Preparation methods of amino triazine derivative macromolecular char forming agent and polypropylene flame retardant

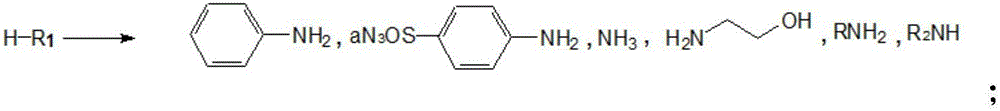

A technology of aminotriazine and derivatives, which is applied in the field of preparation of charcoal agents and flame retardants, can solve the problems of poor compatibility, strong water absorption, easy discoloration, etc., and achieve the effect of solving precipitation and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

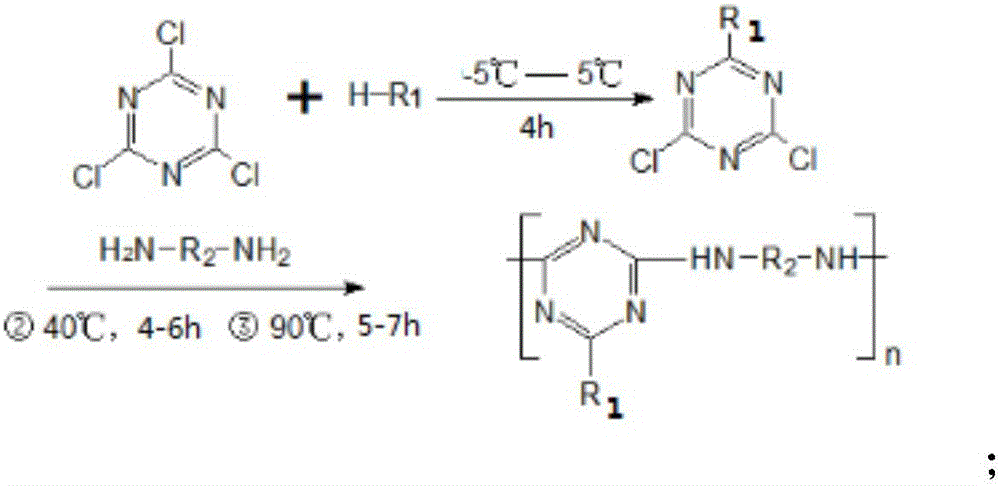

Method used

Image

Examples

example 1

[0045] Add 46g of cyanuric chloride and 200ml of dioxane solution in a 500ml reaction flask equipped with a reflux condenser, constant pressure dropping funnel, stirrer and thermometer, fully stir to make the cyanuric chloride disperse evenly, then in Under the condition of -5°C-5°C, 15g ethanolamine, 20g diethylamine and NaOH solution (10gNaOH dissolved in 25ml distilled water) were evenly added dropwise while stirring, and reacted for 1-3h; Add 8g of ethylenediamine and NaOH solution (10gNaOH dissolved in 25mL of distilled water) dropwise evenly in the solution, raise the reaction temperature to 40°C-65°C after the dropwise addition, and stir the reaction for 4-6h under this condition, at 40°C-65°C Under the condition of ℃, continue to drop 8g ethylenediamine and NaOH solution (10gNaOH dissolved in 25ml distilled water) evenly to the reaction flask, then increase the reaction temperature, first distill and recover dioxane, then add 40ml distilled water, and in the reflux stat...

example 2

[0047] Add 46g of cyanuric chloride to a 500ml reaction flask equipped with a reflux condenser, a constant pressure dropping funnel, a stirrer and a thermometer, then add 100ml of tetrahydrofuran, stir fully to make the cyanuric chloride disperse evenly, and then Under the condition of ℃-5℃, add 23g of aniline and NaOH solution (10gNaOH dissolved in 25ml of distilled water) dropwise evenly while stirring. Increase the temperature to room temperature, and then evenly add 30g of hexamethylenediamine and NaOH solution (10gNaOH dissolved in 25mL of distilled water) dropwise to the reaction flask. After the dropwise addition, raise the reaction temperature to 40°C-65°C, and stir the reaction under this condition 4-6h, then under the condition of 40°C-65°C, continue to add 30g of hexamethylenediamine and NaOH solution (10gNaOH dissolved in 25mL of distilled water) evenly dropwise into the reaction flask, then raise the reaction temperature, first distill and recover tetrahydrofuran, ...

example 3

[0049]Add 93g of cyanuric chloride and 200mL of dioxane in a 500ml reaction flask equipped with a reflux condenser, a constant pressure dropping funnel, a stirrer and a thermometer, stir fully to make the cyanuric chloride disperse evenly, and then in- Under the condition of 5℃-5℃, add 30g ethanolamine, alkylamine (diethylenetriamine) and NaOH solution (200g NaOH dissolved in 300mL distilled water) dropwise evenly while stirring. React at ℃ for 2-3 hours, then raise the temperature to room temperature, then evenly add 30g of 1,3-piperazine and NaOH solution (20g NaOH dissolved in 30mL of distilled water) dropwise to the reaction flask, and then the temperature rises When the reaction temperature reaches 40-65°C, stir the reaction for 5-6h under this condition, and then continue to add 30g of 1,3-piperazine and NaOH solution (10gNaOH dissolved in 20mL distilled water), then increase the reaction temperature, distill and recover dioxane first, then add 50mL distilled water, reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com