Environment-friendly TPE material for new energy electric vehicle charging pile cable and preparation method of environment-friendly TPE material

A technology for electric vehicles and charging piles, applied in circuits, electrical components, plastic/resin/wax insulators, etc. Poor fatigue resistance and other problems, to achieve the effect of improving long-term static thermal aging life, excellent physical and mechanical properties, and processing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

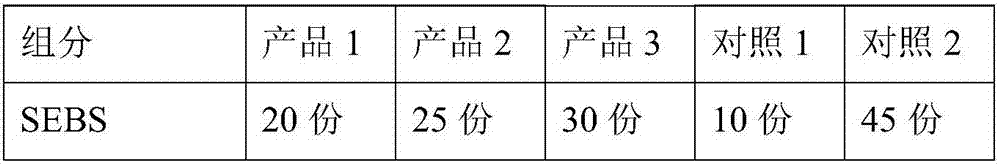

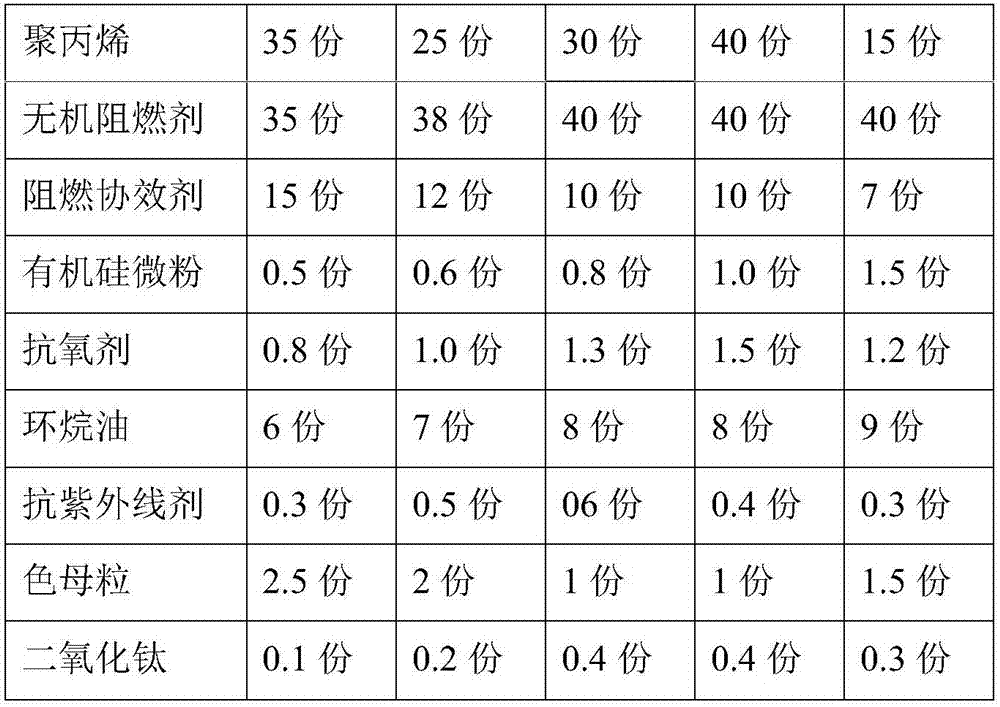

[0026] An environmentally friendly TPE material for a new energy electric vehicle charging pile cable, the composition of which is shown in Table 1.

[0027] Table 1 TPE material formula table

[0028]

[0029]

[0030] Wherein, SEBS is a linear three-block copolymer with polystyrene as the end segment and ethylene-butylene copolymer as the middle elastic block; the melt index of the polypropylene is 2-3 g / min. The flame retardant synergist is one or more of melamine uric acid ester, nano silicon dioxide and nano bentonite. Silicone powder is Dow Corning RM-7081, GE SFR-100 or silicone masterbatch. The antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-butylphenyl) propionate] pentaerythritol ester, three [2,4-di-tert-butylphenyl] phosphite, β-(3,5-di-tert-butyl-4-anthylphenyl)propanoic acid n-octadecyl ester and N,N,-bis[β-(3,5-di-tert-butyl-4-anthyl One or two or more of phenyl) propionyl] hydrazines. The anti-ultraviolet agent is: 2-hydroxy-4-n-octyloxybenzophenone. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com