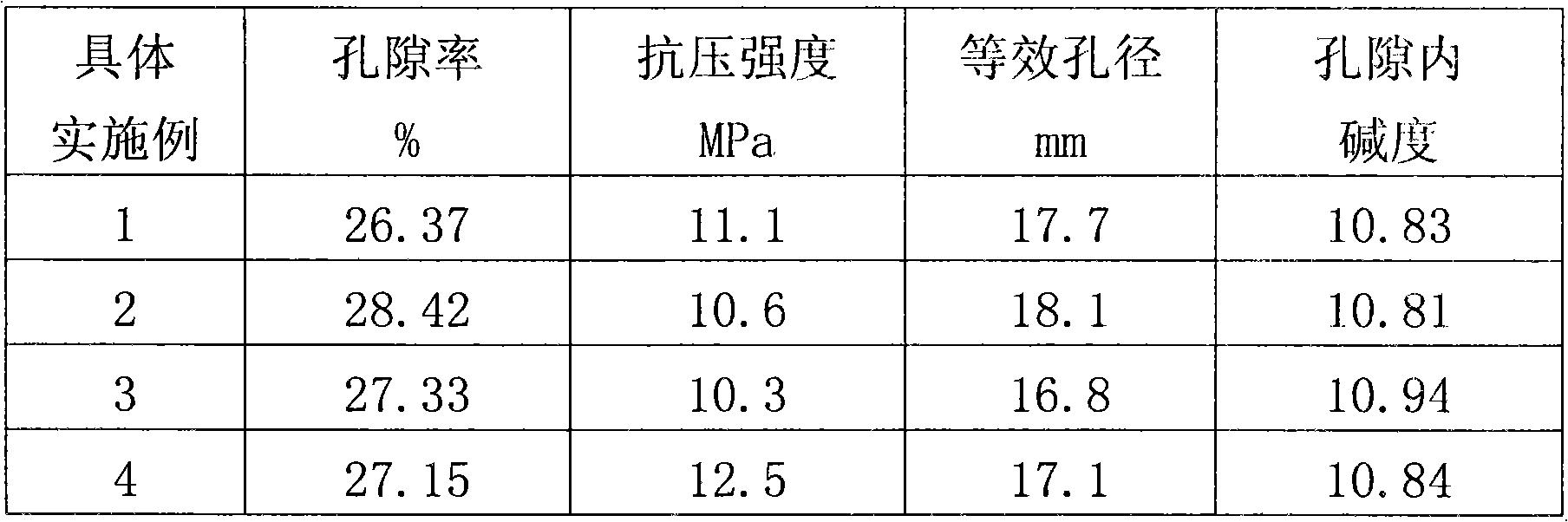

Examples

Embodiment 1

[0027] Add 6kg of water to 1800kg of clean gravel and stir to make the surface of the gravel wet. The particle size of the gravel is 10-20mm. Then pour 360kg of cement and 36kg of slag into the mixer and stir for 15 seconds to coat the surface of the gravel with a layer of cement slurry. shell, and finally add 112kg of water to stir, so that the cement slurry shell on the surface of the gravel becomes thicker and uniform, and stir for 3 minutes to obtain the mixture. Using the layered pressing method, pour the mixture prepared above into the mold three times, flatten and compact the mixture added each time and vibrate slightly to increase the contact points between the spheres and reduce the spacing, so that The tissue structure of porous concrete is more dense and stable. Start watering 1 day after pouring, and cover with plastic film, and release the mold on the 2nd day after pouring. In this way, water more than 2 times a day, and maintain with plastic film for 3 consecuti...

Embodiment 2

[0029] Add 20kg of pre-mixed water to 2000kg of clean gravel and stir to make the surface of the gravel wet. The particle size of the gravel is 20-30mm. Then pour 335kg of cement and 67kg of slag into the mixer and stir for 30s to coat the surface of the gravel with a layer. Cement slurry shell, finally add the remaining 115kg of mixing and stir, so that the cement slurry shell on the surface of the crushed stone becomes thicker and uniform, and stir for 5 minutes to obtain the mixture. Using the layered pressing method, pour the mixture prepared above into the mold three times, flatten and compact the mixture added each time and vibrate slightly to increase the contact points between the spheres and reduce the spacing, so that The tissue structure of porous concrete is more dense and stable. Start watering 1 day after pouring, and cover with plastic film, and release the mold on the 2nd day after pouring. In this way, water more than 4 times a day, and maintain with plastic ...

Embodiment 3

[0031] Add 17kg of pre-mixed water to 1600kg of clean crushed stone and stir to make the surface of the crushed stone wet, wherein the crushed stone is a mixture of crushed stones with a particle size of 10-20mm (accounting for 30%) and a particle size of 20-30mm (accounting for 70%), and then Pour 400kg of cement and 120kg of fly ash into the mixer and stir for 45s, so that the surface of the gravel is covered with a layer of cement slurry shell, and finally add the remaining 139kg of mixing water and stir to make the cement slurry shell on the surface of the gravel thicker and uniform, and stir for 10 minutes , to obtain the mixture. Using the layered pressing method, pour the mixture prepared above into the mold three times, flatten and compact the mixture added each time and vibrate slightly to increase the contact points between the spheres and reduce the spacing, so that The tissue structure of porous concrete is more dense and stable. Start watering 1 day after pouring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com