Halogen-free flame-proof resin composition and preparation method thereof

A technology of flame retardant resin and composition, applied in the field of polymer composition, can solve the problem of product smoothness, water absorption rate is not satisfactory, flame retardant affects the use and appearance of products, phosphate ester flame retardant has low phosphorus content and other problems, to achieve the effect of good chemical stability, beautiful appearance and smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

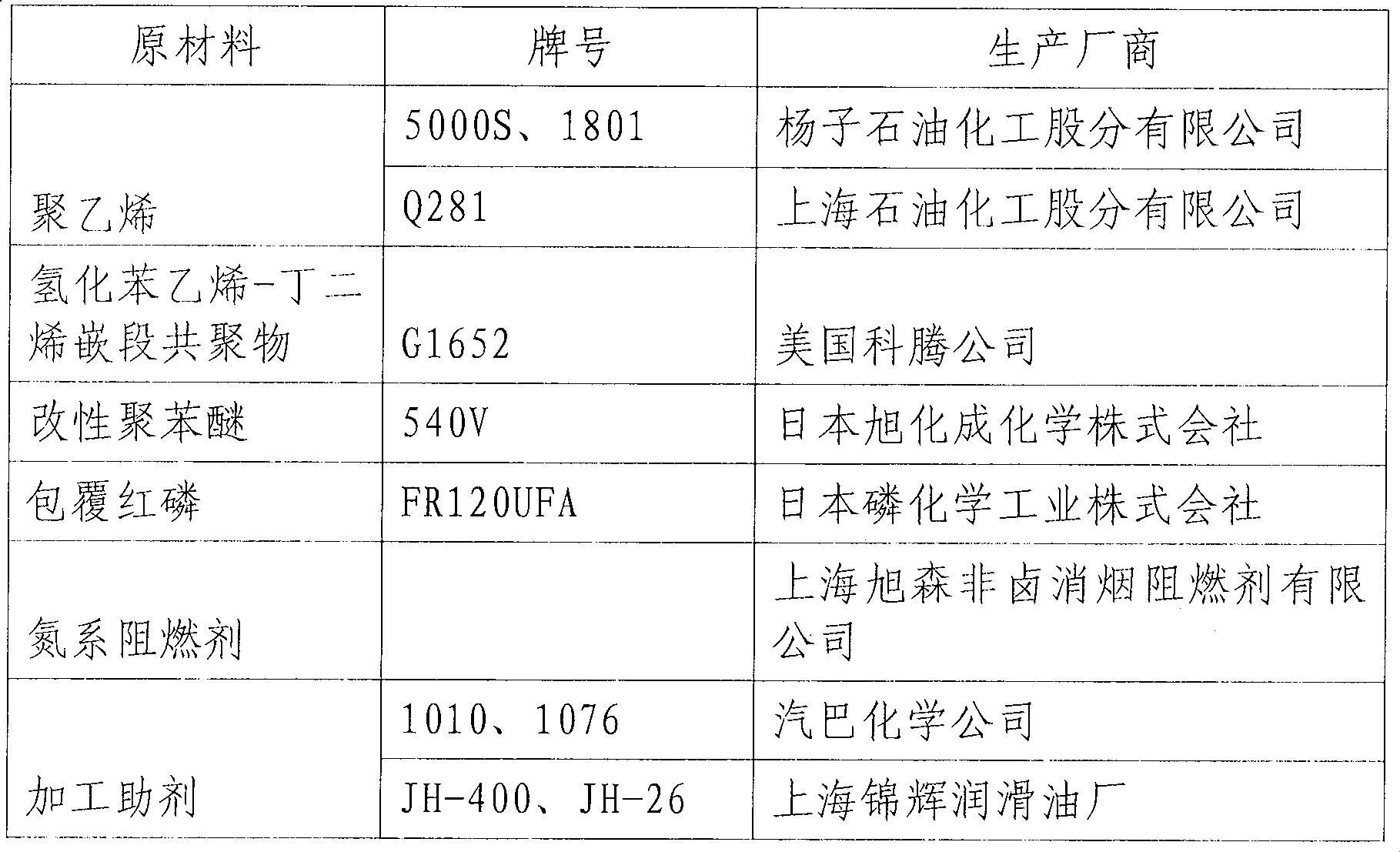

[0012] The halogen-free flame-retardant resin composition is used to prepare materials suitable for soft wire and cable coverings, power cord injection molding plugs, and the like. The raw materials of the composition can be purchased directly from the market, and Table 1 lists in detail the grades and manufacturers of some compositions that can be selected for use in the present invention.

[0013] Table 1: Brands and manufacturers of compositions

[0014]

Embodiment 2

[0016] A power cord injection molding plug material is prepared by using a halogen-free flame-retardant resin composition. Put the following components into a high-speed mixer: 1-15% by weight of polyethylene, 15-50% by weight of modified polyphenylene ether, 15-45% by weight of hydrogenated styrene-butadiene block copolymer, and halogen-free resistor Fuel. The halogen-free flame retardant is a mixture of microencapsulated coated red phosphorus and nitrogen-based flame retardant, wherein, 1-10% by weight of coated red phosphorus, 5-20% by weight of nitrogen-based flame retardant and 5-28% by weight Processing aids. After dispersion and mixing, it is melted, extruded, cooled, pelletized, dried and packaged through a twin-screw extruder. The preparation process is simple and continuous, the production efficiency is high, and the product quality is stable. The prepared plug material has good heat resistance and flame retardancy, excellent electrical insulation and strong wear ...

Embodiment 3

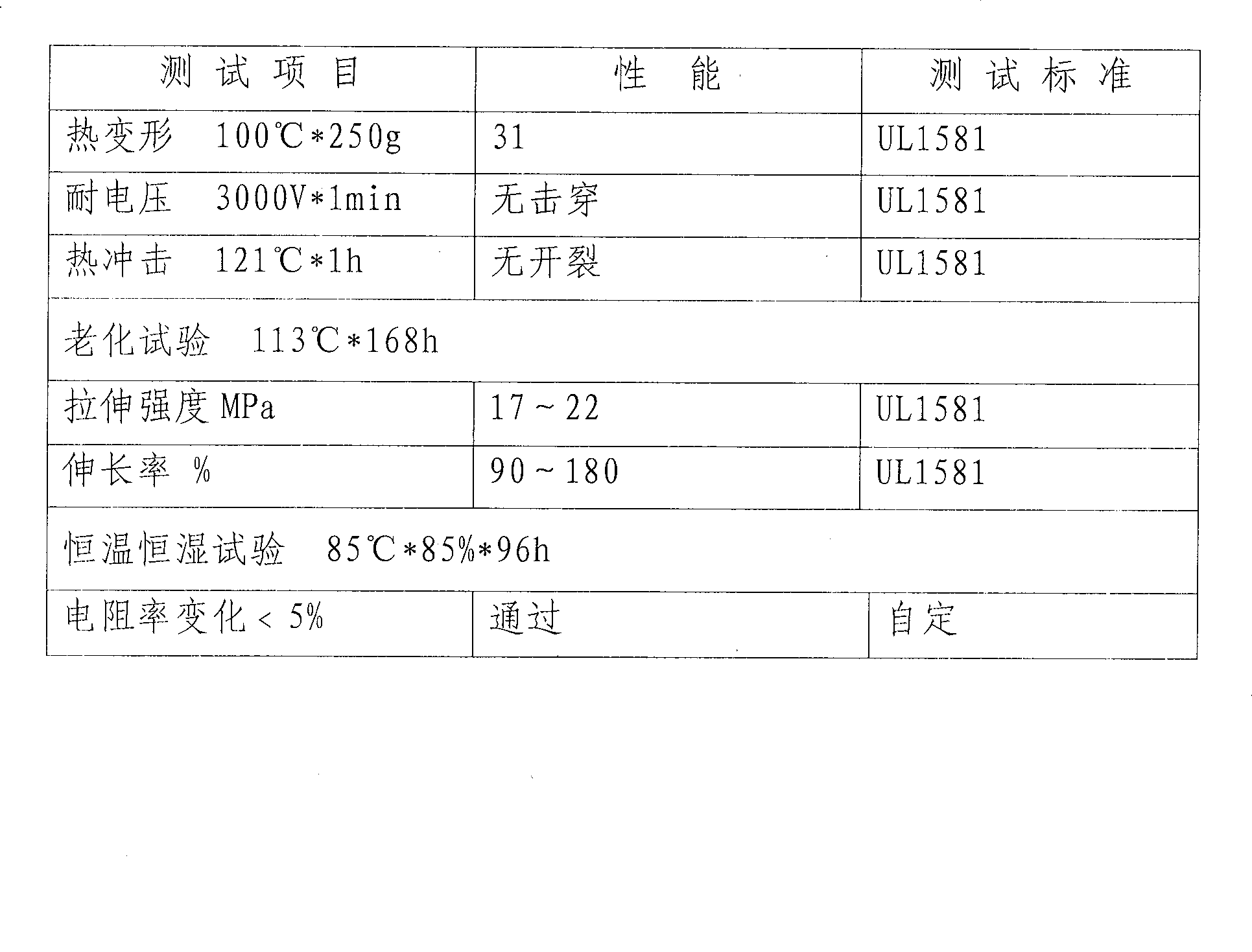

[0021] Using the halogen-free flame-retardant resin composition, a wire and cable covering material with a wire specification of 1.38*2.80mm is prepared. The proportion of the composition is: 4-12% by weight of high-density polyethylene, 30-45% by weight of modified polyphenylene ether, 18-30% by weight of hydrogenated styrene-butadiene block copolymer, 1- 4% by weight of coated red phosphorus, 9-14% by weight of nitrogen-based flame retardant and 9-21% by weight of processing aids. After testing, the performance indicators of the product are excellent, see Table 4 for details.

[0022] Table 4: Physical properties and test methods of the wire

[0023] Test items performance standard test Tensile strength MPa 15.50~21.00 UL1581 Elongation % 100~230 UL1581 Hardness Shore A 92~97 GB / T 2411 Density g / cm 3 1.10 GB / T1033 Flame retardant class VW-1 pass UL1581

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com