Injector easy in medicine dispensation

A syringe and dispensing technology, applied in the field of syringes, can solve the problems of post-processing, tedious preparation work, laborious suction of medicinal liquid, time-consuming dispensing process, etc., and achieves the effects of novel structure, reduced drug waste and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

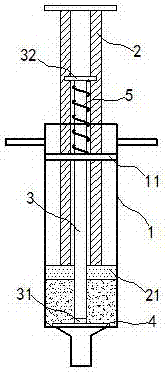

[0016] exist Figure 1 to Figure 3 In the embodiment shown, the easy dispensing syringe includes a syringe 1 and a push rod 2, and the end of the push rod 2 is provided with a piston plate 21, and the piston plate 21 can slide back and forth airtightly along the inner wall of the syringe 1; In the embodiment, the push rod 2 includes a set of parallel and rotationally symmetrical connecting rods;

[0017] A limiter plate 11 is fixedly arranged on the inner wall of the needle cylinder 1, and the push rod 2 passes through the limiter plate 11 and can reciprocate relative to the limiter plate 11;

[0018] A stirring rod 3 is also arranged in the needle cylinder 1, and the stirring rod 3 is parallel to the push rod 2; the stirring rod 3 is arranged between the connecting rods;

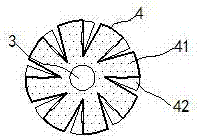

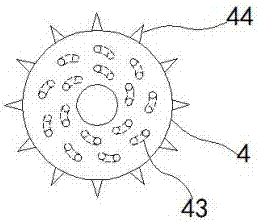

[0019] One end of the stirring rod 3 passing through the piston plate 21 is provided with a stirring blade 4, the stirring blade 4 and the stirring rod 3 are connected by a bearing 31, and the stirring bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com