Vibration damping device

A technology for vibration isolation and mounting components, which is applied in vibration suppression adjustment, non-rotational vibration suppression, spring/shock absorber manufacturing, etc. It can solve the problems of the second rubber elastic body falling off, reduce the dynamic stiffness constant, prevent separation, Effect of Soft Stiffness Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

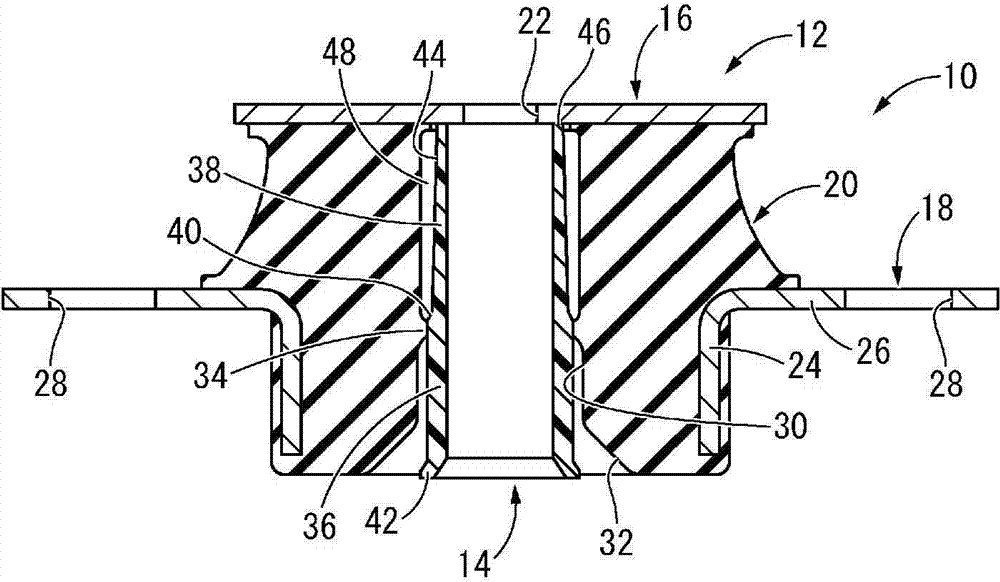

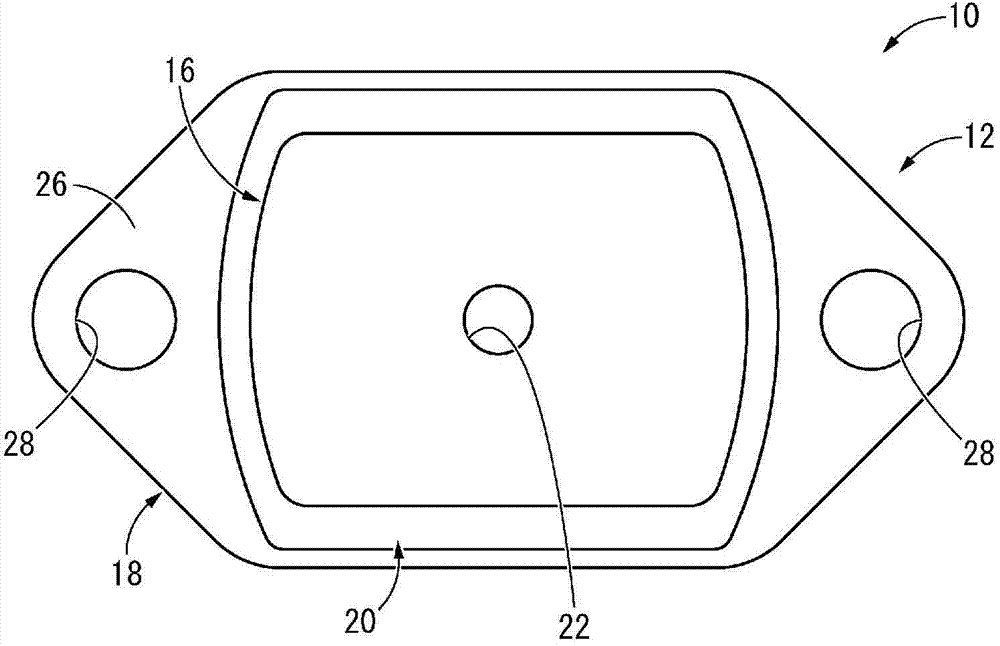

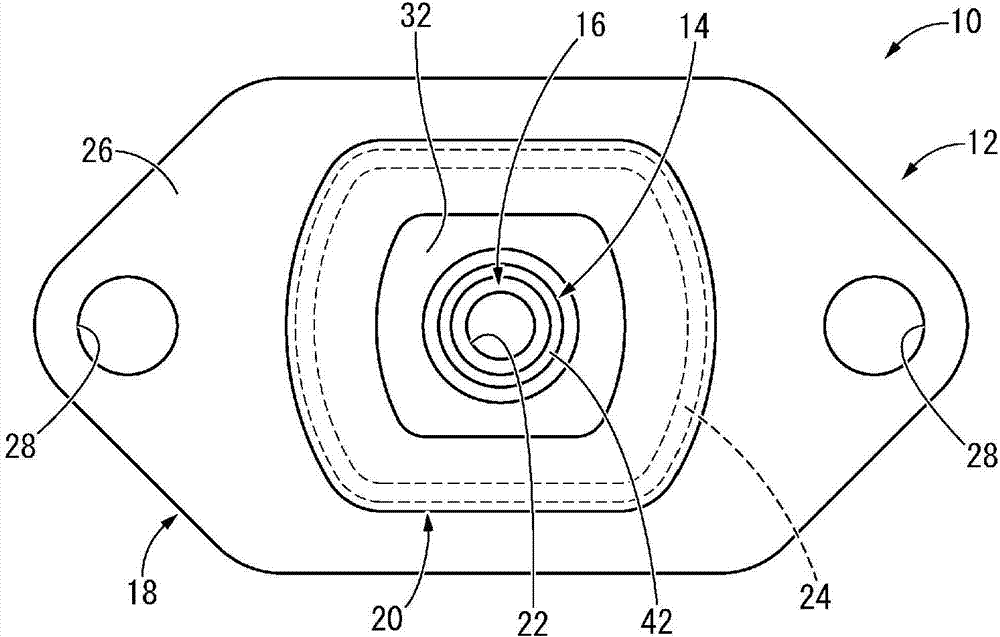

[0054] exist Figure 1 ~ Figure 3 In the figure, the engine mount 10 for automobiles is shown as the first embodiment of the vibration isolating device configured according to the present invention. This engine mount 10 has a structure in which an independent sleeve 14 is assembled on a mount main body 12, and the mount main body 12 has a structure in which a first mounting member 16 and a second mounting member 18 are elastically connected by a main body rubber elastic body 20. . In addition, in the following description, the up-and-down direction refers to the axis direction in principle. figure 1 in the up and down direction. also, figure 1 The upper side of the middle is set as the insertion top end side of the independent sleeve 14, figure 1 The lower side of the center is defined as the insertion base end side of the independent sleeve 14 .

[0055] In mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com