Single-side fire-retardant adhesive tape and preparation method thereof

A flame retardant tape, single-sided technology, applied in the direction of adhesive, adhesive type, film/sheet adhesive, etc., can solve the problem that the performance cannot be stable for a long time, the lack of high-grade flame retardant tape, the amount of flame retardant large and other problems, to achieve the effect of high phosphorus content, good flame retardant effect, and simple mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

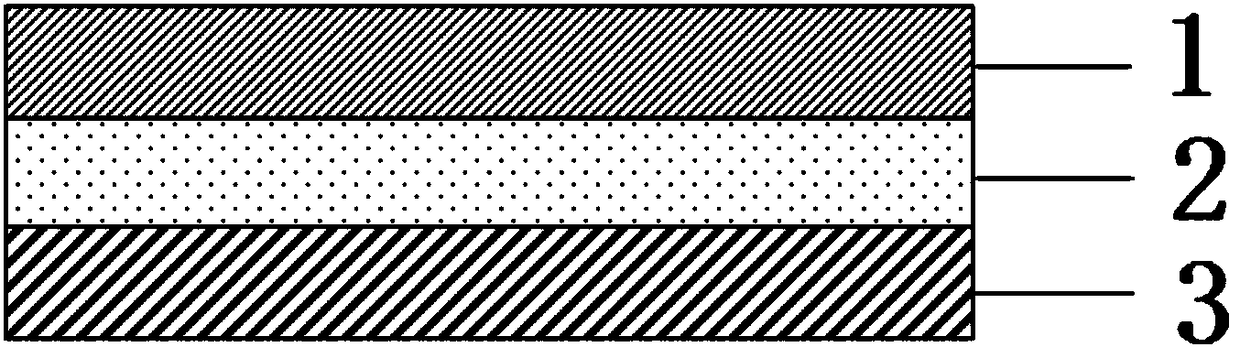

Image

Examples

Embodiment 1

[0029] 1) Rubber mixing:

[0030] Dilute 75kg of solvent-based polyacrylate (number-average molecular weight of 900,000 and acid value of 6mgKOH / g) with 160kg of solvent ethyl acetate, stir at 400rpm for 20min with a high-speed disperser, reduce the speed to 100rpm, and prepare in advance The flame retardant solution (mixed with 13kg diethylaluminum hypophosphite and 12kg bisphenol A-bis(diphenyl phosphate) and 65kg ethyl acetate) was added to the system, continued to stir at a high speed of 400rpm for 20min, and then slowed down to 100rpm, and finally pour the pre-prepared curing agent solution (mixed with 0.5kg GA240 curing agent and 4.5kg ethyl acetate) into the above system slowly, restore the speed to 400rpm and continue stirring for 30min, stop stirring, and stand for use ;

[0031] 2) Coating:

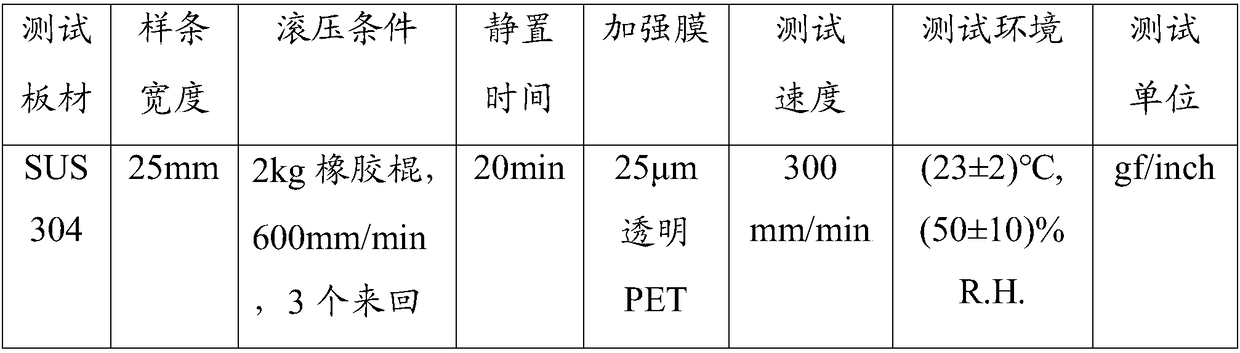

[0032] Select a 36μm single-sided polyester release film with a release force of 8-12gf / inch, supply glue through a filter system with a size of 20μm, and apply a 24μm thickne...

Embodiment 2

[0038] 1) Rubber mixing:

[0039] Dilute 70kg of solvent-based polyacrylate (number average molecular weight of 1 million, acid value of 9mgKOH / g) with 370kg of solvent ethyl acetate, stir at 400rpm for 20min with a high-speed disperser, reduce the speed to 100rpm, and prepare in advance The flame retardant solution (10kg diethyl aluminum hypophosphite and 15kg bisphenol A-bis (diphenyl phosphate) and 50kg ethyl acetate mixed) was added to the system, and continued to stir at a high speed of 400rpm for 20min, and then the speed was reduced to 100rpm, and finally pour the pre-prepared curing agent solution (mixed with 0.8kg GA240 curing agent and 7.2kg ethyl acetate) into the above system slowly, restore the speed to 400rpm and continue stirring for 30min, stop stirring, and stand for use ;

[0040] 2) Coating:

[0041] Select a 25μm single-sided polyester release film with a release force of 8-12gf / inch, supply glue through a filter system with a size of 20μm, and apply a 18...

Embodiment 3

[0047] 1) Rubber mixing:

[0048]Dilute 80kg of solvent-based polyacrylate (number-average molecular weight of 700,000 and acid value of 4mgKOH / g) with 100kg of solvent ethyl acetate, stir at 400rpm for 20min with a high-speed disperser, and reduce the speed to 100rpm. Flame retardant solution (mixed with 15kg aluminum diethyl hypophosphite and 10kg bisphenol A-bis(diphenyl phosphate) and 75kg ethyl acetate) was added to the system, and continued to stir at a high speed of 400rpm for 20min, then reduced to 100rpm, and finally pour the pre-prepared curing agent solution (mixed with 0.3kg GA240 curing agent and 2.7kg ethyl acetate) into the above system slowly, restore the speed to 400rpm and continue stirring for 30min, stop stirring, and stand for use;

[0049] 2) Coating:

[0050] Select double-sided PE-coated release paper with a grammage of 110g and a release force of 8-12gf / inch, supply glue through a filter system with a size of 50μm, and use a comma roller to coat the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com