A method for preparing transparent, antifreeze and flame retardant polyvinyl alcohol film

A technology of polyvinyl alcohol film and polyvinyl alcohol powder, which is applied in the direction of coating, can solve the problems of difficult thermoplastic processing, flame retardant and anti-freezing properties, etc., to improve the thermoplastic film-forming and appearance, and maintain transparency. , to avoid the effect of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

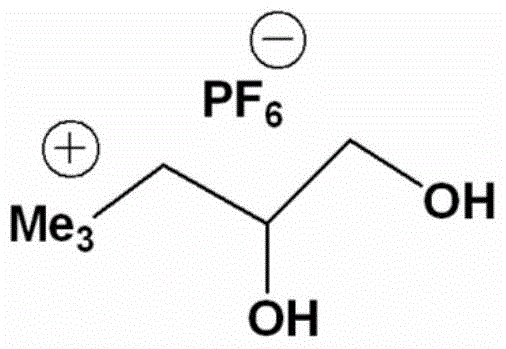

[0028] Get number-average particle diameter and be 0.01mm, average degree of polymerization is 1500, degree of alcoholysis is 70 kilograms of polyvinyl alcohol powders of 99.8% and chemical structural formula is 30 kg of ionic liquid was physically mixed in a high-speed mixer, and then the mixture was injected into a conical twin-screw extruder, melted and extruded at a temperature of 160 ° C, and the screw speed was 60 rpm. The residence time in the extruder is 12 minutes, the extrusion pressure is normal, the extruded melt is cooled in the air, pelletized, and then the obtained pellets are injected into a single-screw extruder for blow molding at a temperature of 180°C Formed into a film, the average thickness of the obtained film is 0.028mm, the surface is smooth and free of bubbles, the visible light transmittance is 90%, the elongation at break at 20°C and -20°C is 95% and 65% respectively, and the limiting oxygen index is 28%, vertical combustion is UL94-V0 level.

Embodiment 2

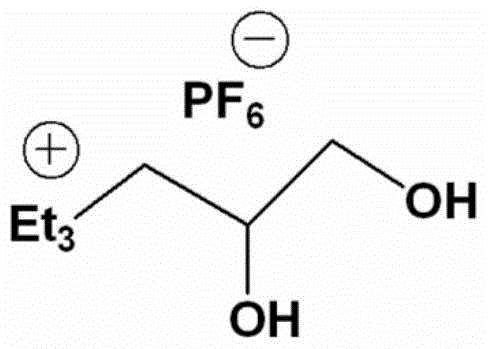

[0030] Get number-average particle diameter and be 0.055mm, average degree of polymerization is 1700, degree of alcoholysis is 80 kilograms of polyvinyl alcohol powders of 88% and chemical structural formula is 15 kg of ionic liquid and 5 kg of triethylene glycol were physically mixed in a high-speed mixer, and then the mixture was injected into a conical twin-screw extruder, melted and extruded at a temperature of 170 ° C, and the screw speed was 72 rpm The residence time of the melt in the twin-screw extruder is 10 minutes, the extrusion pressure is normal, the extruded melt is cooled in the air, pelletized, and then the resulting pellets are injected into the single-screw extruder, at 190 The average thickness of the obtained film is 0.016mm, the surface is smooth and free of bubbles, the visible light transmittance is 92%, and the elongation at break at 20°C and -20°C are 110% and 100% respectively. 68%, the limiting oxygen index is 30%, and the vertical combustion is UL9...

Embodiment 3

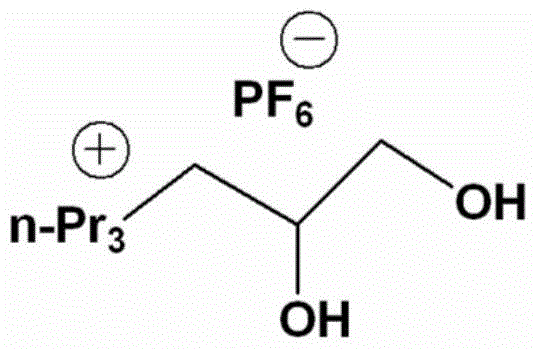

[0032] It is 90 kilograms of polyvinyl alcohol powder that the number average particle diameter is 0.1mm, the average degree of polymerization is 1600, and the degree of alcoholysis is 93.9% and the chemical structural formula is 5 kg of ionic liquid and 5 kg of triethylene glycol were physically mixed in a high-speed mixer, and then the mixture was injected into a conical twin-screw extruder, melted and extruded at a temperature of 180 ° C, and the screw speed was 90 rpm points, the residence time of the melt in the twin-screw extruder is 8 minutes, the extrusion pressure is normal, the extruded melt is cooled in the air, pelletized, and then the resulting pellets are injected into the single-screw extruder, at 200 The film was calendered at a temperature of ℃, the average thickness of the obtained film was 0.045mm, the surface was smooth and free of bubbles, the visible light transmittance was 88%, and the elongation at break at 20°C and -20°C were 89% and 60%, respectively....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com