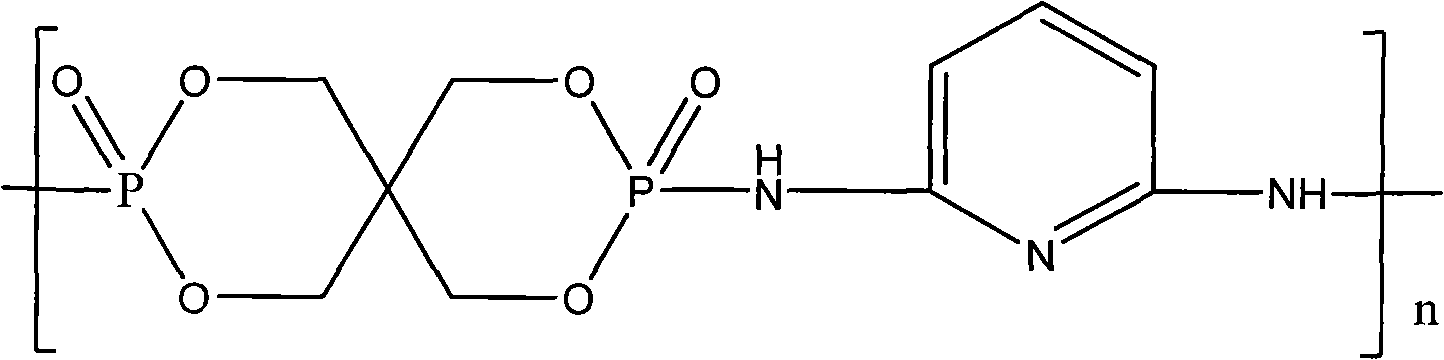

Macromolecular intumescent flame retardant with phosphorus and nitrogen and synthesis method thereof

An intumescent flame retardant and a synthesis method technology, applied in the field of intumescent halogen-free flame retardants, can solve the problems of large molecular weight, etc., and achieve the effects of no halogen, good compatibility, and high carbon-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

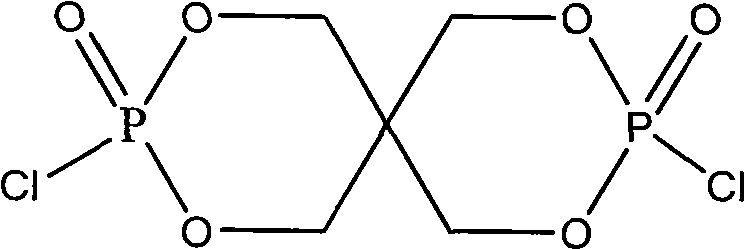

[0022] (1) Add 59.4g of chlorinated spirocyclic phosphate and 100mL of acetonitrile into a 250mL reactor equipped with a nitrogen protection and stirring device, heat to 50°C to 60°C and keep stirring to completely dissolve the chlorinated spirocyclic phosphate in Acetonitrile solvent;

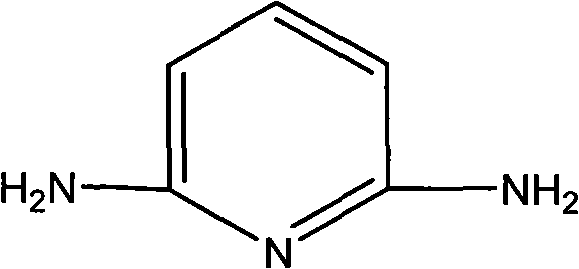

[0023] (2) Get 19g of 2,6-diaminopyridine and dissolve it in 60mL of acetonitrile solvent to make a concentration of 2.9mol / L containing 2,6-diaminopyridine in acetonitrile solution, which contains 2,6-diaminopyridine The acetonitrile solution is added dropwise in the solution of step (1) gained;

[0024] (3) Add 15 mL of catalyst pyridine dropwise into the solution obtained in step (2), raise the temperature to 80° C. and react for 4 hours, during which light yellow powder is continuously formed;

[0025] (4) Cool to room temperature, filter the reaction product, and wash the filter cake repeatedly with ethanol for 3 to 5 times to purify the product;

[0026] (5) Vacuum drying at 80°C for 1...

Embodiment 2

[0028] (1) Add 59.4g of chlorinated spirocyclic phosphate and 120mL of acetonitrile into a 250mL reactor equipped with a nitrogen protection and stirring device, heat to 50°C to 60°C and keep stirring to completely dissolve the chlorinated spirocyclic phosphate in Acetonitrile solvent;

[0029] (2) Get 21g of 2,6-diaminopyridine and dissolve it in 40mL of acetonitrile solvent to make a concentration of 4.9mol / L containing 2,6-diaminopyridine in acetonitrile solution, which contains 2,6-diaminopyridine The acetonitrile solution is added dropwise in the solution of step (1) gained;

[0030] (3) Add 20 mL of catalyst triethylamine dropwise into the solution obtained in step (2), raise the temperature to 80° C. and react for 6 hours, during which light yellow powder is continuously formed;

[0031] (4) Cool to room temperature, filter the reaction product, and wash the filter cake repeatedly with water for 3 to 5 times to purify the product;

[0032] (5) Vacuum drying at 80°C fo...

Embodiment 3

[0034] (1) Add 29.7g of chlorinated spirocyclic phosphate and 80mL of acetonitrile into a 250mL reactor equipped with a nitrogen protection and stirring device, heat to 50°C to 60°C and keep stirring to completely dissolve the chlorinated spirocyclic phosphate in Acetonitrile solvent;

[0035] (2) Get 9.5g of 2,6-diaminopyridine and dissolve it in 80mL of acetonitrile solvent to make a concentration of 1.1mol / L containing 2,6-diaminopyridine in acetonitrile solution, which contains 2,6-diaminopyridine The acetonitrile solution of pyridine is added dropwise in the solution obtained in step (1);

[0036] (3) Add 10 mL of catalyst pyridine dropwise into the solution obtained in step (2), raise the temperature to 80° C. and react for 3 hours, during which light yellow powder is continuously formed;

[0037] (4) Cool to room temperature, filter the reaction product, and wash the filter cake repeatedly with ethanol for 3 to 5 times to purify the product;

[0038] (5) Vacuum drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com