Three-column fuel supply structure for hypersonic aircraft scramjet

A scramming and hypersonic technology, applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problem that the fuel supply structure cannot work for a long time, solve the problem of aerodynamic heat load and aerodynamic stagnation, and realize the cooling demand and flow distribution, improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

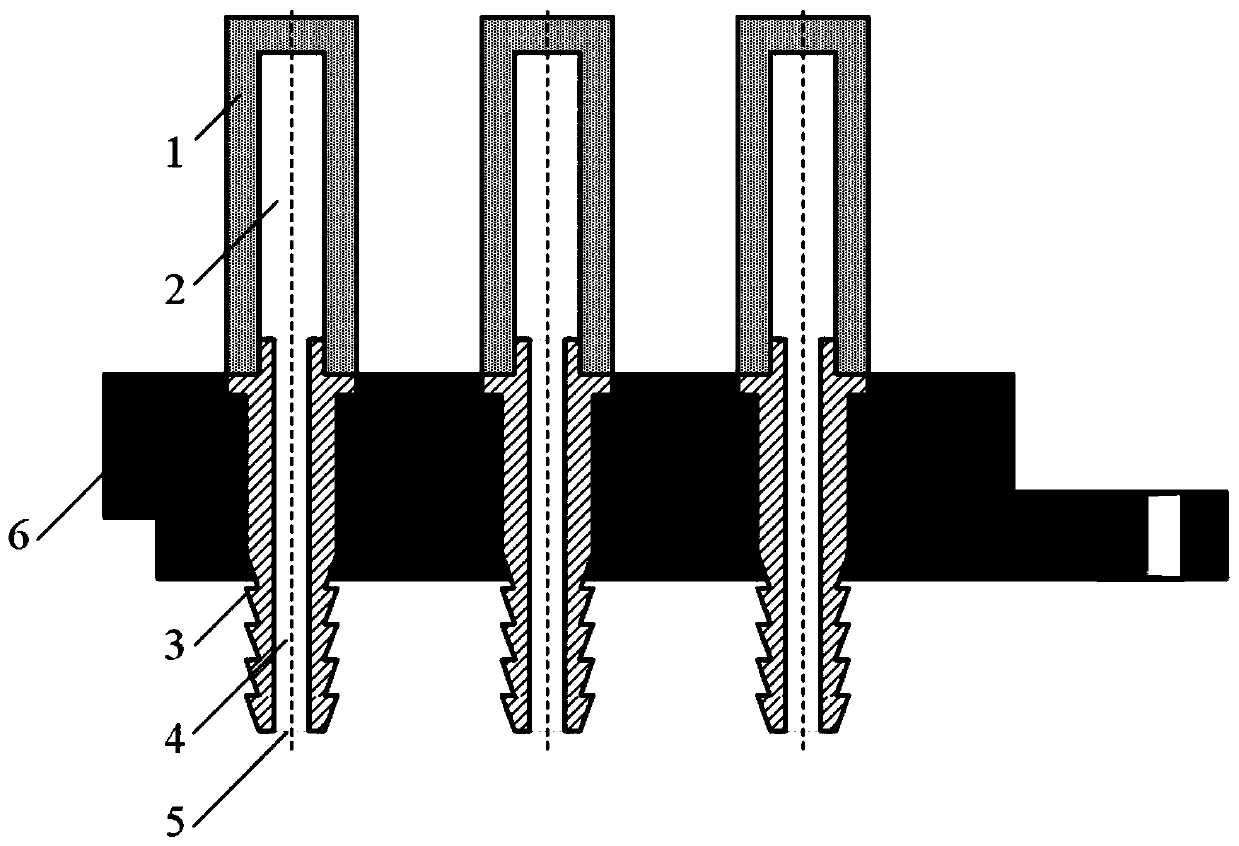

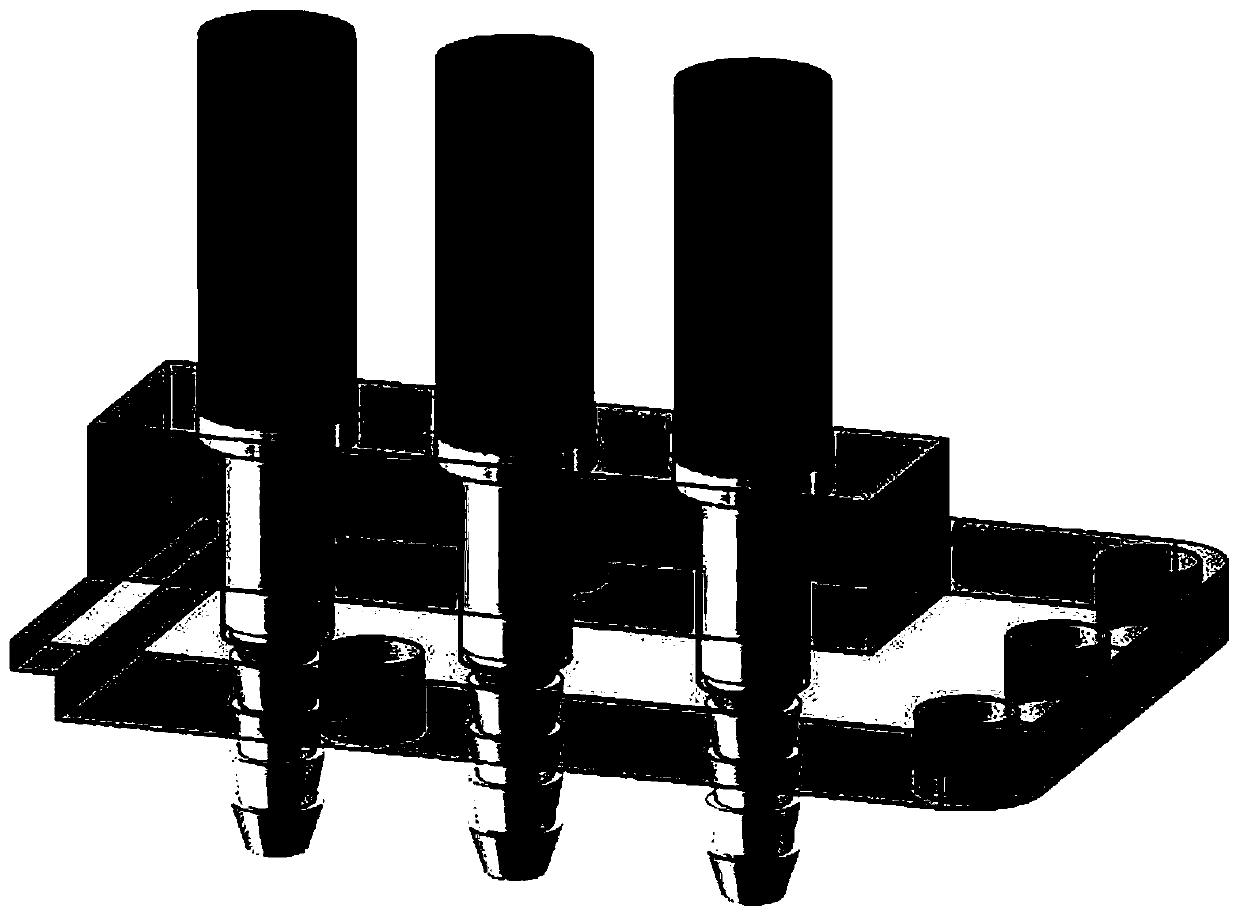

[0026] Specific implementation mode one: see Figure 1-Figure 5 This embodiment will be described. The three-column fuel supply structure for hypersonic aircraft scramjet described in this embodiment includes three column structures and a base 6, and the upper parts of the three column structures are all arranged above the base 6, The lower part runs through the base 6, and the arrangement of the three columnar structures is in a straight line, with a distance of 5mm between them; the columnar structure includes a porous shell 1 and a hollow support rod 3, and the porous shell 1 is wrapped in a hollow The top of the support rod 3 is sintered into a cylindrical structure, and the hollow support rod 3 penetrates the base 6; the porous shell 1 is a hollow cylindrical structure with a cavity 2 inside, and the porous shell 1 is sintered with metal particles The material composition of the metal particles is 06Cr17Ni12Mo2, the size of the metal particles is 25 to 35 microns, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com