Porous monocolumn fuel supply structure for supersonic vehicle ramjet

A technology for ramjet and fuel supply, applied in the field of ramjet, can solve the problem that the fuel supply structure cannot be cooled, and achieve the effects of enhancing atomization and gasification effects, improving mixing effects, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

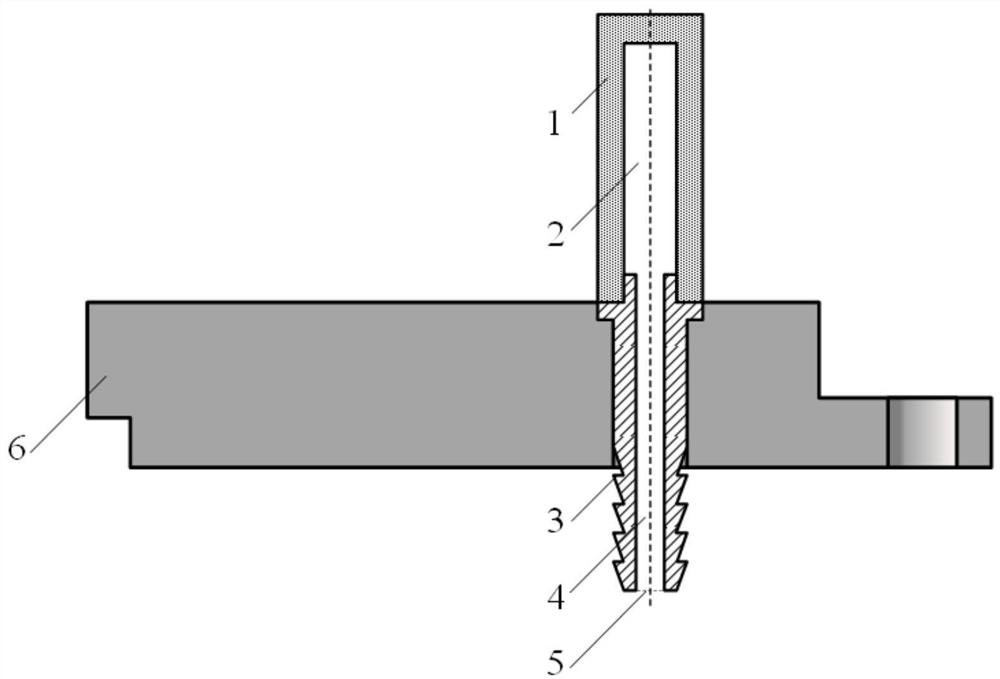

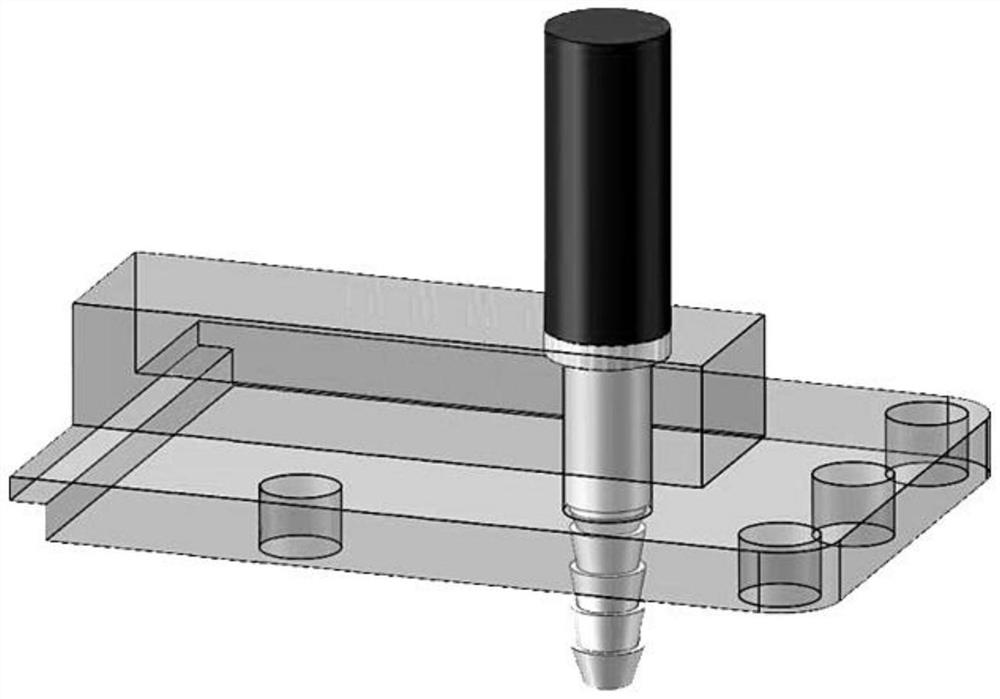

[0024] Specific implementation mode one: see Figure 1-Figure 5 This embodiment will be described. The metal particle sintered porous single-column fuel supply structure for supersonic aircraft ramjet described in this embodiment includes a column structure and a base 6, the upper part of the column structure is arranged above the base 6, and the lower part penetrates the base 6. The column structure includes a porous shell 1 and a hollow support rod 3, the porous shell 1 is wrapped on the top of the support rod 3 and sintered into a whole column structure, and the hollow support rod 3 passes through the base 6; The porous shell 1 is a hollow cylindrical structure with a cavity 2 inside. The porous shell 1 is made of a porous medium material sintered with metal particles. The material composition of the metal particles is 06Cr17Ni12Mo2, and the size of the metal particles is from 25 to 35 microns, the porosity of the sintered porous media material is 0.25 to 0.35, and the por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com