Lead-carbon super battery anode material and preparation method thereof

A technology of super battery and negative electrode material, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of increasing the overall cost of the battery, difficult industrialization process, adverse battery performance, etc. Small, the effect of preventing carburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a preparation method for the anode material of the above-mentioned lead-carbon super battery, comprising the following specific steps:

[0049] 1) Material preparation: Dissolve graphite oxide in water to prepare a graphite oxide solution of 0.5-10 mg / ml (preferably 0.5-3 mg / ml); dissolve soluble lead salt in deionized water to prepare a concentration of 0.01-2 mol / l lead salt solution; soluble lead salt is one or more of nitrate, acetate, carbonate, hydrochloride, sulfate and complex salts containing lead elements;

[0050] 2) Mixed material: ultrasonically treat the graphite oxide solution to disperse it into a uniform graphene oxide colloidal solution, then add the above-mentioned lead salt solution to it, oscillate ultrasonically for 5-30 minutes, and pour it into a high-pressure reactor;

[0051] 3) Hydrothermal reaction: Fix the high-pressure reactor and place it in a constant temperature explosion-proof box. The temperature of ...

Embodiment 1

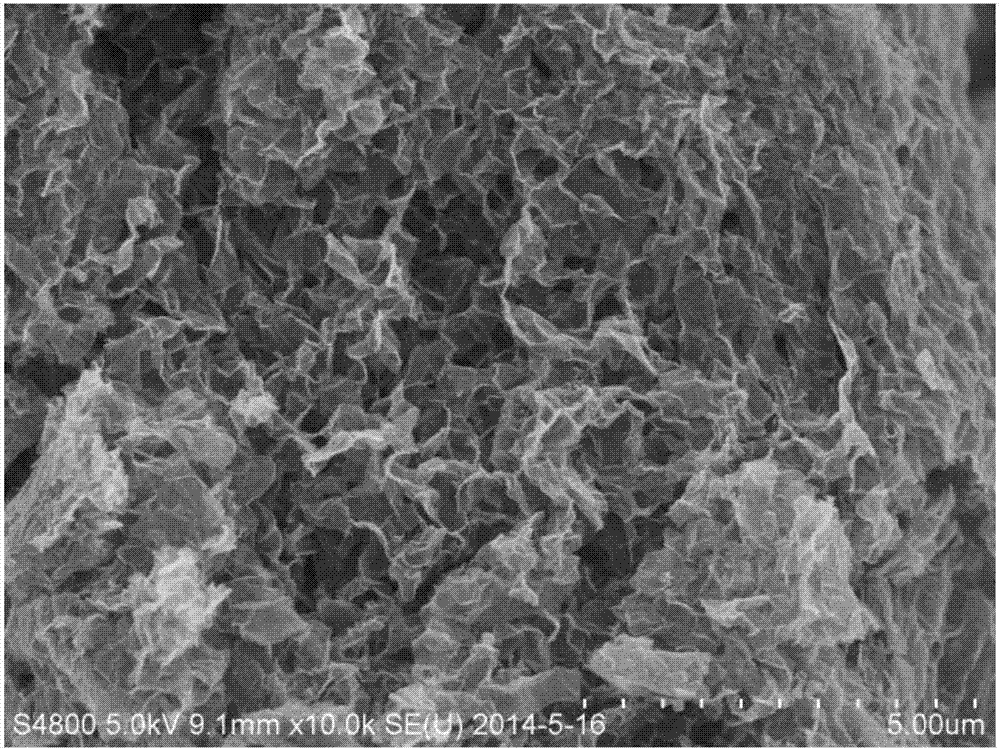

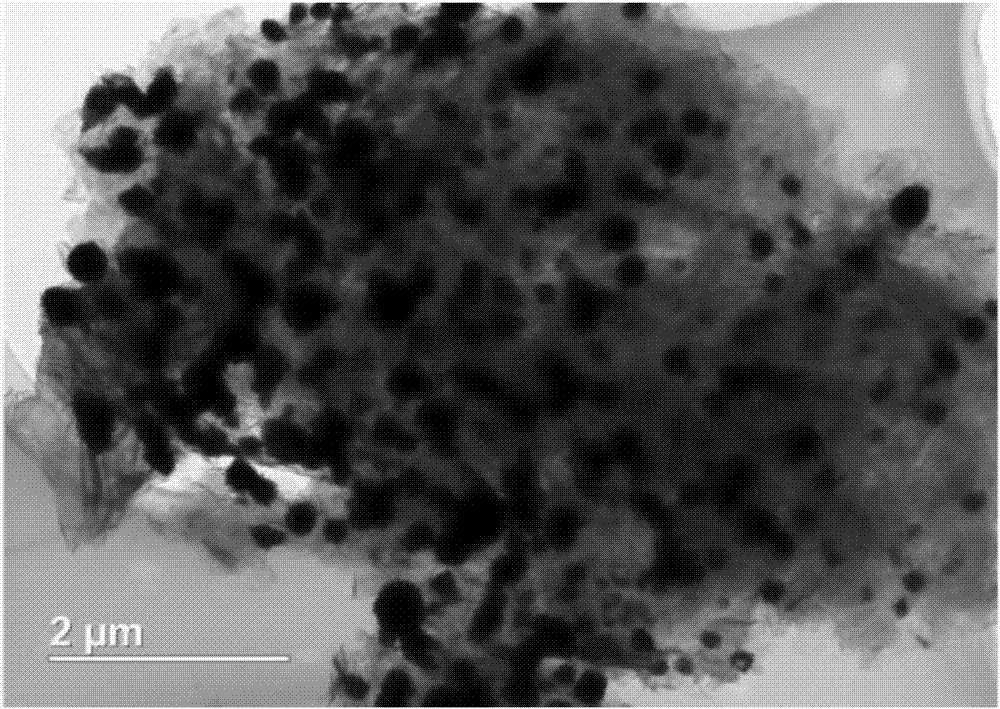

[0058] Prepare an aqueous solution of lead acetate with a concentration of 0.1M, and add a graphite oxide solution with a concentration of 2ml / mg. The volume ratio of lead acetate aqueous solution to graphene oxide solution is 90:10, heated in water for 25-30 hours, dried under nitrogen at 80°C, and heat-treated in an inert atmosphere in an atmosphere furnace to obtain a lead / carbon composite material.

Embodiment 2

[0060] Prepare an aqueous solution of lead nitrate with a concentration of 0.1M, and add a graphite oxide solution with a concentration of 2ml / mg. The volume ratio of lead acetate aqueous solution to graphene oxide solution is 90:10, heated in water for 25-30 hours, dried under nitrogen at 80°C, and heat-treated in an inert atmosphere in an atmosphere furnace to obtain a lead / carbon composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com