Textile slurry composition replacing for polyvinyl alcohol and preparing method thereof

A technology for textile sizing and polyvinyl alcohol, which is applied in textiles, papermaking, fiber processing, etc., can solve the problems of inconvenience of use, loss of textile mills, complicated manufacturing process, etc., achieve easy biodegradation, reduce sizing cost, and manufacture simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

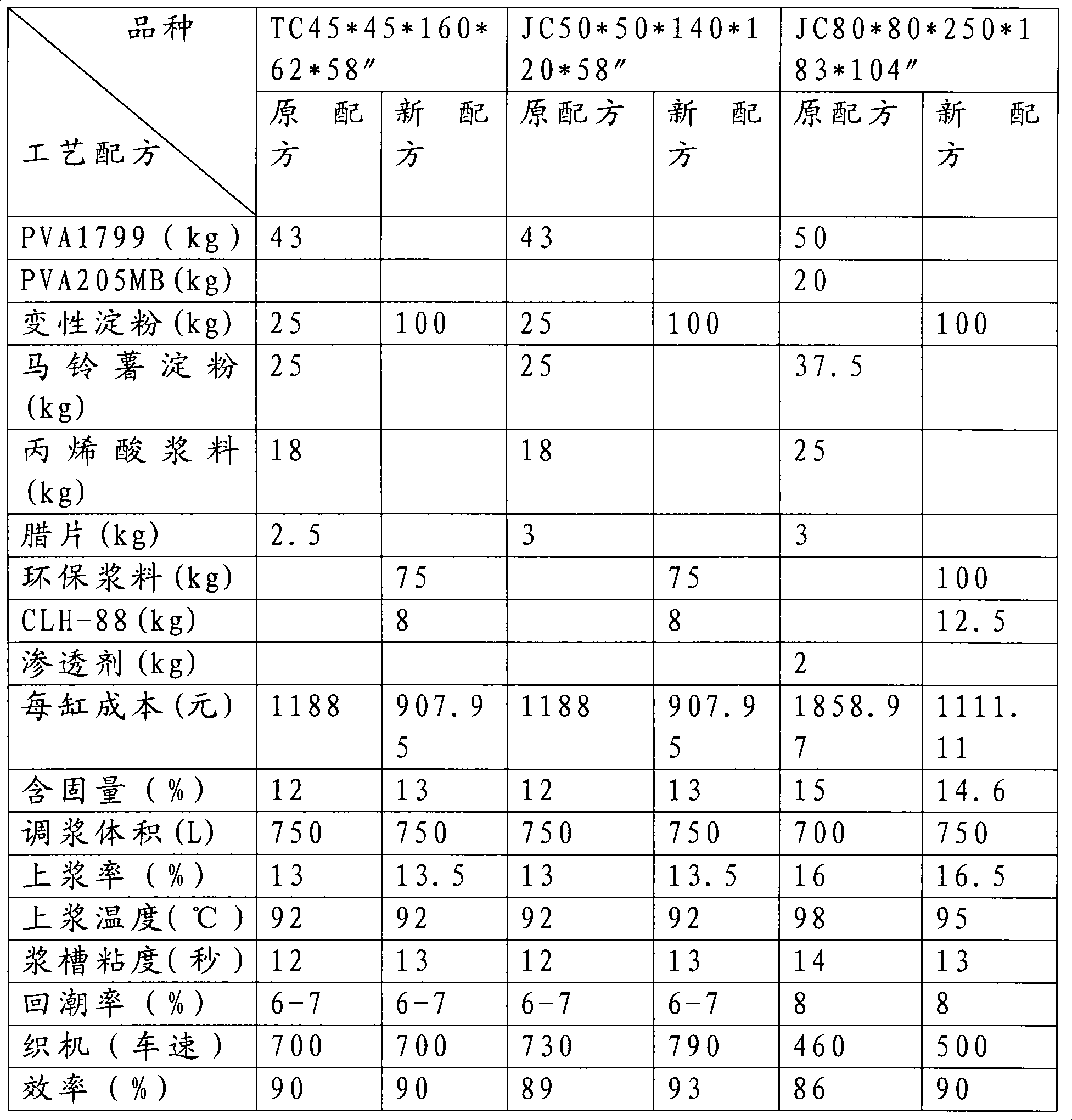

Method used

Image

Examples

Embodiment 1

[0030] In the first embodiment, 2%-8% of the total weight of the ultrafine inorganic material, 20%-30% of the polyacrylic acid slurry and the balance of water are mixed. Among them, the ultrafine inorganic material is powder SiO 2 , The particle size is 10nm-1um, the solid content is 90%-95%, the polyacrylic acid slurry is a granular powder made of acrylamide, acrylonitrile, and vinyl acetate, and the solid content is 90%-95%.

[0031] Since the existing ultrafine inorganic materials and polyacrylic slurries can be divided into liquid and solid forms according to the different solid content, no matter which one you choose, as long as the ratio of the effective ingredients of the ultrafine inorganic materials to the total weight is 1 %-10%, the proportion of the polyacrylic acid slurry to the total weight is 10%-40%.

Embodiment 2

[0032] In the second embodiment, 5%-40% of the total weight of the ultrafine inorganic material, 60%-90% of the polyacrylic acid slurry and the balance of water are mixed. Among them, the ultrafine inorganic material is SiO 2 , TiO 2 And Al 2 O 3The compound is milky white liquid with a particle size of 10nm-1um and a solid content of 10%-50%. The polyacrylic acid slurry is prepared by emulsion copolymerization of acrylamide, butyl methacrylate and styrene with water as a solvent. It becomes a viscous liquid with a solid content of 10%-50%.

Embodiment 3

[0033] In the third embodiment, 5%-40% of the total weight of the ultrafine inorganic material, 10%-30% of the polyacrylic acid slurry and water are mixed. Among them, the ultrafine inorganic material is Al 2 O 3 And TiO 2 The mixture, the appearance is milky white liquid, the particle size is 10nm-1um, the solid content is 10%-50%; the polyacrylic acid slurry is a granular powder made of acrylic acid, acrylamide, acrylonitrile, and vinyl acetate. The solid content is 90%-95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com