Dust removal air duct polishing method

A technology for air ducts and polishing machines, applied in the field of machinery, can solve the problems of affecting the quality of polishing, inconvenient maintenance, and increasing costs, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

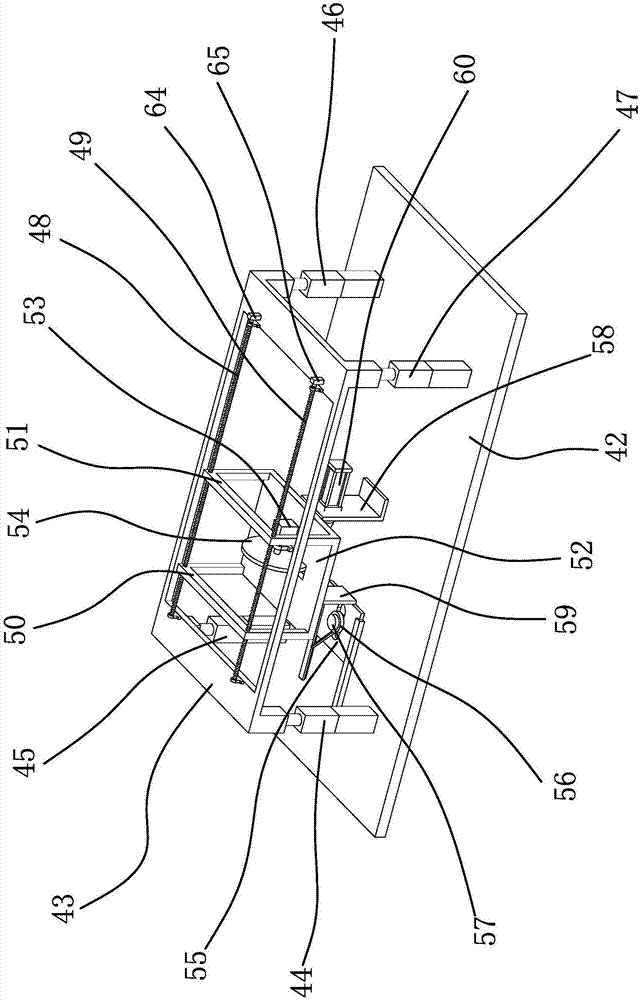

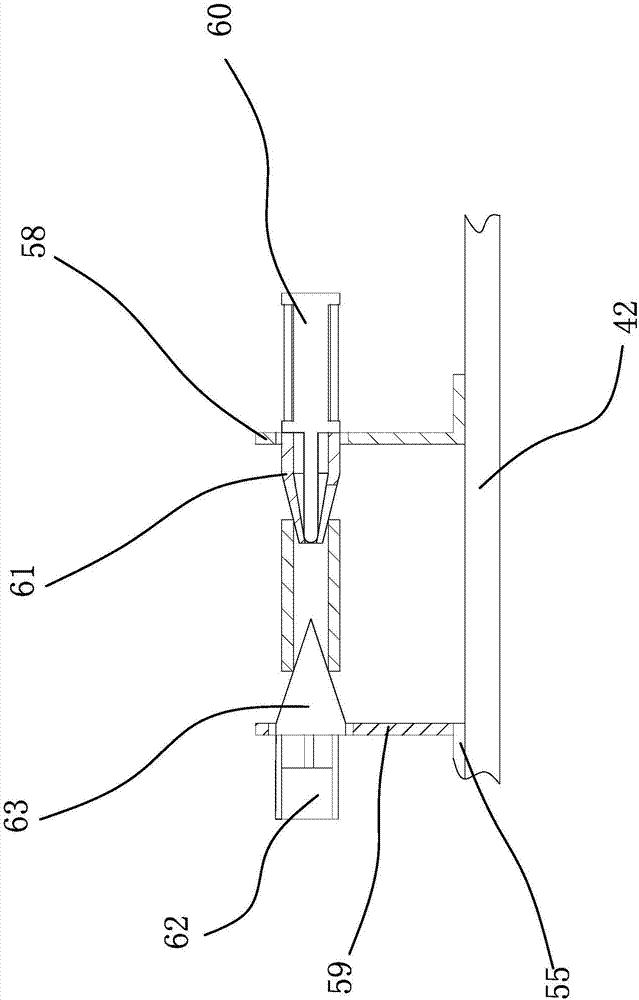

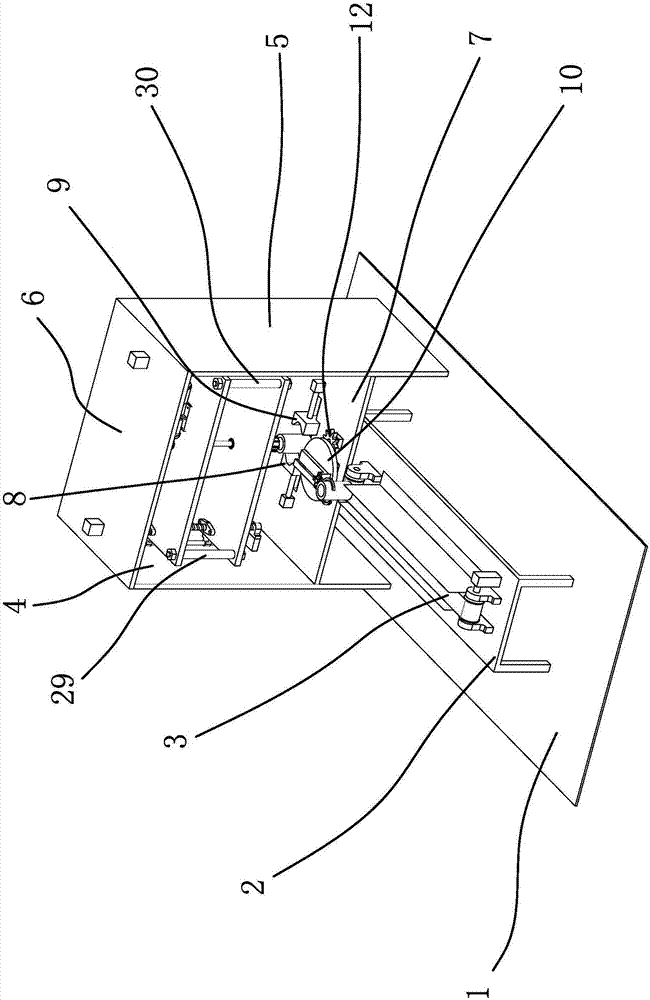

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0044] A method for polishing a dust-removing air duct, comprising the following steps:

[0045] a. Clamp the prepared dust-removing air duct on the outer wall polishing machine, start the polishing disc, and polish and deburr the outer wall of the dust-removing air duct. The outer wall polishing time is 8-12 minutes;

[0046] b. Put the dust-removing air duct after the outer wall is polished to the conveying device;

[0047] c. The dust removal air duct is transported to the transfer mechanism through the conveyor belt on the conveying device, and moved between the clamping block 1 and the clamping block 2 by the mechanical arm on the transfer mechanism for clamping;

[0048] d. Start the inner wall polishing machine, tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com