Roller bearing with a window cage with positioning elements in the bearing pockets for altering the pocket play by means of temperature-dependent change in shape of the positioning elements for exampl

A bearing cage, rolling bearing technology, applied in the direction of bearing components, bearings, shafts and bearings, etc., can solve the problems of wear, short service life, large bearing resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

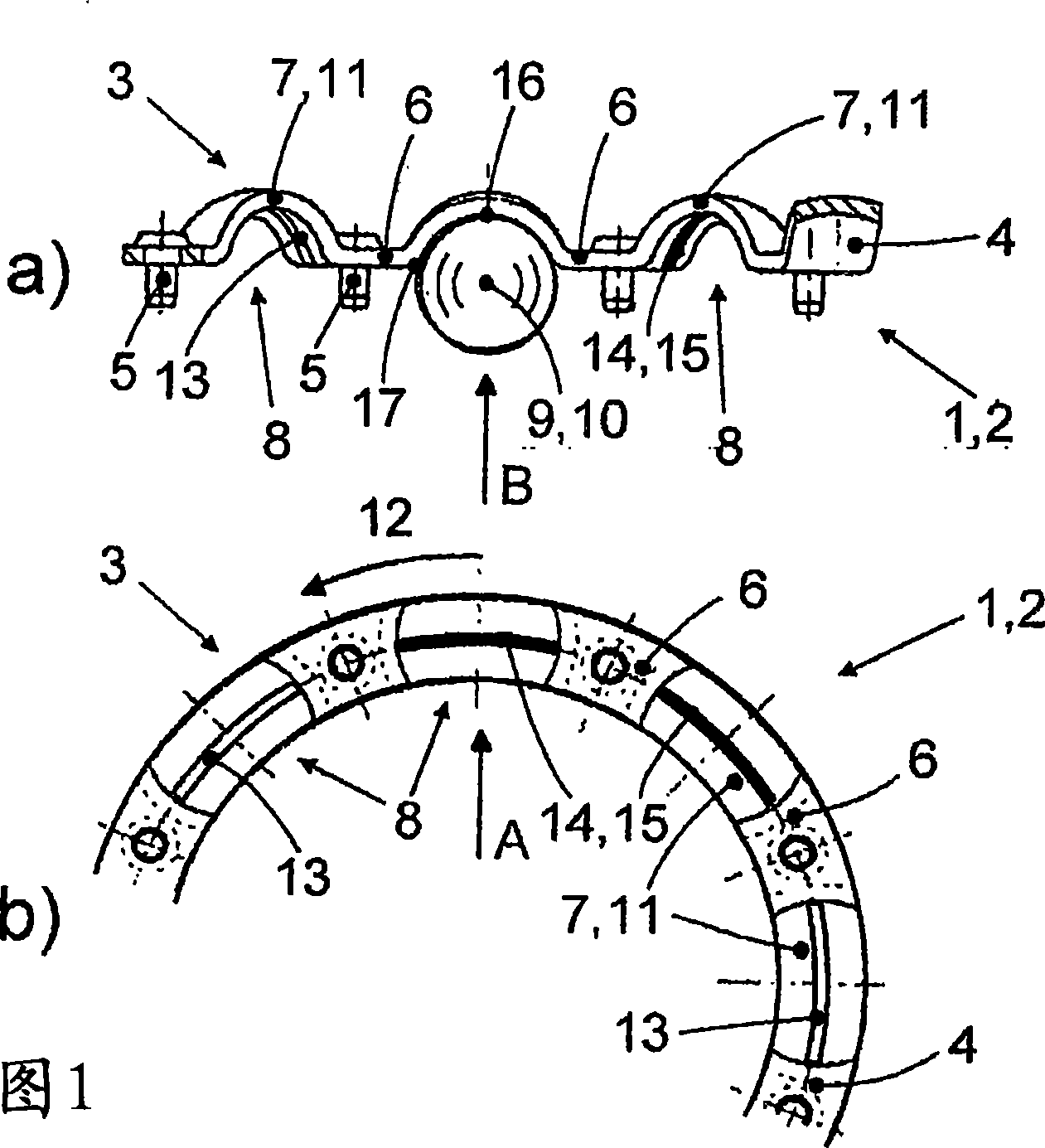

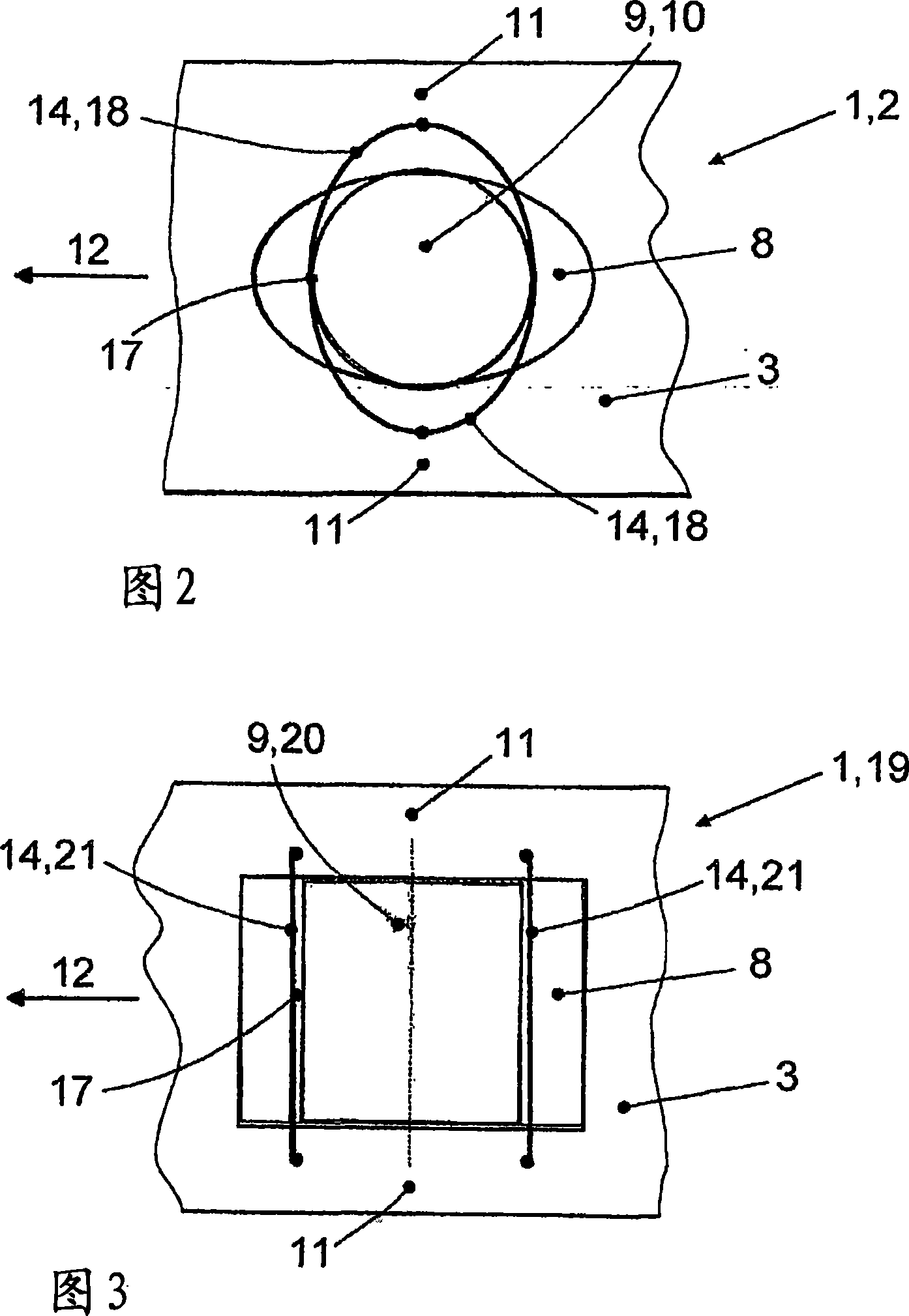

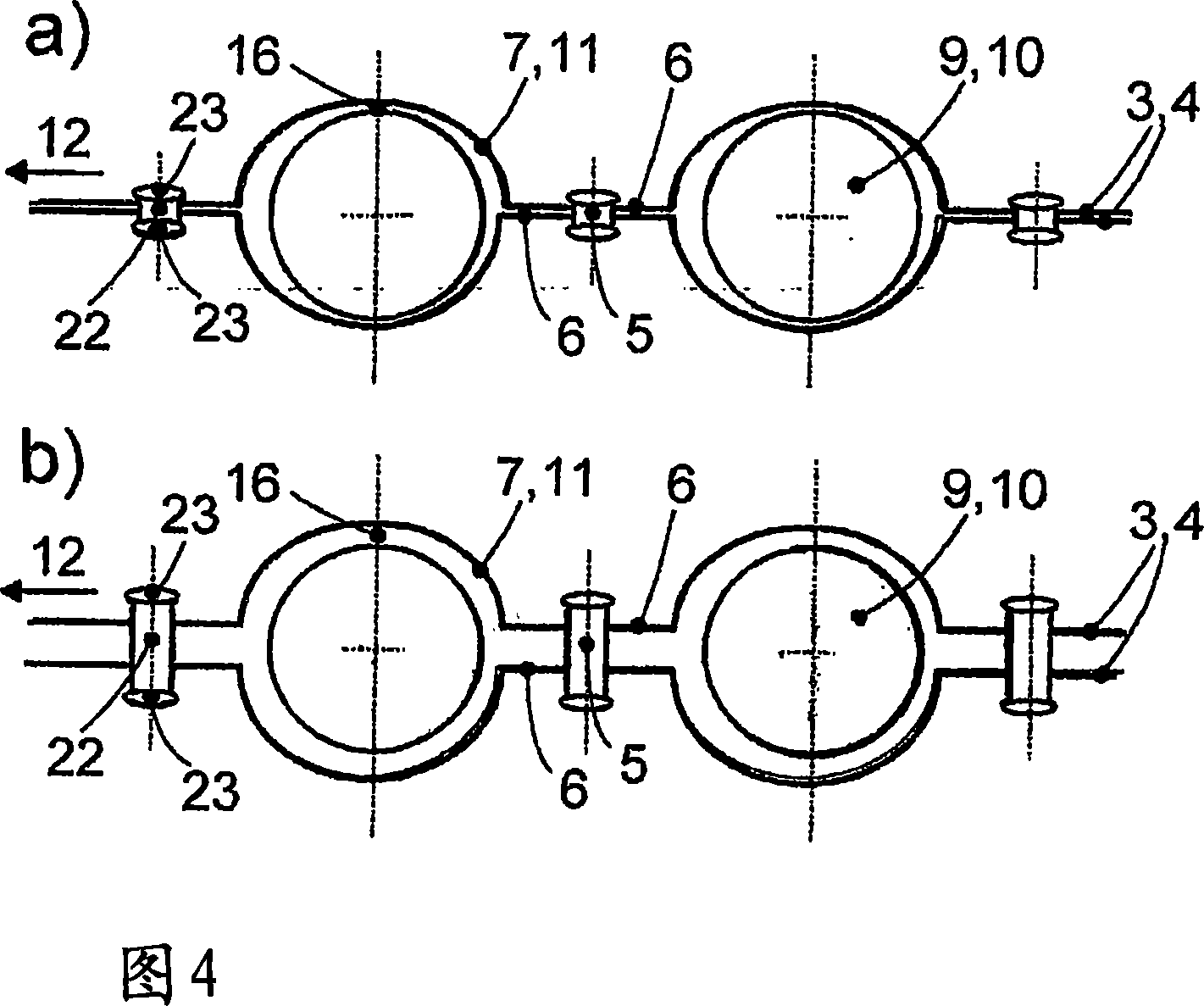

[0028] A rolling bearing 1 designed as a ball bearing 2 has a riveted bearing cage 3, which is shown in FIG. 1 in a radial view A with a section 1a and in an axial view B with a section 1b, the bearing cage 3 consists of two symmetrical cage rings 4 connected by means of rivets 5 . The cage ring 4 has an axial arc-shaped arched pocket section 7 distributed uniformly over the circumference between every two connecting beams 6 . In the assembled state of the bearing cage 3, the pocket segments 7 of the mutually riveted cage rings 4 form closed bearing pockets 8 arranged evenly distributed on the circumference, each of which is fitted with a rolling bearing designed here as a ball 10. Body 9.

[0029] According to the invention, the pocket sections 7 which mainly function as the axial side walls 11 of the bearing pocket 8 each have an inner groove 13 oriented in the circumferential direction, that is to say in the direction of rotation 12 of the rolling bearing 1 , in the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com