Lead/carbon composite for storage battery and preparation method of lead/carbon composite material

A carbon composite material and composite material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unfavorable battery performance and uniform mixing, achieve the suppression of hydrogen evolution on the negative plate, increase battery capacity, and make the paste process simple and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

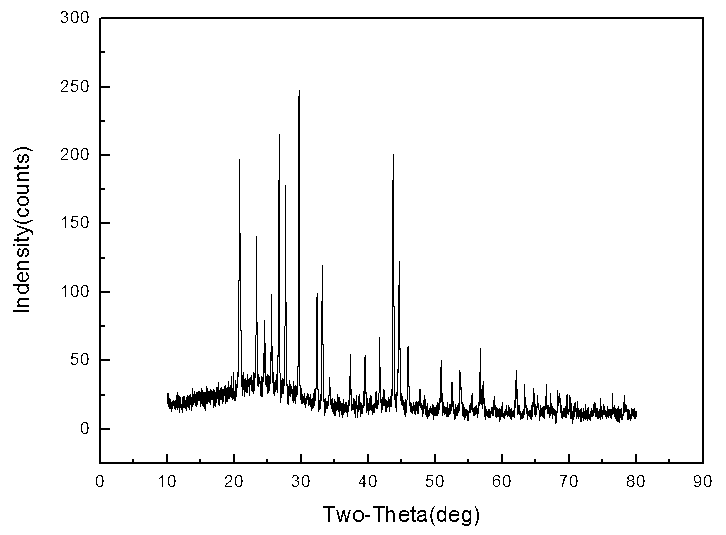

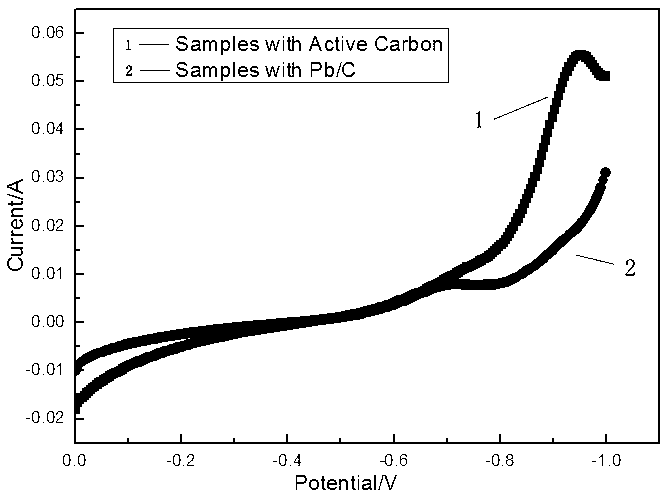

Image

Examples

Embodiment 1

[0031] The molar concentration is 0.1M lead salt solution 85%, conductive carbon material 15%.

[0032] Wherein, the soluble lead salt in the lead salt solution is selected from sulfate or nitrate containing lead element. The conductive carbon material is a mixture of activated carbon and acetylene black.

Embodiment 2

[0034] The lead salt solution with a molar concentration of 0.8M is 99.9%, and the conductive carbon material is 0.1%.

[0035] Wherein, the soluble lead salt in the lead salt solution is selected from carbonate, hydrochloride or complex salt containing lead element. The conductive carbon material is a mixture of carbon black, carbon nanotubes, and carbon aerogels.

Embodiment 3

[0037] The lead salt solution with a molar concentration of 0.5M is 92.5%, and the conductive carbon material is 7.5%.

[0038] Wherein, the soluble lead salt in the lead salt solution is selected from acetate containing lead element. The conductive carbon material is made of conductive carbon fiber.

[0039] The preparation method of lead / carbon composite material for accumulator that the present invention proposes, the steps are as follows:

[0040] Step 1. First, weigh the soluble lead salt according to the formula ratio of the lead / carbon (Pb / C) composite material for storage battery, and mix it with deionized water to form a lead salt solution. The concentration of the lead salt solution is the molar concentration, and can also be converted into a weight percent concentration. Then weigh the conductive carbon powder according to the formula ratio of the lead / carbon composite material for storage battery, add it into the lead salt solution, and stir to obtain a mixture. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com