Patents

Literature

121results about How to "Solve the precipitation problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

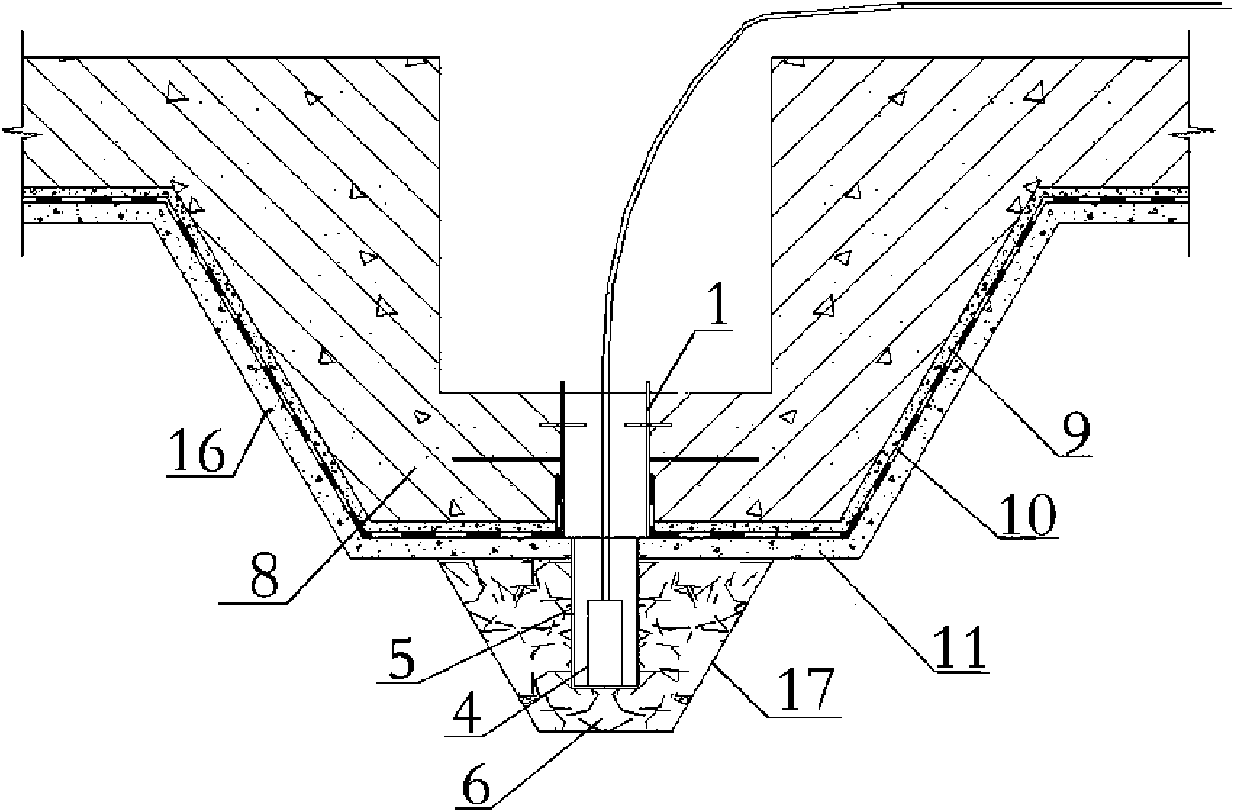

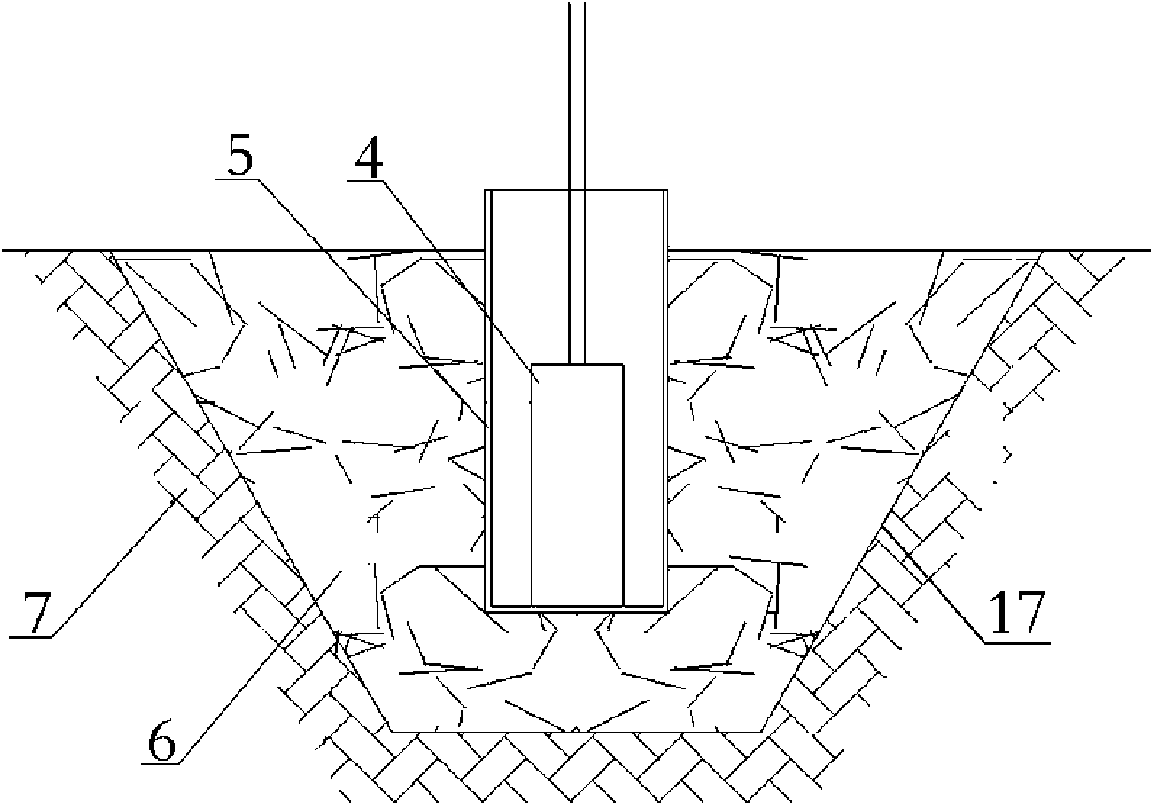

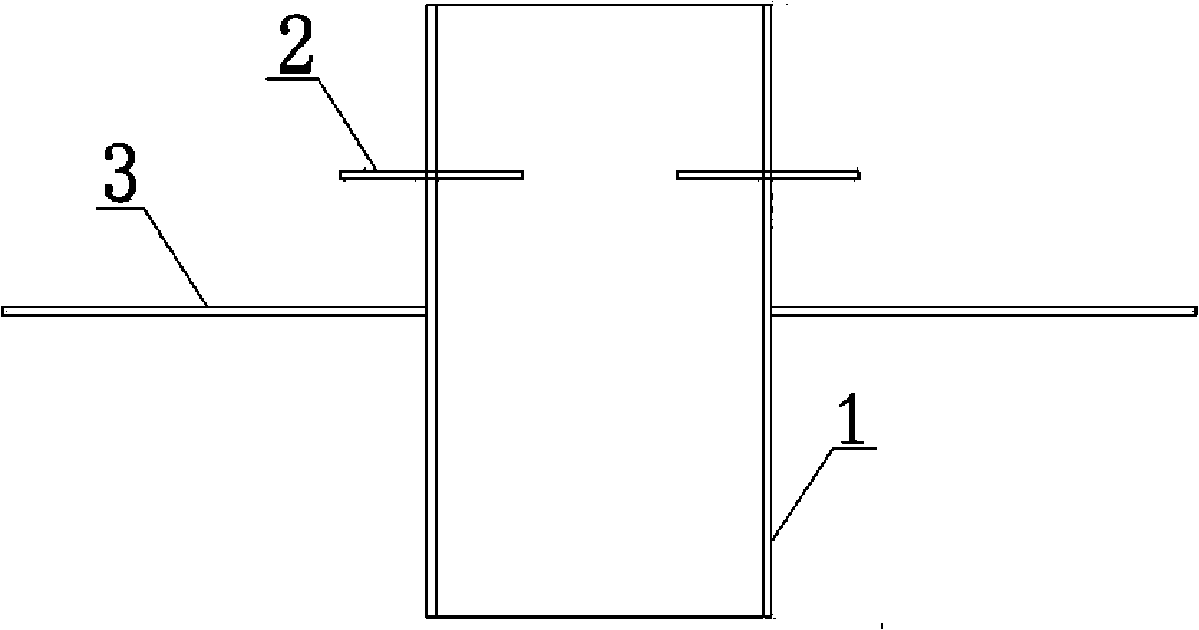

Base pit dewatering and water saving device and construction method thereof

InactiveCN101768976ASolve the precipitation problemEfficient use ofProtective foundationExcavationsWater savingBaseboard

The invention relates to a base pit dewatering and water saving device and a construction method thereof. The middle part of the base pit of a baseboard structure is provided with a well pit; the well pit is internally and vertically provided with a no-sand tube; pebbly sand is filled between the bottom and periphery of the no-sand tube; the top of the no-sand tube is higher than the top surface of the well pit; a water pump is arranged in the no-sand tube; blinding layer concrete is poured at the top surface of the well pit which is at the periphery of the no-sand tube and the side wall of the base pit of the baseboard structure; and the top elevation of the no-sand tube is flush with the elevation of a blinding layer; a dewatering conduit is pre-buried in a base pit baseboard right above the no-sand tube, a waterproof layer is paved on the blinding layer concrete, a layer of waterproof and protective concrete is poured on the waterproof layer, and the base pit baseboards are poured above the waterproof and protective concrete and at the periphery of the dewatering conduit. The method of the invention has lower investment, saved cost and less amount of dewatering amount, thereby reducing the loss of underground water and protecting water resource; and the method can be adopted for a project in which the well point dewatering method is not ideal for dewatering or a project in which the underground water is near the base pit elevation.

Owner:CSCEC CITY CONSTR DEV +1

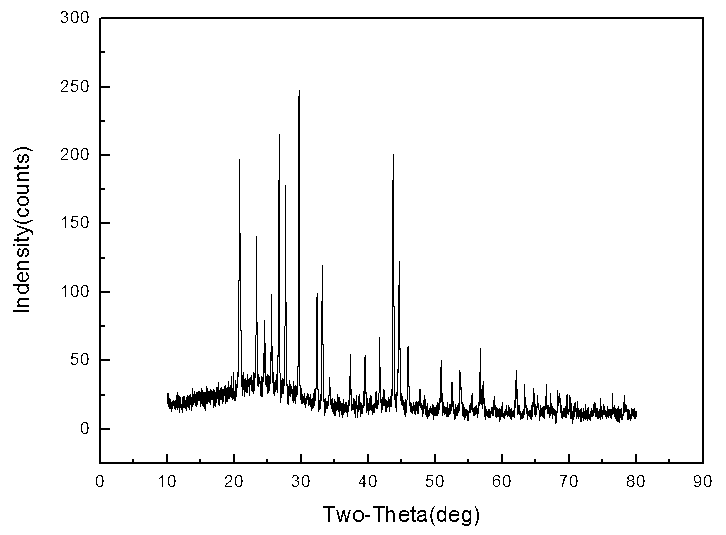

Method for producing oriented silicon steel band by continuous casting and rolling of thin plate slab

InactiveCN1743127ASavings in the slab cooling processSolve the problem of high temperature and easy damageFurnace typesOther manufacturing equipments/toolsThin slabPrecipitation

A method for producing orientated silicon strip by continuously casting and rolling sheet blank is disclosed. The processing step as follows: continuously cast the sheet blank, equally heat it by a equal-heating furnace, hot continuous roll, normalizing anneal, cold roll, decarburizing anneal, high temperature anneal. In the equal-heating furnace the temperature is controlled at 1050-1150 deg.C, time is 10-120 min. Advantages: the sheet blank cooling procedure is saved to solve the problem of inhibitor precipitation; it uses low temperature heating to replace high temperature heating so as to avoid the damage of heating furnace; reduced energy consumption and raised production efficiency and product quality.

Owner:NORTHEASTERN UNIV

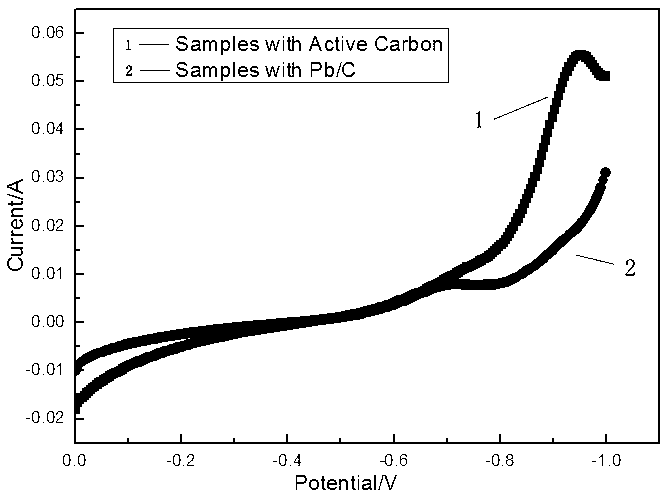

Lead/carbon composite for storage battery and preparation method of lead/carbon composite material

ActiveCN103137955AIncrease the proportionAvoid uneven mixingCell electrodesCarbon compositesCharge current

The invention discloses a lead / carbon composite for a storage battery. The lead / carbon composite is prepared from the following raw materials in percent by weight: 85-99.9 percent of lead-salt solution and 0.1-15 percent of conductive carbon material, wherein the lead salt solution is prepared from a soluble lead salt and deionized water, and the mol concentration of the lead salt solution is 0.1-0.8M. The invention also discloses a preparation method of the lead / carbon composite for the storage battery. The lead / carbon composite is substantially a conductive carbon material modified by lead oxide. Lead has the characteristics of low resistivity, high plasticity and high hydrogen evolution overpotential. The characteristics of the lead ensure that the hydrogen evolution overpotential of the carbon material after modified by PbO in a lead-acid battery is remarkably increased; and meanwhile the charging current occupied by partial hydrogen evolution reaction in a charging process is reduced, and the charging efficiency is increased.

Owner:SHENZHEN CENT POWER TECH

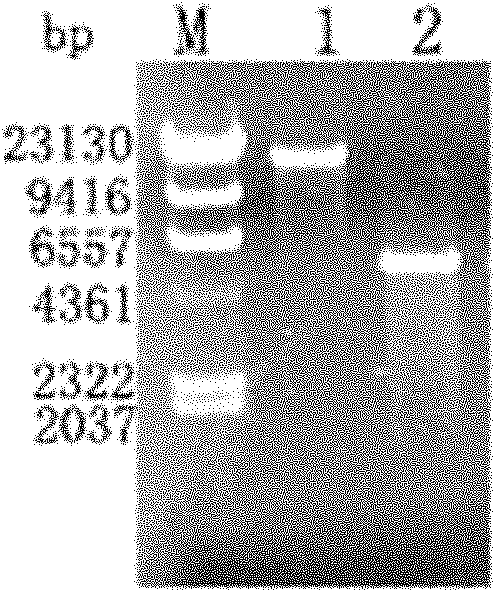

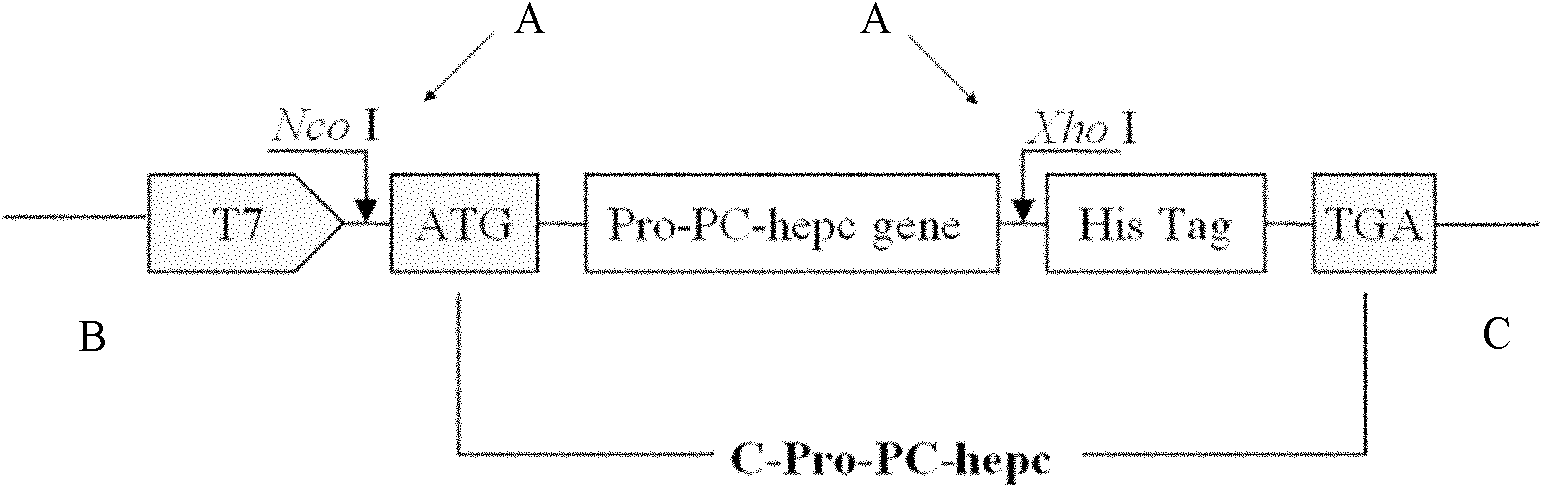

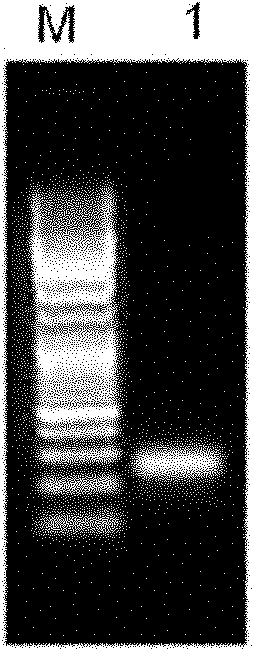

Large yellow croaker hepcidin antibacterial peptide and preparation method thereof

ActiveCN101974082AHigh molecular weightOptimizing Denaturation and Refolding ConditionsPeptide preparation methodsFermentationProkaryotic expressionGene engineering

The invention discloses a large yellow croaker hepcidin antibacterial peptide and a preparation method thereof, relating to fish gene engineering in the biotechnology field, and providing a large yellow croaker hepcidin antibacterial peptide and a preparation method thereof. The preparation method of the large yellow croaker hepcidin antibacterial peptide comprises the following steps: cloning a large yellow croaker hepcidin antibacterial peptide gene; constructing a recombinant vector; converting a host cell; selecting positive clone for prokaryotic expression; separating and purifying an expression product; and obtaining the large yellow croaker hepcidin antibacterial peptide. During separation and purification, the yield of protein is improved, thus solving the problem of protein precipitation when the hepcidin antibacterial peptide expresses renaturation. The solution has simple preparation and low cost. The prepared large yellow croaker hepcidin antibacterial peptide has high broad-spectrum antimicrobial activity, can be used for scientific researches, can serve as feed additive for preventing and curing diseases of sea farming fishes and has wide application prospect.

Owner:XIAMEN UNIV

Method for measuring fructosamine NBT in blood serum

InactiveCN101135688ASolve the precipitation problemReduce distractionsMaterial analysis by optical meansBiological testingFructosamine MeasurementAlkalinity

The method comprises: its standard solution uses the healthy human blood serum as base substance; the fructosamine measuring reagent box uses a combination of dual reagents R1 and R2; said R1 comprises NBT reaction component, pH is neutrality; said R2 is alkalinity potassium carbonate buffer solution; the ratio of R1,P2 to the sample under test is 40-50: 8-12: 3.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

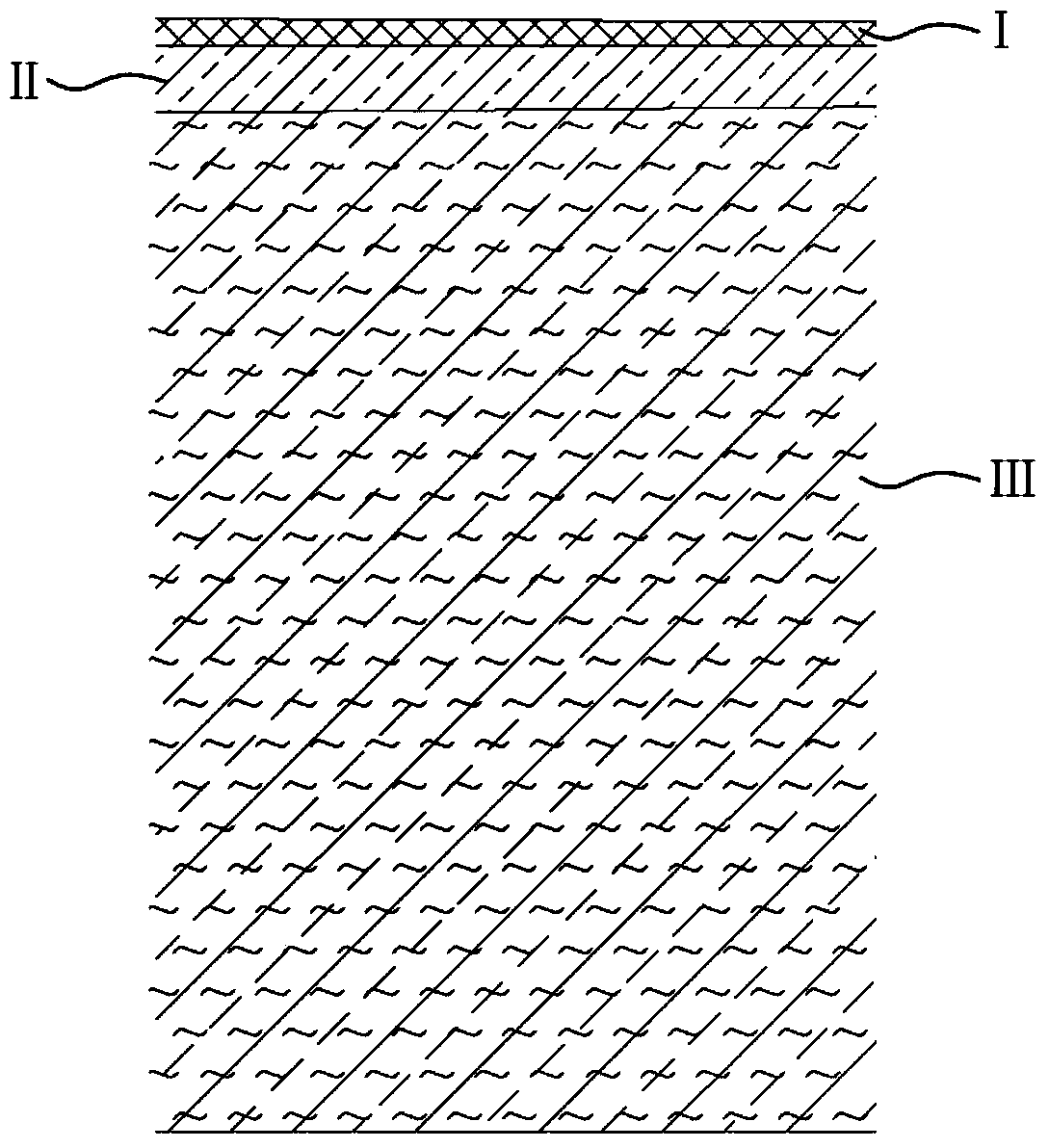

Phase-change thermal-insulating powder for energy-saving thermoregulation of buildings and preparing method thereof

ActiveCN106045428ASolve the precipitation problemSolve the leakHeat-exchange elementsThermal insulationBuilding energy

The invention discloses phase-change thermal-insulating powder for energy-saving thermoregulation of buildings and a preparing method thereof and relates to the field of building energy-saving thermal insulation materials. The phase-change thermal-insulating powder is characterized in that the phase-change thermal-insulating powder is obtained by coating the surfaces of phase-change material fine particles with nanometer hydraulic gel. By means of a shell formed by the nanometer hydraulic gel, solid-liquid phase-change circulation of a phase-change material is achieved in a relatively independent space, and precipitation and leakage are avoided; particularly, massive adding can be conducted to improve energy-saving thermoregulation property without influencing the strength of a building material. Due to the fact that the shell of the phase-change material is made of the hydraulic gel, the adaptability of the powder in the building material is high, and the powder is well compatible with and can be well mixed with concrete, mortar, putty and paint. Furthermore, a heat conduction agent is added to the hydraulic gel, thermoregulation sensitivity is improved, the phase-change material can absorb or release heat in time, energy is saved, and the temperature in a building can be adjusted to be at a proper level all the time. The production process is easy to control, cost is low, and technical support is provided for the application of the phase-change material to energy-saving thermoregulation of buildings.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

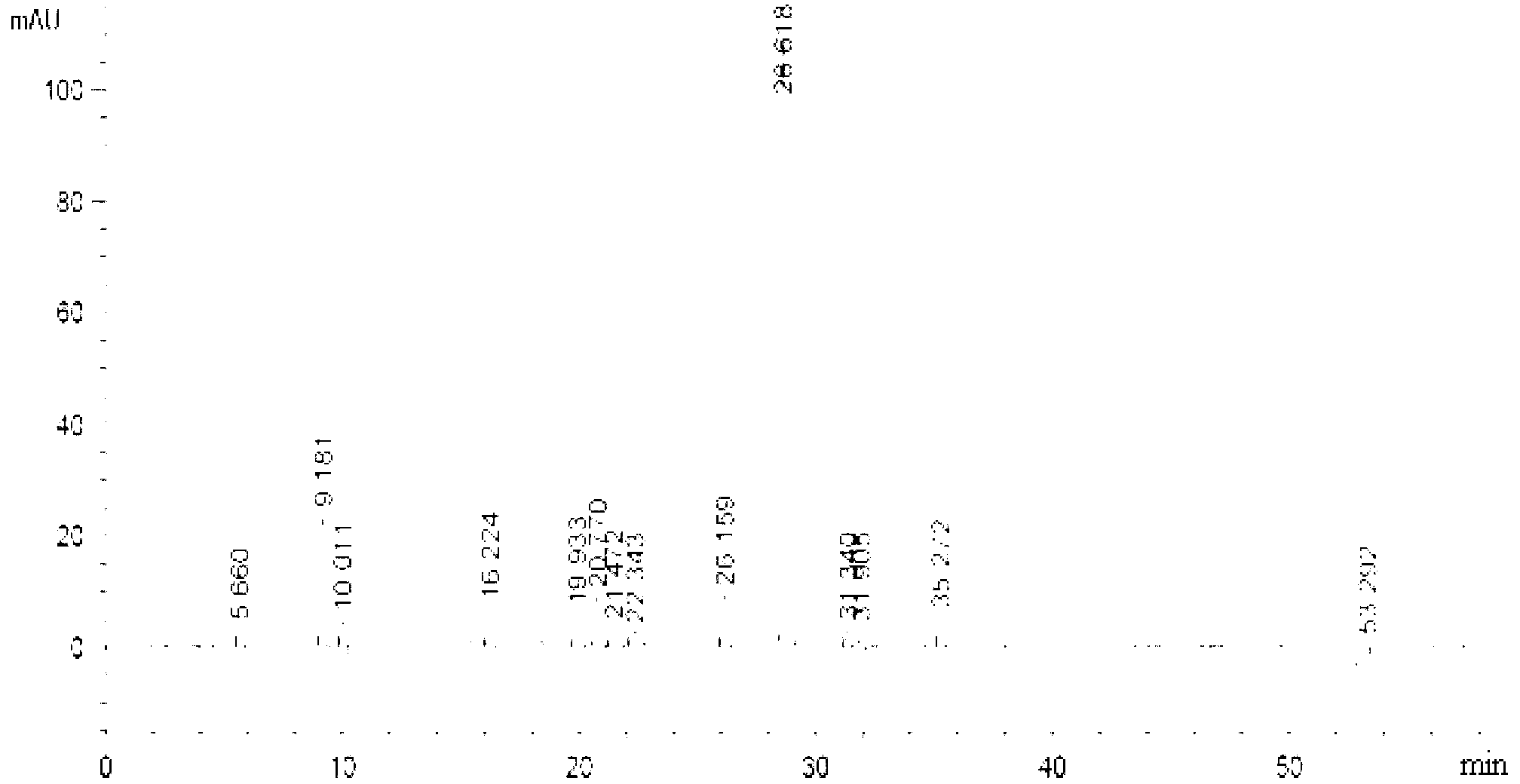

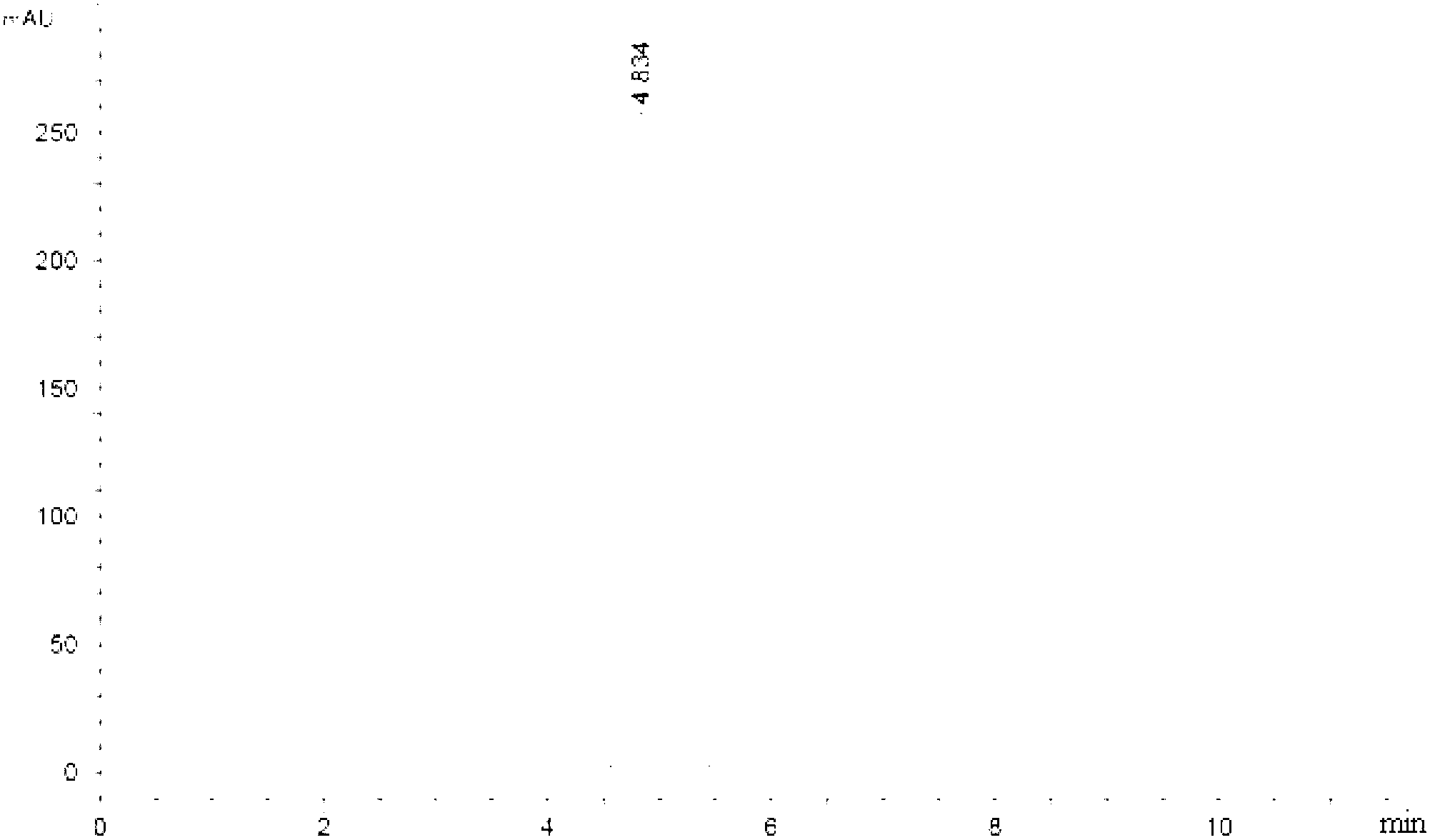

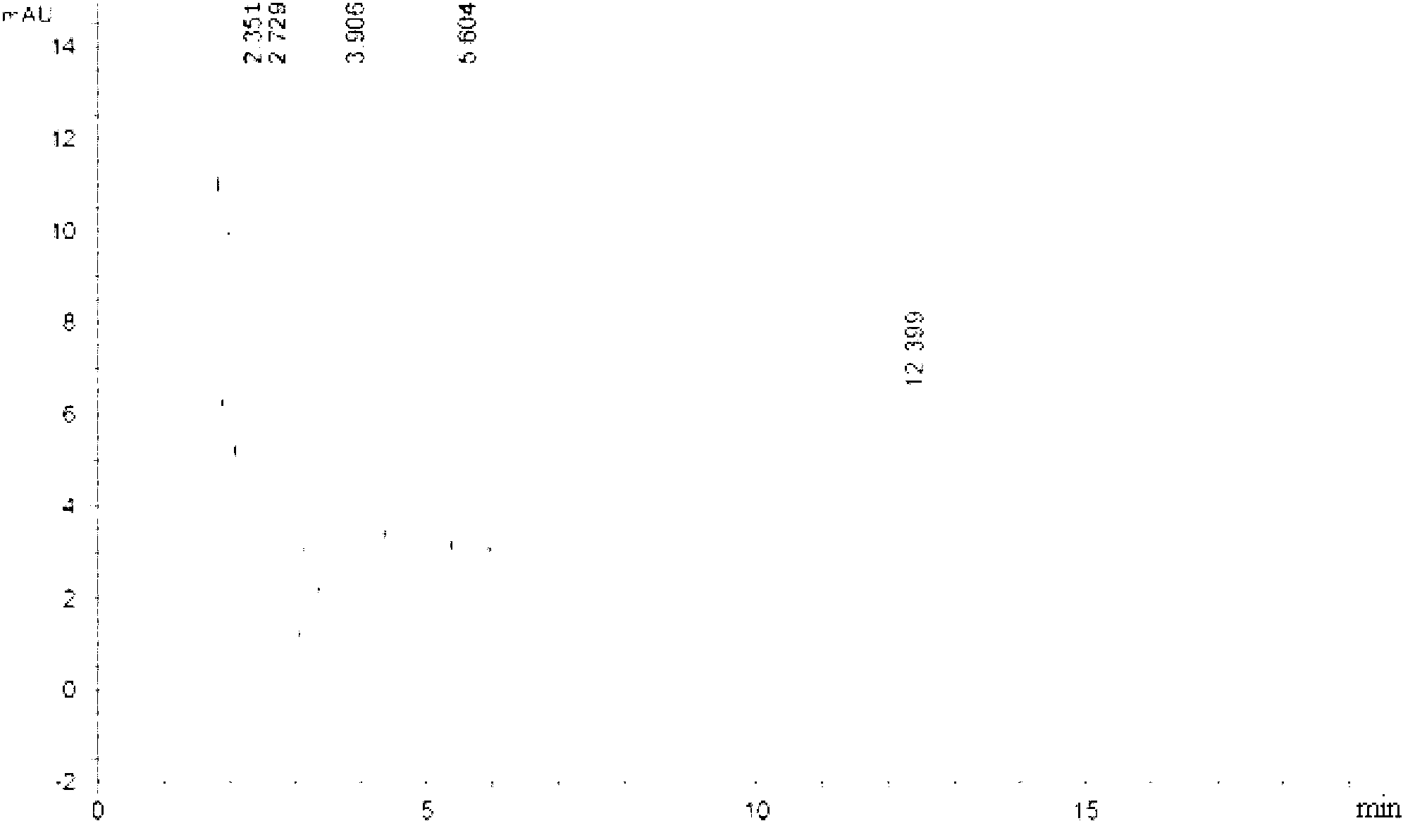

Method for content determination of multiple components in traditional Chinese medicinal preparation Shuanghuanglian for injection

ActiveCN103308615AAvoid driftingSolve the precipitation problemComponent separationIsochlorogenic acidContent determination

The invention relates to a method for content determination of multiple components in traditional Chinese medicinal preparation Shuanghuanglian for injection, aiming at solving the problems of an existing method for content determination of Shuanghuanglian for injection which is complex in sample processing, time, labor and detection equipment-consuming to detect Shuanghuanglian, and long in detection period. The detection method provided by the invention can be used for synchronously determining the contents of more than 10 components such as forsythin, forsythiaside A, caffeic acid, neochlorogenic acid, chlorogenic acid, cryptochlorogenin acid, isochlorogenic acid A, isochlorogenic acid C, baicalin, scutellarin and oroxylin-7-O-glucuronic acid in the Shuanghuanglian for injection, and meanwhile monitoring a fingerprint spectrum. The method can be used for completing previous detection in one time just by one detection system, and is more accurate, stable, comprehensive and rapid in control over the quality of the Shuanghuanglian for injection.

Owner:哈药集团中药有限公司

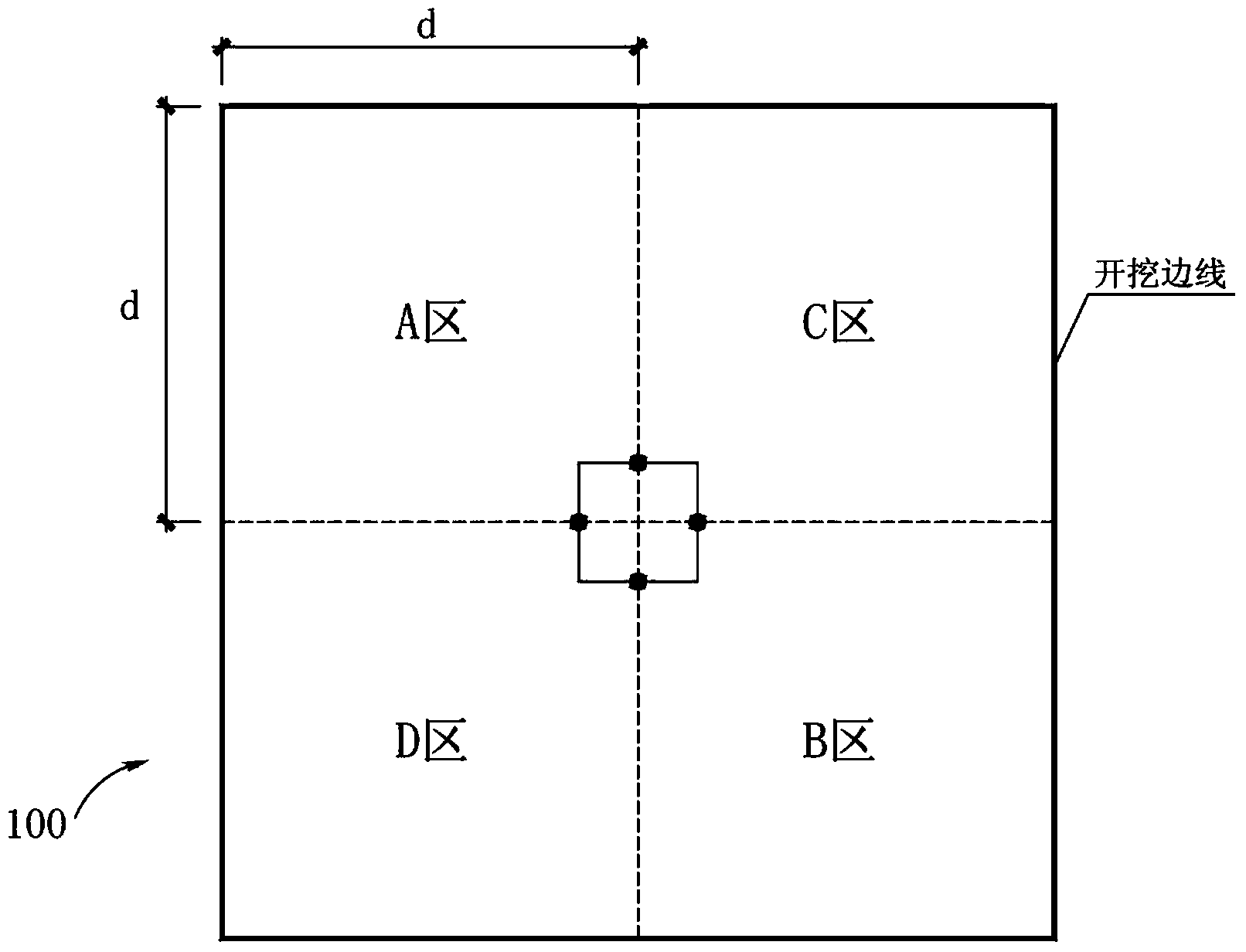

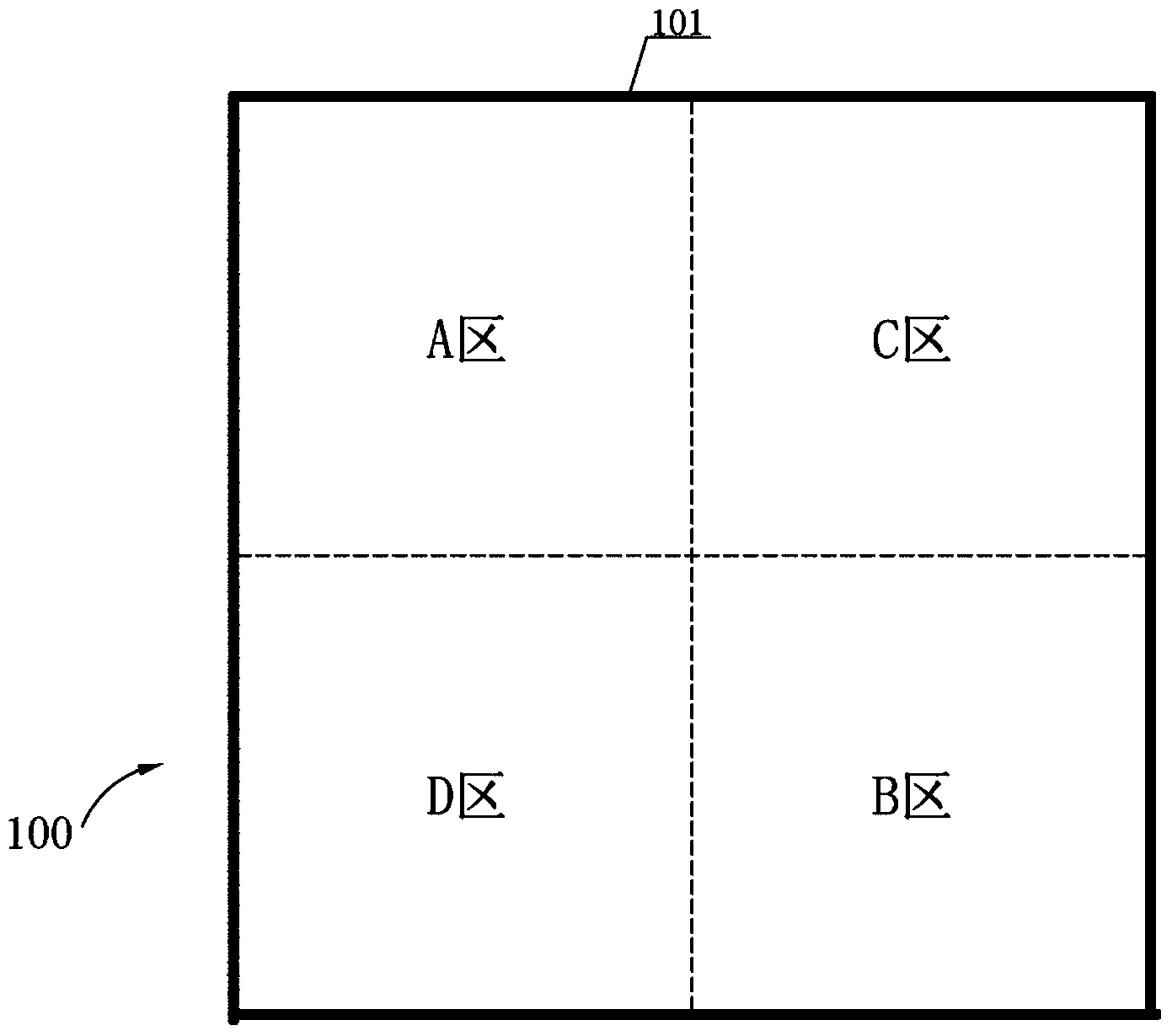

Construction method for large-area pit support structure in deep-sludge type soft soil area

InactiveCN104110038AReduce the long side effectControl deformationExcavationsBulkheads/pilesEnvironment effectSludge

The invention discloses a construction method for a large-area pit support structure in a deep-sludge type soft soil area and relates to the technical field of geotechnical engineering. The construction method solves the problems that for a soil layer with distribution of deep sludge and a construction site large in area and small in dredging depth, an existing pit support structure construction method is large in influence to surrounding environments, high in engineering cost and long in construction period. The construction method includes: 1, separating an area within a foundation pit excavation sideline into at least four subareas; 2, constructing piles along the excavation sideline by a construction method and fixing concrete ring beams on the piles; 3, constructing within one subarea and laying light well point pipes before earth excavation; 4, excavating earth in the current subarea, pouring a baseplate and brackets and erecting steel tube diagonal bracings on the brackets; 5, removing the steel tube diagonal bracings in the construction subarea after construction meets requirements, pulling out H-shaped steels, and circularly applying the steel tube diagonal bracings and the H-shaped steels to construction for the next subarea; 6, repeating the steps from step 3 to step 5 until constructions for all the subareas are completely sequentially, and thereby finishing the construction for the integral foundation pit support structure.

Owner:上海市建工设计研究总院有限公司

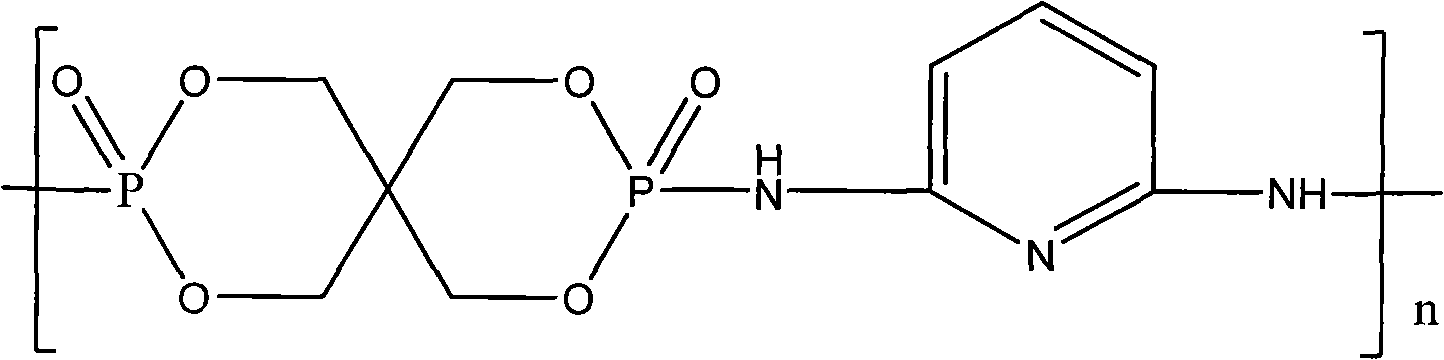

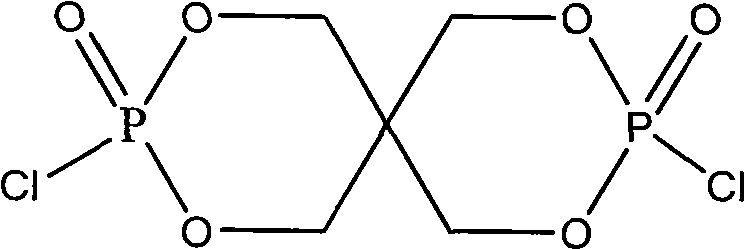

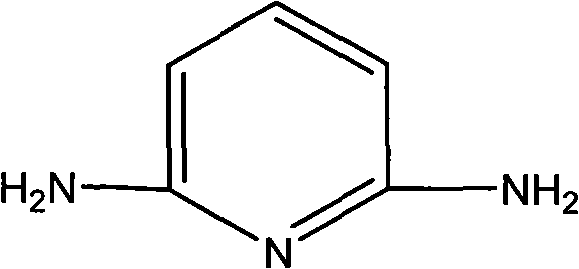

Macromolecular intumescent flame retardant with phosphorus and nitrogen and synthesis method thereof

The invention discloses a macromolecular intumescent flame retardant with phosphorus and nitrogen and a synthesis method thereof. The synthesis method comprises the following steps: using acetonitrile as solvent and 3,9-dichloro-2,4,8,10-tetraoxa-3,9-diphosphaspiro-3,9-dioxa[5.5]undecane and 2,6-diaminopyridine as raw materials to react under the action of catalyst, and purifying the product to obtain poly(3,9-dichloro-2,4,8,10-tetraoxa-3,9-diphosphaspiro-3,9-dioxa[5.5]undecane)-2,6-diaminopyridine. The method of the invention is simple and is easy to control; the synthetized macromolecular intumescent flame retardant with phosphorus and nitrogen has better compatibility with the matrix and higher char forming characteristic; by adopting the method, the problem of migration, precipitationor volatilization in the machinings of the flame retardant and the polymer matrix can be solved basically; and the flame retardant does not contain halogen, thus the flame retardant is environmentally friendly and has good application prospect.

Owner:ANHUI ZHONGDING SEALING PARTS

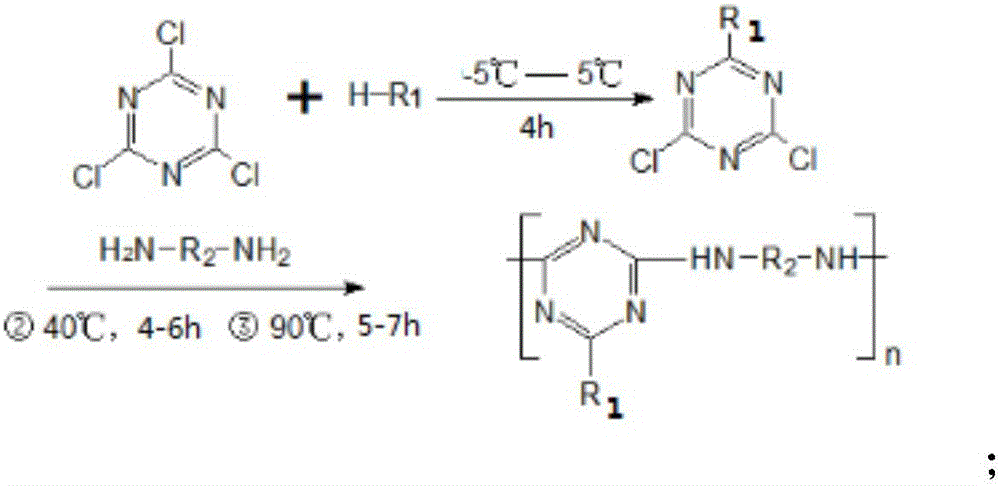

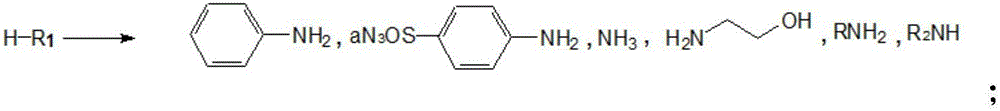

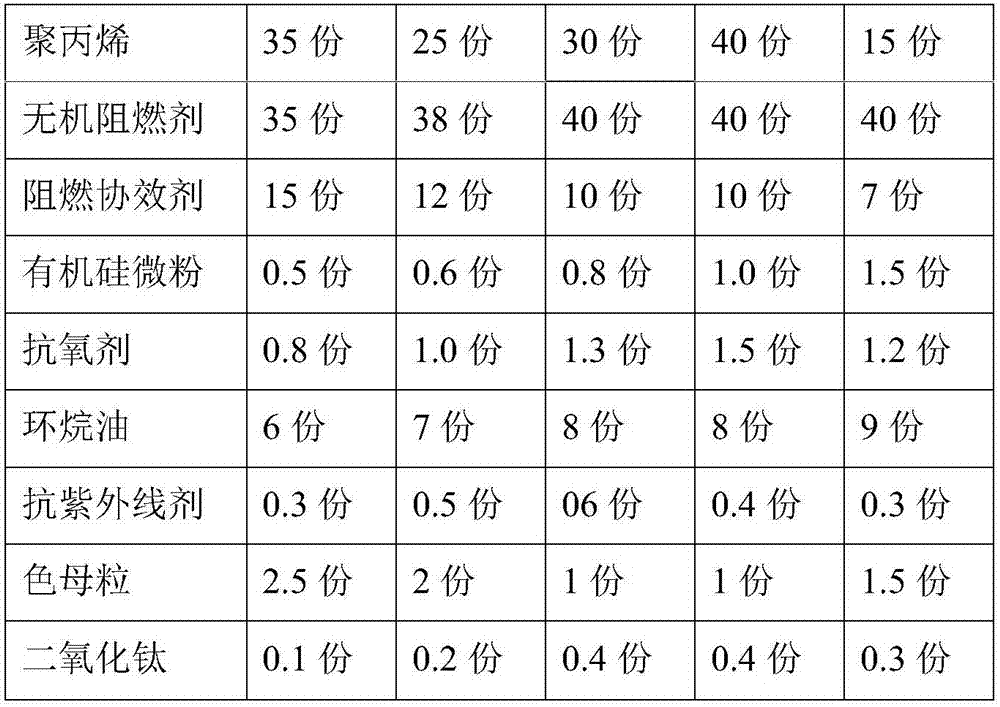

Preparation methods of amino triazine derivative macromolecular char forming agent and polypropylene flame retardant

InactiveCN105968352AGood compatibilitySolve the precipitation problemRoom temperatureTriazine derivative

The invention relates to preparation methods for an amino triazine derivative macromolecular char forming agent and a polypropylene flame retardant. Cyanuric chloride and a solvent are added into a reaction kettle, and alkylamine-containing mixed amine and an acid-binding agent are added dropwise to generate a unitary substituendum; diamine and the acid-binding agent are added dropwise at room temperature to generate a binary substituendum; the amino triazine derivative macromolecular char forming agent is obtained by subsequent treatment, the flame retardant is prepared from the char forming agent, and the flame retardant is high in compatibility in a PP (propene polymer). The preparation methods have the advantages that hydramine is replaced or partially replaced with alkylamine, so that the compatibility of the triazine char forming agent and the PP is improved, and the problem of difficult separation of the triazine char forming agent is solved; with adoption of the non-acetone solvent, the problem of discoloration of the triazine carbonizing agent is solved; the amino triazine derivative macromolecular char forming agent and the polypropylene flame retardant are widely applied to the flame-retardant fields of automobiles, household appliances, building materials and the like.

Owner:GUANGZHOU UNIVERSITY +1

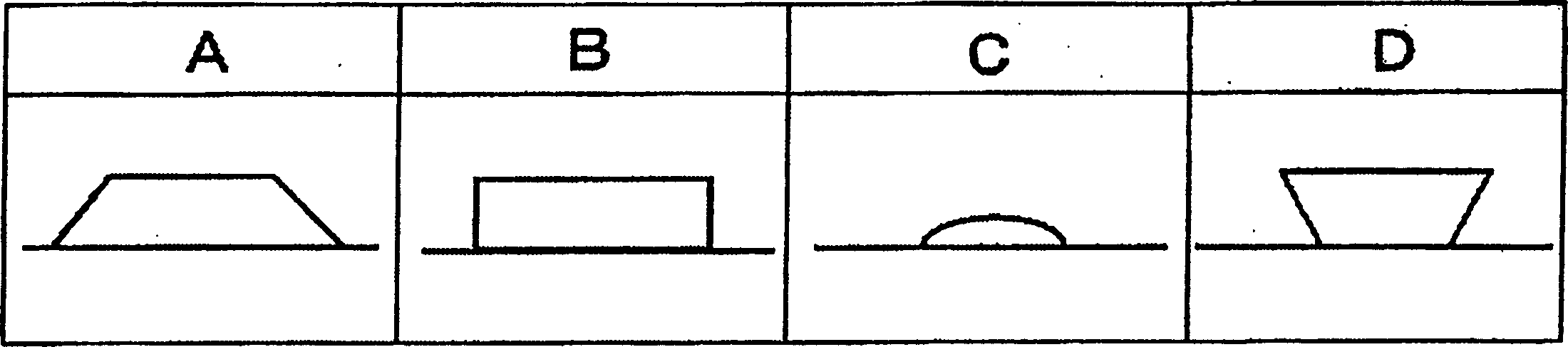

Radiation sensitive resin composition, gap, its forming method and LCD element

InactiveCN1696827AImprove adhesionHigh strengthSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEpoxyLiquid-crystal display

The present invention provided a radiation sensitive resin composition which has high sensitivity, can faithfully reproduce the design size of a mask pattern, is superior in adhesion to a substrate, makes it possible to obtain a satisfactory spacer shape and thickness with an exposure energy of <=1,500 J / m2, solves the problem of deposition of a photopolymerization initiator in a developing solution, and can form spacers for a liquid crystal display element which is superior also in strength and heat resistance. The radiation sensitive resin composition contains (A) a copolymer of (a1) an ethylenically unsaturated carboxylic acid and / or an ethylenically unsaturated carboxylic acid anhydride, (a2) an epoxy-containing ethylenically unsaturated compound and (a3) another ethylenically unsaturated compound, (B) a polymerizable compound having an ethylenically unsaturated bond and (C) a photopolymerization initiator, wherein the content of the photopolymerization initiator (C) is 0.1-5 pts.wt., with respect to 100 pts.wt. of the polymerizable compound (B).

Owner:JSR CORPORATIOON

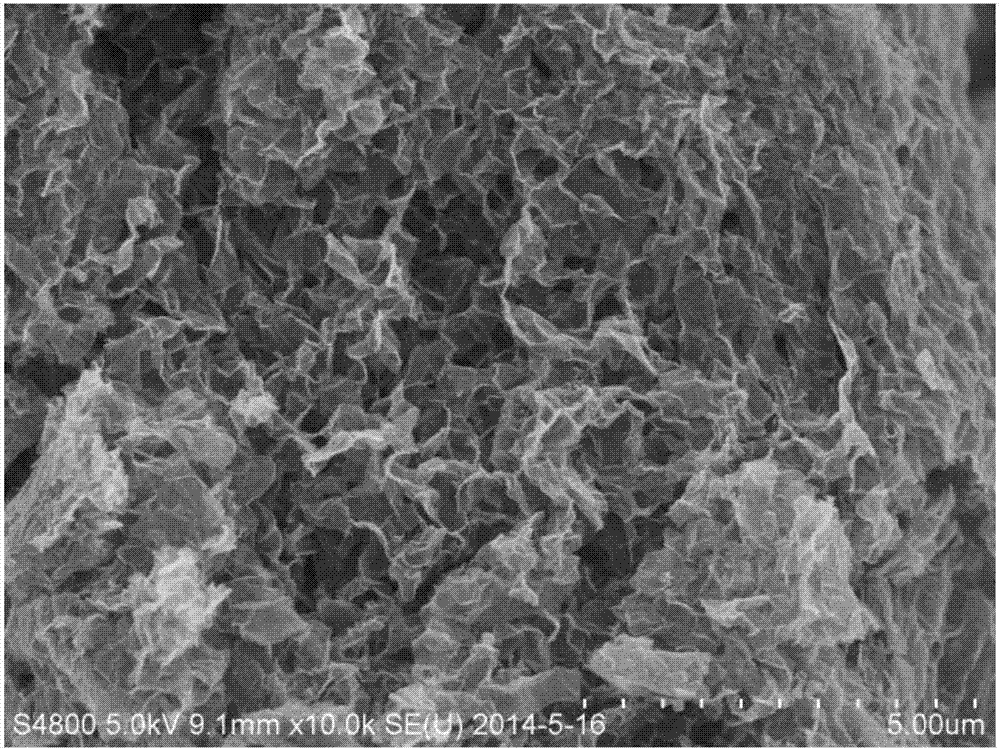

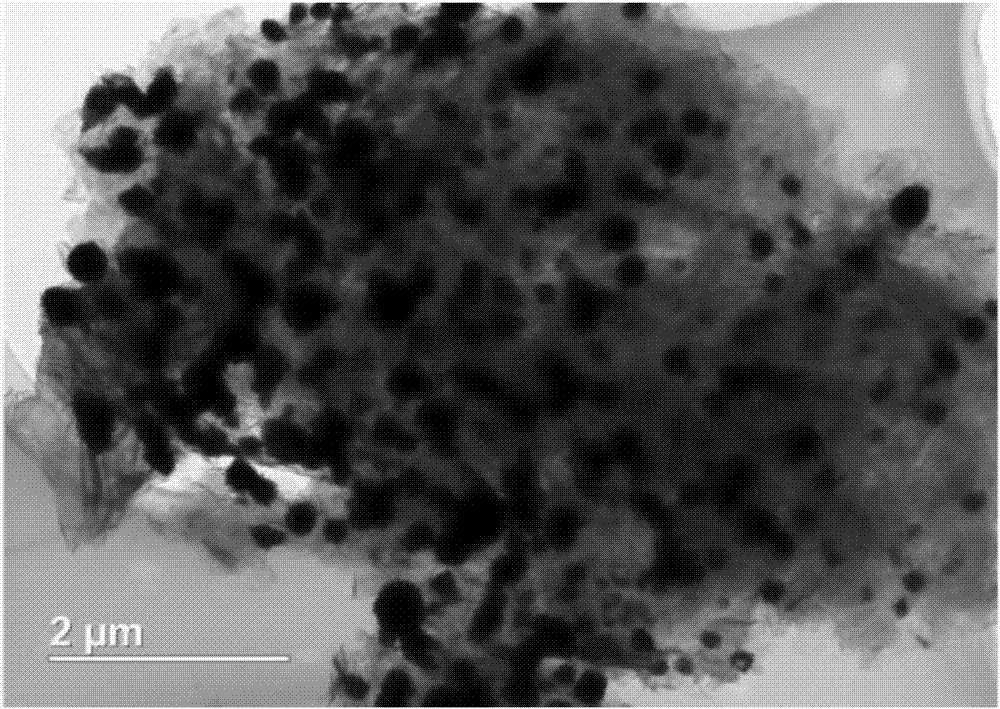

Lead-carbon super battery anode material and preparation method thereof

The invention provides a lead-carbon super battery anode material which is a graphene / Pb nano composite material. The lead-carbon super battery anode material is prepared by mixing a lead salt solution with a graphite oxide solution, carrying out hydrothermal reaction, and then carrying out macro body freeze drying and burning. The lead-carbon super battery anode material is prepared from 91 to 99.5 percent of lead and 0.5 to 9 percent of graphene. The lead salt solution is prepared by dissolving soluble lead salt into deionized water; the soluble lead salt is one or several of lead-containing nitrate, acetate, carbonate, hydrochloride, sulfate and complex salt. The invention further provides a preparation method of the lead-carbon super battery anode material. The preparation method provided by the invention has the advantages of high efficiency, environmental friendliness, high uniformity and the like; the prepared lead-carbon super battery anode material is high in uniformity, high in stability and wide in application prospect.

Owner:江苏强劲新能源科技有限公司

Slurrying method for fructus cannabis protein slurry

ActiveCN103445259AMeticulous and rigorous craftsmanshipSolve the precipitation problemFood scienceCannabisFlavor

The invention belongs to the technical field of beverages, and in particular relates to a slurrying method for fructus cannabis protein slurry. The slurrying method comprises specific slurrying technical steps of poaching, pulping or grinding to produce slurry, filtering and separating slurry residues and the like, particularly, adding the filtered residues into low-temperature alpha-amylase for enzymolysis, carrying out enzymolysis on a large quantity of starch in filtered residues to produce enzymatic hydrolysate containing maltose, glucose and fructus cannabis flavor substances, and mixing the enzymatic hydrolysate with fructus cannabis protein liquor so as to prepare the fructus cannabis albumen slurry. Resources are effectively and fully used; the problem of precipitates in the beverage caused by the starch is solved. According to the slurrying method provided by the invention, the defect of precipitation in a production technology for the fructus cannabis protein beverage can be solved, and various types of protein beverages can prepared by the fructus cannabis albumen slurry obtained by the slurrying method. The fructus cannabis protein slurry is milky-white, smooth, sweet, soft and rich in nutrition.

Owner:东台海滨科技创业园管理有限公司

Kitchen wet tissue complex formulation liquid and preparation method thereof

ActiveCN104059786AEasy to cleanNo smellOrganic detergent compounding agentsNon-ionic surface-active compoundsCarbamateNon ionic

The invention discloses a kitchen wet tissue complex formulation liquid and a preparation method thereof. The wet tissue complex formulation liquid comprises the following substances by weight percentage: 30-60% of environmental protection solvent, 2-4% of nonionic surfactant, 3-8% of anionic surfactant, 0.5-2% of organosilicon antifoaming agent, 0.5-2% of protection film, 0.05-0.1% of iodine propiolic n-butyl carbamate, 0.05-1% of diazolidinyl urea, 0.05-1% of 1,3 dihydroxytoluene-5,5-dimethyl hydantoin and the balance of RO water. The invention also provides a preparation method of the kitchen wet tissue complex formulation liquid. The kitchen wet tissue complex formulation liquid has the advantages of environmental protection, easy biodegradation, strong cleaning capability, no peculiar smell, little foam, no stimulation and no sticky hand feeling, a protection layer is formed on a hard surface, the kitchen wet tissue complex formulation liquid has antifouling characteristic and is convenient for cleaning at next time.

Owner:XIAMEN GOLDEN BIOTECH

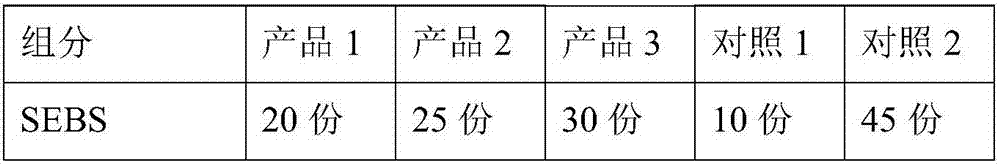

Environment-friendly TPE material for new energy electric vehicle charging pile cable and preparation method of environment-friendly TPE material

InactiveCN106867104AIncrease heat aging lifeGood physical and mechanical propertiesPlastic/resin/waxes insulatorsPolypropyleneSurface finishing

The invention discloses an environment-friendly TPE material for a new energy electric vehicle charging pile cable and a preparation method thereof. The TPE material is prepared from the following components in parts by mass: 25-40 parts of SEBS, 20-30 parts of polypropylene, 35-45 parts of inorganic matter fire retardant, 5-15 parts of fire retardant synergist, 0.6-1.5 parts of organosilicon micro powder, 0.5-1.5 parts of antioxidant, 6-10 parts of naphthenic oil, 0.6-1.6 parts of anti-ultraviolet agent, 1-3 parts of color master batch and 0.1-0.5 part of processing aid, wherein the inorganic fire retardant needs to be firstly treated by a surface treating agent accounting for 1-2% in part by mass. The preparation method of the cable material comprises the process steps of surface treatment on the inorganic matter fire retardant, cold oil charge on the SEBS, automatic burdening, mixing, fusion, extrusion, pelleting and the like. Compared with the prior art, the TPE material disclosed by the invention has the following characteristics: excellent flame retardation, fatigue durability, artificial weather ageing resistance, ultraviolet resistance and processing property; the extrusion speed can achieve 150-200m / min, the precipitation is avoided, the density is low, the TPE material can be repeatedly processed and used, is environment-friendly and excellent in economy.

Owner:YANGZHOU HAONIANHUA POLYMER MATERIALS CO LTD

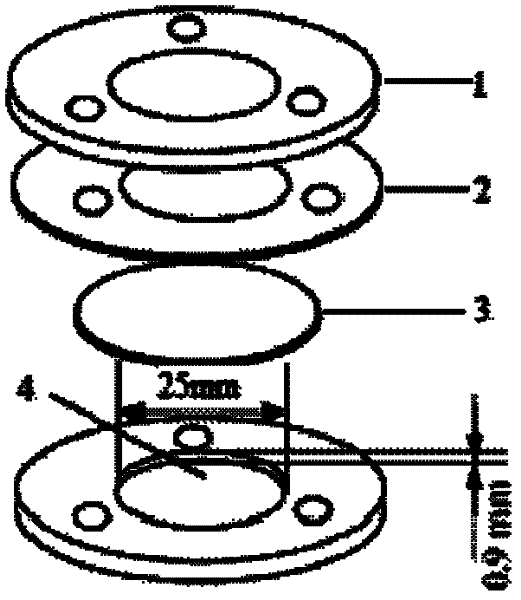

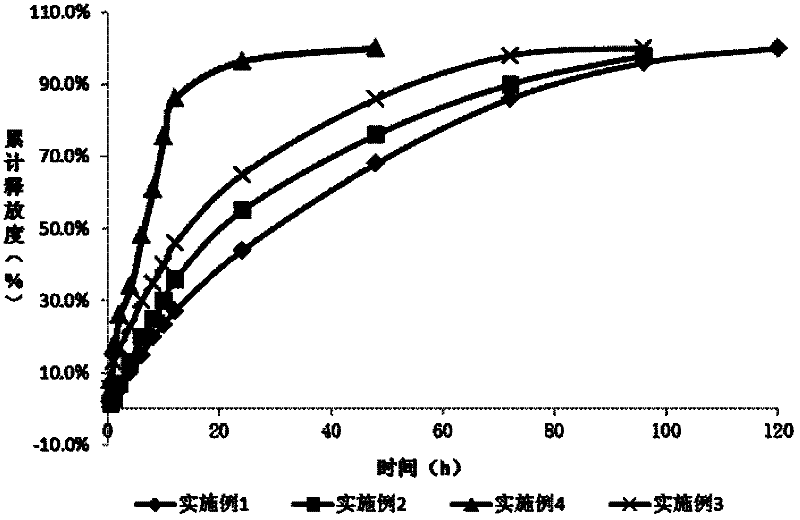

Pharmaceutical composition for treating periodontitis, and preparation method and application thereof

ActiveCN102240277ASpecial physical propertiesSensitive to temperatureOrganic active ingredientsAerosol deliveryControlled releaseLiquid state

The invention relates to a pharmaceutical composition for treating periodontitis and a preparation method thereof, wherein the pharmaceutical composition comprises chlorhexidine or derivatives thereof, poloxamer 407, a release speed adjusting agent, a stabilizer and other additives. The pharmaceutical composition has particular physical characteristics; when the temperature reaches the gel point, the composition can undergo phase transition from liquid to semisolid gel; the composition is liquid at the room temperature; after being used, the composition changes into semisolid gel quickly under the human body temperature condition and then is adhered on the surface of periodontal mucosa to release the medicine, thus a therapeutic effect is obtained; the composition has specific controlled-release property, and can achieve a controlled-release effect of 4 to 5 days of sustained medicine release by adjusting types and dosages of the release speed adjusting agents, thereby reducing the medicine using times, and improving the medication compliance of patients; and the composition is good in stability, and convenient to produce, transport and store.

Owner:SHENZHEN SOUTH CHINA PHARMA

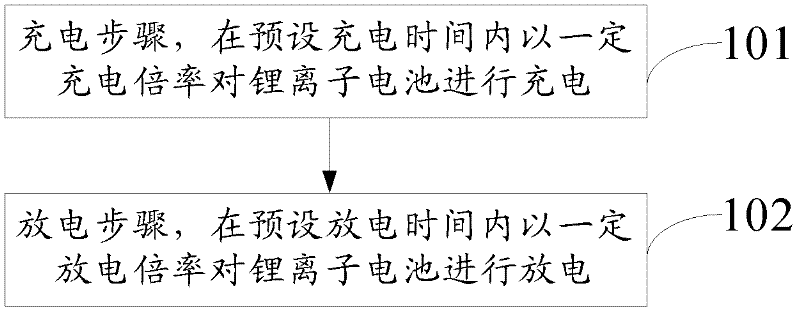

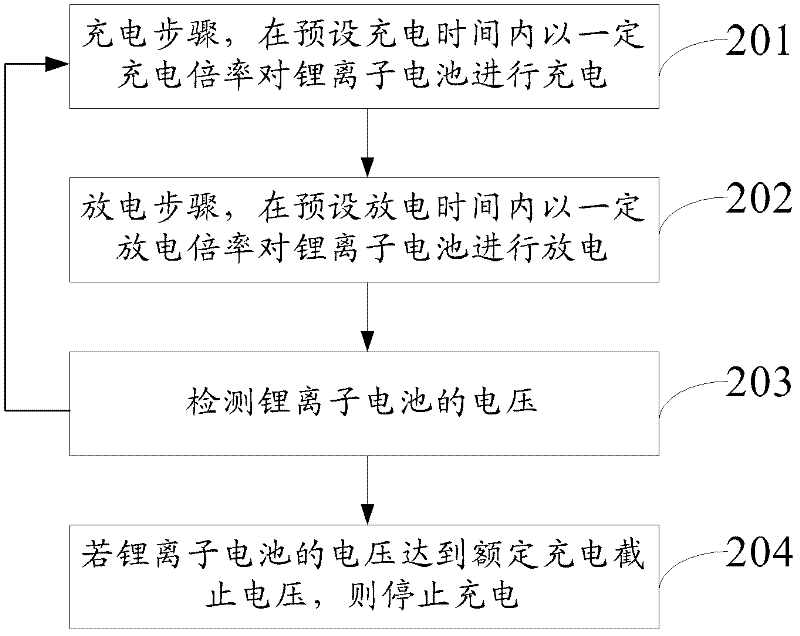

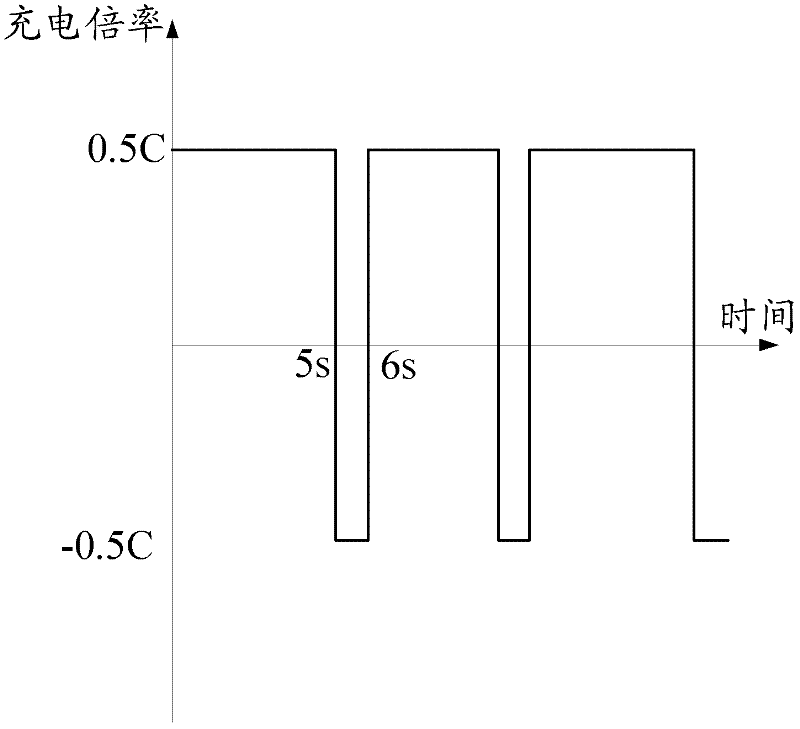

Charging method for lithium ion battery, and charger

InactiveCN102569927AImprove securityExtended service lifeBatteries circuit arrangementsSecondary cells charging/dischargingLithium electrodeBattery charge

The embodiment of the invention provides a charging method for a lithium ion battery, and a charger, and relates to a battery charging technology. The problem that lithium dendritic crystal is precipitated can be solved, so that the safety of the battery is improved, and the service life of the battery is prolonged. The charging method comprises the following steps of: charging, namely charging the lithium ion battery within a preset charging time period at a certain charging rate; discharging, namely discharging the lithium ion battery within a preset discharging time period at a certain charging rate; and circulating the charging step and the discharging step. The embodiment of the invention is applied to charging of the lithium ion battery.

Owner:HUAWEI TECH CO LTD

Preparation method of environment-friendly high-stripping polyurethane/foam compositetype football leather

The invention discloses a preparation method of environment-friendly high-stripping polyurethane / foam compositetype football leather. The preparation method comprises the following steps: firstly scrape coating a piece of releasetype paper with waterborne polyurethane surface layer slurry, drying, and obtaining a polyurethane synthetic leather surface layer; then scrapeblade coating the surface layer with closed aliphatic polyurethane intermediate layer slurry, drying, and obtaining a polyurethane synthetic leather intermediate layer; and pouring smearing solvent-free two-component polyurethane adhesive layer resin onto the surface of the intermediate layer, drying until a semi-dry state, laminating a foam elastic basic material, then continuing the reaction, finally stripping the synthetic leather and the release type paper, and obtaining the football leather. When the football leather is produced and processed, the football leather can be formed in one step, a leather sample does notneed to be cured with the release type paper, and the production efficiency is high; and a stripping strength of the football leather product is high (greater than or equal to 12N / 3cm, 150mm / min), the pattern shape is good, and the beating resistance is excellent (greater than 6000 times, GB / T 22892-2008).

Owner:ANHUI ANLI MATERIAL TECH

Flame-retardant ageing-resistant sealing ring rubber material

The invention discloses a flame-retardant ageing-resistant sealing ring rubber material which comprises the following raw materials in parts by weight: 80-100 parts of natural rubber, 20-40 parts of butadiene styrene rubber, 10-30 parts of ethylene propylene diene monomer, 10-30 parts of a phosphate modified polyurethane elastomer, 2-4 parts of dicumyl peroxide, 0.5-1 part of sulfur, 1-3 parts of an accelerant DM, 2-4 parts of an accelerant TAIC, 3-8 parts of zinc oxide, 1-3 parts of stearic acid, 6-10 parts of carbon black N660, 5-10 parts of titanium dioxide, 2-5 parts of quartz powder, 10-18 parts of calcite in powder, 6-15 parts of opal powder, 1-4 parts of a silane coupling agent, 2-8 parts of zinc borate, 1-4 parts of melamine, 1-2 parts of an anti-aging agent 4010NA, 2-4 parts of an anti-aging agent MB and 1-3 parts of an anti-aging agent AW. The rubber material disclosed by the invention has good flame-retardant property, ageing resistance and excellent weather resistance.

Owner:天长市康宁甘油科技有限公司

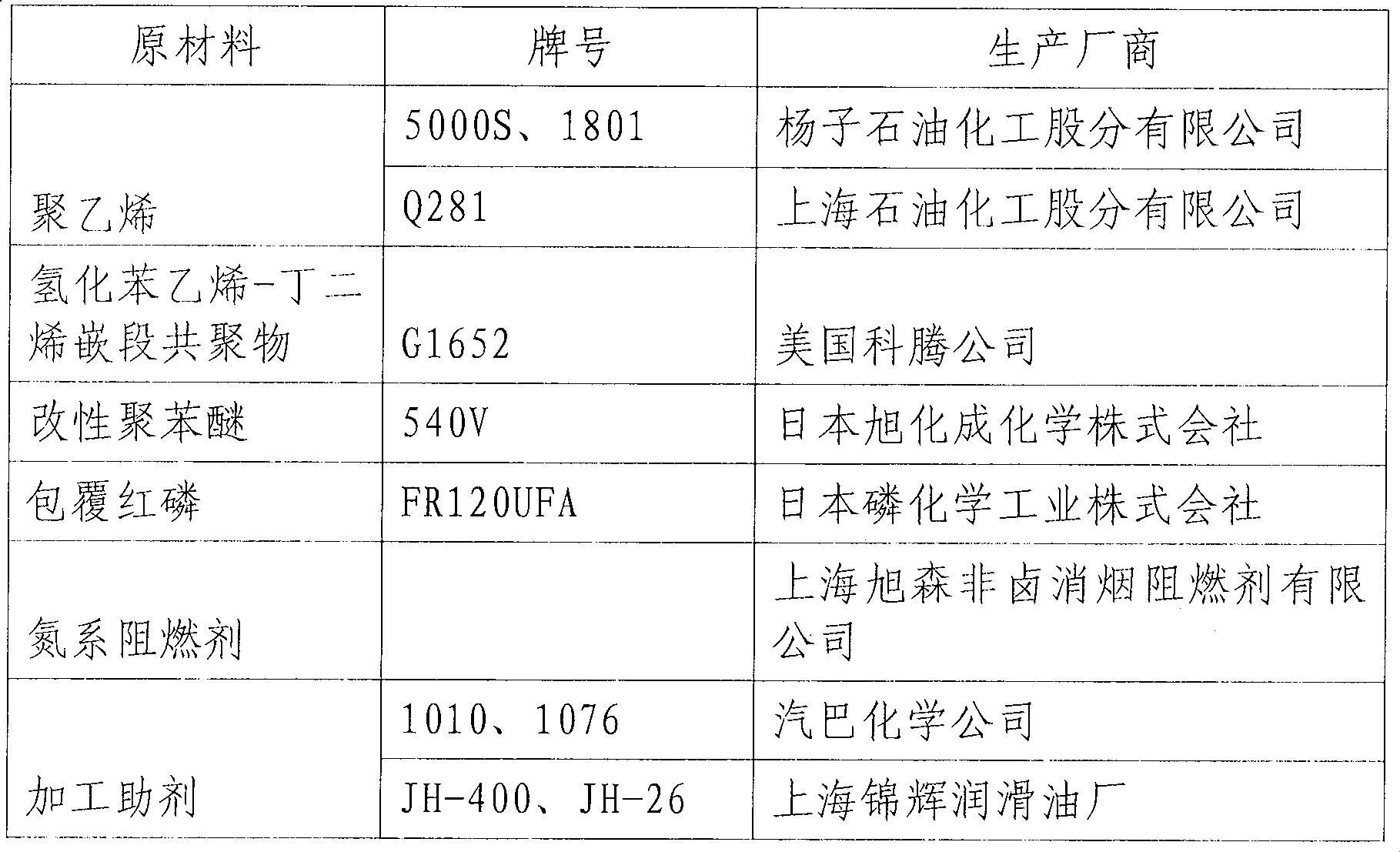

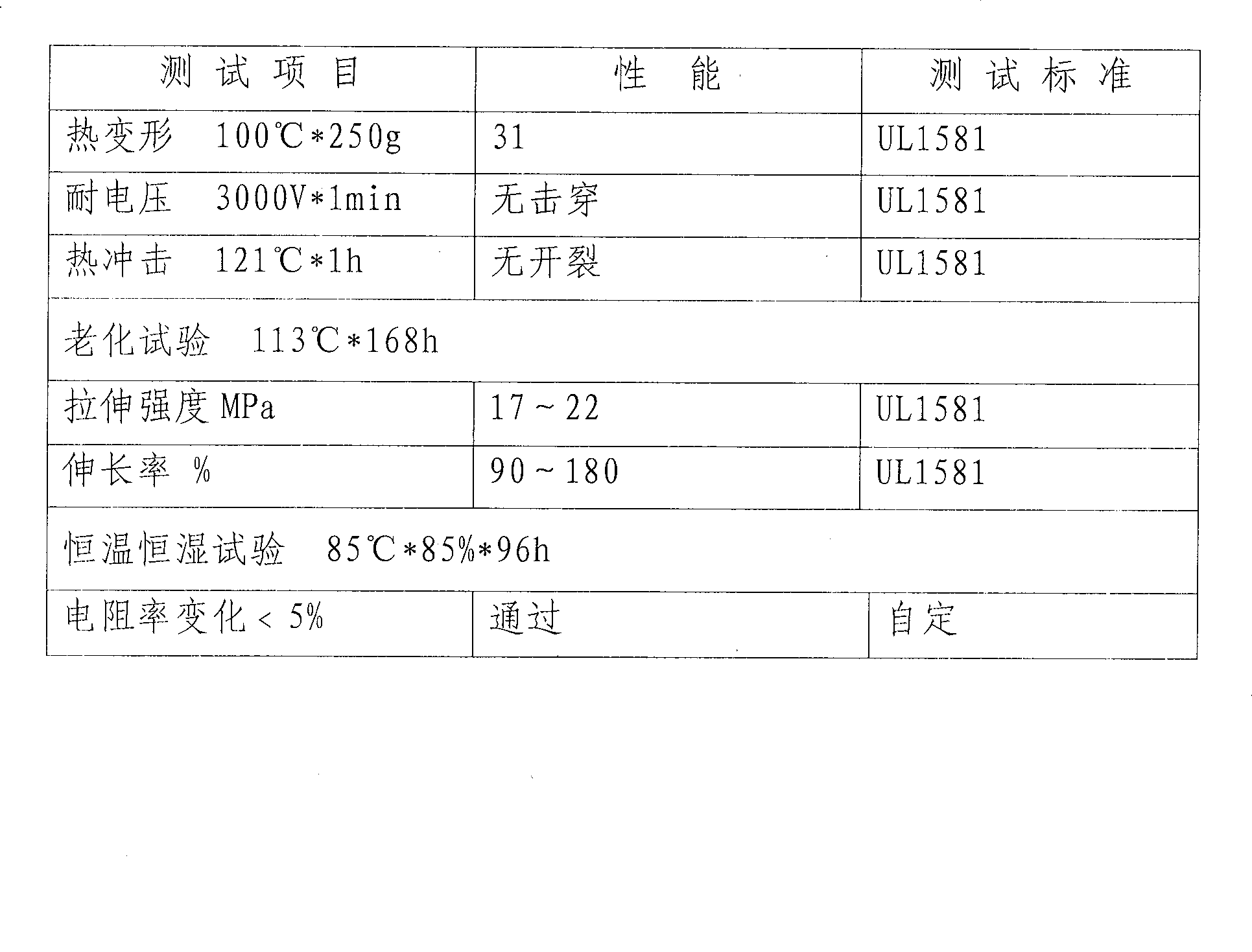

Halogen-free flame-proof resin composition and preparation method thereof

ActiveCN100509938CImprove liquidityImprove wear resistanceInsulated cablesInsulated conductorsProcedure AgentsPolymer science

The invention discloses a halogen-free flame-retardant resin composition, including polyethylene (PE), modified polyphenylene oxide (MPPO), hydrogenated styrene-butadiene block copolymer (SEBS) and a halogen-free flame retardant , a mixture of non-halogenated red phosphorus, nitrogen-based flame retardants and processing aids. During preparation, the mixture of polyethylene, modified polyphenylene ether, hydrogenated styrene-butadiene block copolymer, microencapsulated coated red phosphorus and nitrogen-based flame retardant is put into a high-speed mixer by weight %, dispersed and mixed Finally, it is melted, extruded, cooled, pelletized, dried and packaged by a twin-screw extruder. The mixture of the invention is suitable for the production of various soft and semi-hard products, such as: coverings for electric wires and cables, injection molded plugs for power cords, etc. The processing flow of the invention is simple and continuous, the production efficiency is high, the cost is low, and the product quality is stable. The product made by the composition of the invention has beautiful appearance, smooth surface and no precipitates.

Owner:WEIFANG QIANYUAN PLASTIC

Flame-retardant thermoplastic rubber material for wires and cables and preparation method thereof

The invention discloses a flame-retardant thermoplastic rubber material for wires and cables. The flame-retardant thermoplastic rubber material is prepared from the following raw materials in parts by weight: 10-300 parts of EPDM (Ethylene Propylene Diene Methylene), 40-160 parts of polypropylene, 30-100 parts of thermoplastic polyurethane elastomer, 5-15 parts of compatibilizer, 15-40 parts of organophosphorus ester, 5-10 parts of trimethyl phosphate, 5-20 parts of polyphenyl ether, 10-60 parts of inorganic filler, 3-6 parts of silane coupling agent, 0.2-10 parts of crosslinking agent, 1-5 parts of active zinc-oxide powder, 1-3 parts of antioxidant, 1-3 parts of ultraviolet absorbent, 20-100 parts of processing oil and 2-6 parts of lubricant. The preparation method of the organophosphorus ester comprises the following steps of: obtaining propenyl dimethyl phosphate after reaction of phosphorus oxychloride, allyl alcohol and methyl alcohol, carrying out olefin polymerization on the propenyl dimethyl phosphate, and obtaining the organophosphorus ester. The flame-retardant thermoplastic rubber material disclosed by the invention has the advantages of excellent flame retardance, high-temperature resistance and flexibility.

Owner:天长市康宁甘油科技有限公司

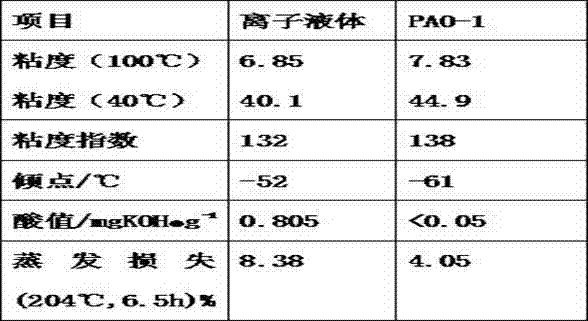

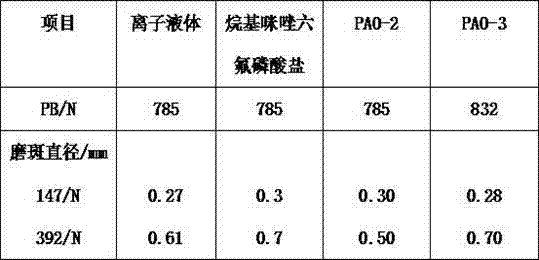

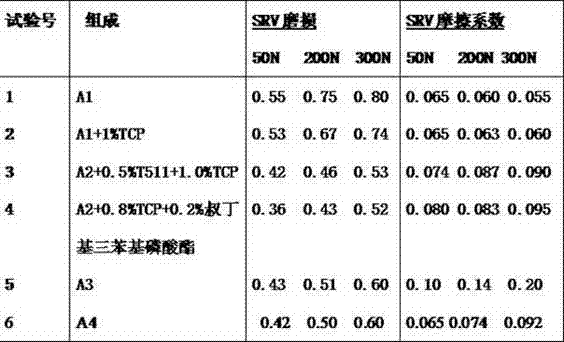

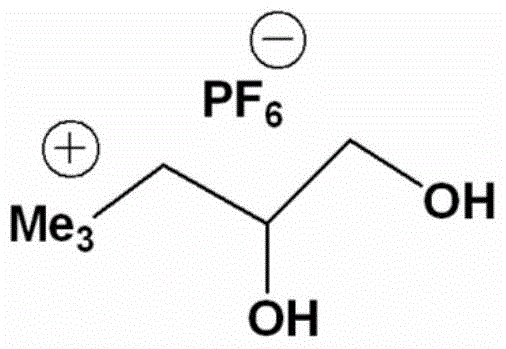

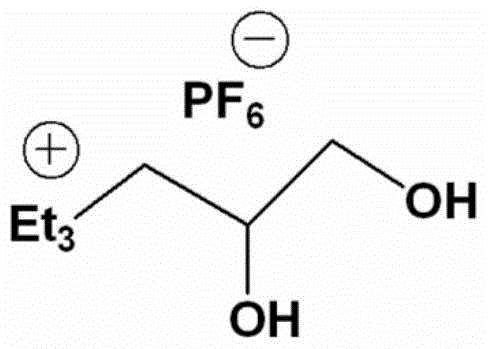

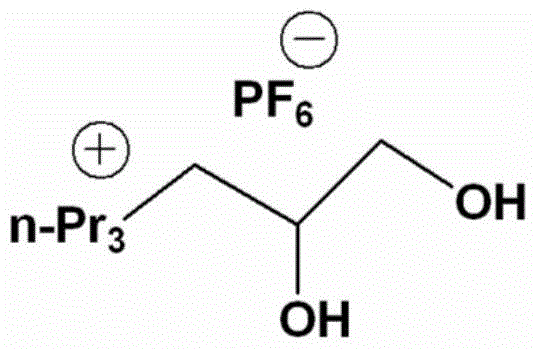

Cis-12 hydroxy octadecenoic acid-3-methyl-imidazole hexafluorophosphate ionic liquid and four-stroke engine lubricating oil composition containing same

ActiveCN102775352AReduce volatilityHigh viscosityOrganic chemistryAdditivesFour-stroke engineOil production

The invention discloses cis-12 hydroxy octadecenoic acid-3-methyl-imidazole hexafluorophosphate ionic liquid and a four-stroke engine lubricating oil composition containing the same, and belongs to the field of lubricating oil production. The lubricating oil composition is mainly mixed by the following raw materials according to the weight ratio: lubricating oil base oil, cis-12 hydroxy octadecenoic acid-3-methyl-imidazole hexafluorophosphate, a viscosity index improver, a dispersing agent, a clearing agent, an oxidation and corrosion inhibitor, a base number reserving agent and an antifoaming agent. Compared with the prior art, the cis-12 hydroxy octadecenoic acid-3-methyl-imidazole hexafluorophosphate ionic liquid solves the problem that various annexing agents are easy to separate out when lubricating oil is placed for a long time, has the characteristics of good usability, environmental protection, energy saving and the like, and has a good application and dissemination valve, and abrasion of an engine can be obviously reduced.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

A method for preparing transparent, antifreeze and flame retardant polyvinyl alcohol film

ActiveCN103709567BReduce hydrogen bondingEnables thermoplastic processingCoatingsBlow moldingPolymer science

The invention discloses a method for preparing a transparent, antifreezing and flame retardant polyvinyl alcohol film. The method comprises the following steps: physically mixing polyvinyl alcohol powder with a modification additive containing an ionic liquid uniformly according to a weight ratio of (70 / 30)-(90 / 10); injecting the mixture into a twin-screw extruder with a heating device, then carrying out melt extrusion on the mixture at 160-180 DEG C and enabling the melt time of the mixture in the twin-screw extruder to be 8-12 minutes by adjusting the screw speed; cooling and granulating the extruded melt in the air; and injecting the obtained granules into a single-screw extruder with a heating device to form the film by blow molding, curtain coating or calendering at 180-200 DEG C. The ionic liquid adopted in the method carries out hydrogen bond complexing with polyvinyl alcohol in the thermoplastic processing course, so that the prepared polyvinyl alcohol film has high transparency, antifreezing property and flame retardance and has application advantages in the fields of packaging, building materials and the like.

Owner:YONGAN SYF WATER SOLUBLE FILMS

Cymene water-based formula and application thereof in external skin preparation

InactiveCN107280987AImprove stabilityAvoid low temperature crystal precipitationAntibacterial agentsCosmetic preparationsSolventDrugs preparations

The invention discloses a cymene water-based formula which is prepared from the following raw materials in parts by weight: 0.01-0.1 part of cymene, 1.5-20 parts of a wetting agent, 0-7.0 parts of ethanol and 0.01-1.0 part of a solubilizer. According to the formula, the problem that the cymene tends to be separated out in the formula system is solved. The formula can further serve as a component in a transparent external drug preparation or an external skin preparation and is high in stability.

Owner:SHANGHAI ZHONGYI DAILY CHEM CO LTD

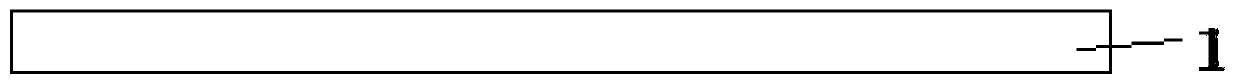

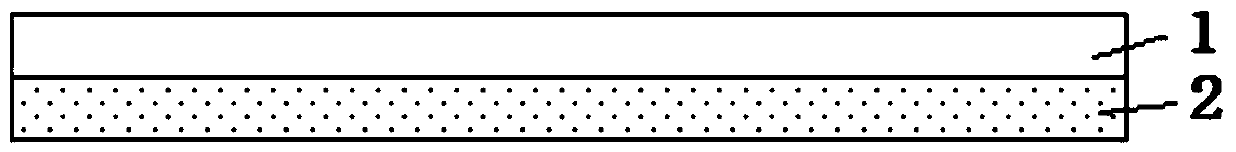

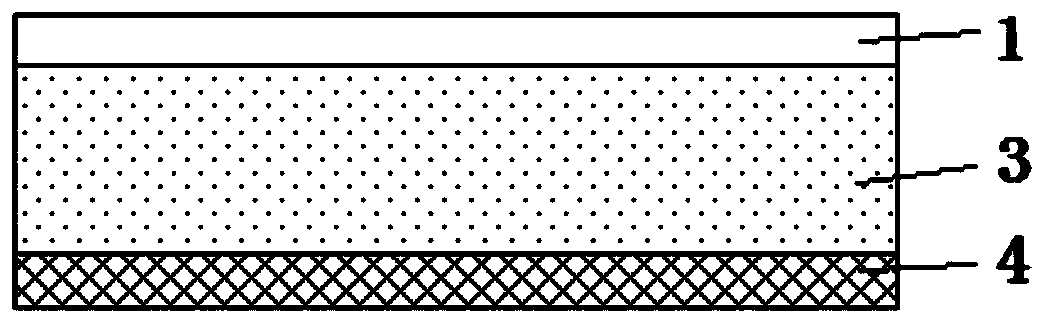

Polyolefin film for backboard of photovoltaic cell and preparation method thereof

InactiveCN109971061AImprove peel forceGood compatibilitySynthetic resin layered productsElectrical equipmentPolymer sciencePolyolefin

The invention provides a polyolefin film for the backboard of a photovoltaic cell and a preparation method thereof. The polyolefin film comprises an EVA coating lateral connection layer, which comprises following components in parts by weight: 20 to 40 parts of polypropylene, 50 to 60 parts of polyethylene, 1 to 10 parts of grafting modified polyolefin, 10 to 20 parts of titanium dioxide, 0.5 to 1.5 parts of a light stabilizer, and 0.1 to 1 part of an antioxidant. The preparation method is simple, and a prepared photovoltaic cell backboard has the advantages that the binding force between polyolefin film and EVA is good, the compatibility between a base material and an aid is improved, and the aid will not be precipitated out under hot and wet conditions.

Owner:CYBRID TECHNOLOGIES INC

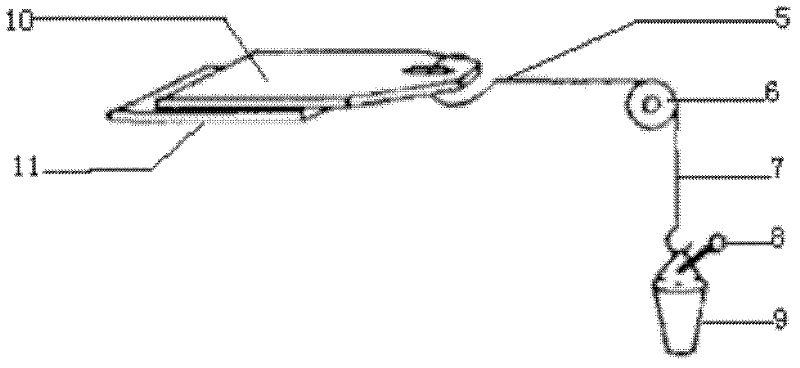

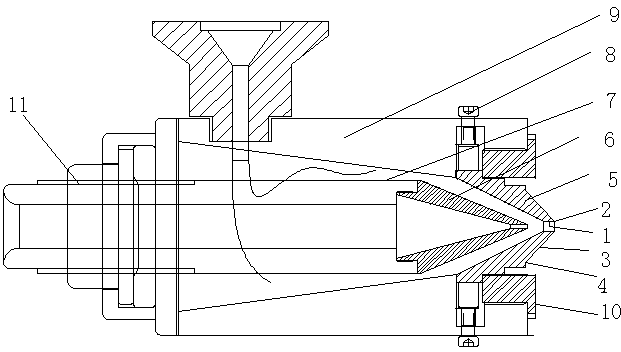

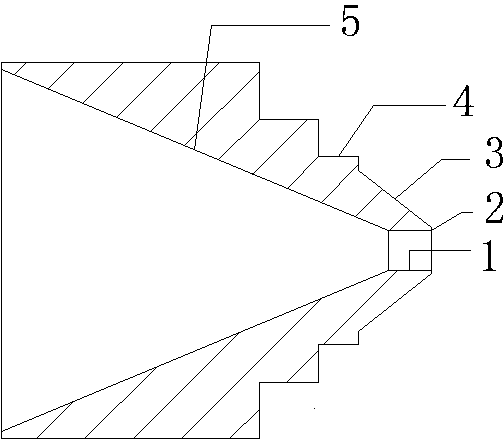

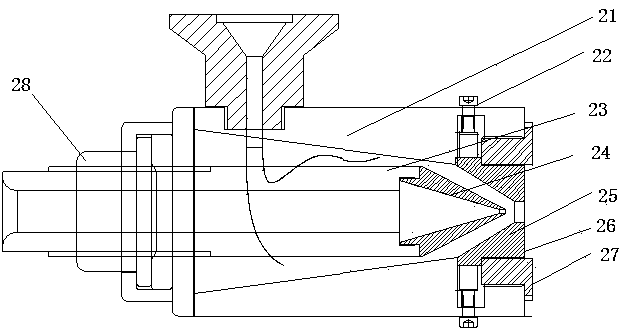

Novel mold structure for preventing materials from stacking at mold opening

The invention discloses a novel mold structure for preventing materials from stacking at a mold opening. The novel mold structure comprises a mold core and a mold sleeve, wherein the mold sleeve is fixed on a machine head by virtue of a mold sleeve cover, and the extrusion concentricity is adjusted by virtue of a mold sleeve alignment screw; the mold core is fixed on a mold core seat, and the relative position between the mold core and the mold sleeve is adjusted by virtue of a mold core seat bolt; the mold sleeve comprises a mold forming area, a mold sleeve opening chamfer, a mold sleeve tapered area, a mold sleeve step area and a mold deformation area; the mold sleeve tapered area and the mold sleeve step area are arranged on the outer side of the mold sleeve respectively; the tapered mold deformation area is arranged on the inner side of the mold sleeve; the mold sleeve tapered area is connected with the mold forming area in a circular arc transition manner by virtue of the mold sleeve opening chamfer. By virtue of the design of layering and tapering the front section of the mold sleeve, the problem of separation of the materials at the mold opening in the extrusion process in the current cable industry is well solved, the problems that the surface of a cable is poor and unqualified products and waste products are produced due to material separation are solved, the quality of products is guaranteed, the production efficiency is improved, and the cost is reduced.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

Method for preparing processinga id for rare earths of a sort of polyvinyl chloride

A process for preparing the stabilizer of PVC includes such steps as esterifying reaction between castor oil and maleic anhydride, dissolving lanthanum oxide in diluted hydrochloric acid, and dripping said esterified substance into said solution. It can improve the machinability and strength of PVC product.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

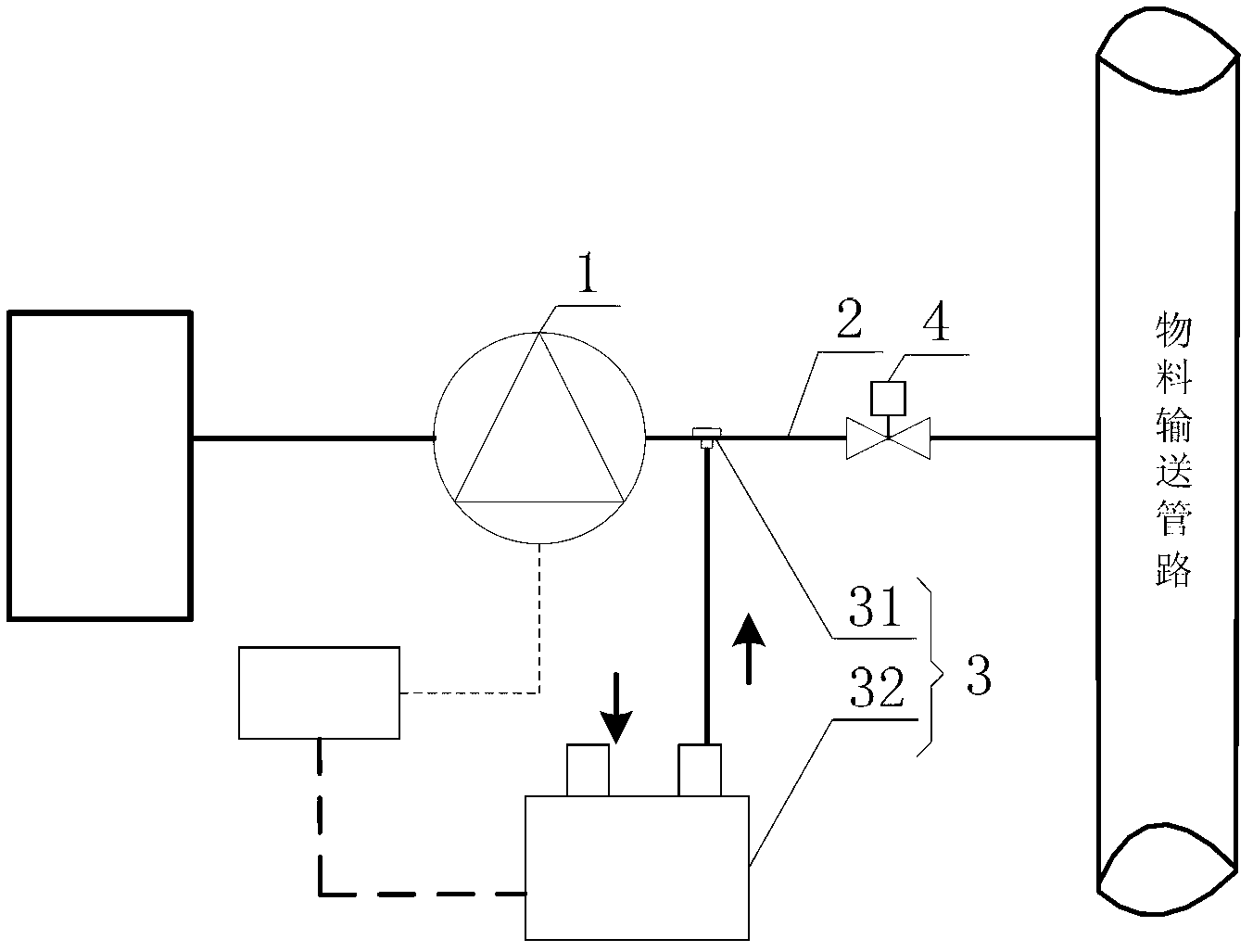

Sampling system for process analysis

InactiveCN102854038AAvoid cloggingSolve the blockageWithdrawing sample devicesCrystallizationChemical engineering

The invention discloses a sampling system for process analysis, comprising a sampling pump, and a sampling tube connected with the sampling pump, and further comprising a heating component capable of heating the sampling tube, and a cleaning component capable of performing air-sweeping cleanness on the sampling tube. The scheme for solving the problem of blockage of the sampling tube disclosed by the invention is as follows: 1, the heating component capable of heating the sampling tube is arranged on the sampling tube, so that the temperature of the sampling tube keeps in a range which is approximate to the temperature of a sample, thus solving the problem of crystallization of the sample; and 2, the cleaning component for performing air-sweeping cleanness on the sampling tube is additionally arranged, and used for performing pipeline cleanness on the sampling tube after sampling is concluded, thus avoiding the residue of the sample; and via the structure, the blockage of the sampling tube caused by the residue of the sample in the sampling tube is solved.

Owner:LIHE TECH (HUNAN) CO LTD

Wear-resistant flame-retardant damping gasket material

InactiveCN106750694AImprove flame retardant performanceIncrease elasticityChemistryDiphenyl phosphate

The invention discloses a wear-resistant flame-retardant damping gasket material which is prepared from epoxidized natural rubber, chloroprene rubber, polyisoprene rubber, a phosphate-modified polyurethane elastomer, stearic acid, zinc oxide, an accelerator TT, an accelerator CZ, sulfur, N,N'-m-phenylenedimaleimide, dicumyl peroxide, opal, nano titanium dioxide, nano silicon aluminum tubes, a silane coupling agent, zinc borate, diphenyl phosphate, melamine, an anti-aging agent, an anti-aging aid, glycidyl methacrylate and diglycol dibenzoate. The wear-resistant flame-retardant damping gasket material has the advantages of favorable wear resistance, favorable flame-retardant effect, excellent weather resistance, high radial tensile strength, moderate hardness, favorable elasticity, long service life and low cost.

Owner:天长市康宁甘油科技有限公司

Reinforced and scratch-resistant polypropylene material and preparation method thereof

The invention relates to a reinforced and scratch-resistant polypropylene material and a preparation method thereof, wherein the material is prepared from 70-95 parts of polypropylene, 30-5 parts of SiAlON, 0.1-0.5 part of a coupling agent, 0.1-1 part of a thermal stabilizer, 0-1 part of a lubricant, and 0-0.5 part of white oil, and the weight sum of the polypropylene and the SiAlON is 100 parts. According to the present invention, the one-dimensional beta-SiAlON adopted as the scratch-resistant agent is added to the polypropylene material so as to concurrently provide advantages of material scratch resistance enhancing and material strength increasing and overcome the disadvantage of the material scratch resistance reducing of the traditional reinforcing filling material; and the obtained reinforced and scratch-resistant polypropylene material is used in vehicle interior decoration materials, and does not have disadvantages of scratch-resistant agent precipitation, odor, appearance and the like compared to the traditional scratch-resistant agent adding material.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com