Patents

Literature

176results about How to "Change gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

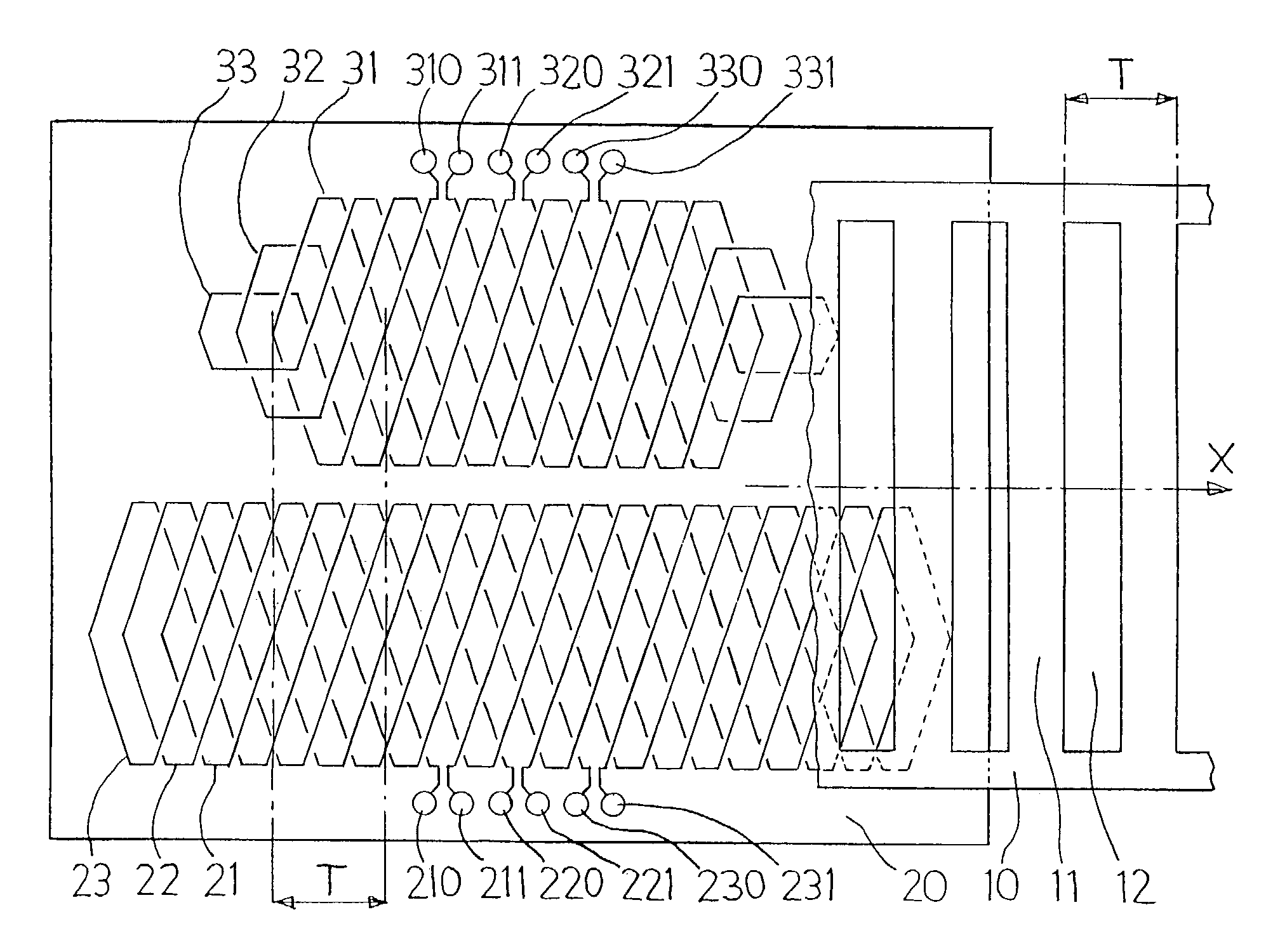

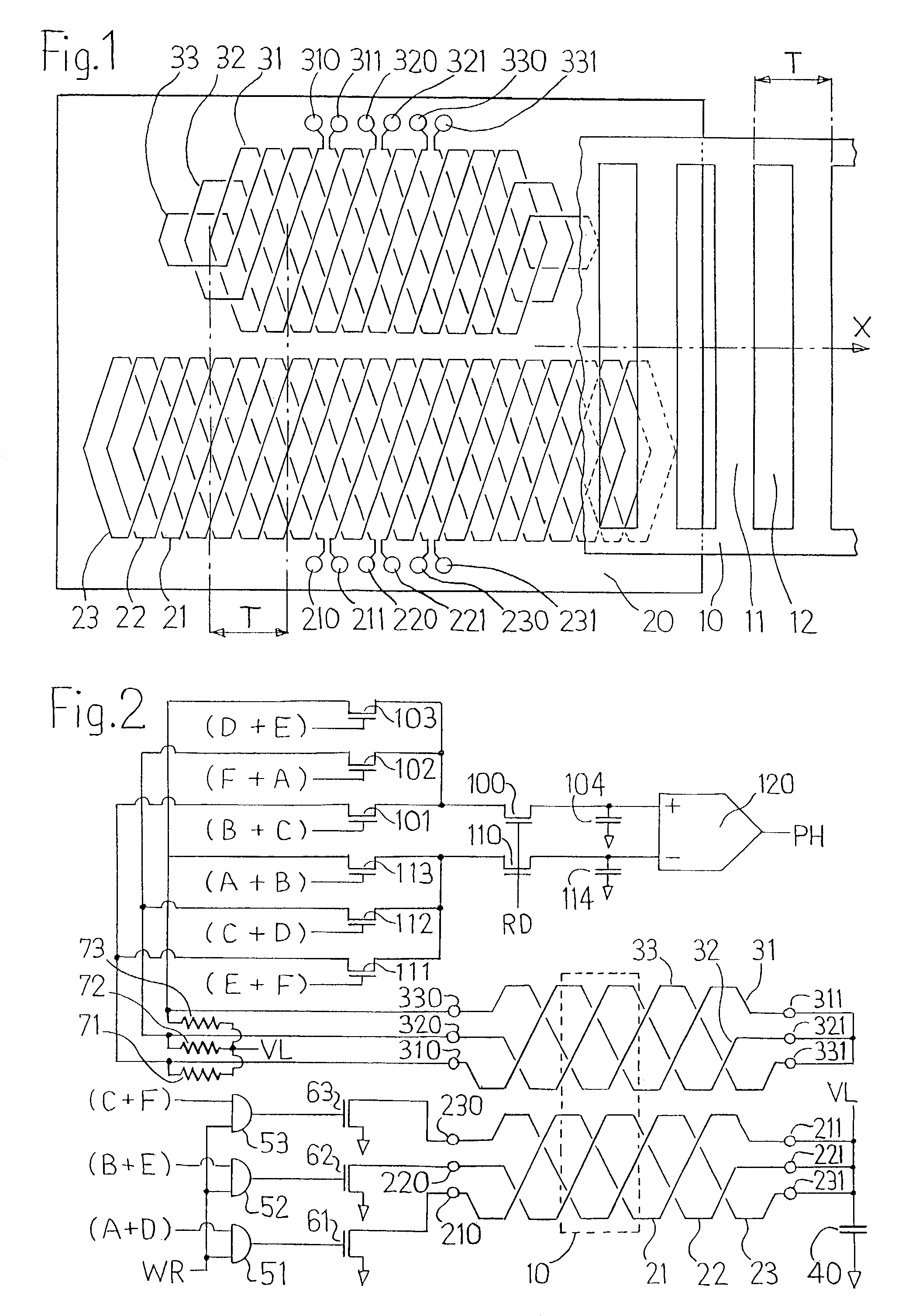

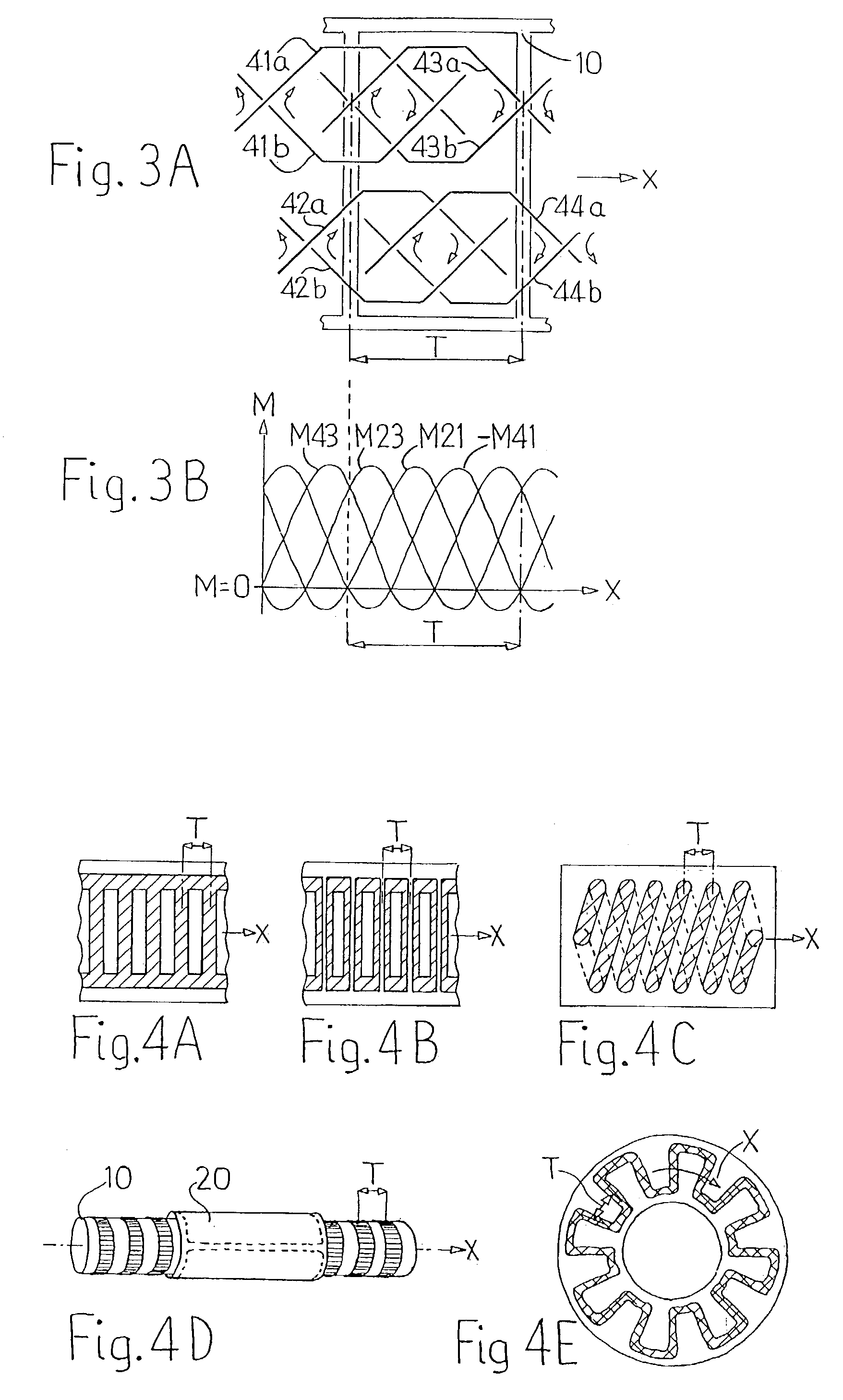

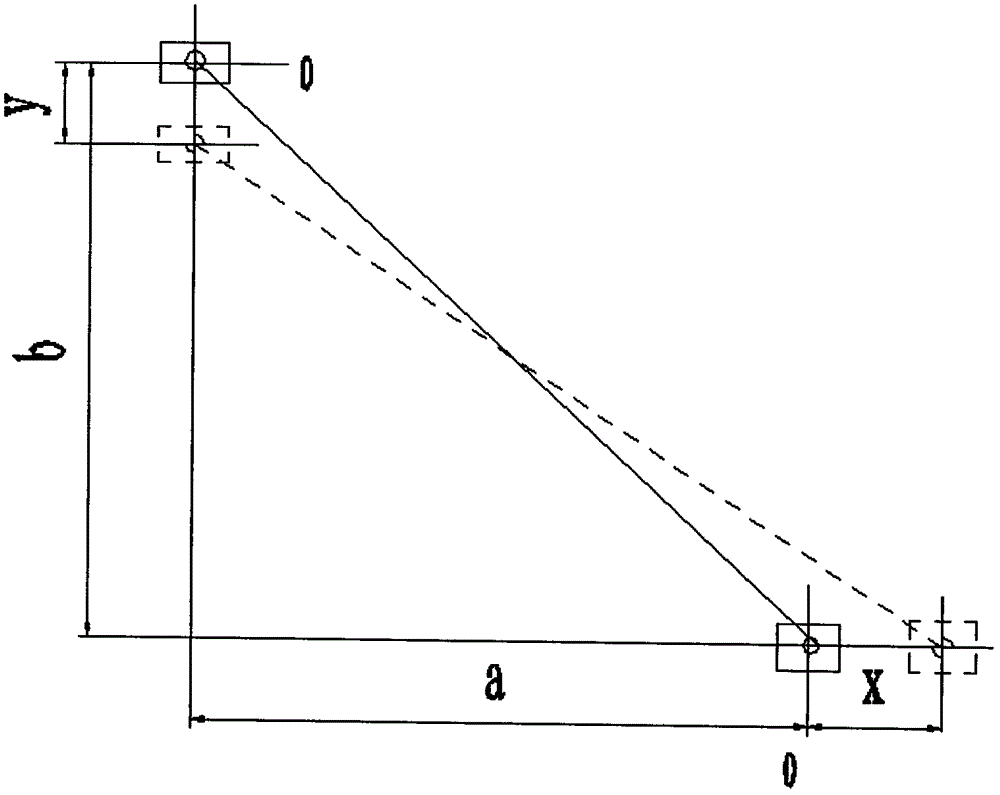

Inductive position sensor with a cursor and a coupling scale

ActiveUS7015687B2Improve accuracyChange gapElectric signal transmission systemsUsing electrical meansElectrical conductorCoupling

The inductive position sensor includes a scale (10) with a series of conductive loops spaced out by a pitch T and a cursor (20) provided with conductors forming each a series of alternating hairpin turns spaced out by a pitch T, the inducing (21 to 23; 42, 44) and induced (31 to 33; 41, 43) cursor conductors are laid out in two separate interlaced conductor groups, coupling between inducing and induced conductors of the second group taking place only via the scale loops. Such a sensor is simple, robust, accurate, insensitive to external electromagnetic fields and tolerant of misalignment between cursor and scale.

Owner:MEYER GMBH

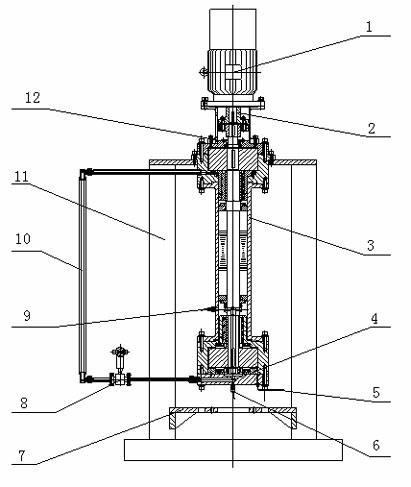

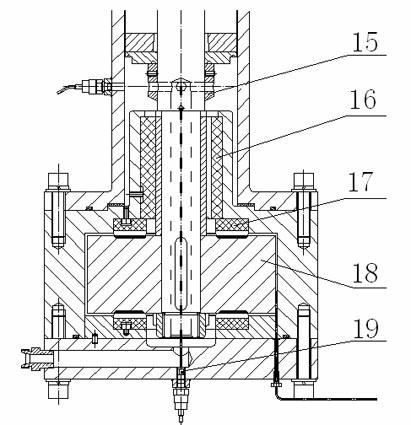

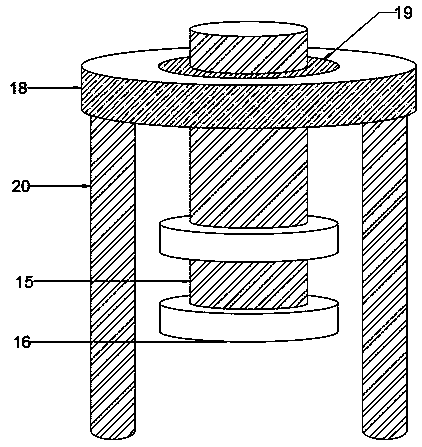

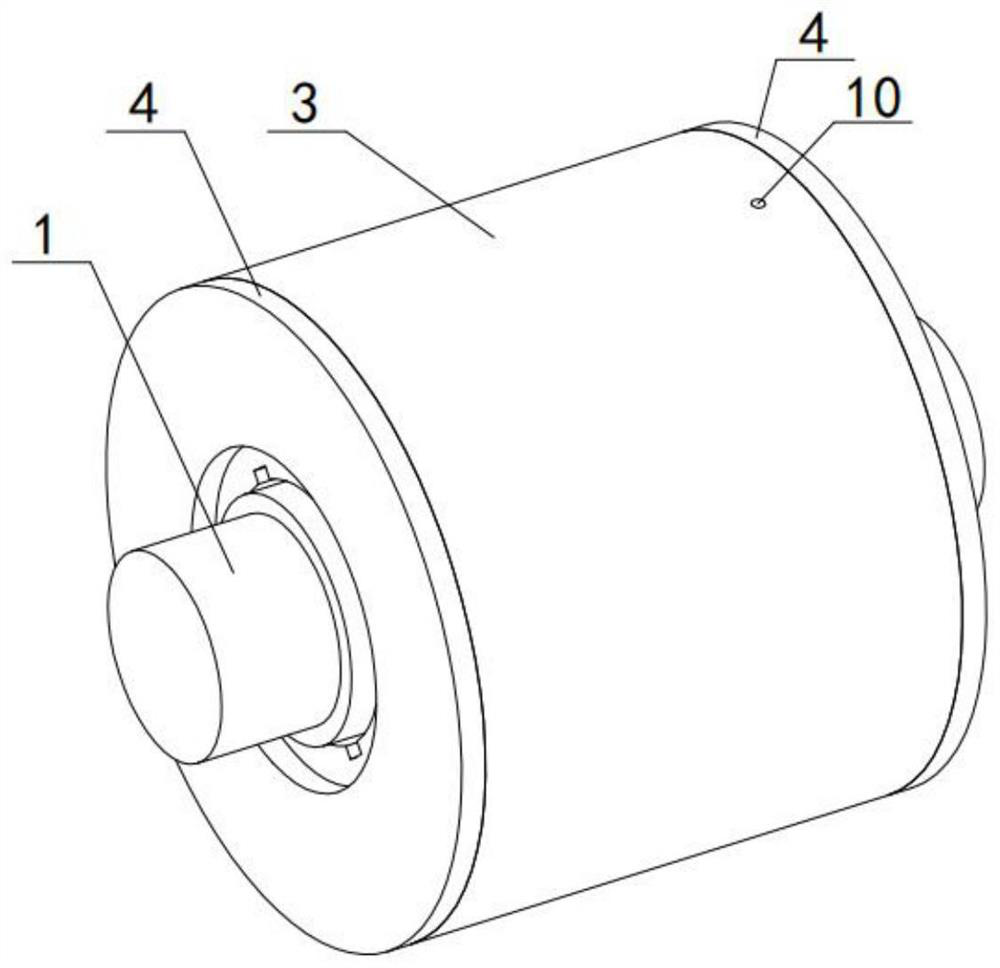

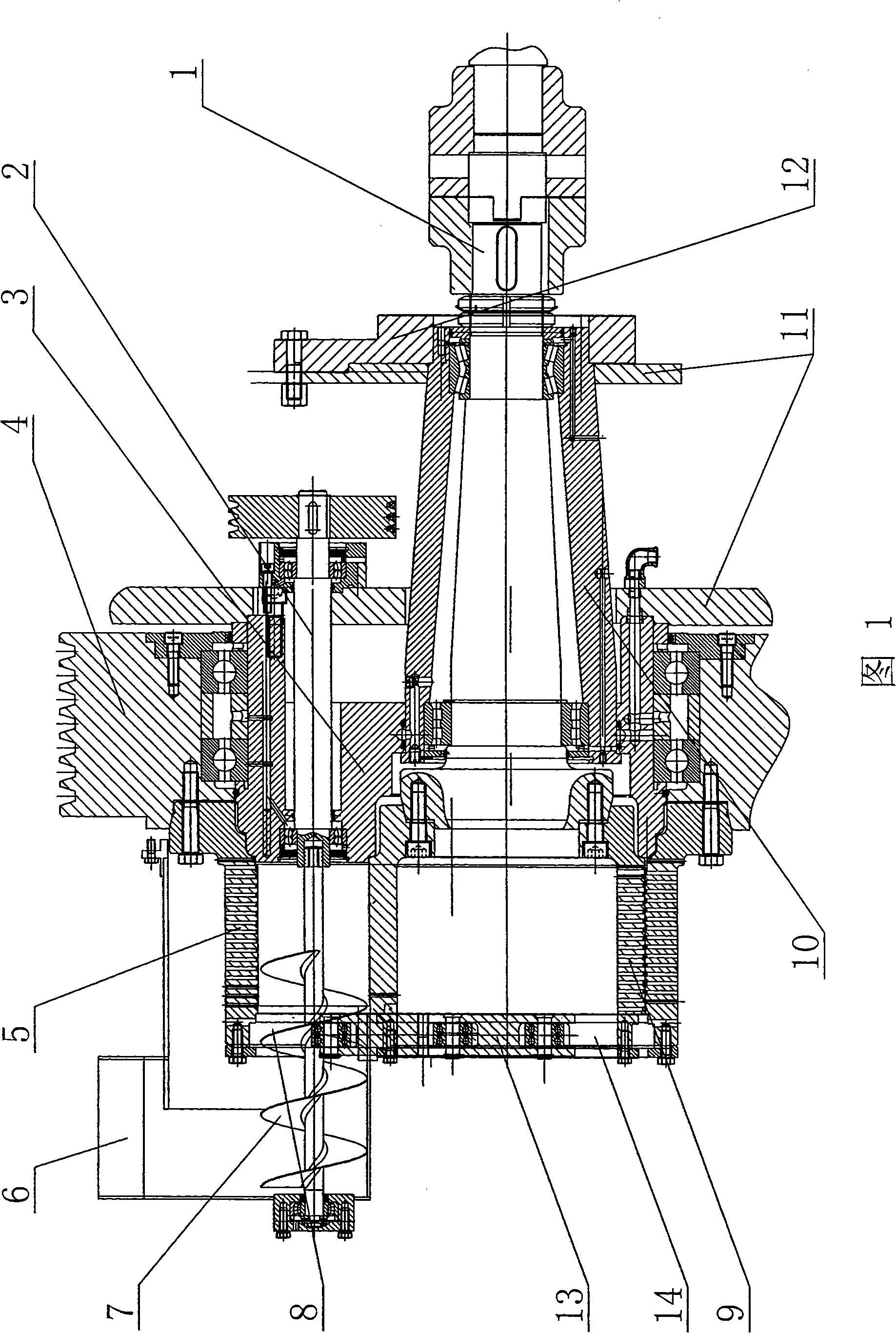

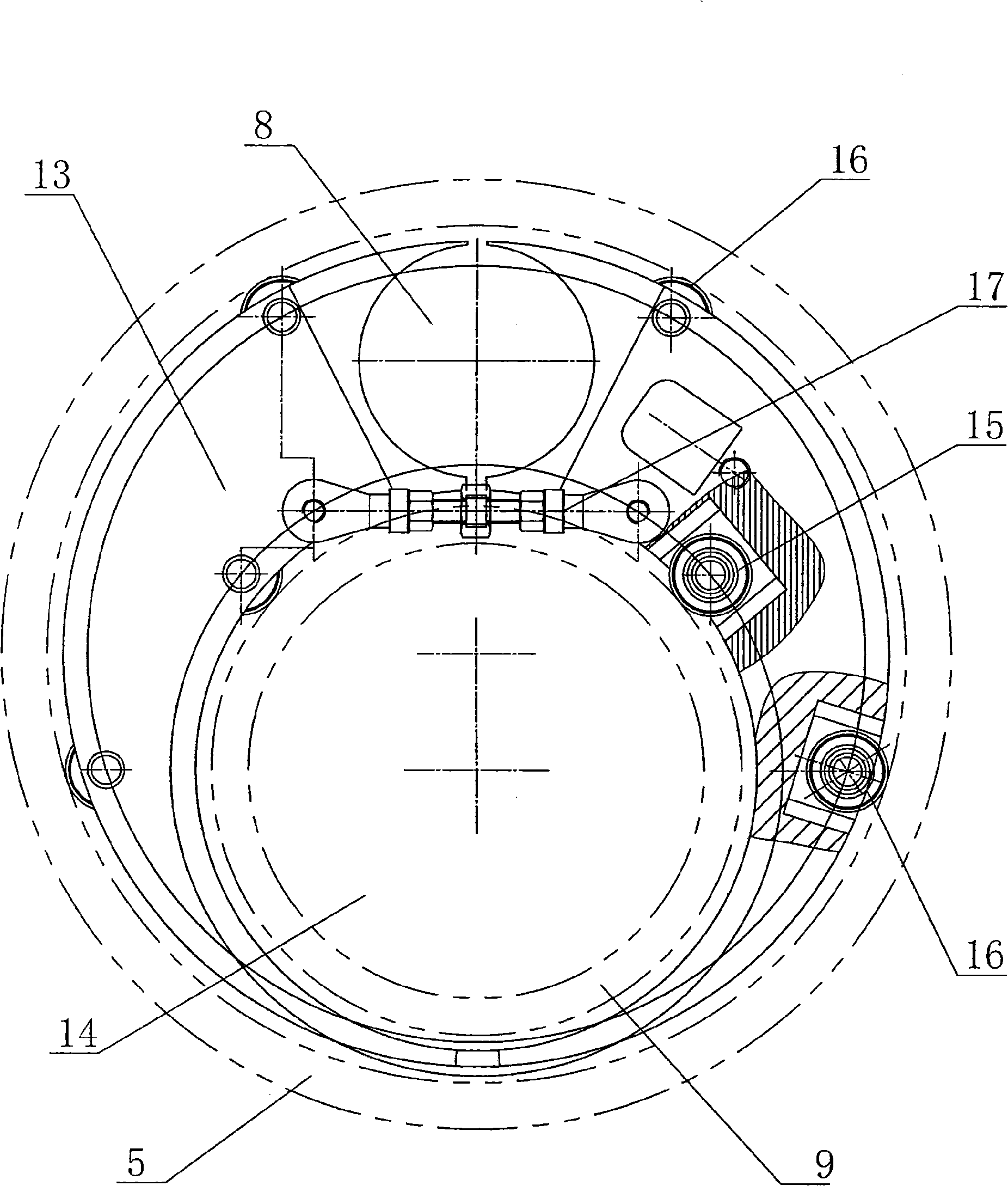

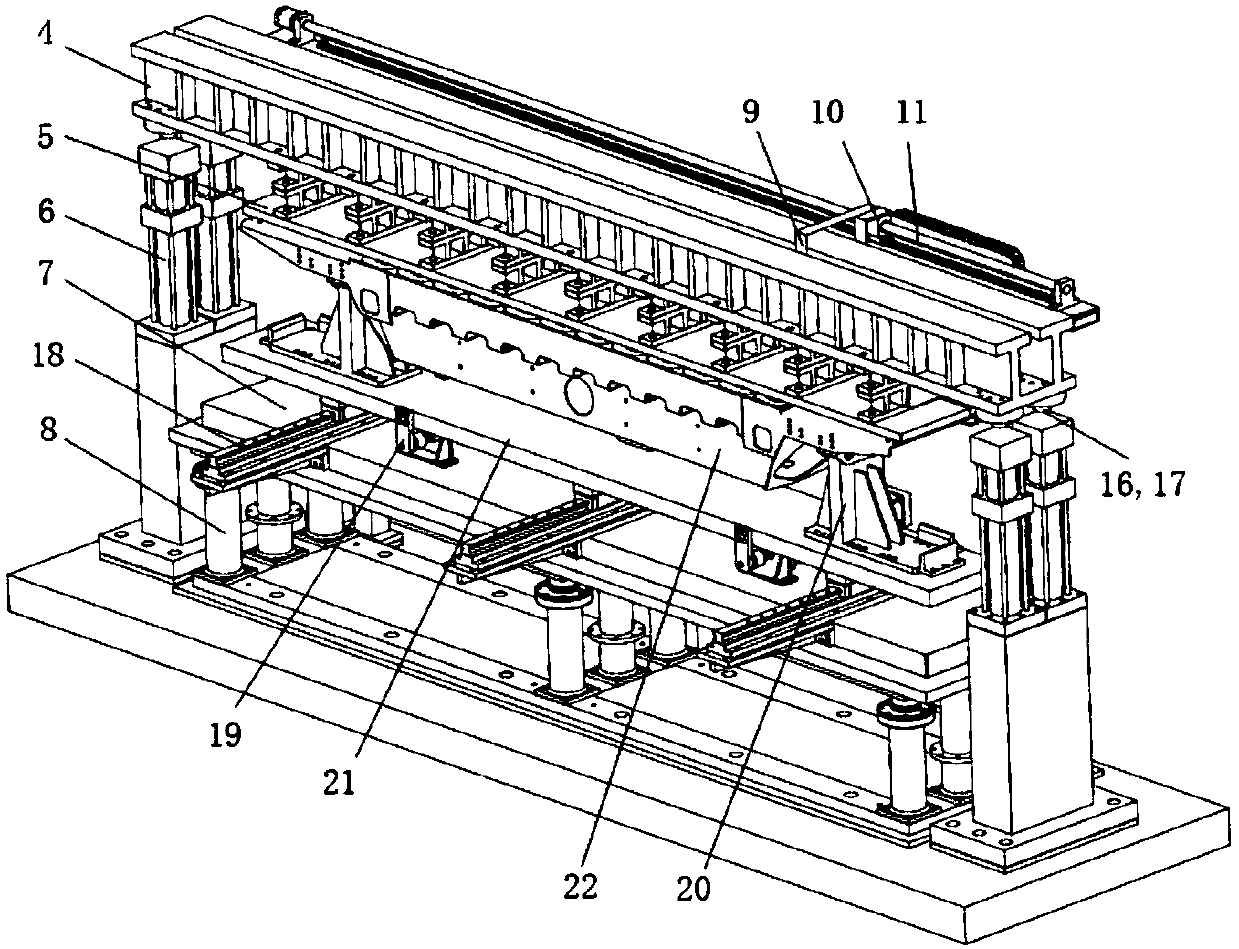

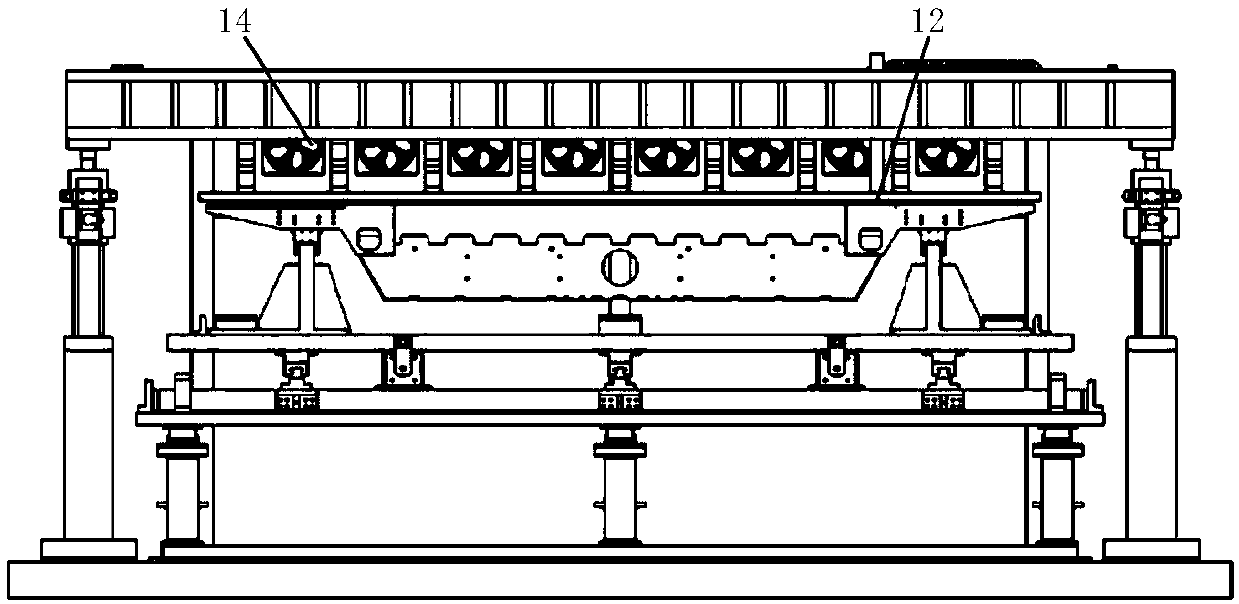

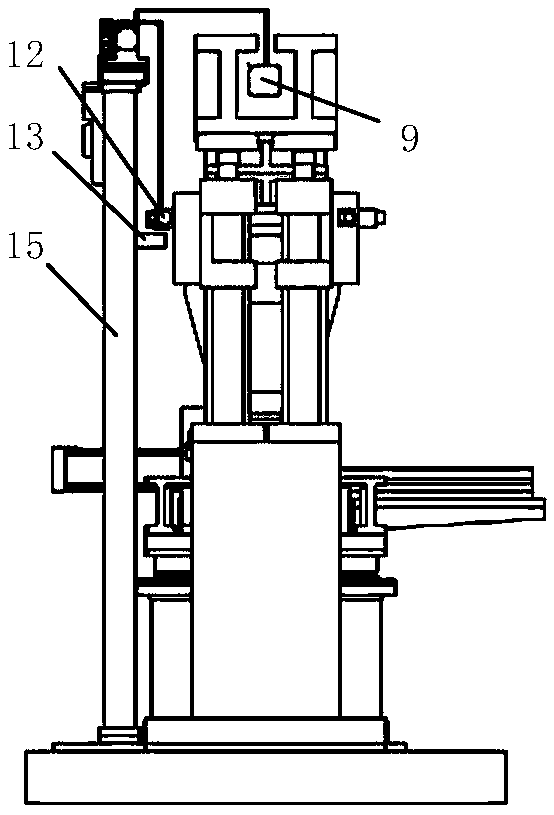

Hydraulic loss testing platform and testing method of canned motor rotor system

ActiveCN102410234ASolve shielding lossFacilitates the measurement of hydraulic power lossesPump controlNon-positive displacement fluid enginesImpellerEngineering

The invention discloses a hydraulic loss testing platform and testing method of a canned motor rotor system. The platform comprises a variable frequency motor, a coupling, a canned motor, a static tube, a flow meter, a pressure sensor, a motor pallet, a circulation pipeline, a supporting bracket and a seal ring. According to the invention, a canned motor is dragged and simplified by an external variable frequency motor, thereby eliminating the canning loss of the canned motor; the pressure difference generated by an auxiliary impeller is obtained by the pressure sensor, and the flow through the middle part of the auxiliary impeller is obtained by the flow meter, thereby separating quickly the power loss of the pressure flow of the canned motor; a replaceable auxiliary impeller is mounted at the middle part of the canned motor pump rotor, so at to regulate the amount of the pressure flow; and the clearance between the rotor and the stator of the canned motor pump is changed by replacing a sleeve of the stator, and the impact of different clearances on the power loss of the pressure flow and the shear flow of the canned pump can be studied. By using the hydraulic loss testing platform and testing method provided by the invention, the hydraulic loss of the canned motor can be obtained, which provides reference for the structural parameter optimization of the canned motor.

Owner:SHANGHAI JIAO TONG UNIV

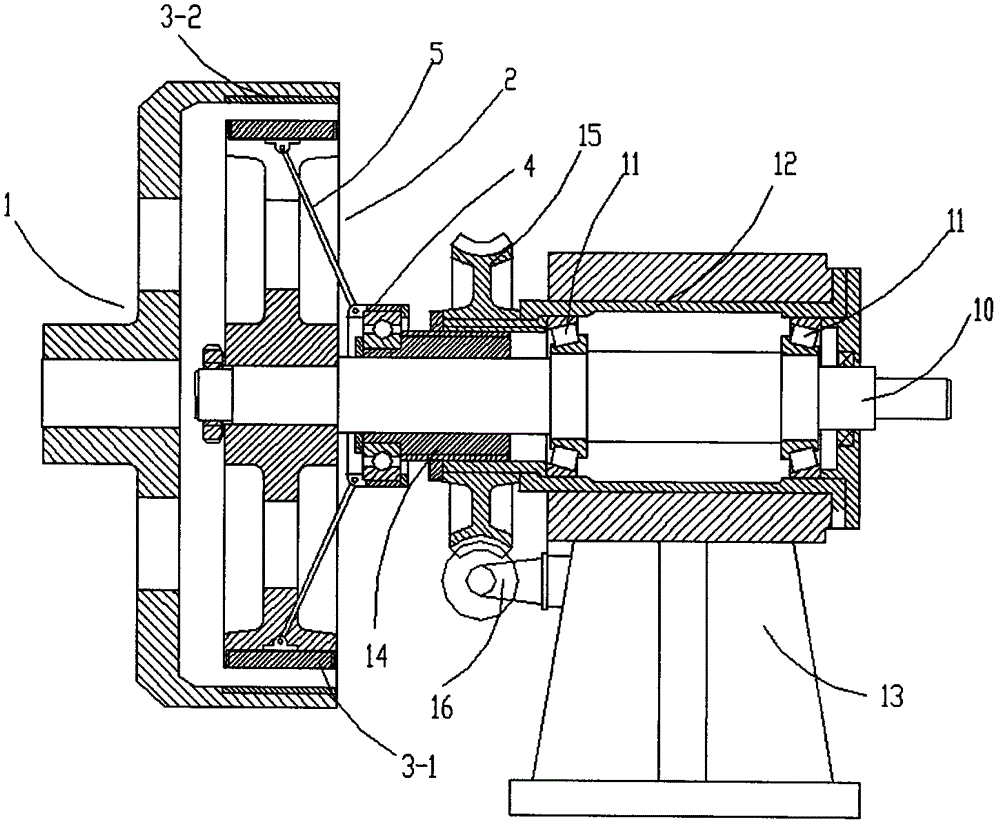

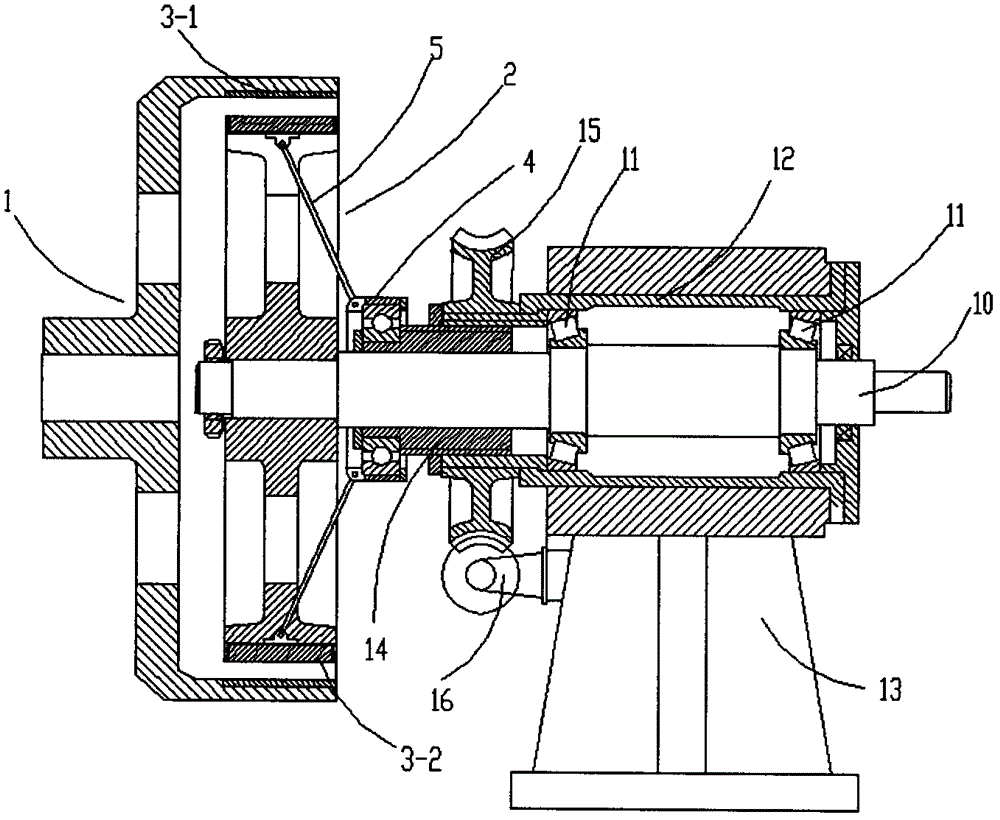

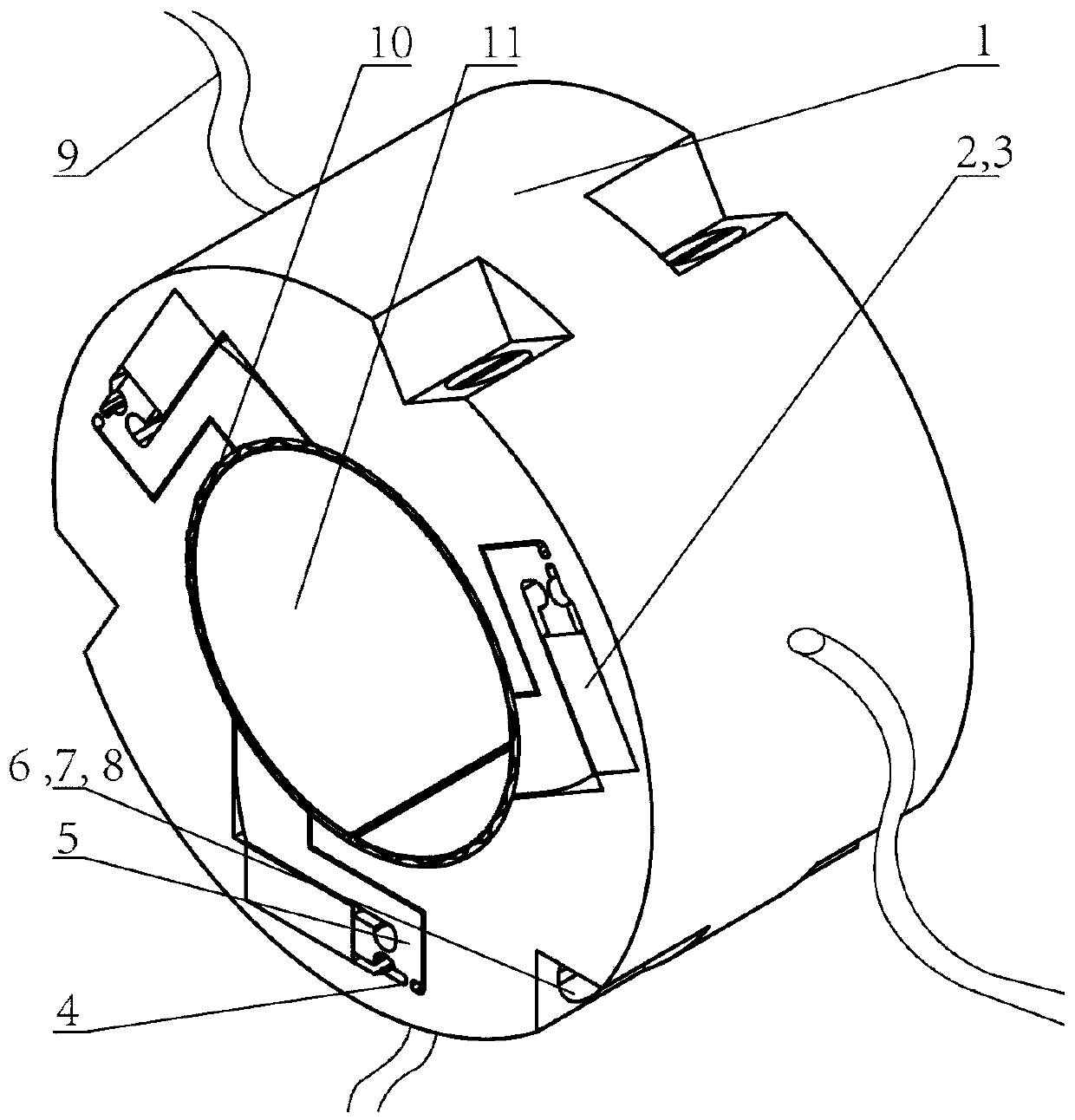

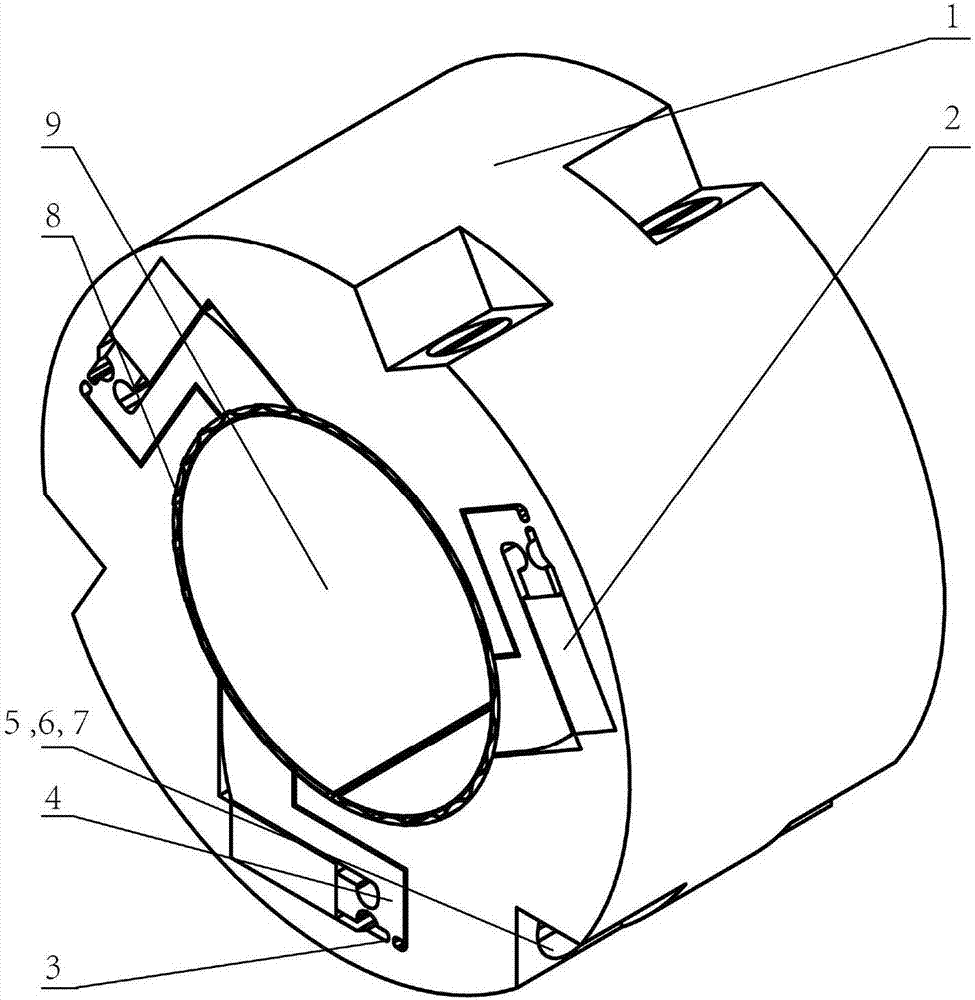

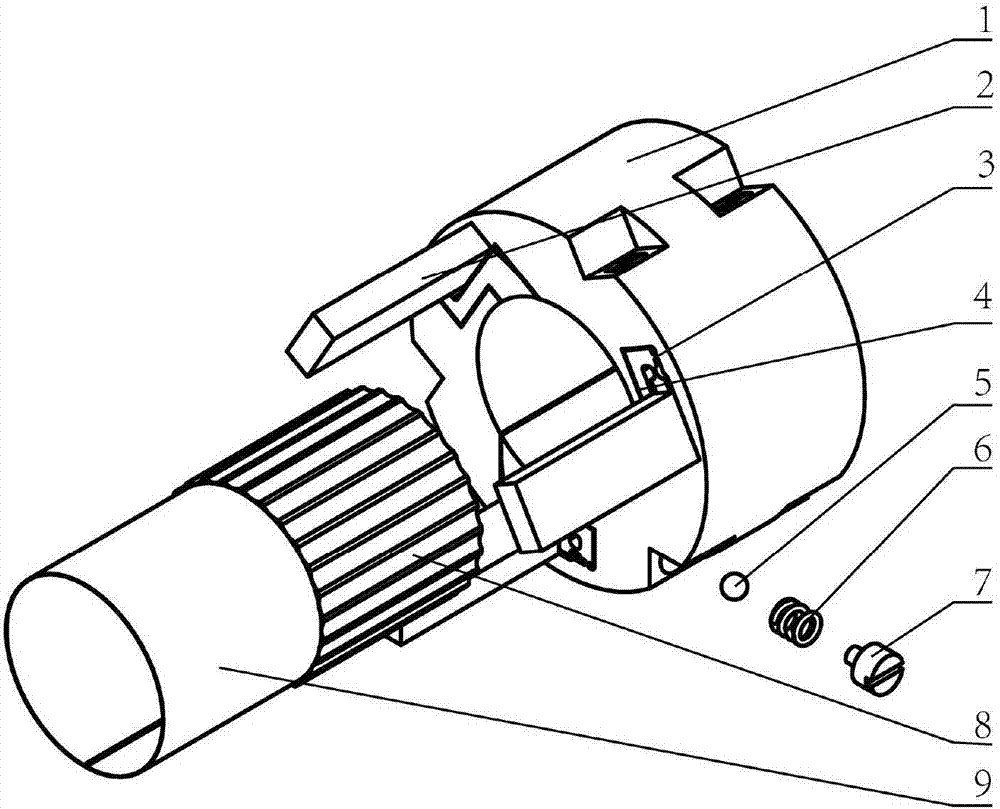

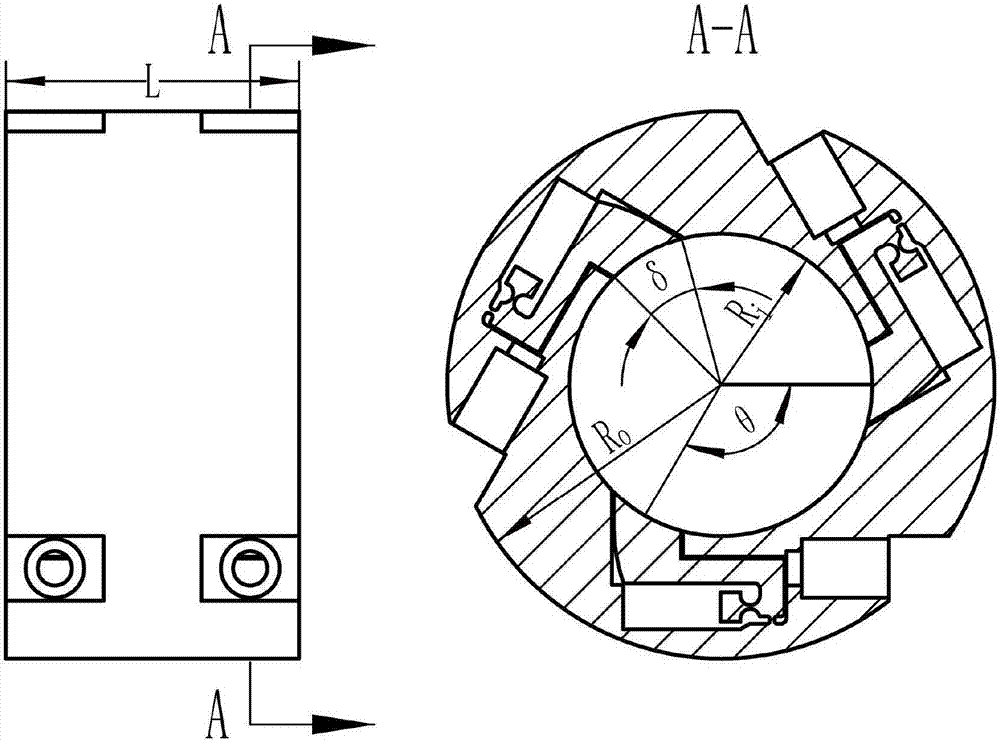

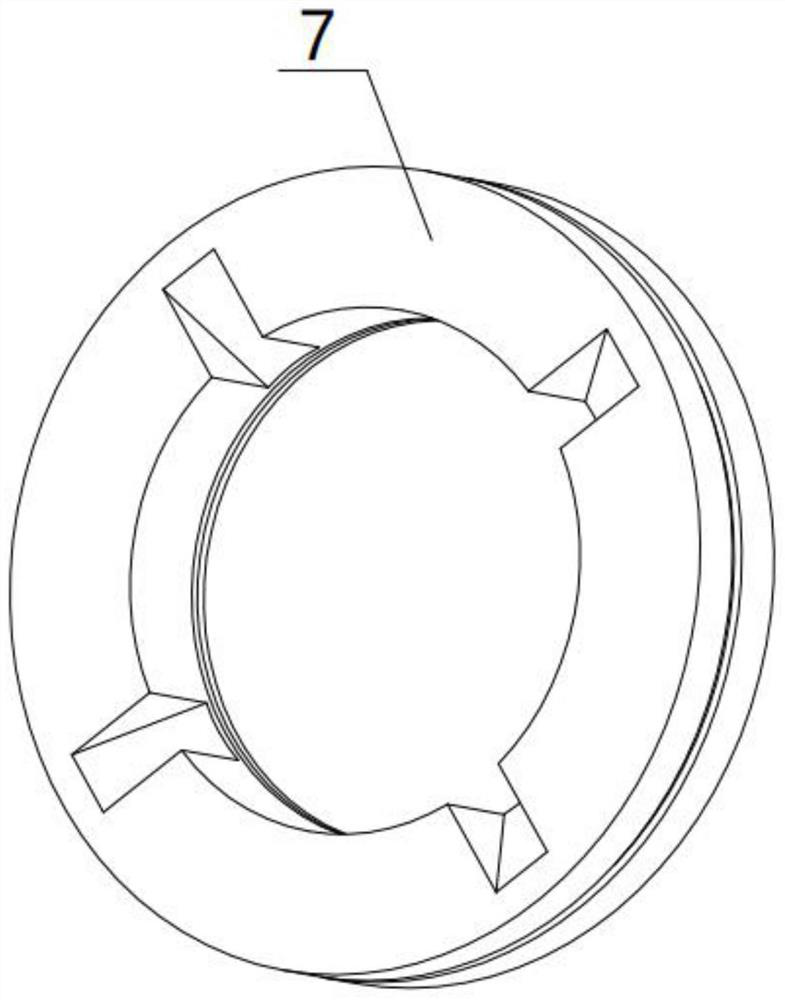

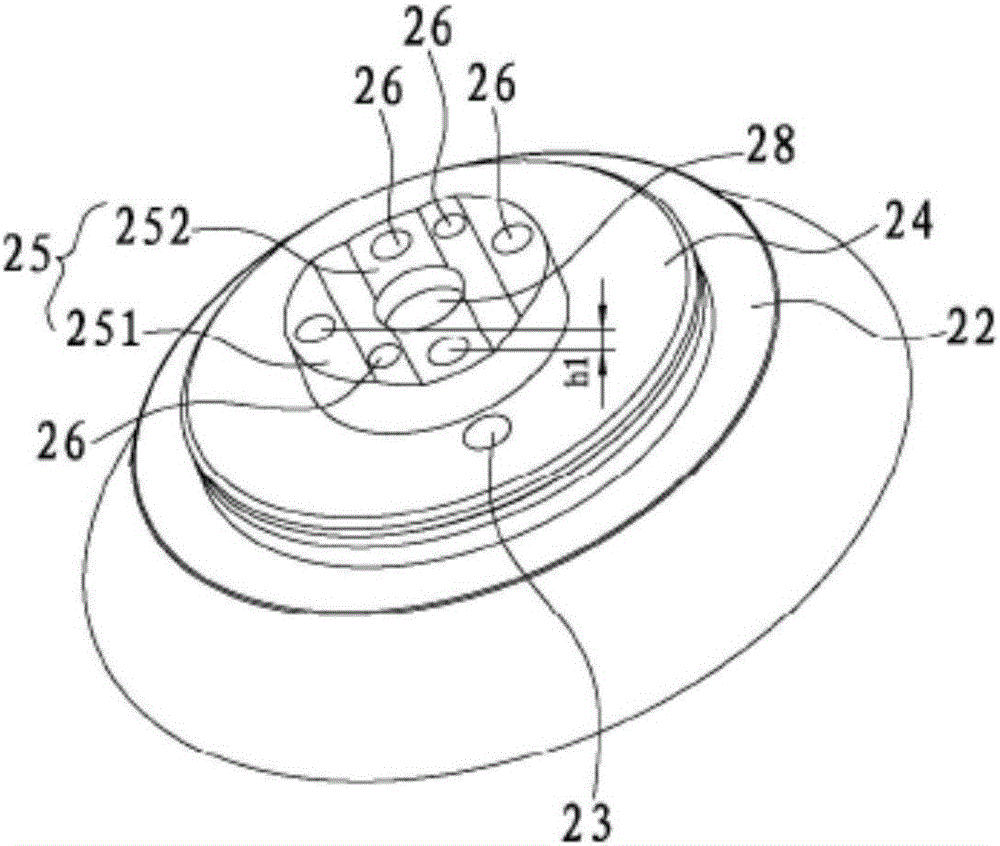

Radial-clearance-adjustable permanent magnet speed regulation device

The invention discloses a radial-clearance-adjustable permanent magnet speed regulation device. The speed regulation device is characterized by comprising a first barrel-type rotation assembly and a second barrel-type rotation assembly, wherein the first barrel-type rotation assembly and the second barrel-type rotation assembly are coaxially installed, and the outer surface of the second rotation assembly is provided with a permanent magnet or an electric conductor; the speed regulation device further comprises a push-pull sleeve connected with the permanent magnet or the electric conductor, and one end of the push-pull sleeve is connected with a clearance adjustment device. The speed regulation device is small in overall size, light in weight and large in transmission torque; a speed regulation mechanism is simple, and the radial clearance can be regulated in a labor-saving mode; the air-gap size can be changed, and also the coupling area can be changed.

Owner:诸暨和创磁电科技有限公司

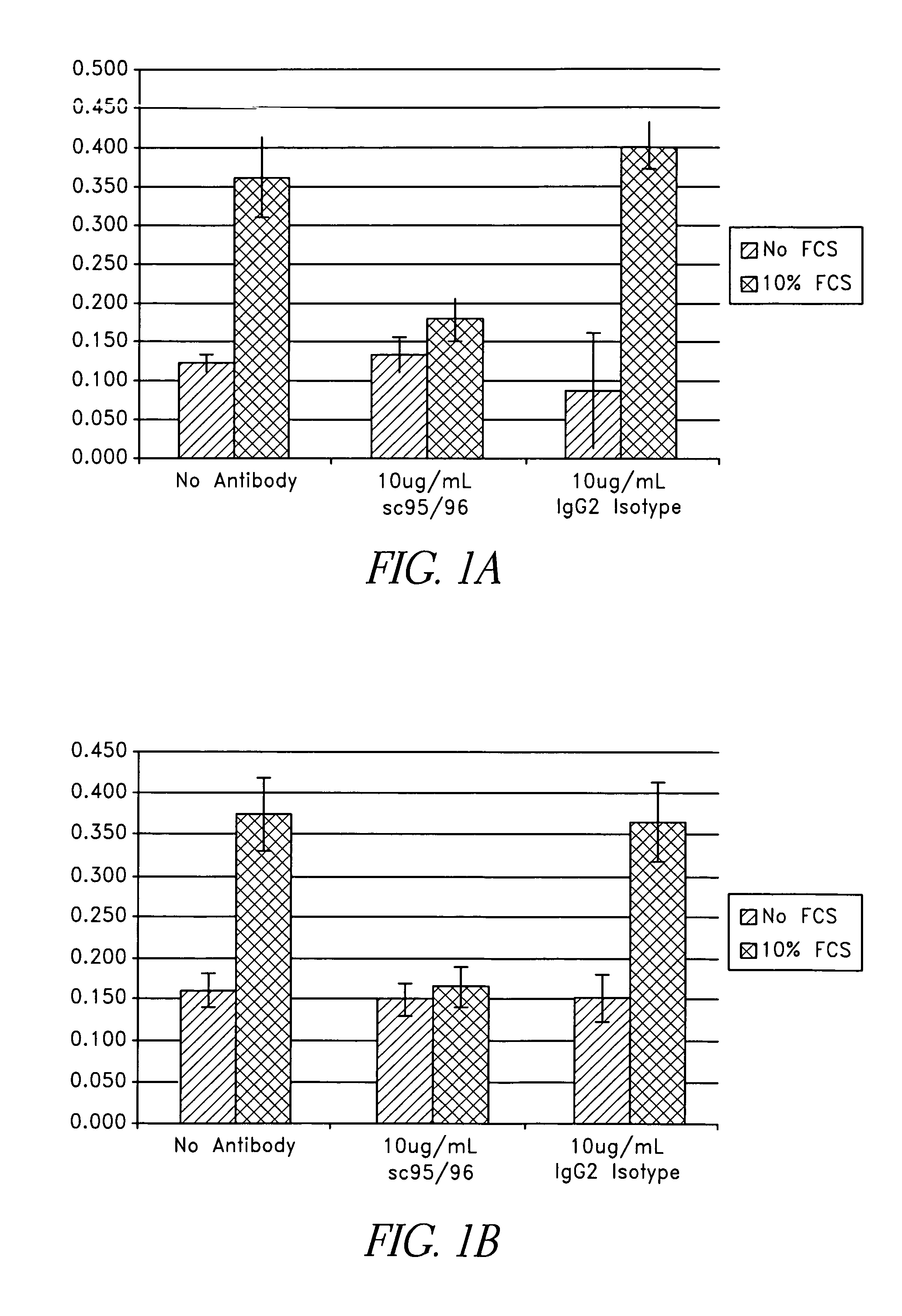

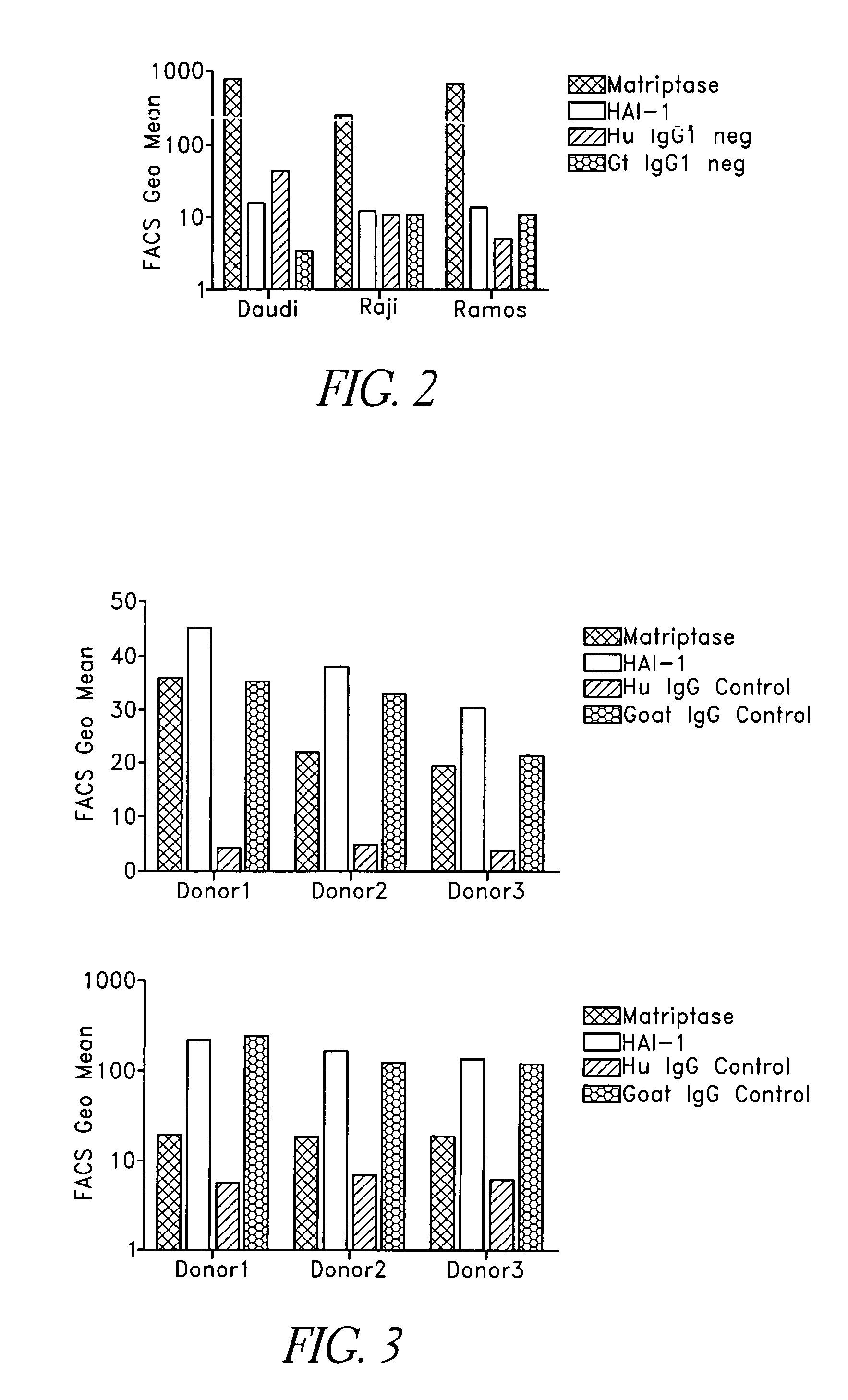

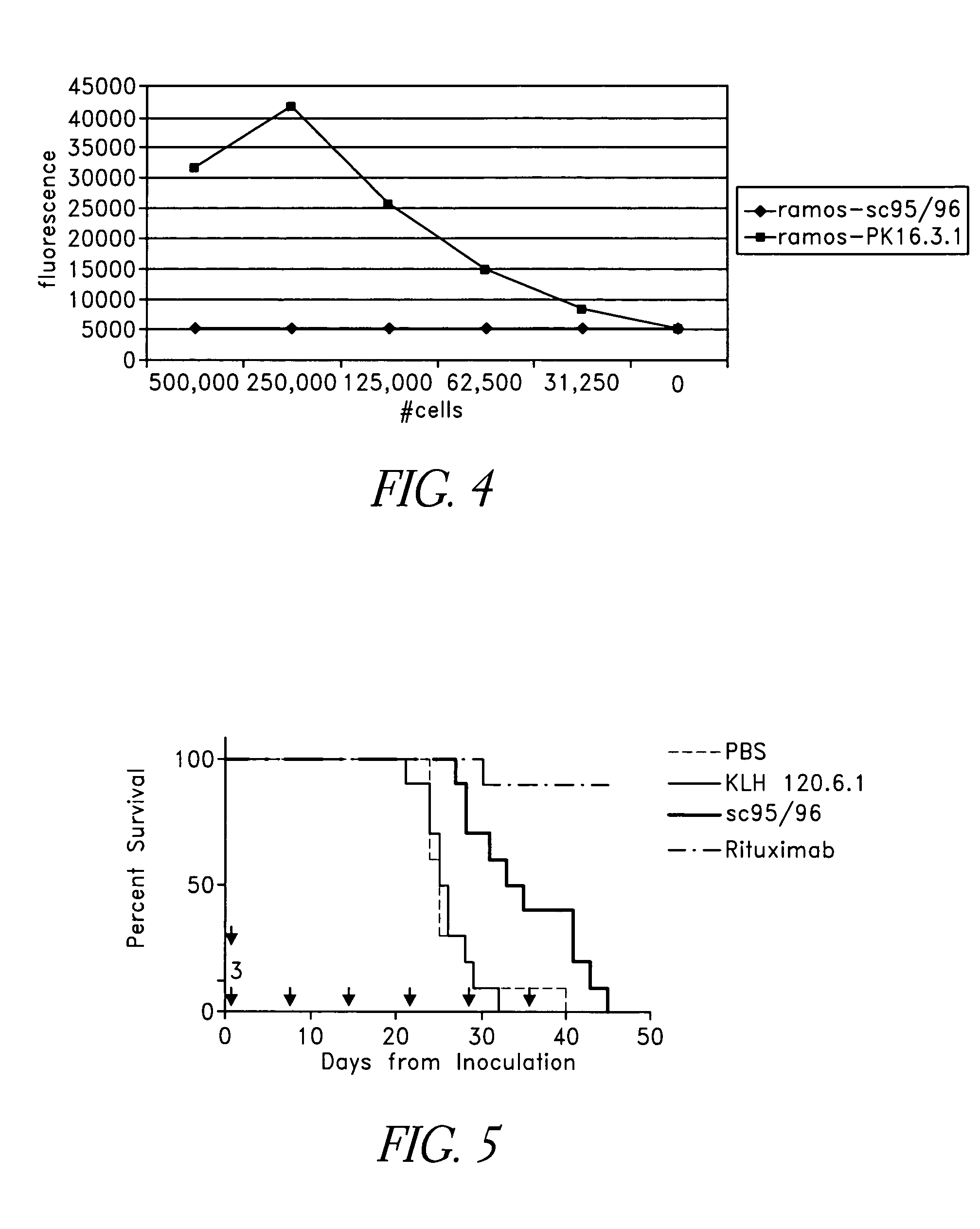

Binding proteins specific for human matriptase

ActiveUS7572444B2Effective treatmentEnhance their capability of fixing complementCompound screeningApoptosis detectionDiseaseAntigen

Binding proteins, such as fully human monoclonal antibodies and fragments thereof, directed to the antigen Matriptase and uses of such binding proteins are disclosed. Nucleotide sequences encoding, and amino acid sequences comprising heavy and light chain immunoglobulin molecules capable of binding to Matriptase are also disclosed. The invention also discloses cell lines expressing such immunoglobulin molecules and monoclonal antibodies to Matriptase. The antibodies can be used to detect, prevent, and treat diseases such as cancer.

Owner:DENDREON PHARMA LLC +1

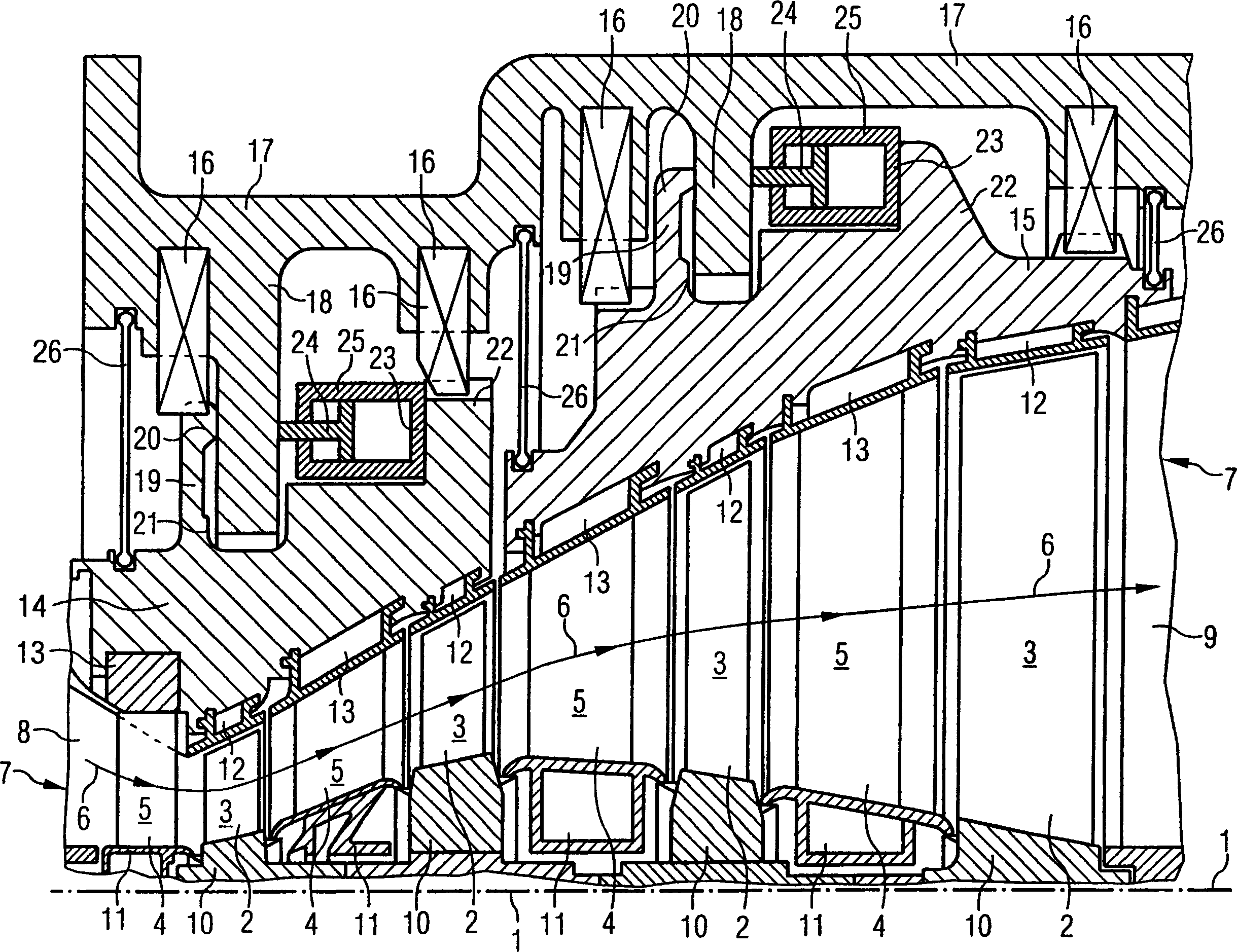

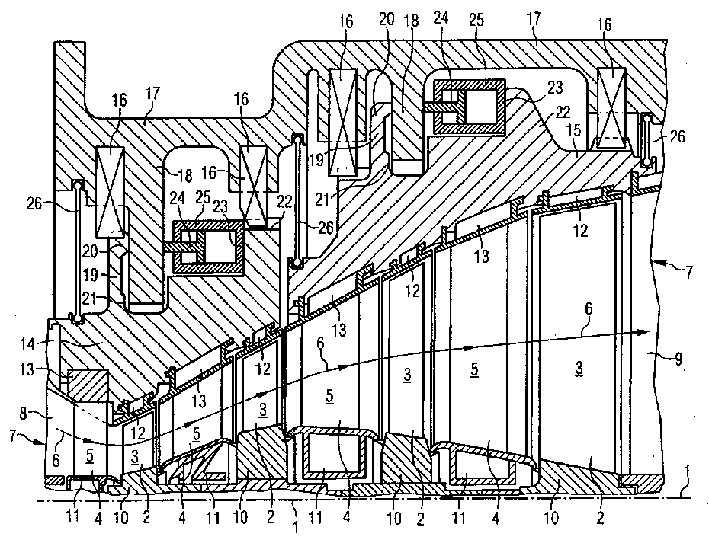

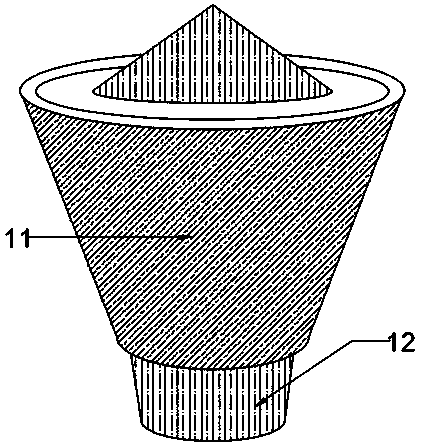

Combustion turbine with axial relative movel guide unit

InactiveCN1381670AAdjust the clearanceChange gapLeakage preventionGas turbine plantsCombustionEngineering

In order to balance different thermal expansions caused by thermal instability, the gas turbine of the present invention has a relatively movable guide part (14 / 15) in the axial direction, which surrounds a funnel-shaped gas channel (7) from the outside. In order to obtain an optimum working blade tip clearance, the invention proposes that at least one funnel-shaped guide part (14 / 15) can be moved axially controlled by a motor. By means of this axial movement, and due to the funnel-shaped configuration of the guide part, the width of the gap between the tips of the rotor blades can be varied.

Owner:SIEMENS AG

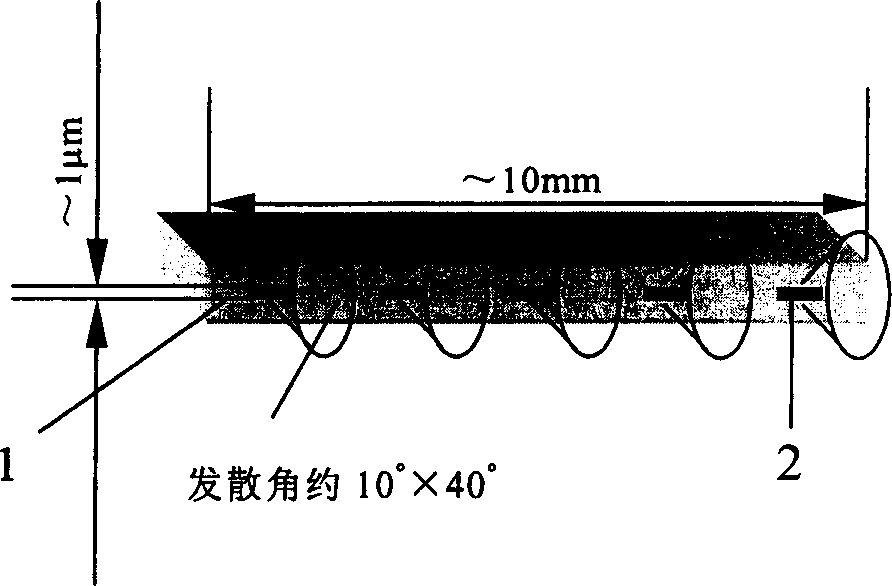

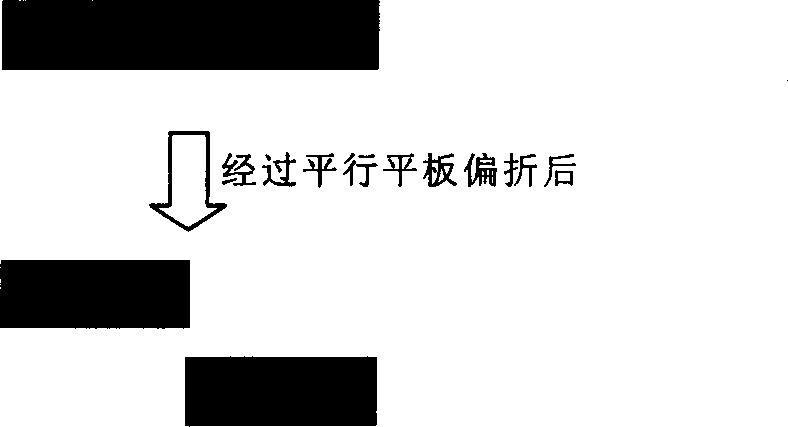

Method for realizing bar array semiconductor laser shaping by means of reflecting prism stack

This invention relates to method for shaping the strip semi-conductive laser by using the refracting and reflecting prism stack, which is characterized by the following: (1) using one or several parallel plats to split slow axial light spot of the strip semi-conductive laser; (2) using a group of stepwise reflecting prism stacks to align the splitting spots along the fast axial for the purpose of shaping the light beam.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

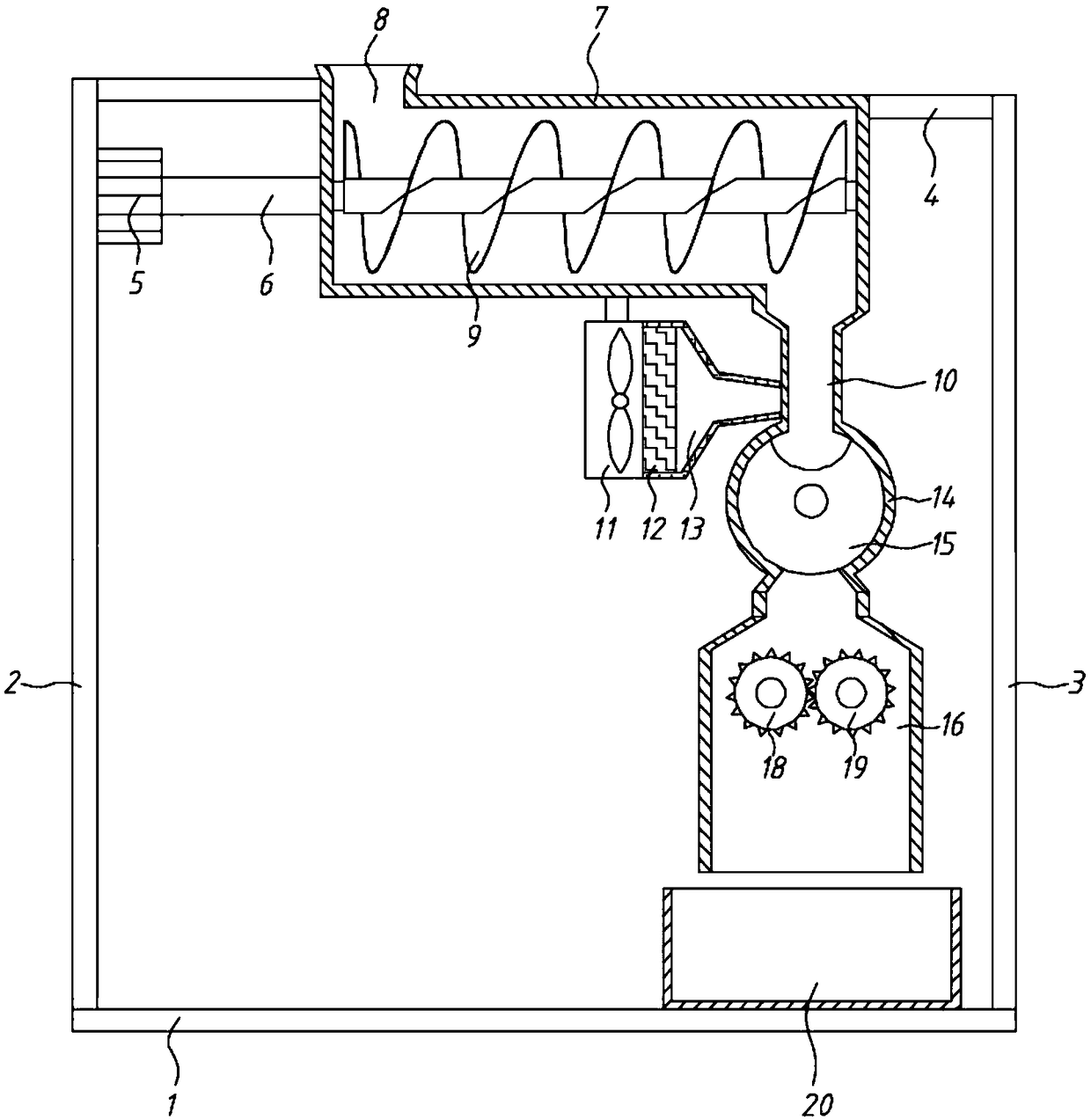

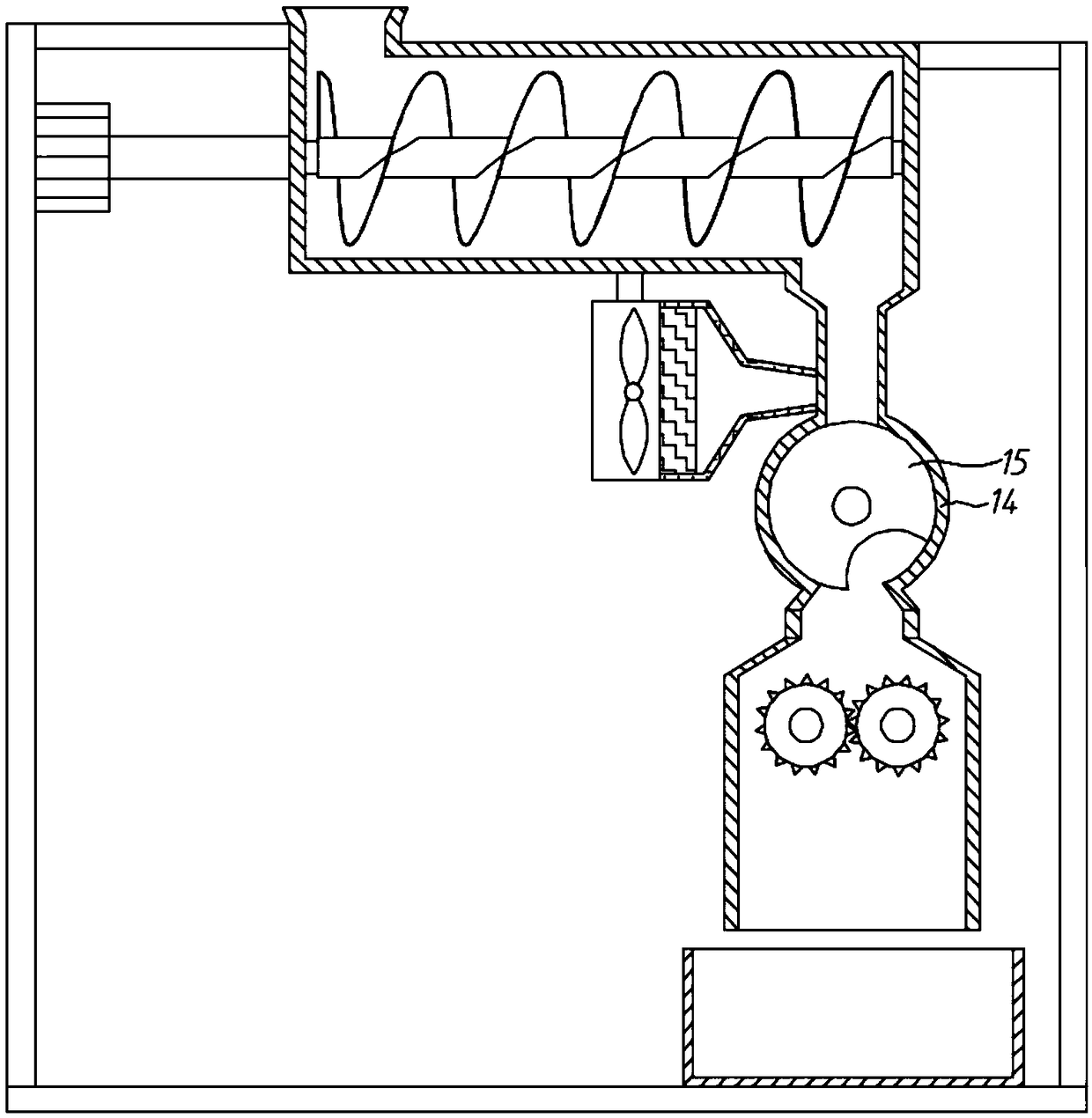

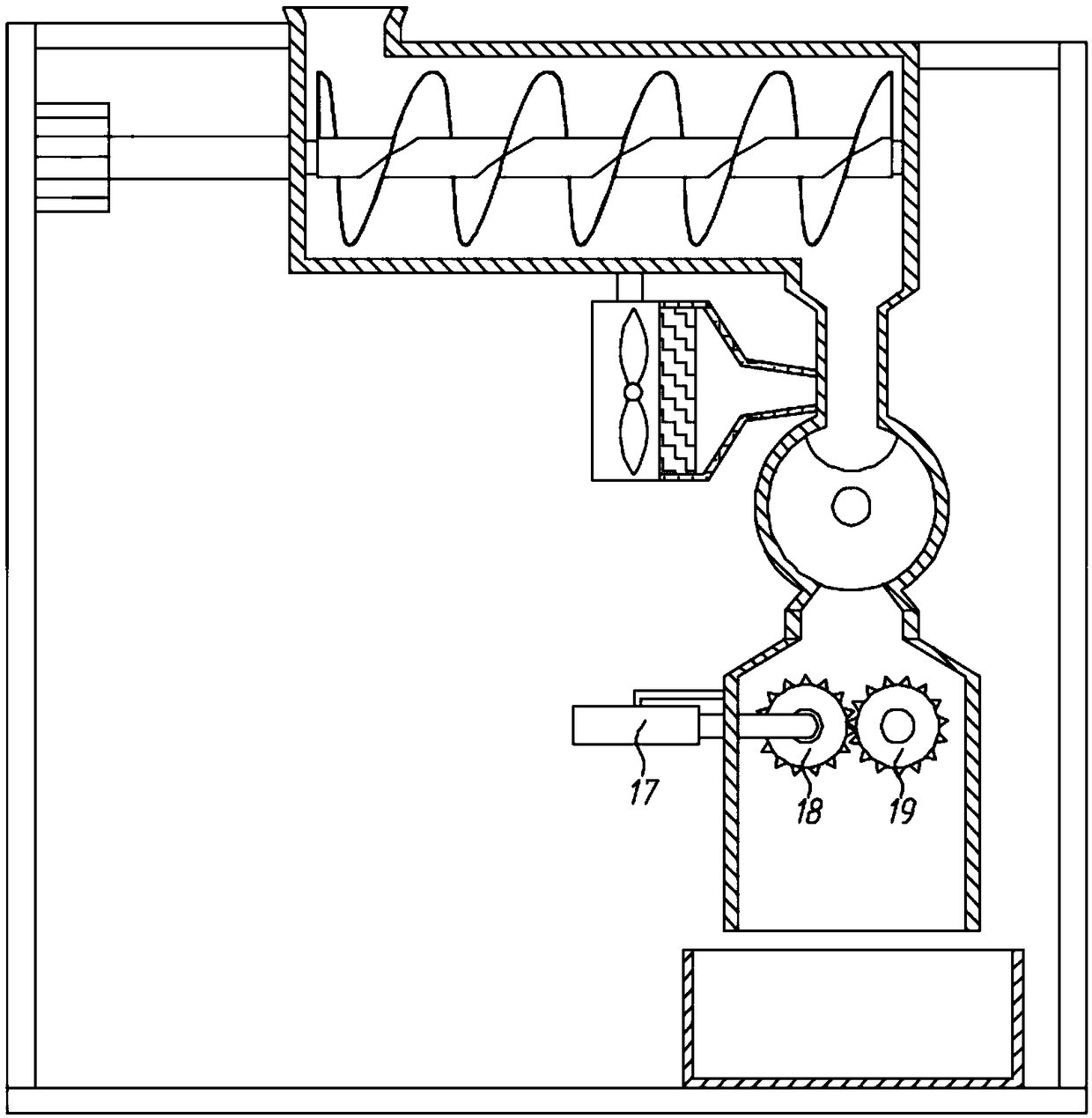

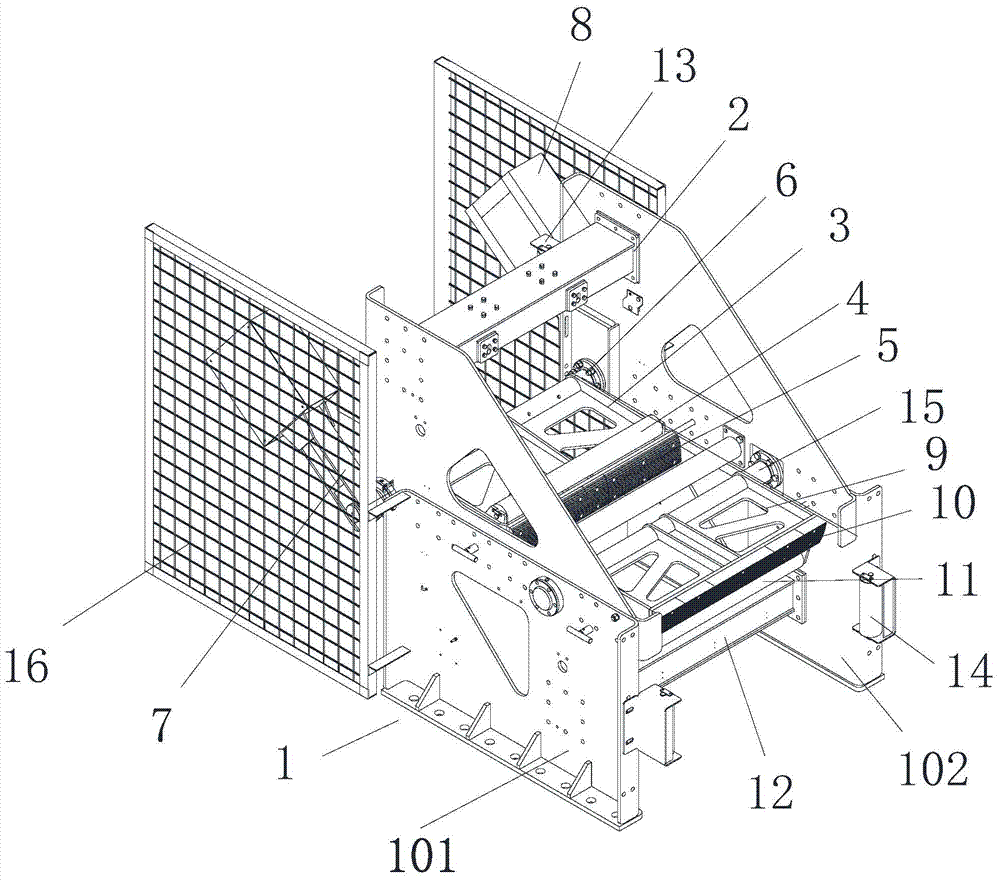

PVC tub recycling pulverizer with drying function

ActiveCN109397579AGuaranteed crushing efficiencyAvoid the poor effect of secondary crushingPlastic recyclingGrain treatmentsDual stageGear wheel

The invention relates to the technical field of PVC tube recycling, in particular to a PVC tube recycling pulverizer with a drying function. By adopting dual-stage pulverizing, according to first-stage pulverizing, a rotating shaft drives a spiral packaging auger to work, PVC tubes are pulverized while being conveyed, then, a pulverizing roller inside a second-stage pulverizing cylinder is adoptedfor secondary pulverizing, and the pulverizing efficiency is ensured; a storage pipe is connected to the discharging end of the primary pulverizing cylinder, a drying assembly is arranged at one sideof the storage pipe, and the preliminary pulverized PVC tubes fall into a storage tube, a fan heats air through a heating cavity and is introduced into the storage tube, and the PVC tube is dehumidified and dried; a drive motor drives a driving shaft to rotate, a driving bevel gear and a driven bevel gear act to drive the driven shaft to rotate, a connecting rod drives a push-pull rod to reciprocate, the push-pull rod periodically collides with the secondary pulverizing cylinder, PVC particles stuck to the cylinder wall are shaken down, and resides are reduced.

Owner:靖江市易凯通风设备有限公司

Copper strip surface degreasing device

The invention discloses a copper strip surface degreasing device, which comprises a container containing cleaning agent. The container and a frictional cleaning device are fixed in a box body. The container is provided with a conveying device conveying the cleaning agent to the frictional cleaning device. The frictional cleaning device comprises an upper friction body and a lower friction body, between which a gap is left for the end part of a copper strip to insert. The invention can clean the greasy dirt accumulating on the surface of the copper strip thoroughly and has the advantages of clean cleaning and high efficiency.

Owner:常州模威科技有限公司

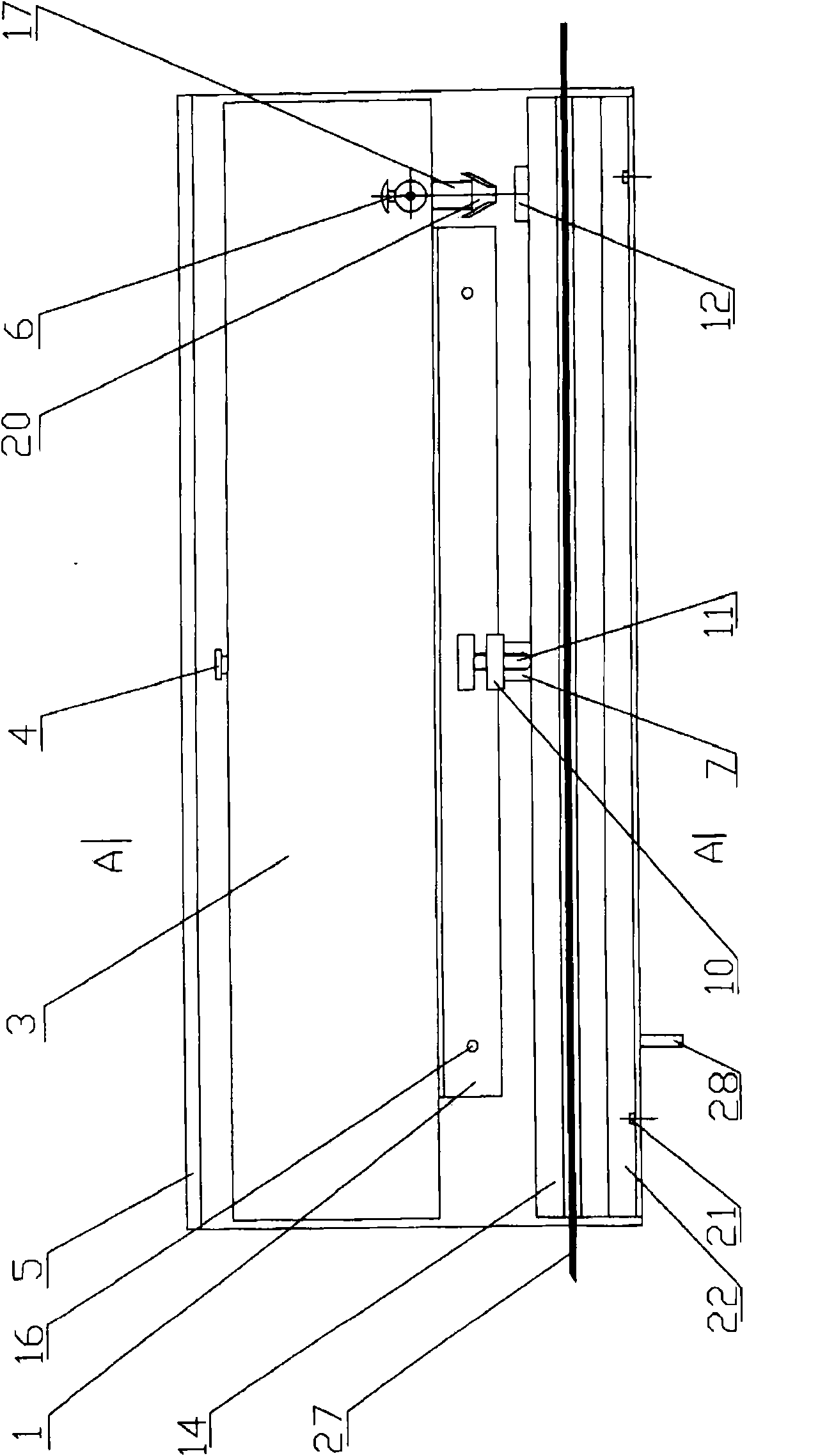

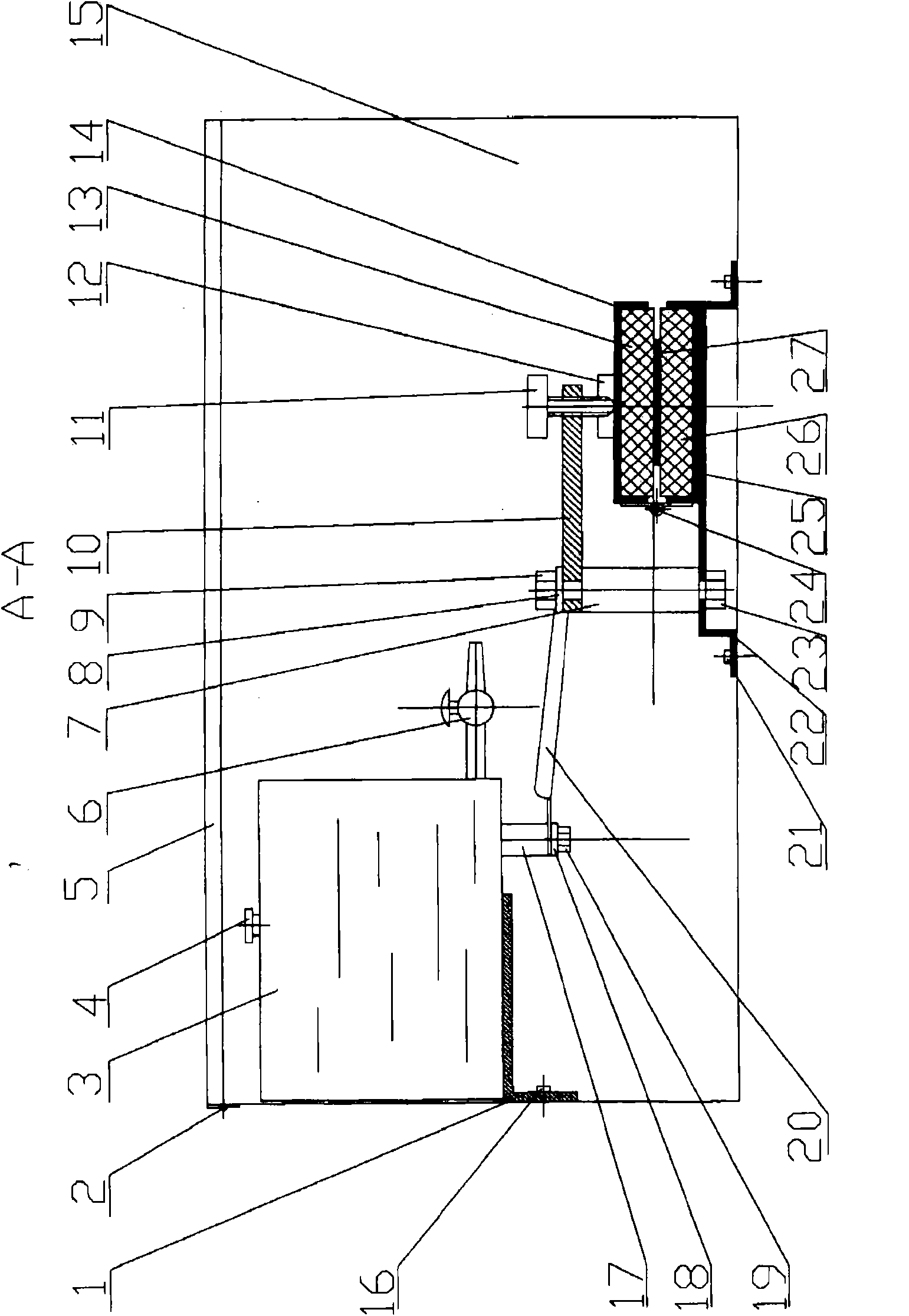

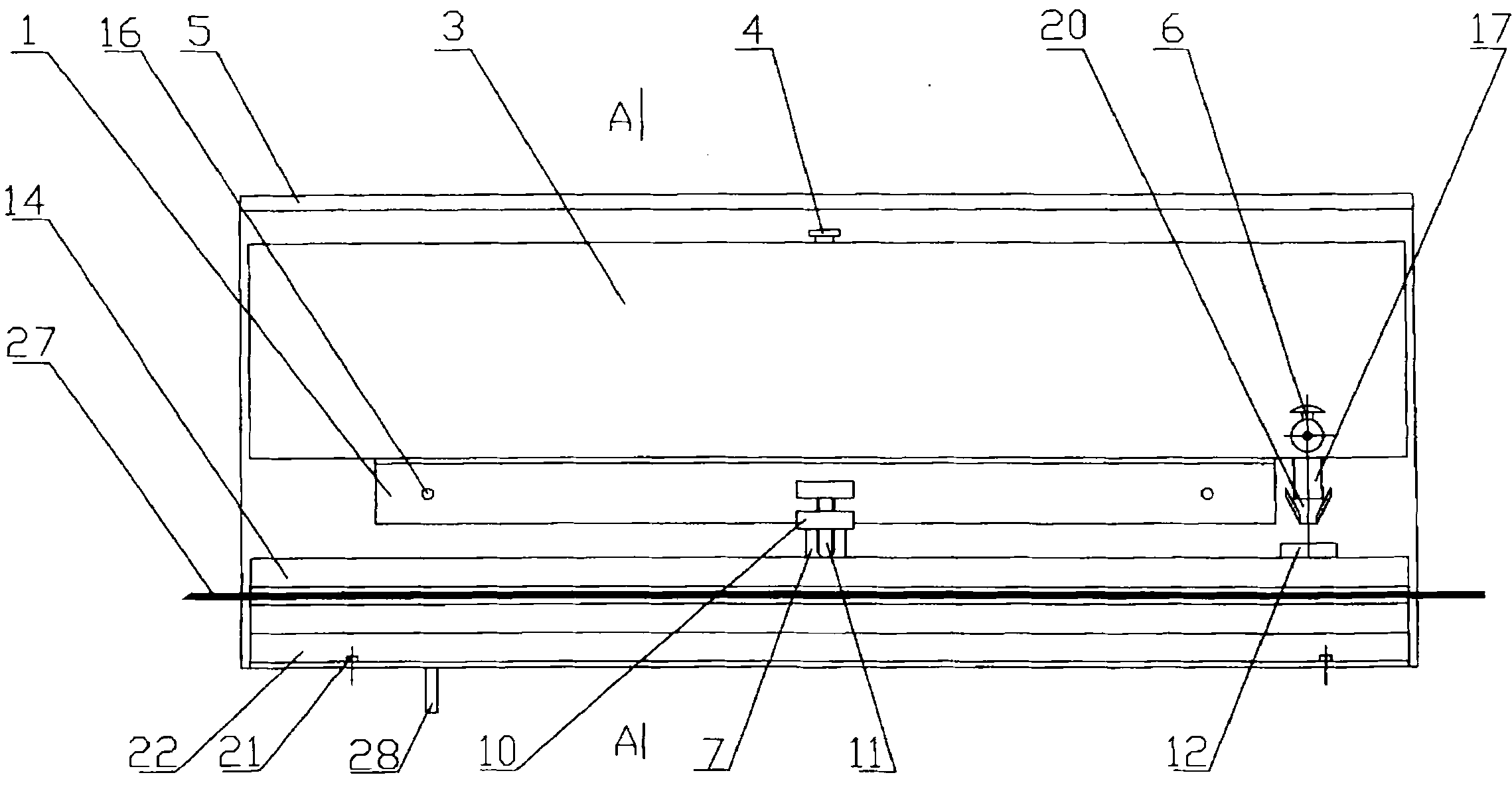

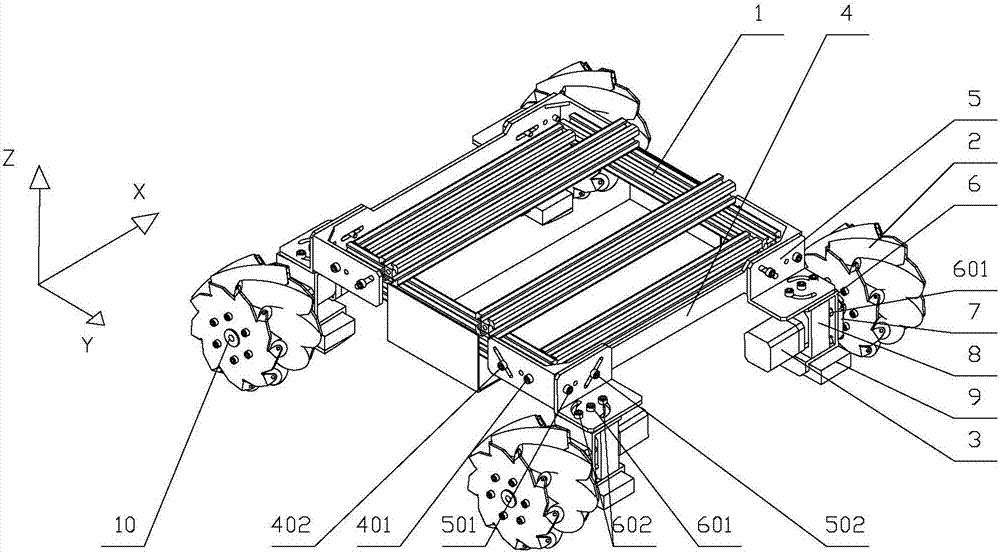

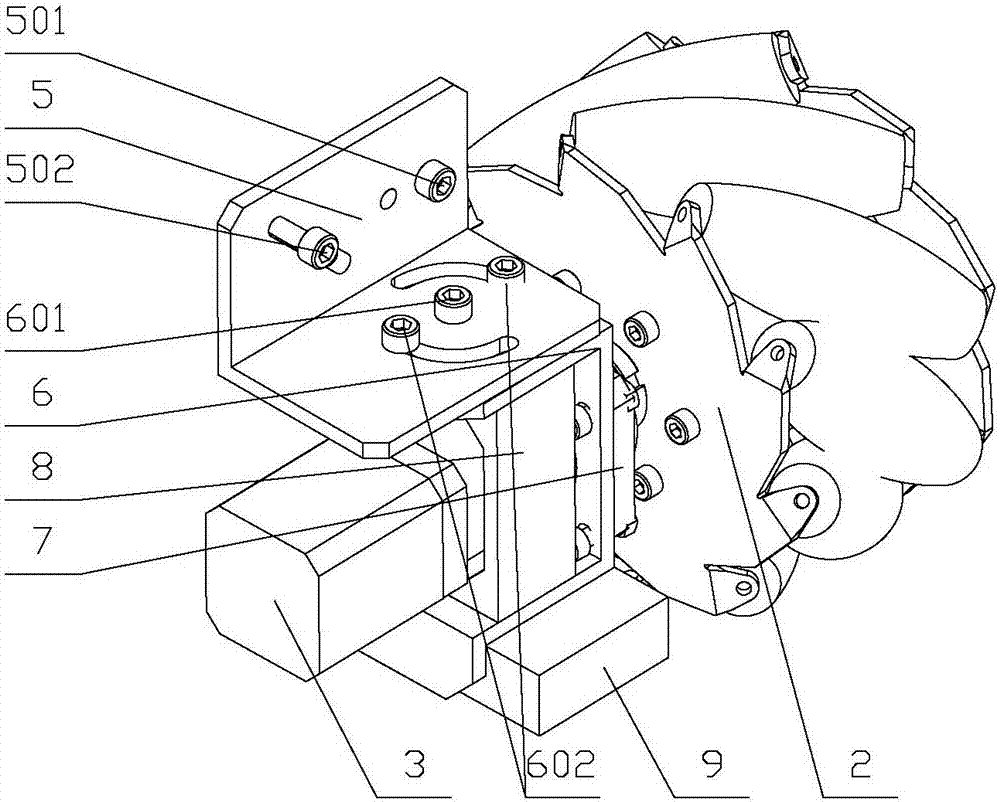

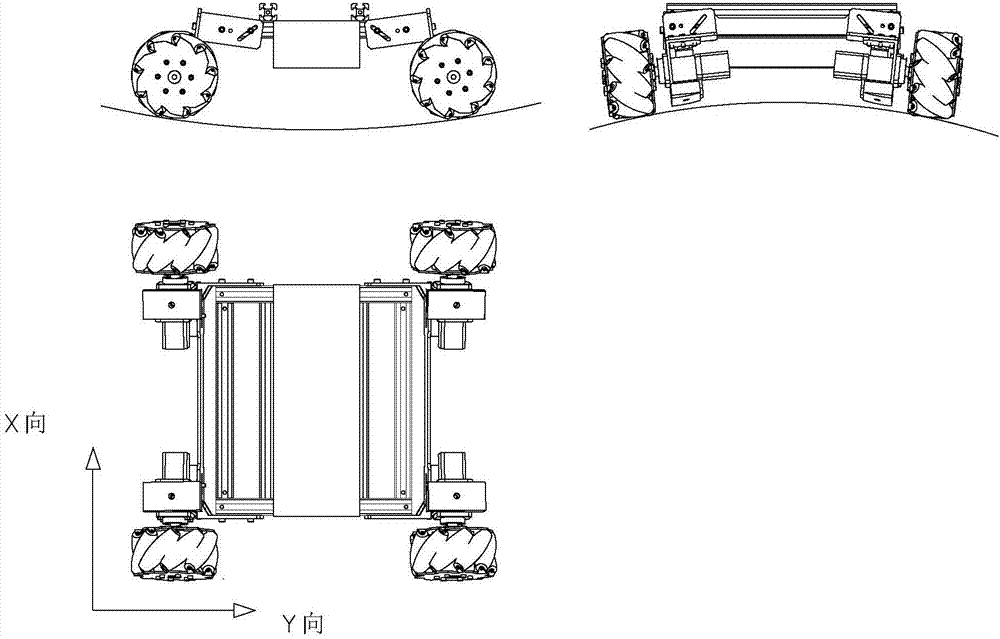

Suspension fork mechanism with three adjustable axial-direction angles for robot

ActiveCN107226146AChange axis angleSports reliableResilient suspensionsVehicle springsVehicle frameEngineering

The invention discloses a suspension fork mechanism with three adjustable axial-direction angles for a robot. The suspension fork mechanism comprises a vehicle frame, two Y-direction rotating frames and four suspension fork sub mechanisms, wherein the two Y-direction rotating frames are arranged on the vehicle frame in parallel; every two suspension fork sub mechanisms are independently arranged on each Y-direction rotating frame; and each suspension fork sub mechanism comprises an X-direction rotating frame, a Z-direction fixing seat and a wheel, wherein each X-direction rotating frame is mounted on the corresponding Y-direction rotating frame, each Z-direction fixing seat is mounted on the corresponding X-direction rotating frame, and each wheel is mounted on the corresponding Z-direction fixing seat through a corresponding wheel shaft and a corresponding bearing seat. According to the suspension fork mechanism disclosed by the invention, through changing the positions of corresponding bolts and corresponding sliding grooves, the angles of the wheels and magnets in the X-direction, Y-direction and Z-direction can be changed, the angle of each wheel and a corresponding contact surface can be changed, and the interval of each magnet and the corresponding contact surface is changed; and through the adoption of the suspension fork mechanism, the adaptation of the wheels to different metal curved surfaces or other curved surfaces is realized, and high movement reliability is provided for the robot to adapt to the curved surfaces.

Owner:SOUTHEAST UNIV

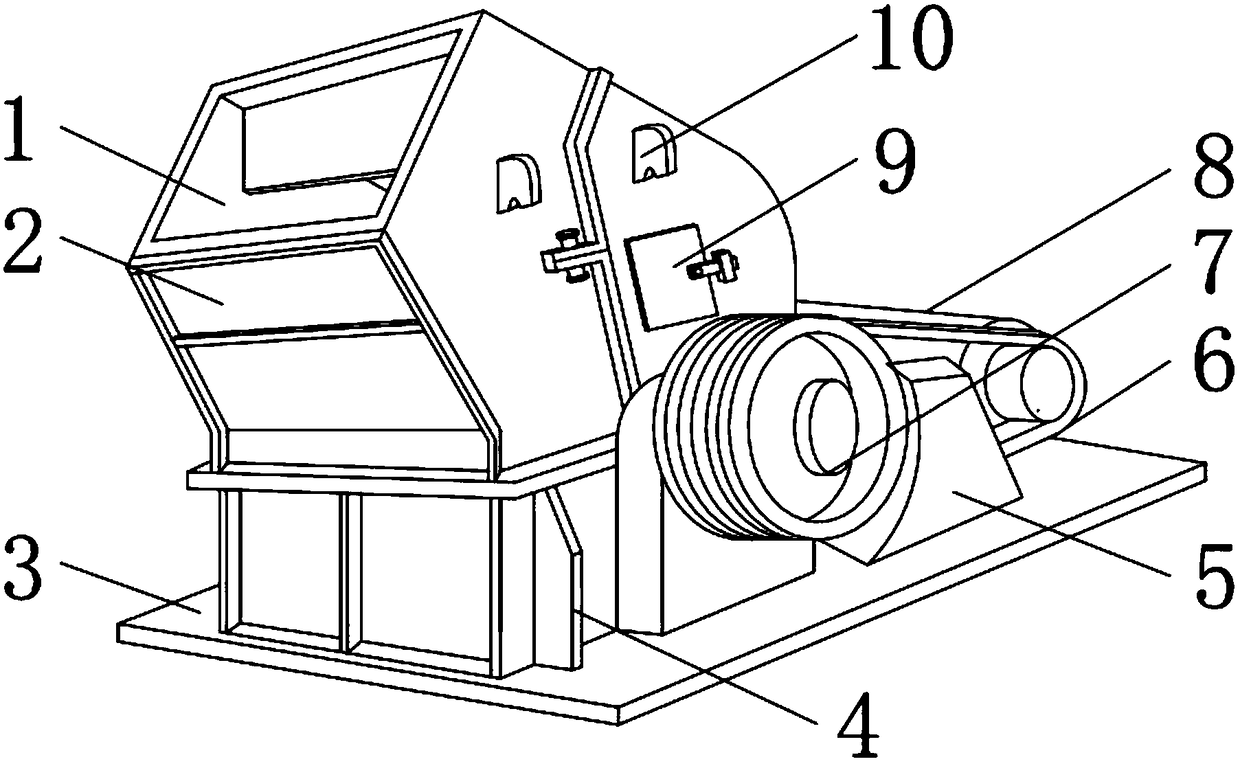

Impact crusher for ore mining

The invention discloses an impact crusher for ore mining. The impact crusher for ore mining comprises a housing, wherein a bottom plate is fixedly connected to the lower end surface of the housing; afixing mounting plate is fixedly connected to the side end surface of the housing; a transmission wheel is rotatably connected to one side, deviated from the fixing mounting plate, of the side end surface of the housing; a conveyor belt is rotatably connected to the outer end surface of the transmission wheel; a motor is rotatably connected to the inner end surface of the conveyor belt; a detecting door is rotatably connected to one side, deviated from the transmission wheel, of the side end surface of the housing; a fixing block is fixedly connected to one side, deviated from the detecting door, of the side end surface of the housing; a feeding port is formed in the upper end surface of the housing; a conveyor belt protecting body is in sliding connection with the upper end surface of thebottom plate; a discharging port is formed in the lower end surface of the housing; a rotating shaft is fixedly connected to the side end surface of the transmission wheel. According to the impact crusher for the ore mining, the conveyor belt is mounted for protecting a crusher body; and the problem that a conveyor belt of a traditional crusher is easily damaged by ore can be solved.

Owner:ANHUI UNIV OF SCI & TECH

Volute tongue and centrifugal fan comprising same

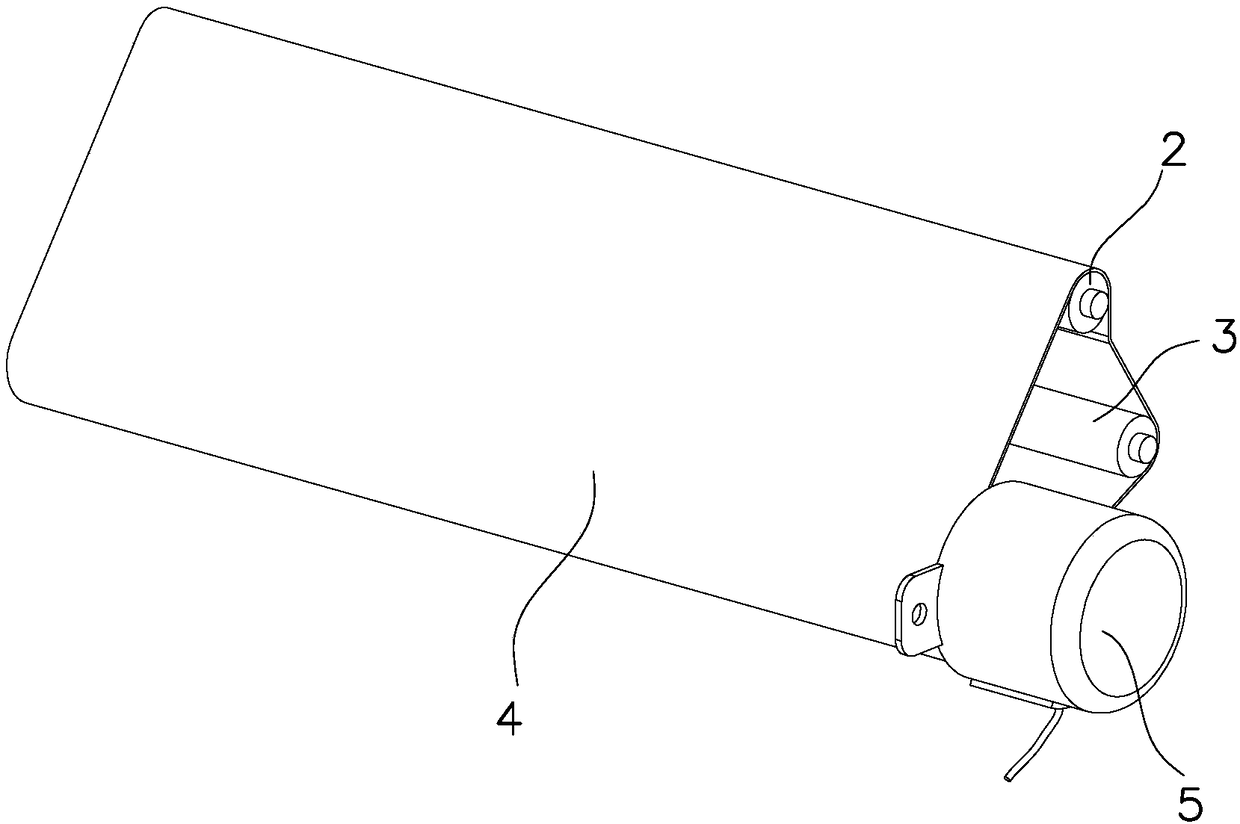

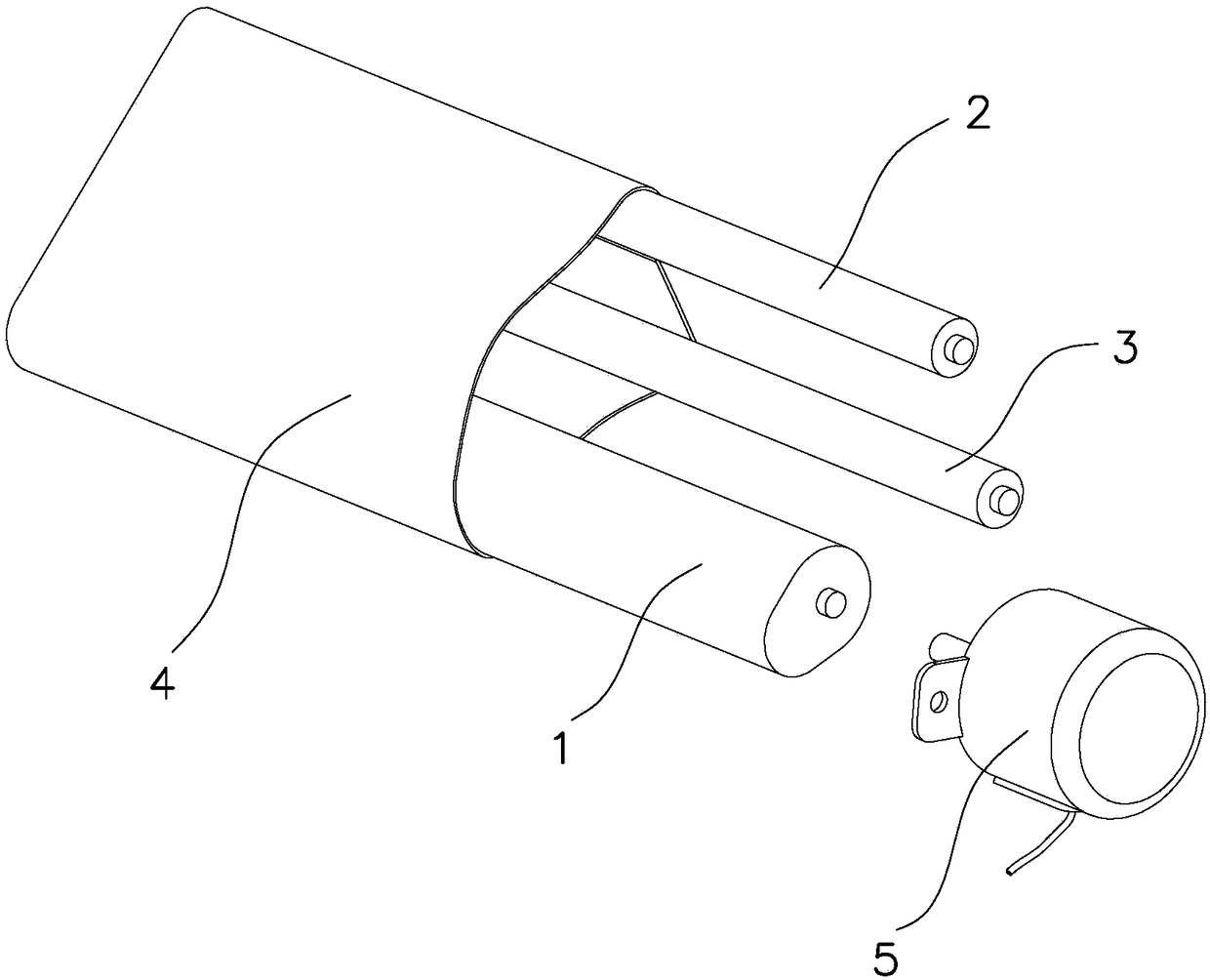

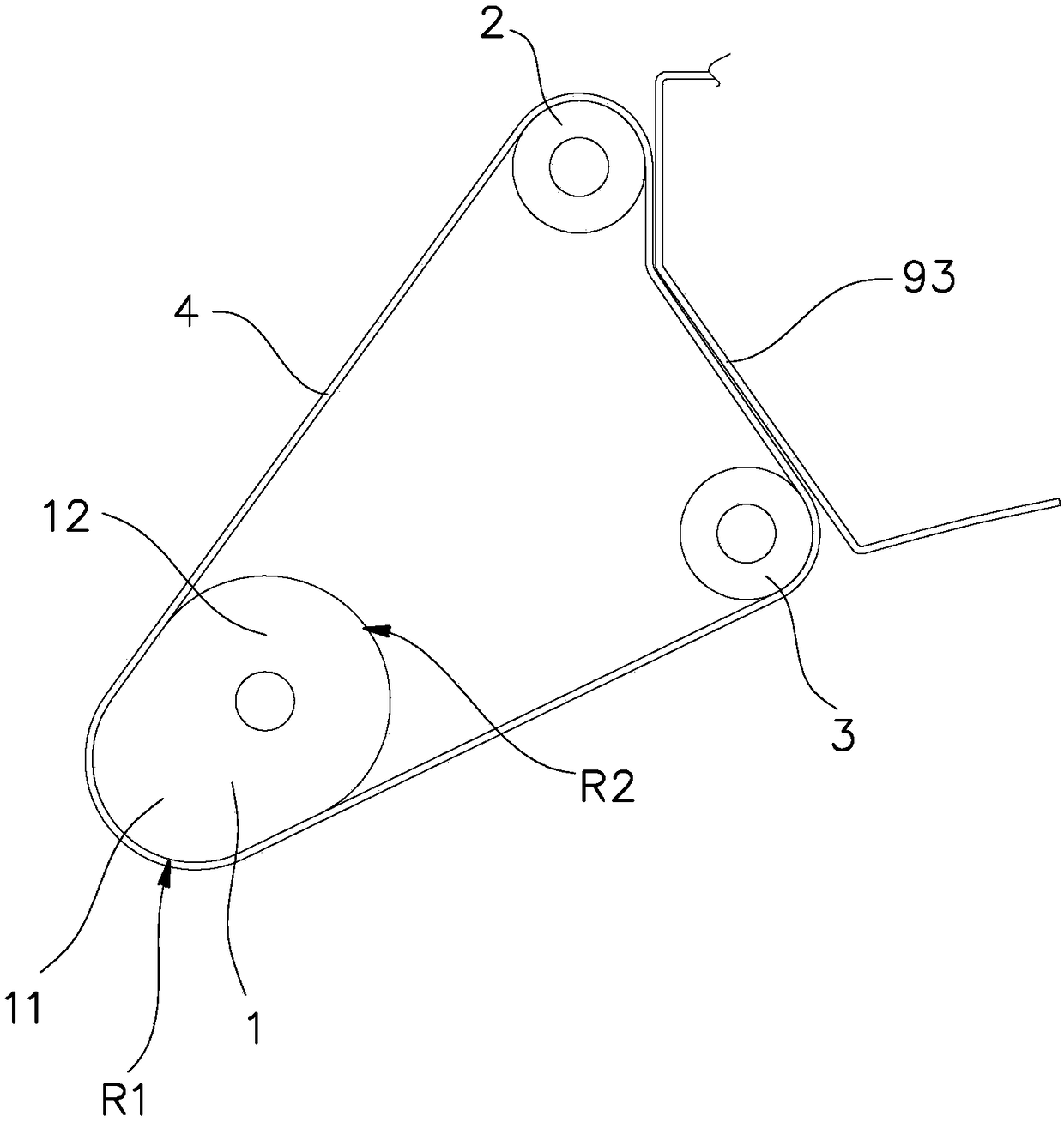

The invention discloses a volute tongue. The volute tongue is characterized by comprising a supporting frame and a flexible volute tongue wall forming the outer contour of the volute tongue; the supporting frame comprises an upper supporting body, a lower supporting body and a variable-R column body, the upper supporting body and the lower supporting body are arranged at the root of the volute tongue, and the variable-R column body is arranged at the head of the volute tongue; the upper supporting body, the lower supporting body and the variable-R column body are distributed in a triangle shape; the volute tongue further comprises a driving mechanism used for driving the variable-R column body to rotate. The invention further discloses a centrifugal fan comprising the volute tongue. The volute tongue has the advantages that the flexible volute tongue wall of the volute tongue is supported on the upper supporting body, the lower supporting body and the variable-R column body distributedin the triangle shape; the upper supporting body and the lower supporting body are arranged at the root of the volute tongue; the variable-R column body is arranged at the head of the volute tongue;the driving mechanism drives the variable-R column body to rotate and can achieve variable-R adjustment of the volute tongue so as to change the gap between the volute tongue and an impeller; accordingly, the performance of the draught fan is improved or noise is reduced, and the volute tongue can better adapt to various actual working conditions.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

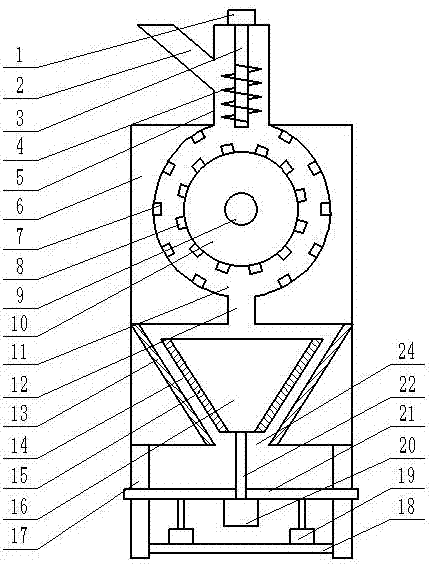

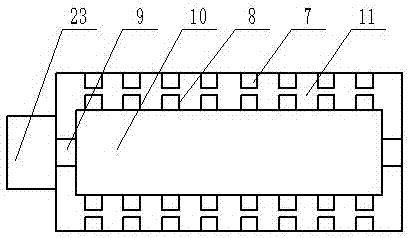

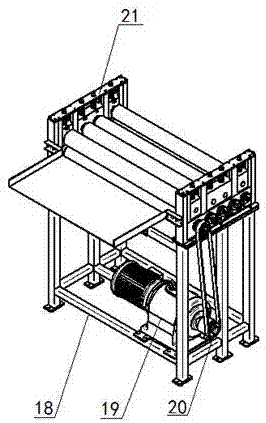

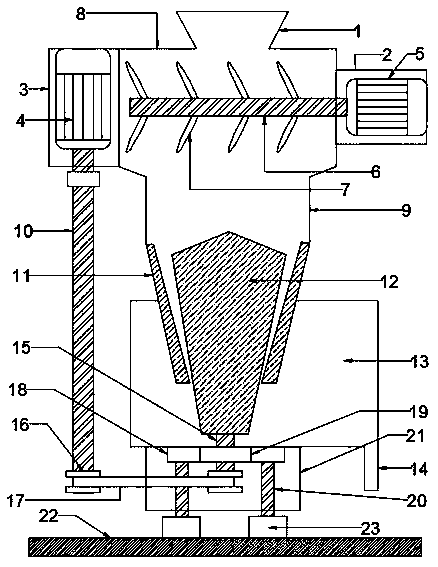

Multistage efficient soybean milk grinder

InactiveCN107362864AAvoid cloggingImprove grinding effectGrain treatmentsMechanical engineeringEngineering

The invention discloses a multistage efficient soybean milk grinder. The multistage efficient soybean milk grinder comprises a machine shell. A crushing bin and a grinding bin are arranged on the upper portion and the lower portion of the machine shell correspondingly. A plurality of fixed crushing hammers are fixedly connected with the inner side wall of the crushing bin. A crushing shaft is arranged in the crushing bin coaxially. A fixing barrel is fixedly connected with the crushing shaft. A plurality of movable crushing hammers are fixedly connected with the fixing barrel. A feeding barrel communicates with the upper portion of the crushing bin. A discharging outlet is formed in the bottom end of the grinding bin. A first grinding blade is fixed to the inner side wall of the grinding bin. A grinding body matched with the grinding bin structure is arranged in the grinding bin. A second grinding blade is fixed to the outer side wall of the grinding body. The multistage efficient soybean milk grinder is simple in structure and reasonable in design, the crushing bin is used for primary crushing before soybeans are ground, so that the later grinding efficiency can be greatly improved; and meanwhile, the grinding body can go up and down, and the practicability of the multistage efficient soybean milk grinder is improved.

Owner:庞明兰

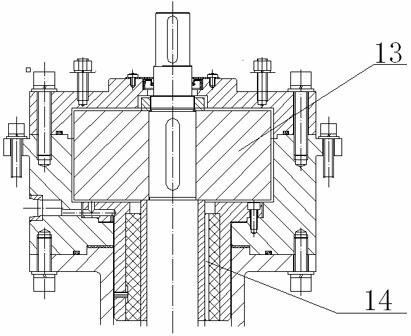

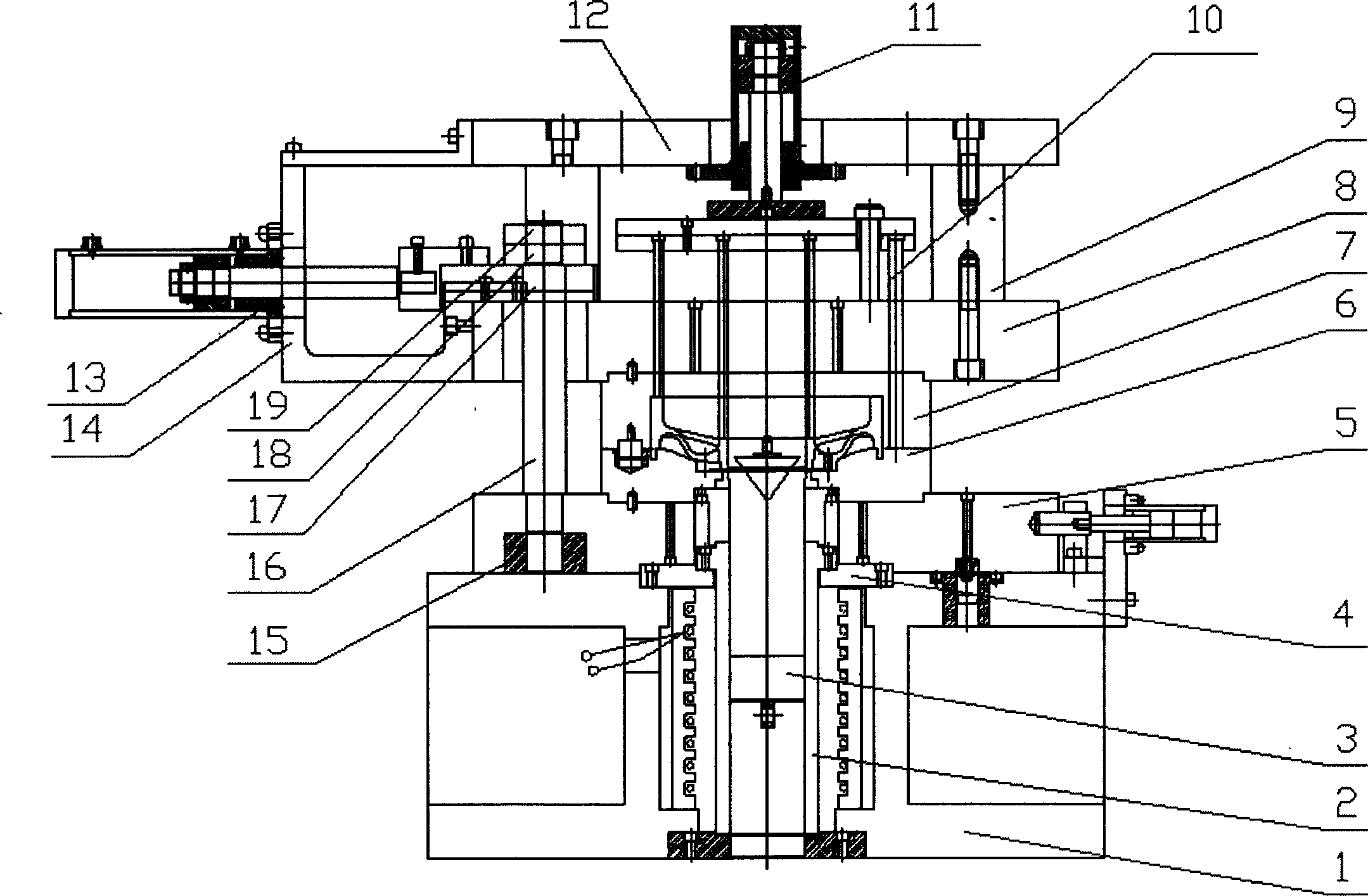

Additional mould locking device of indirect extrusion casting

An additional mould-locking apparatus for indirect extrusion casting features that an additional mould-locking pull rod is used between upper and lower mould seats, its one end is fixed to lower mould seat, its another end has a mould-locking gap regulating block, and a hydraulic cylinder is fixed to a connecting plate for upper mould and its seat for driving the mould-locking block in order to lock or unlock mould.

Owner:SOUTH CHINA UNIV OF TECH

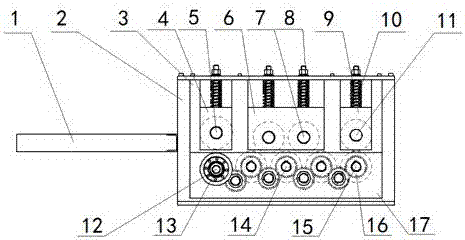

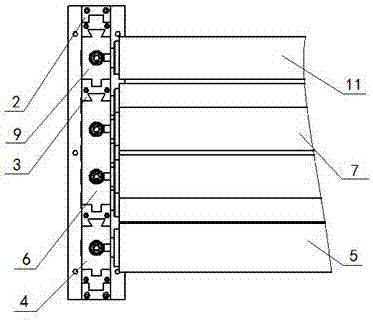

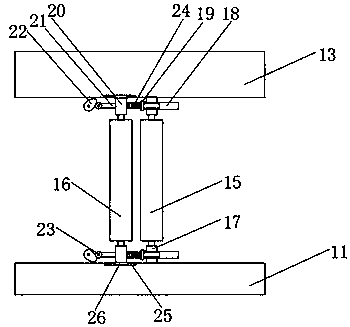

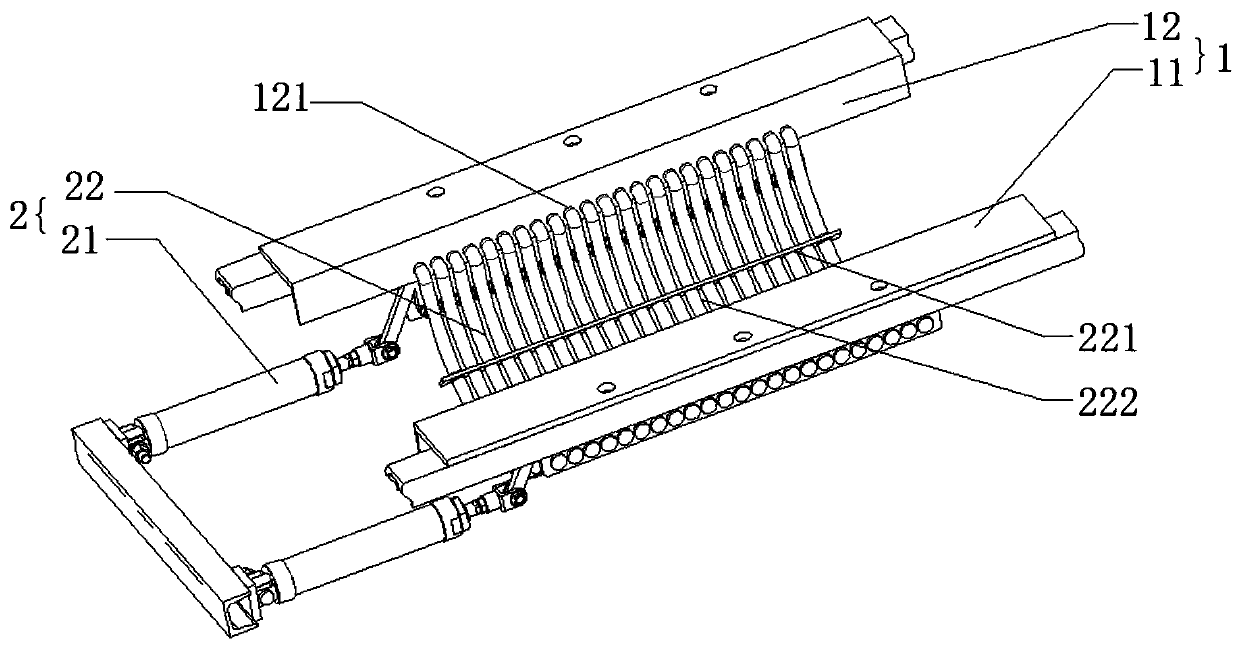

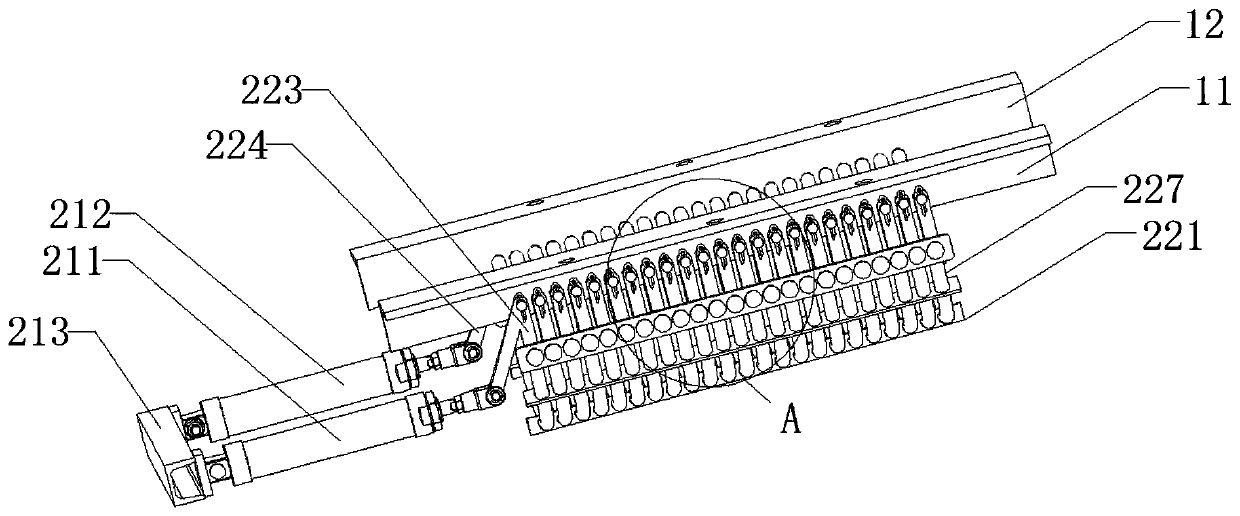

Metal sheet roller straightening machine

InactiveCN107262555AReduce the impact of noiseReduce the impactMetal-working feeding devicesPositioning devicesMetal sheetEngineering

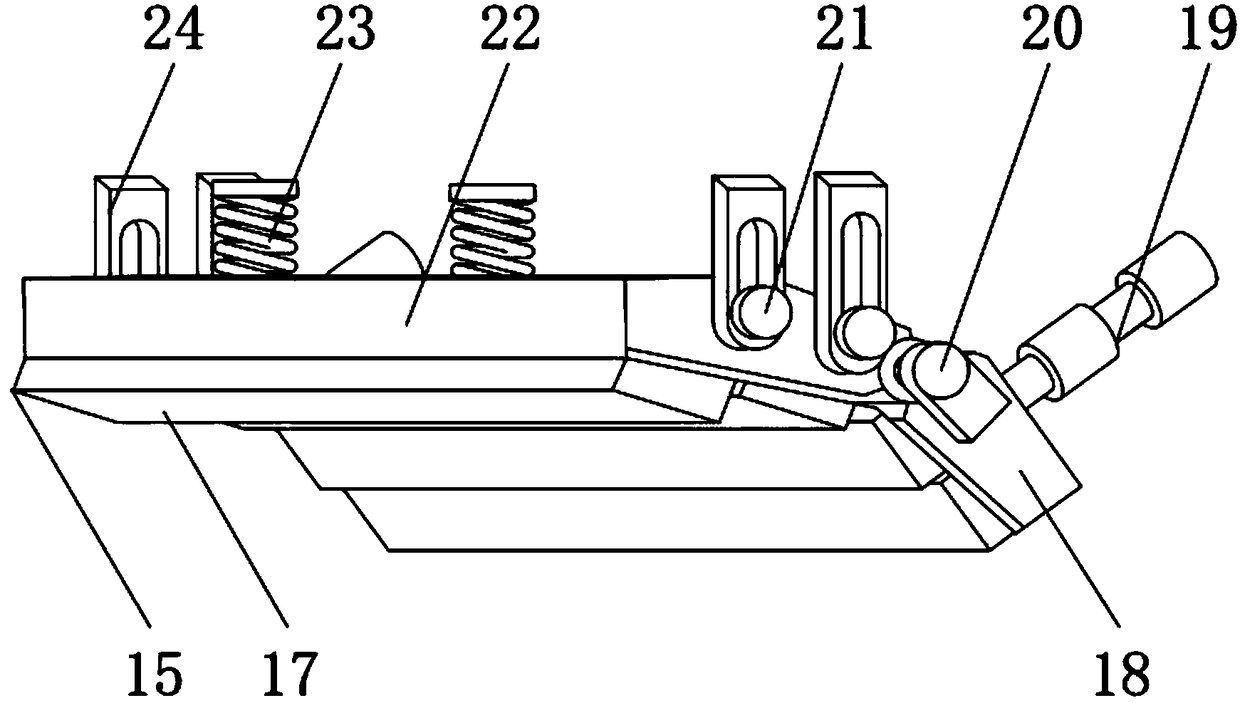

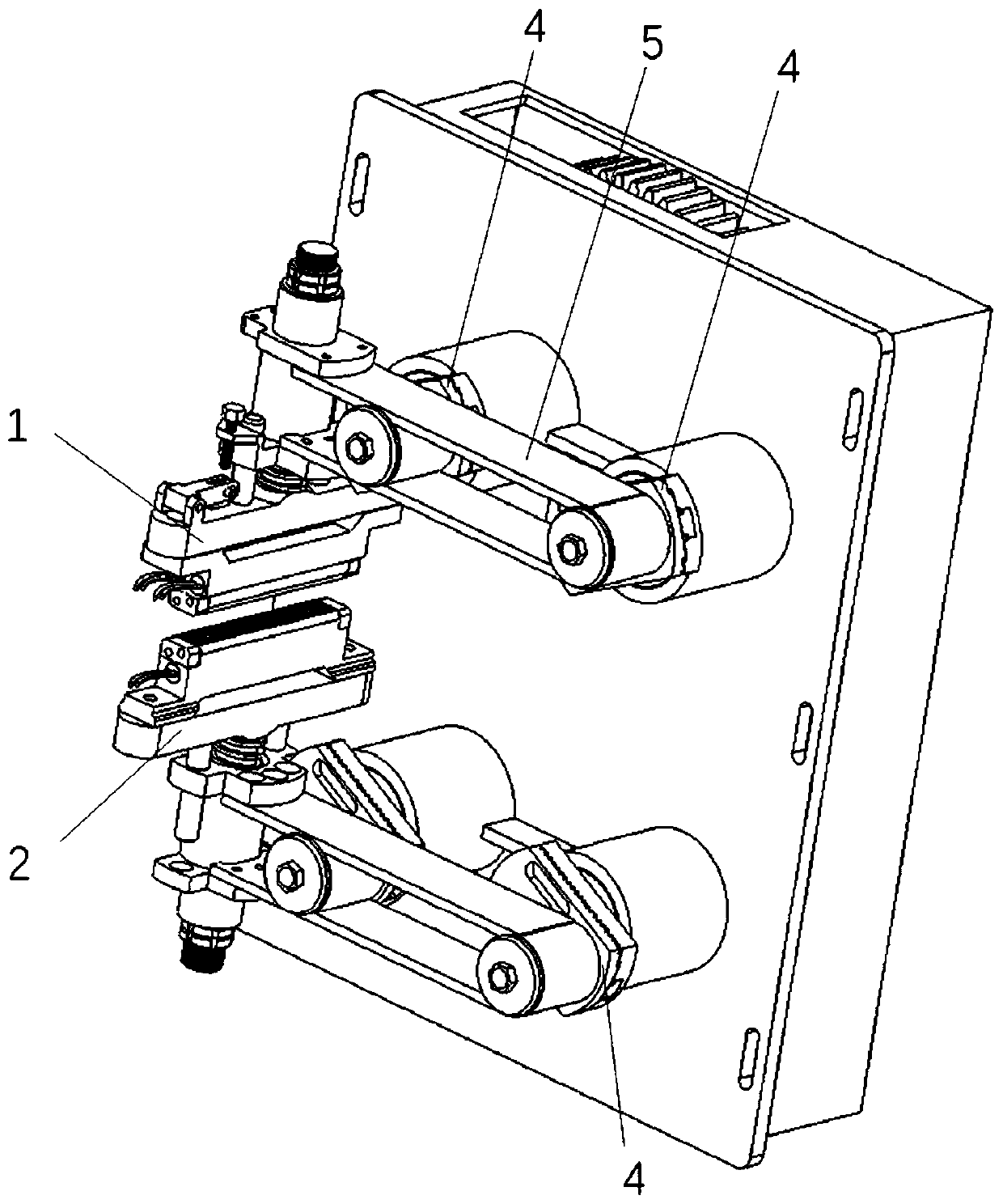

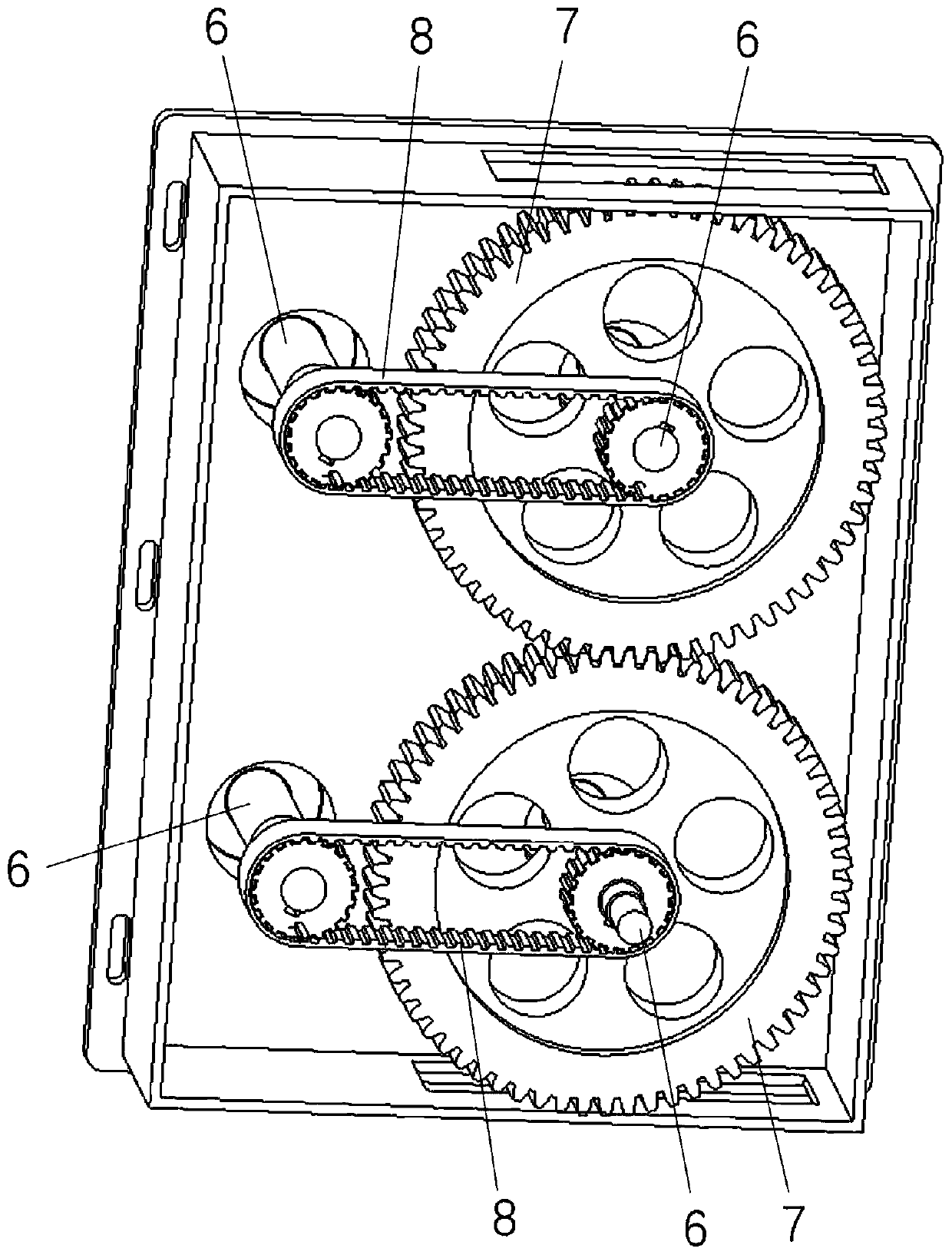

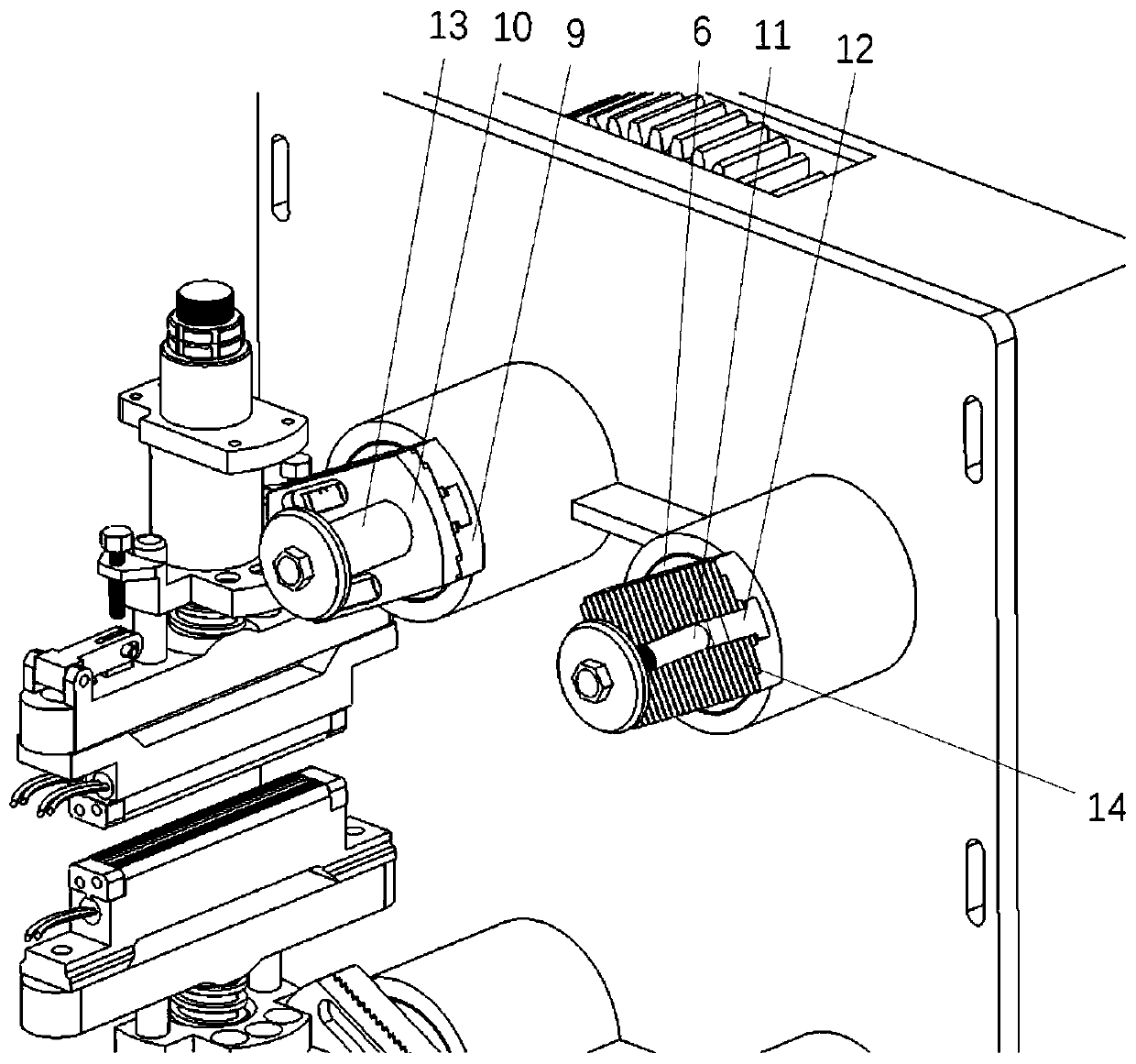

The invention relates to a metal sheet roller straightening machine and belongs to the field of metallurgical machinery. The metal sheet roller straightening machine comprises a feeding plate, an upper straightening device, a lower straightening device, a main fixing frame, a machine frame, a motor and a belt. The upper straightening device comprises an upper feeding roller, a feeding roller bearing seat, an upper straightening roller set, upper straightening roller bearing seats, an upper discharging roller, an upper discharging roller bearing seat, an upper support, a pressing plate, a bolt and an adjusting spring. The lower straightening device comprises a lower feeding roller, a lower straightening roller set, a lower discharging roller, a lower main bearing seat, a V-shaped belt wheel and a transmission set gear. The spring is adopted by the upper straightening device for providing straightening force for straightening rollers, and thus noise generated in the straightening process of the straightening machine is greatly lowered; and meanwhile, bearings of the upper straightening device adopt guiding groove structures, the height of the straightening rollers can be adjusted conveniently so that the straightening machine can adapt to straightening of metal sheets with different thicknesses, production demands are met, dismounting and mounting are easy, and maintaining is convenient. The lower straightening device mainly provides force for moving of the metal sheets and does not provide straightening force proactively.

Owner:KUNMING UNIV OF SCI & TECH

Novel winding machine winding method and device thereof

InactiveCN110589051AFully packagedChange gapWrapping material feeding apparatusWrapping with article rotationWinding machineElectric machinery

The invention provides a novel winding machine winding method and device thereof, and relates to the technical field of winding machines. The novel winding machine winding device comprises a base, a vertical plate is welded to one side of the top of the base, a top seat is vertically welded to the top of the vertical plate, a servo motor is embedded in one side of the interior of the base, a driving end of the servo motor penetrates through the top of the base to be fixedly connected with a rotating disc, the side, close to the vertical plate, of the interior of the base is fixedly connected with a first air cylinder, the piston end of the first air cylinder is fixedly connected with a bottom plate through the base, a top plate is arranged above the bottom plate, and a winding roller is arranged between one side of the top of the bottom plate and the top plate. By means of the arranged moving mechanism, a second tensioning roller can be driven to move, so that the distance between a first tensioning roller and the second tensioning roller is changed, so that the tensioning degree of a winding film is changed, and the object is wound more tightly.

Owner:玉门金环密封材料有限公司

Novel active air foil bearing based on PZT and SMA

InactiveCN111457007AStable jobEnhance the dynamic pressure effectBearing componentsSliding contact bearingsEngineeringMechanical engineering

The invention discloses a novel active air foil bearing based on PZT and SMA. The novel active air foil bearing comprises a shaft sleeve, piezoelectric ceramics (PZT), a memory alloy wire mesh block (SMA block), flexible hinges, a rigid push rod, pre-pressure applying devices, a cooling pipe, a wave foil and a top foil; the PZT and the SMA block are installed in pre-machined through grooves, the corresponding pre-pressure applying devices are designed for the PZT and SMA block, the wave foil is formed by pressing an elastic material, one end of the wave foil is welded, and the other end of thewave foil is free. The top foil overlies the wave foil. Power supply signals of the PZT are controlled, the flexible hinges are coupled, PZT deformation is amplified, the wave foil is supported by the rigid push rod, the wedge-shaped space is enlarged, therefore, the crossed coupling effect is weakened, the dynamic pressure effect of the bearing is enhanced, and the rigidity characteristic of thebearing is improved; by controlling the temperature of the SMA block, the SMA block expands and contracts to generate larger structural damping, and the damping characteristic of the bearing is improved; and finally, the rigidity and damping characteristics of the bearing are actively controlled, and the stability of the system is improved.

Owner:HUNAN UNIV

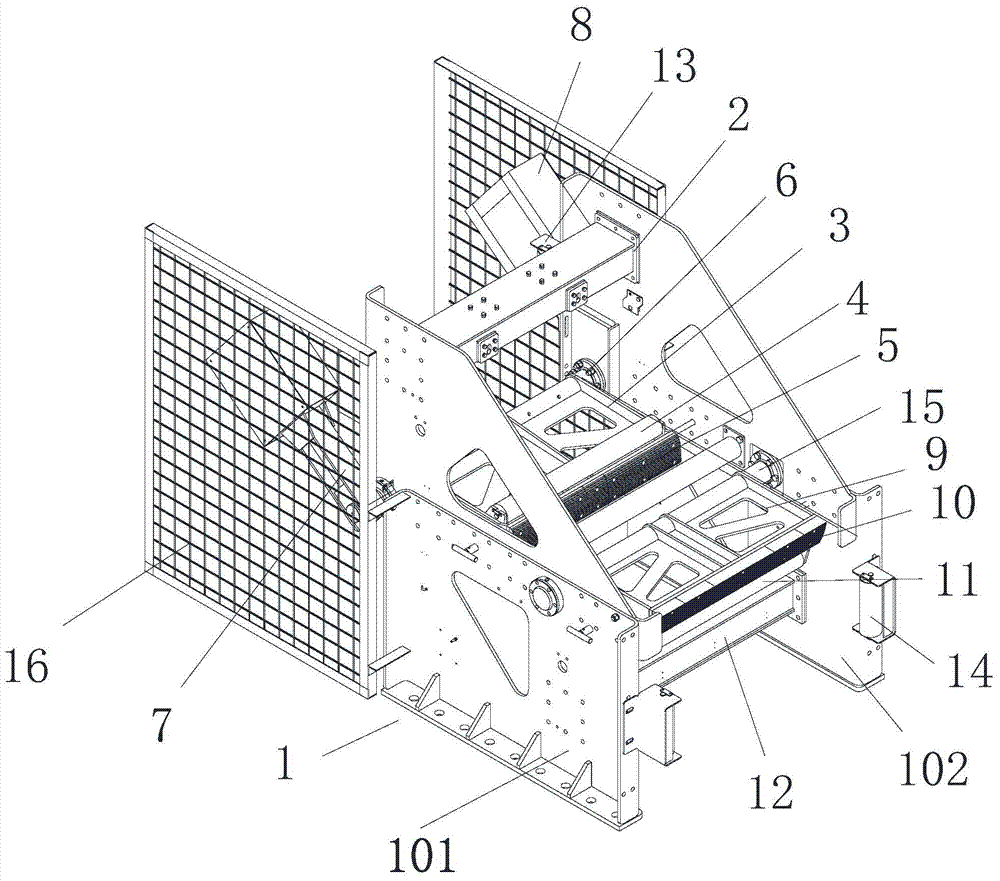

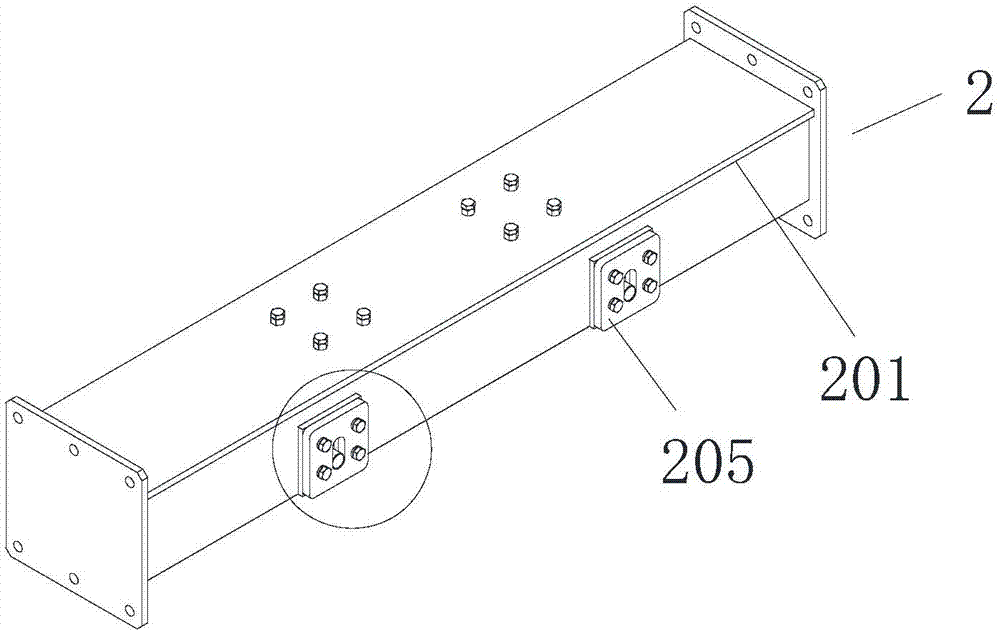

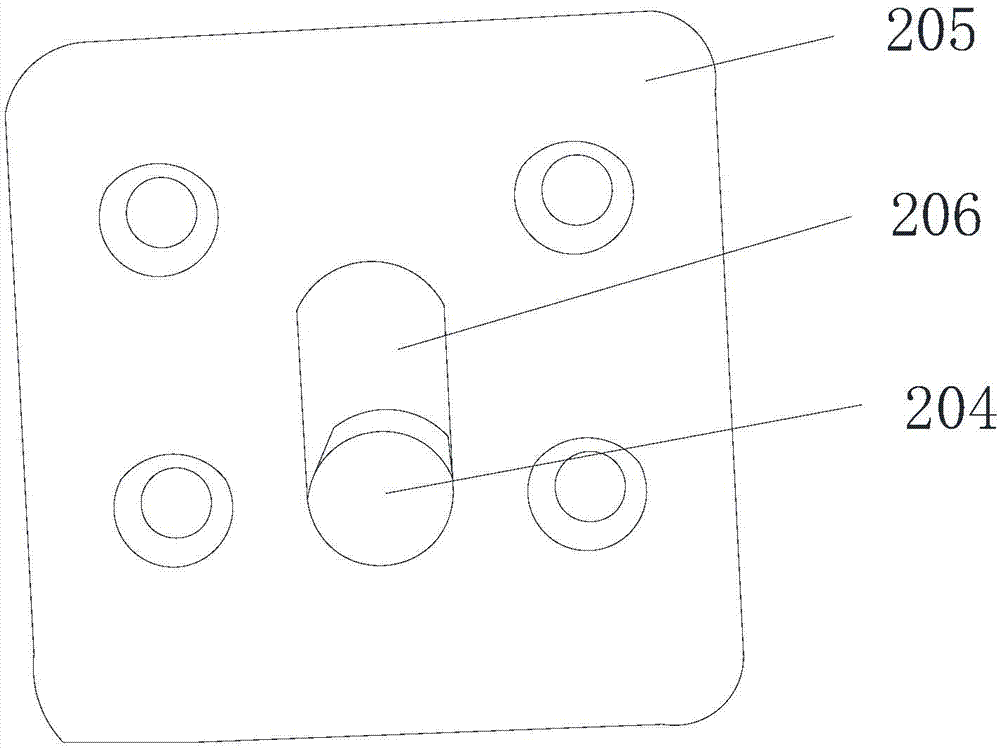

Belt breakage protection device with speed reducing function

ActiveCN103787047AChange gapReduce impact damageControl devices for conveyorsMechanical engineeringEngineering

The invention discloses a belt breakage protection device with a speed reducing function. The belt breakage protection device comprises a machine frame and a capturing mechanism. The capturing mechanism comprises an upper conveying belt capturing portion and a lower conveying belt capturing portion. The upper conveying belt capturing portion comprises a movable upper capturing part which can swing upwards under the effect of gravity and a fixed upper capturing part installed on the upper portion of the machine frame, the movable upper capturing part swings towards and moves close to the fixed upper capturing part located above the movable upper capturing part and is matched with the fixed upper capturing part to form an upper clamping gap which can be used for capturing an upper conveying belt, the fixed upper capturing part serves as an upper capturing cross beam, the upper capturing cross beam comprises a regulator used for buffering and speed reducing, and the regulator comprises a static beam, a movable beam which is located below the static beam and can move upwards under the effect of the movable upper capturing part and a damping structure arranged between the static beam and the movable beam. Through the arrangement of the regulator, a speed reducing effect can be realized for capturing of the conveying belt, impact damage to the machine frame in the capturing process is reduced, and therefore the service life of the machine frame is prolonged.

Owner:SHANDONG KEDA ELECTROMECHANICAL TECH CO LTD

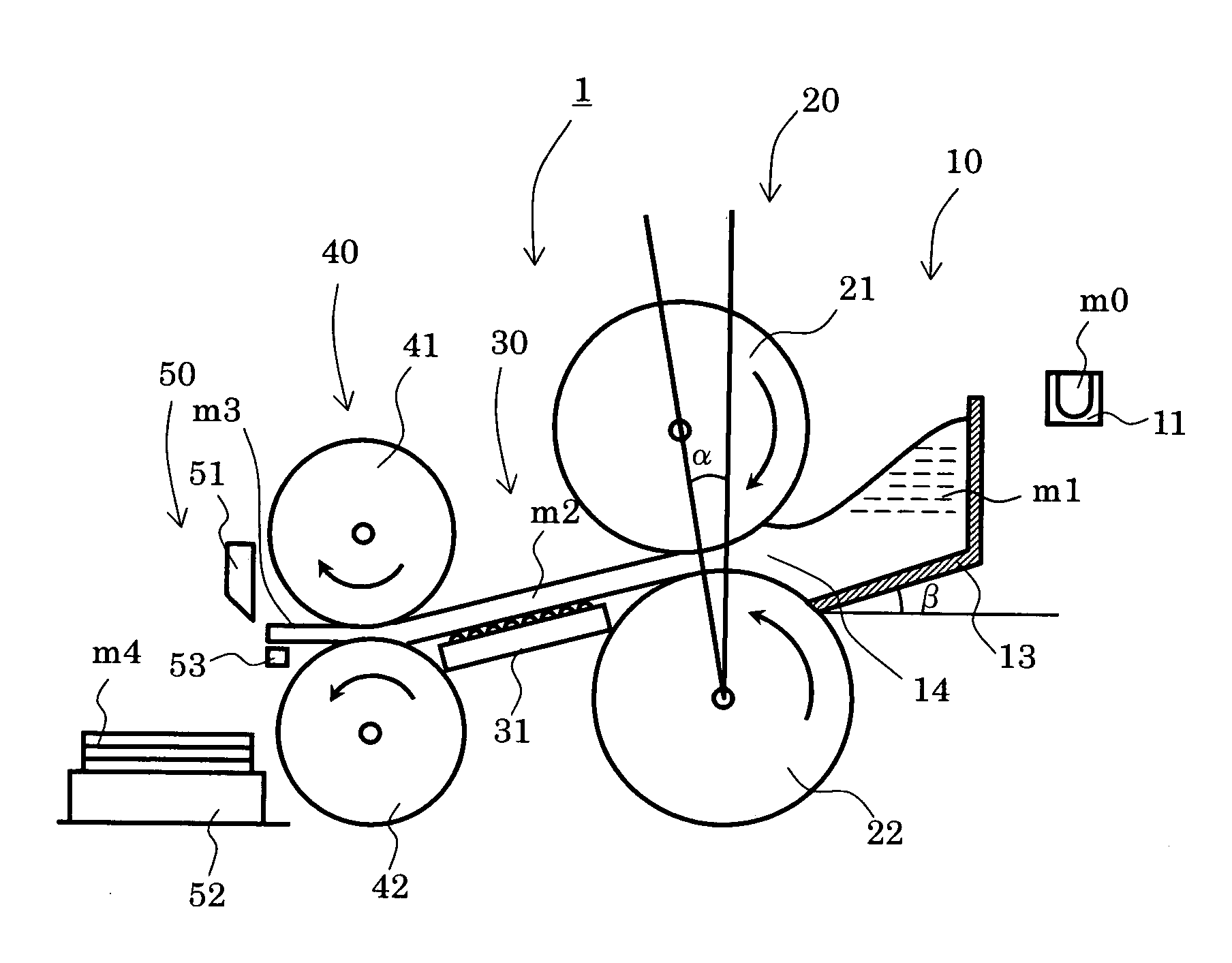

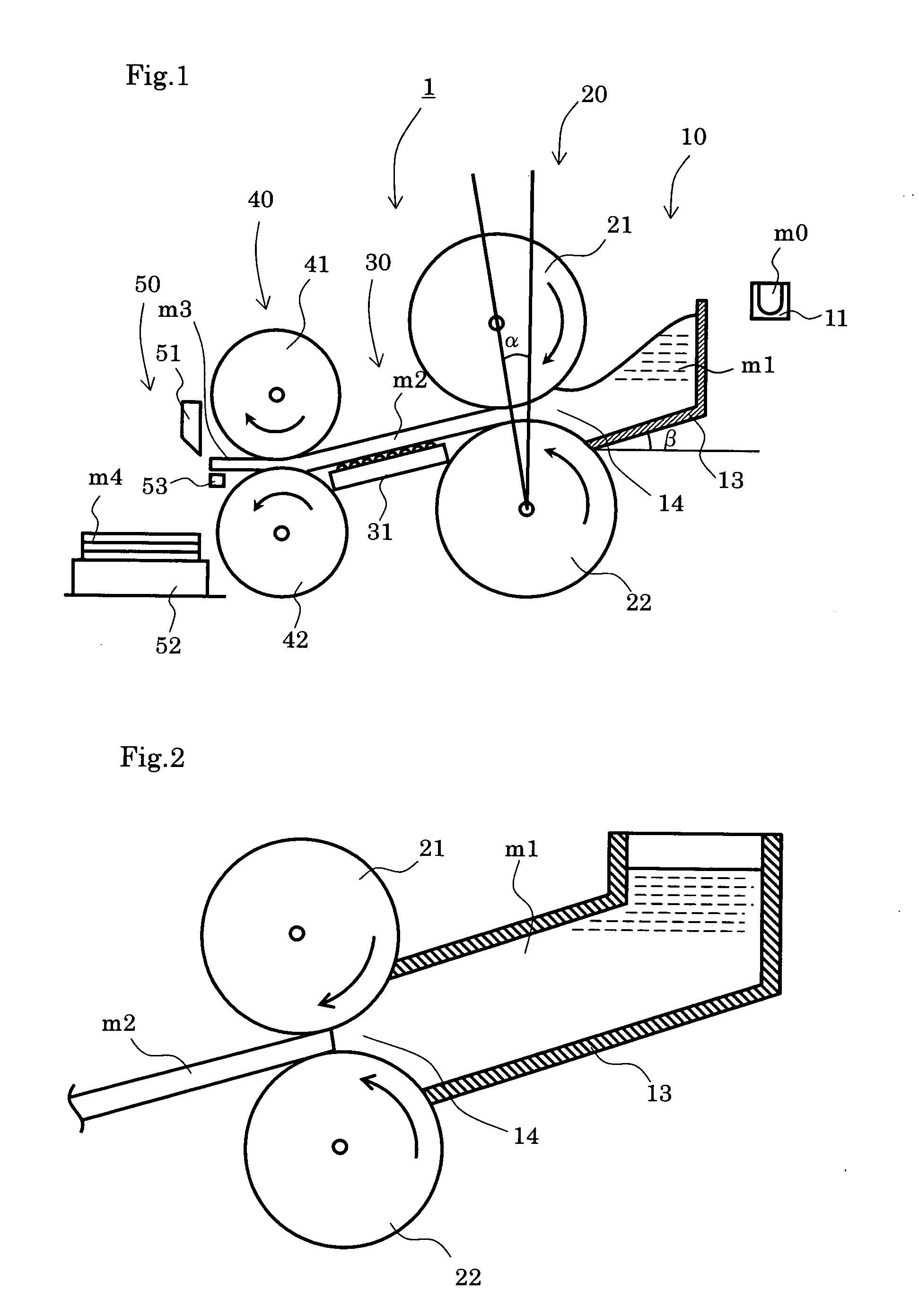

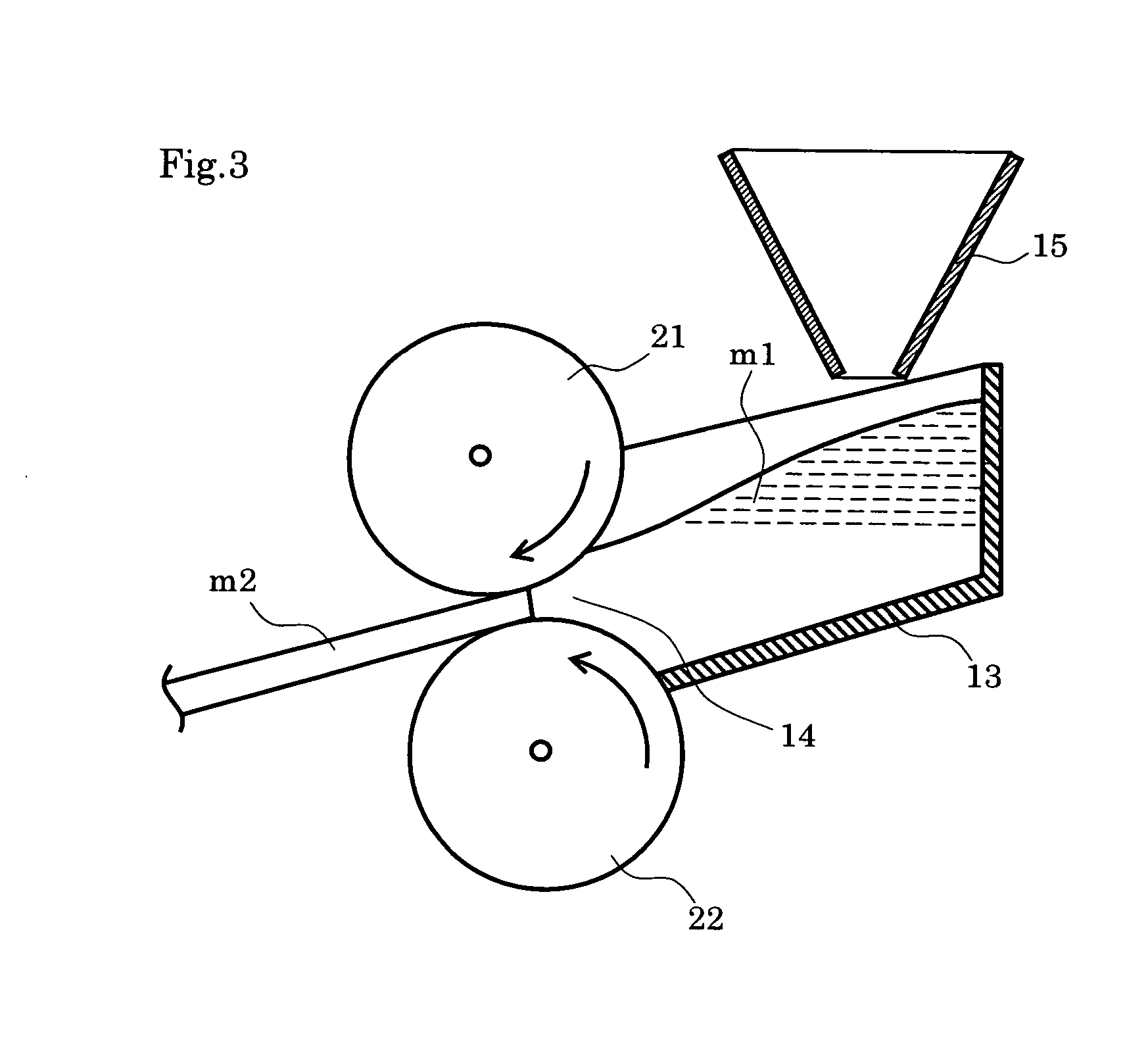

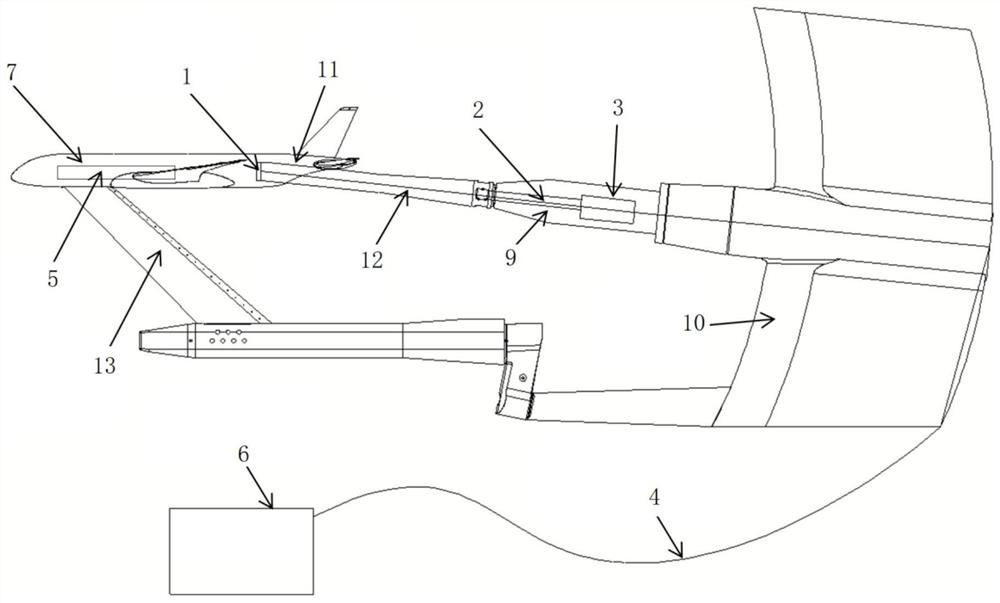

Method and apparatus for producing thin magnesium based alloy plate

ActiveUS20060225862A1Efficient productionEfficiently formedMetal rolling arrangementsMetal foundingThermal energyAlloy

A magnesium metal thin plate manufacturing method includes at least a casting process of supplying a molten metal obtained by melting a magnesium metal to a molten metal bath, drawing out the molten metal, supplying the molten metal into the gap between a pair of casting rolls composed of at least a pair of casting upper roll and casting lower roll, applying pressure to the molten metal, and casting a plate solidified at a predetermined temperature and having a predetermined thickness, and a rolling process of rolling the cast plate by means of at least a pair of rolling rolls by applying pressure thereto to manufacture a magnesium metal thin plate. With the above arrangement, there can be provided a magnesium metal thin plate manufacturing method and manufacturing apparatus that can effectively manufacture a magnesium metal thin plate by plastic working without requiring a heat energy generation step again in rolling.

Owner:GONDA METAL IND

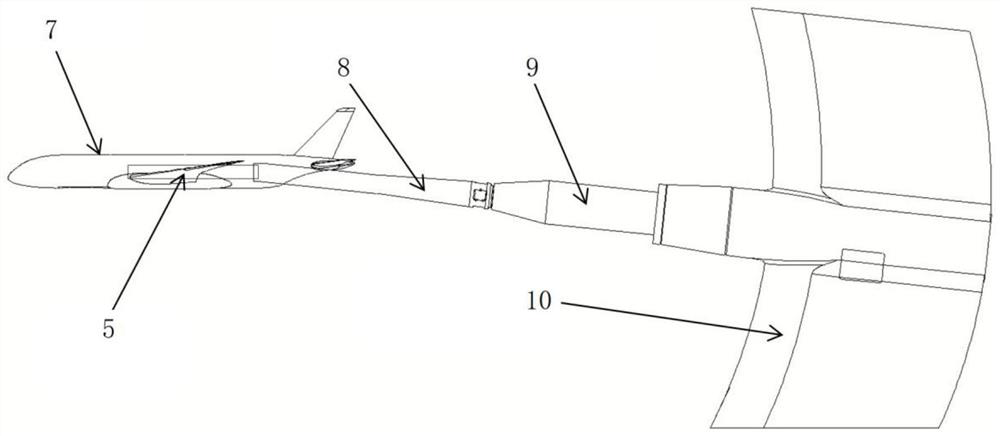

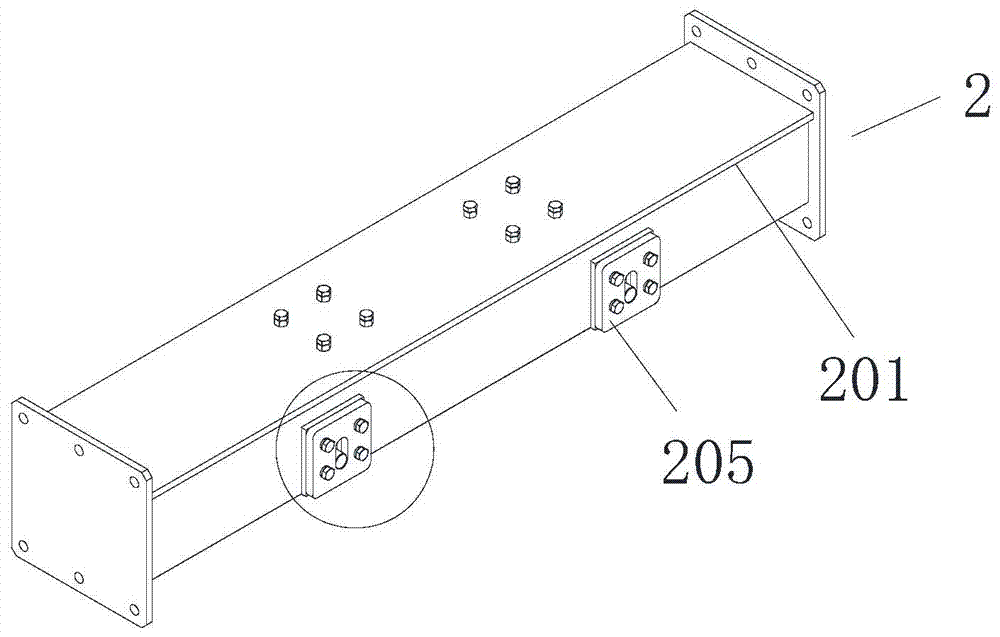

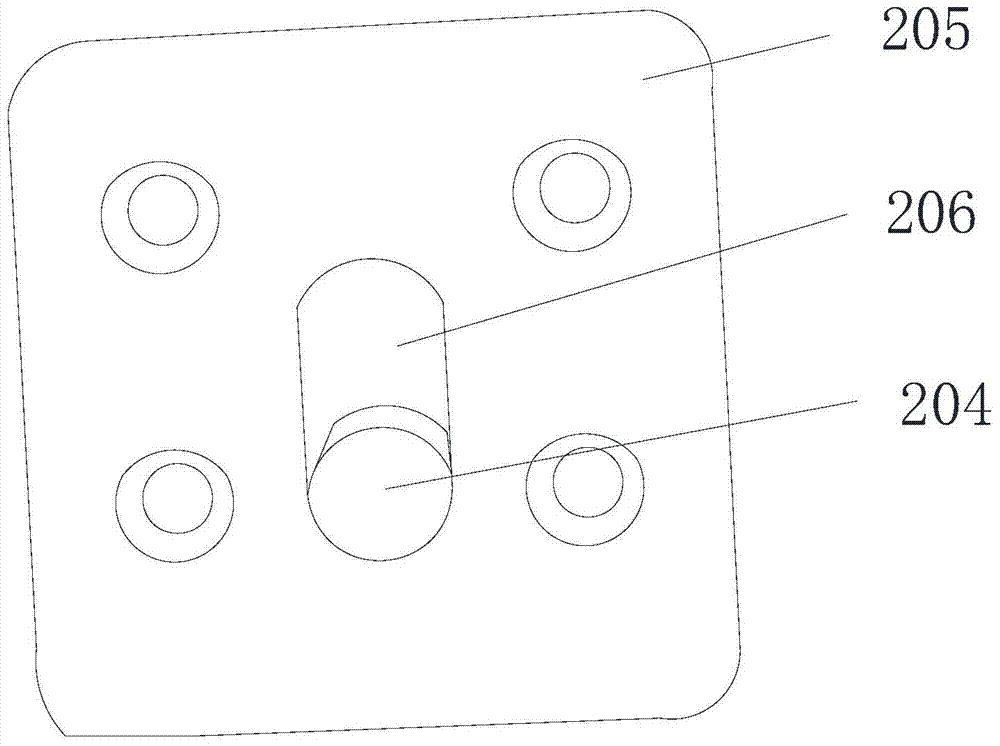

Intelligent false support rod device for high-speed wind tunnel

The invention discloses an intelligent false support rod device for a high-speed wind tunnel. The device comprises a displacement sensor, a transmission mechanism, a driver, a measurement and controlcable for connecting the displacement sensor, the transmission mechanism and the driver, and a subsystem for controlling the displacement sensor, the transmission mechanism and the driver, the displacement sensor is mounted at the head of the false tail support rod to monitor a gap between the false tail support rod and the model; and the transmission mechanism and the driver are installed in an inner cavity of the straight joint, and the driver drives the transmission mechanism to drive the false tail supporting rod to move relative to the model. The subsystem is connected with a measurementand control system of the high-speed wind tunnel and shares one computer with the measurement and control system of the high-speed wind tunnel. The device can realize following motion of the false tail support rod relative to the model, avoids collision between the model and the false tail support rod, and obtains more accurate tail support interference quantity under a larger attack angle; and the false tail support rod can be controlled to move according to an instruction, a gap between the false tail support rod and the model is changed, and the influence of the gap on support interferenceis studied.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

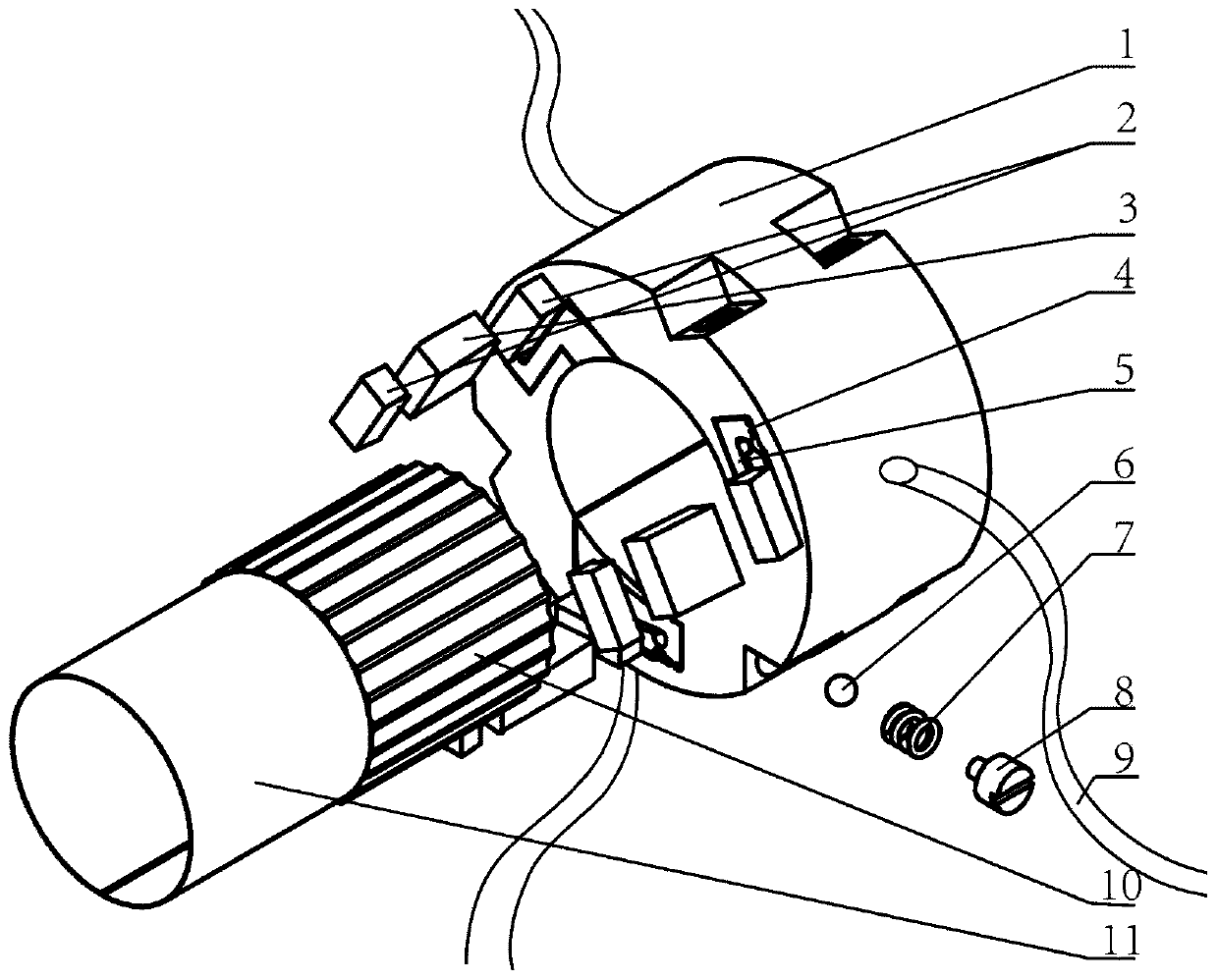

Novel active air foil bearing based on PZTs and flexible hinges

ActiveCN106884870AStable jobImproved stiffness propertiesSliding contact bearingsWire cuttingRound face

The invention discloses a novel active air foil bearing. The bearing comprises a shaft sleeve, the PZTs, the flexible hinges, rigid push rods, precompression exertion devices, wave foil and top foil; the shaft sleeve is machined through wire cutting, three PZT mounting through grooves circumferentially and evenly distributed, the corresponding flexible hinges and the corresponding rigid push rods are obtained, the top ends of the rigid push rods are flush with the inner cylindrical face of the shaft sleeve, the PZTs are mounted in the through grooves, the corresponding precompression exertion devices are designed for the PZTs, the wave foil is formed by pressing of elastic materials, and is arranged on the shaft sleeve and the inner cylindrical faces of the rigid push rods, one end of the wave foil is welded to the inner round face of the shaft sleeve, and the other end of the wave foil is free. The top foil is arranged on the wave foil in a covering manner. Through control over power supply signals of the PZTs, the PZTs mechanically deform, the flexible hinges are enlarged to deform, and are supported through the rigid push rods to be attached to the wave foil on the push rods and the inner wall of the shaft sleeve, a gap between a bearing and a supporting rotor is changed, the wedge space is increased, the crossed coupling effect is weakened, the bearing dynamic pressure effect is enhanced, the rigid characteristic of the bearing is improved, and finally the aims of actively controlling the rigidity characteristics of the bearing and improving the stability of the bearing are achieved.

Owner:HUNAN UNIV

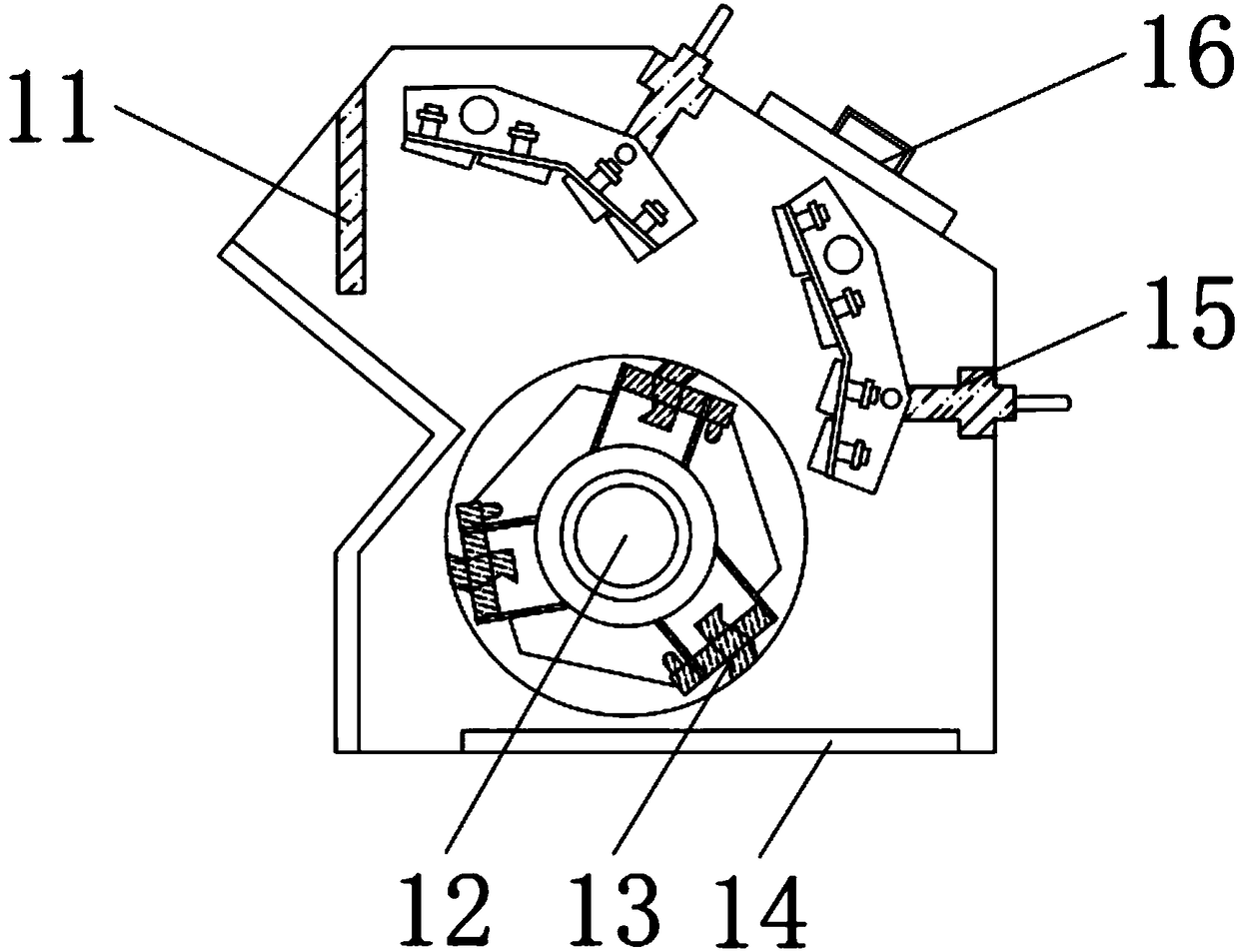

Sand making machine uniform in crushing

InactiveCN108889432AUniform particle sizeMeeting the needs of the modern construction industryGrain treatmentsHydraulic cylinderEngineering

The invention discloses a sand making machine uniform in crushing. The sand making machine comprises a first crushing mechanism, a second crushing mechanism, a transmission mechanism, a lifting mechanism and a base, wherein the first crushing mechanism comprises a first crushing box, a first motor and a first rotating shaft, and the second crushing mechanism comprises a second crushing box, an outer crushing roller and an inner crushing roller; the transmission mechanism comprises a transmission case, a second motor, a second rotating shaft, a bearing and a belt wheel; the lifting mechanism comprises hydraulic cylinders and telescopic columns, and the number of the hydraulic cylinders and the number of the telescopic columns are both two; the lifting mechanism is arranged below the liftingmechanism. The sand making machine can be used for evenly crushing gravel materials.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

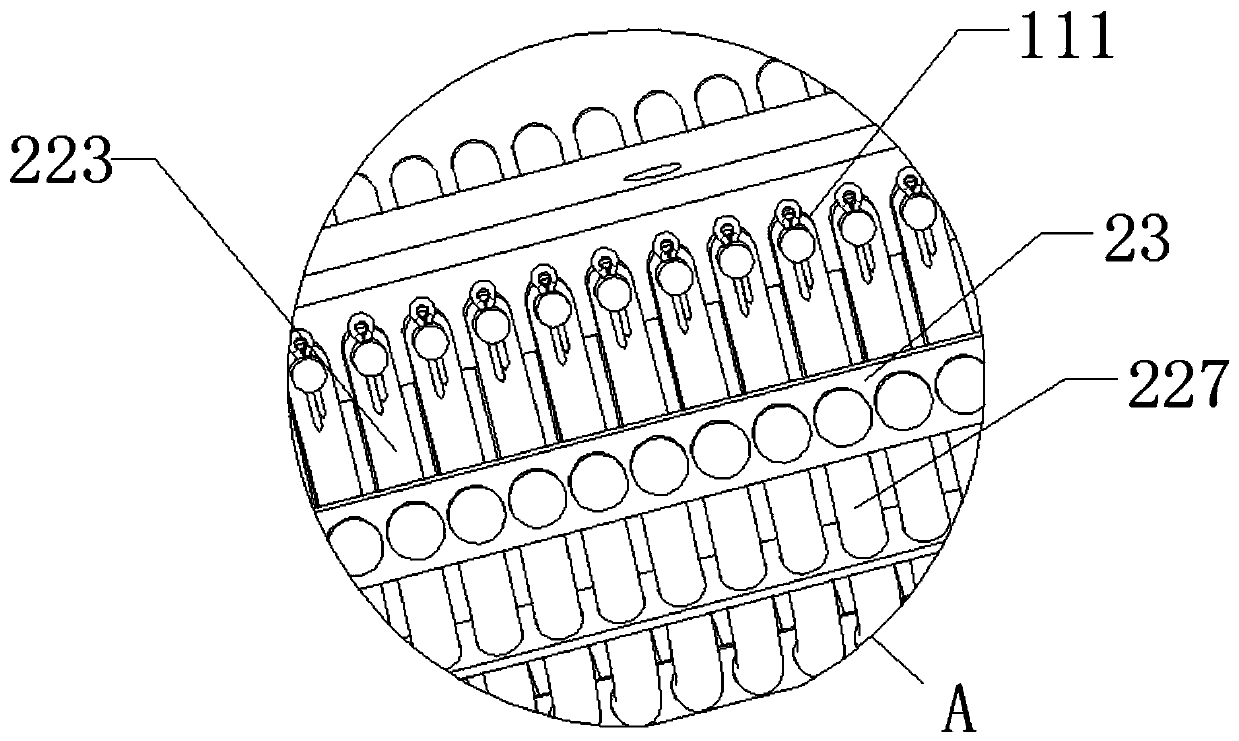

Threshing escape grid device

The invention discloses a threshing escape grid device, and belongs to the technical field of agricultural machines. According to the main aim of the threshing escape grid device, the clearance between a threshing roller and an escape grid can be adjusted in real time. According to the main technical scheme, the threshing escape grid device comprises a fixed part and a grid plate part, and a firstfixed component and a second fixed component are oppositely arranged on a rack; the grid plate part comprises transmission components and a grid plate component, the grid plate component comprises areinforcing component and multiple grid strip components, the reinforcing component is provided with multiple connecting holes, one end of each grid strip component is rotationally connected to the first fixed component, and the other end of each grid strip component penetrates through the corresponding connecting hole and is rotationally connected to the second fixed component. Each grid strip component can rotate in the connecting holes, and the transmission components are connected to the two ends of one grid strip component, and used for enabling each grid strip component to rotate aroundthe first fixed component and the second fixed component. The threshing escape grid device is mainly used for grain threshing.

Owner:XINJIANG AGRI UNIV

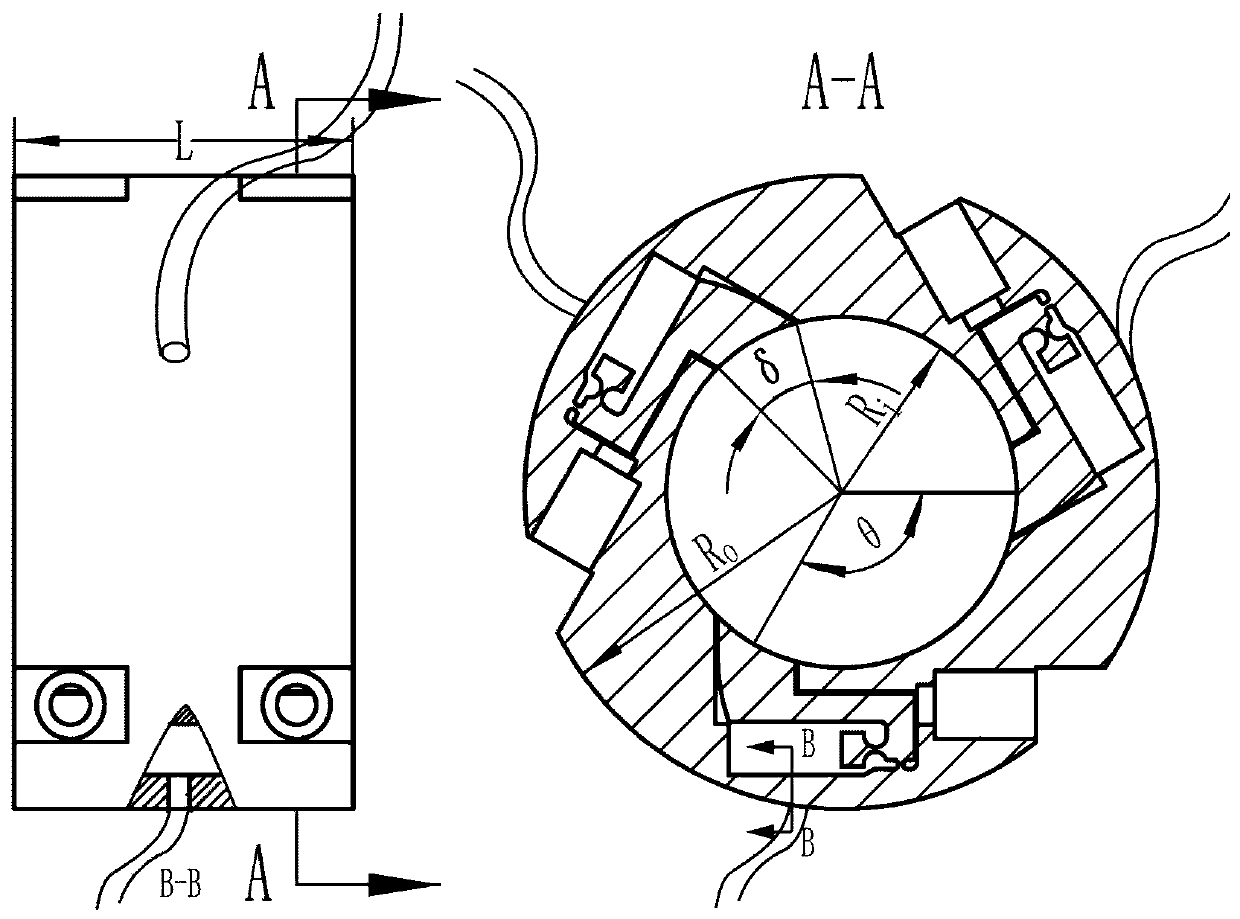

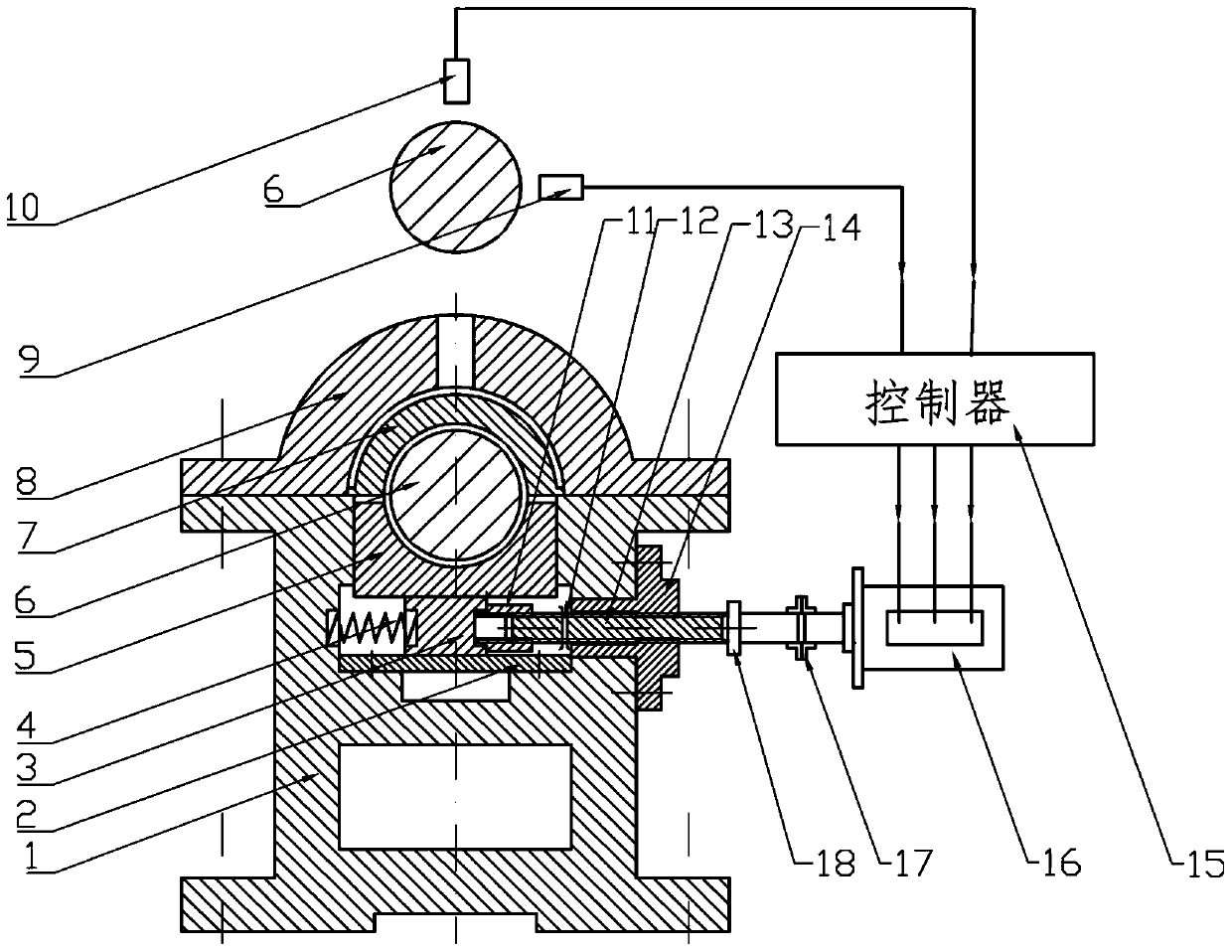

Intelligent support sliding bearing device with adjustable clearance and clearance adjustment method

ActiveCN111188833AImplementation limitOrientation stabilityShaftsRotary machine partsServoWhole systems

The invention discloses an intelligent support sliding bearing device with adjustable clearance and a clearance adjustment method. The intelligent support sliding bearing device comprises a support sliding bearing, an inclined block is arranged under the support sliding bearing, a guide rail is arranged under the inclined block, the bottom surface of the inclined block is matched with the guide rail in a sliding mode, the inclined block moves in the axial direction of the guide rail, the top surface of the inclined block is an inclined plane with a taper of 1 to 125, a pushing mechanism is arranged at one end of the inclined block, the other end of the inclined block is connected with a reset spring, and a vertical displacement sensor and a horizontal displacement sensor are respectively used for detecting the vertical radial displacement and the horizontal radial displacement of a rotor; the vertical displacement sensor and the horizontal displacement sensor are connected with the input end of a monitoring controller, and the output end of the controller is further connected with the control signal input end of a servo motor; when the rotor vibration is too large, signals collected by the sensors are sent to the controller, the controller controls the servo motor to make a certain action, and the clearance between the bearing and the shaft neck is changed, so that the elliptical bearing play a role, the rotor amplitude is reduced, and the whole system has a good effect of vibration reduction and suppression.

Owner:XI AN JIAOTONG UNIV

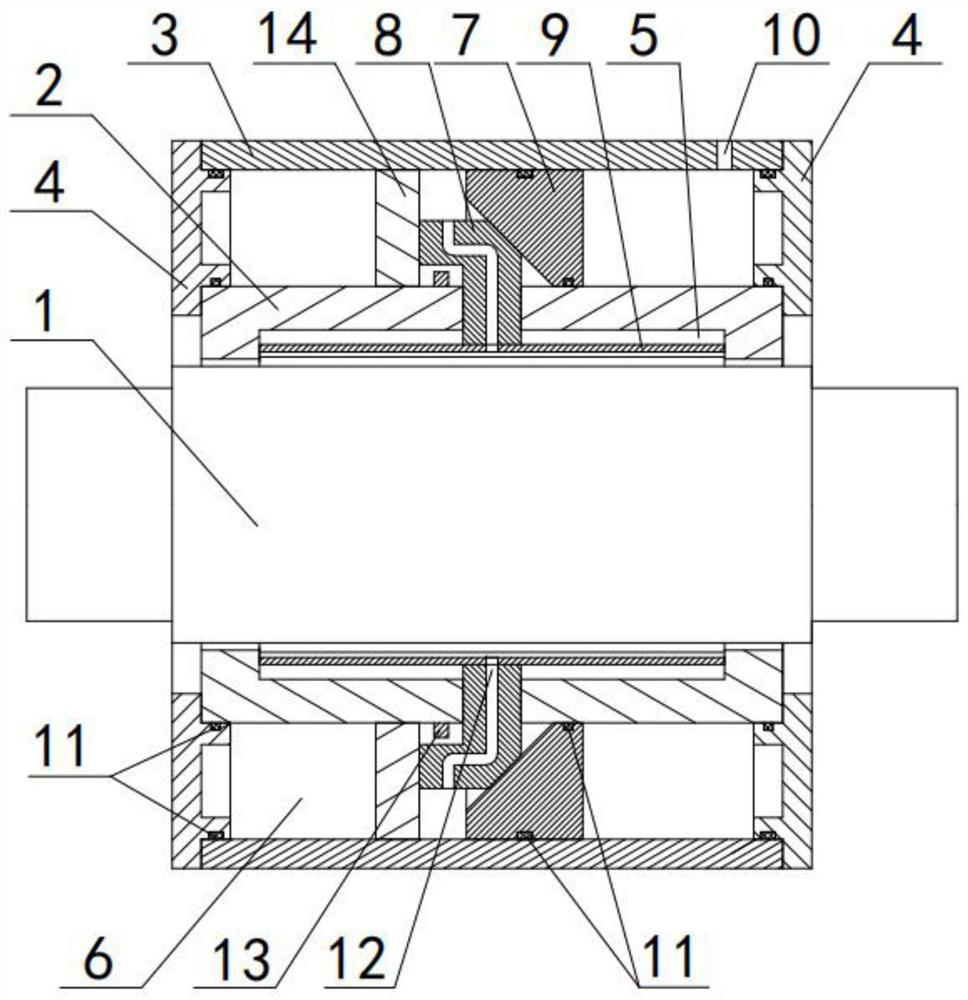

Hydrodynamic journal bearing

PendingCN113833764AAvoid affecting processingImprove the smoothness of movementLiquid cushion bearingsHydrostatic bearingsReciprocating motionProcessing accuracy

The invention discloses a hydrodynamic journal bearing which comprises a main shaft, a shaft sleeve, a bearing outer shell and two sealing end covers. A plurality of oil cavities are evenly distributed in the inner wall of the shaft sleeve, the main shaft is arranged in the middle of the shaft sleeve in a penetrating mode, the bearing outer shell is arranged on the outer side of the shaft sleeve in a sleeving mode, a working cavity is formed between the bearing outer shell and the shaft sleeve, a driving disc is arranged in the working cavity, a plurality of driving blocks are arranged on one side of the driving disc in a sliding mode, and an adjusting plate is arranged at the end, penetrating through a preformed hole in the shaft sleeve, of each driving block. According to the hydrodynamic journal bearing provided by the invention, the pressure of compressed air injected into air holes is adjusted. The driving disc can be controlled to reciprocate in the horizontal direction, so that all the driving blocks are driven to synchronously contract inwards or expand outwards in the direction perpendicular to the main shaft, the adjusting plate is driven to reciprocate, a gap between each oil cavity and the main shaft is changed, the thickness of an oil film is adjusted, the machining requirements of different products are met, the machining precision is improved, and the service life is prolonged.

Owner:JIANGSU JITRI JINGKAI HIGH VALUE MFG CO LTD

Packaging sealing device and packaging machine applying same

The invention relates to a packaging sealing device and a packaging machine applying the same. The packaging sealing device comprises an upper translational arm, a lower translational arm, an upper sealer fixed to the upper translational arm, a lower sealer fixed to the lower translational arm and a driving device, wherein the upper sealer is in sliding connection with the upper translational arm;the lower sealer is in sliding connection with the lower translational arm; sealer compression springs are arranged between the upper sealer and the upper translational arm and between the lower sealer and the lower translational arm; and the driving device drives the upper translational arm and the lower translational arm to move towards each other, away from each other and in a composite motionin the front-back direction. The packaging sealing device and the packaging machine applying the same solves the problems in the prior art, prolongs the contact time of the sealer and the packaging bag, enables the heating time of the sealing part of the packaging bag to be sufficient, and improves the sealing quality; the parallelogram double-crank mechanism is adopted to drive the action of thesealer, so that the stability of the whole machine is improved; additional cutter action devices do not need to be arranged, the structure is simplified, and the cost is reduced.

Owner:李志宏 +1

Granulating machine with double-ring mould built-in

The invention discloses a double-ring die built-in granulating machine in the granulating machine field, comprising a frame and a ring die, wherein, a plurality of die holes are radially arranged on the wall of the ring die; one end of the ring die is provided with a feeding channel; a main sleeve is fixed on the frame; the other end of the rind die is fixed with a belt pulley which is arranged outside the main sleeve through a bearing; a cylindrical inner ring die is arranged in the ring die; a plurality of radial die holes are also arranged on the wall of the inner ring die; one end of the inner ring die is connected with a rotating shaft which is arranged in an adjusting sleeve; the adjusting sleeve is arranged on a machine body; a feeding shaft is arranged on the main sleeve, axially passes through a clearance between the ring die and the inner ring die and extends into the feeding channel, and is provided with a helical propelling blade; and the helical propelling blade extends from the lower side of a feeding port of the feeding channel to the clearance between the ring die and the inner ring die. The double-ring die built-in granulating machine has the plurality of the die holes, can simultaneously granulate on the ring die and the inner ring die with high work efficiency, and can be used for granulating in foodgrain processing and fodder processing.

Owner:JIANGSU MUYANG GRP CO LTD

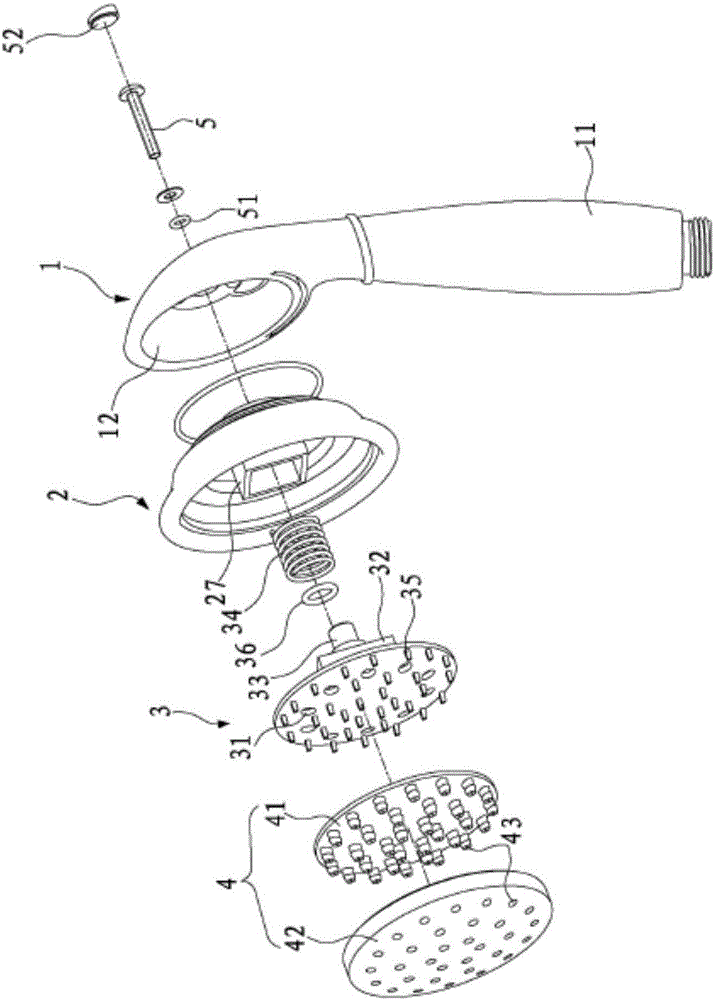

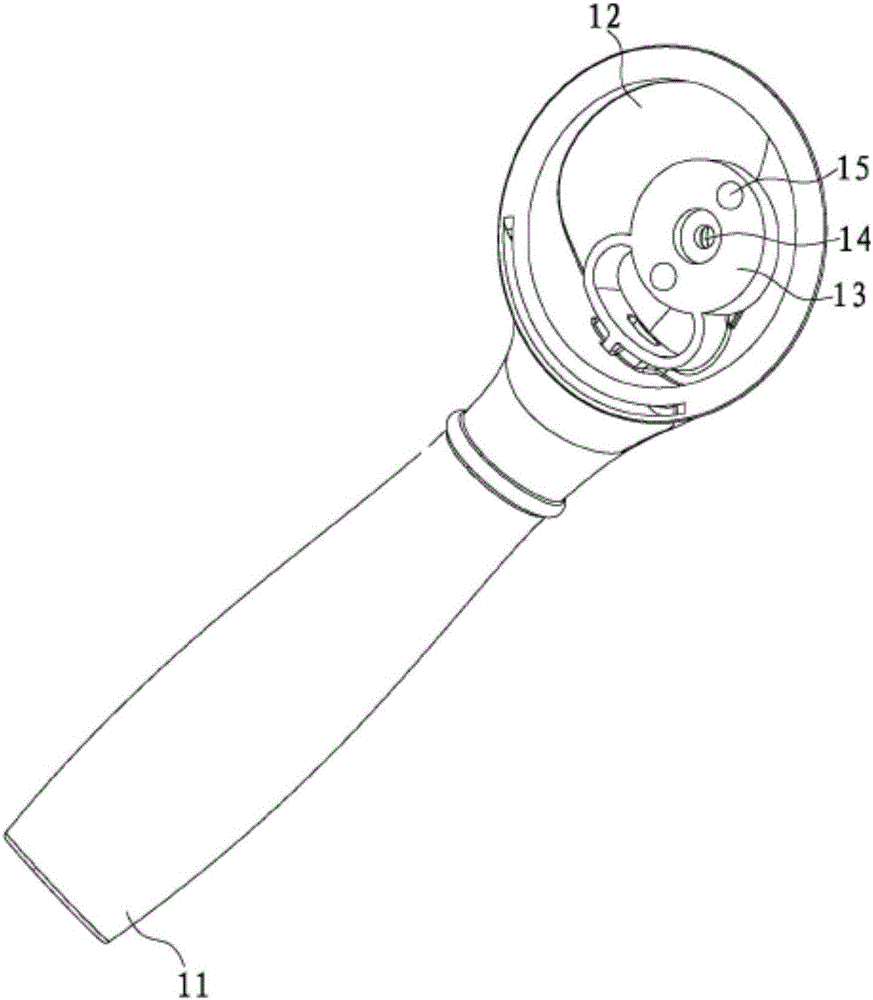

Adjustable type spraying device

The invention relates to an adjustable type spraying device which comprises a body, a rotating body, a spray conversion body and a water outlet body. The body is provided with a water inlet end and a water outlet end which communicates with the water inlet end. The rotating body is arranged on the top of the water outlet end, and the rotating body can generate repeated axial displacement with the water outlet end of the body. The spray conversion body and the water outlet body which cannot rotate relative to the rotating body are sequentially arranged on the top of the opening end of the rotating body from interior to exterior in a clearance manner. Multiple flow passing holes are formed in the spray conversion body, and the end face of the side, facing the water outlet body, of the spray conversion body is provided with multiple protruding water baffles. The water baffles can exactly penetrate in a water outlet in the water outlet body. According to the spraying device, the rotating body is driven to rotate so that the axial displacement of the rotating body is changed, meanwhile, the axial displacement of the spray conversion body is driven, finally, the flow passing area of the water outlet in the water outlet body is changed, the spraying angle between water flow and the water baffles is changed, and flow control and spraying area adjustment are achieved.

Owner:新昌县双彩乡合洪五金厂

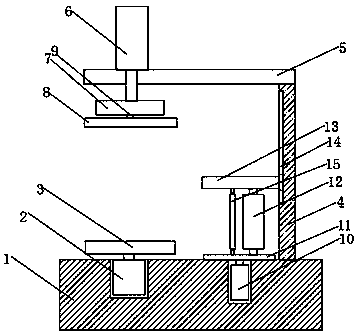

Electromagnet test bench and detection platform

InactiveCN109633498AChange gapFully automatedMagnetic property measurementsHydraulic cylinderEngineering

The invention provides an electromagnet test bench and a detection platform. After an electromagnet is fixed on a carrying platform of the electromagnet test bench, a hydraulic cylinder in the electromagnet test bench can move up and down to drive a guide plate to move vertically so as to change the gap between the electromagnet and the guide plate, so that the static characteristics of the electromagnet are tested. Compared with the related technology not being capable of detecting the own static characteristics of the electromagnet effectively, the electromagnet test bench is able to detectthe static characteristic of the electromagnet to realize test process automation. The electromagnet test bench has characteristics of great convenient in testing, high test accuracy, and comprehensive test items.

Owner:CRRC QINGDAO SIFANG CO LTD

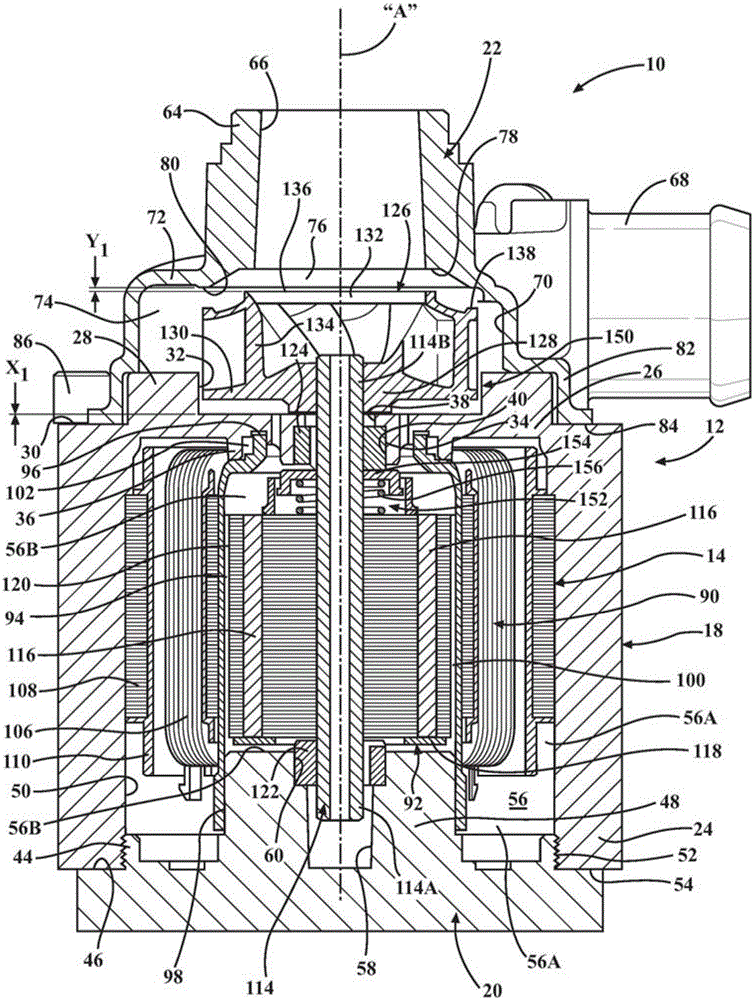

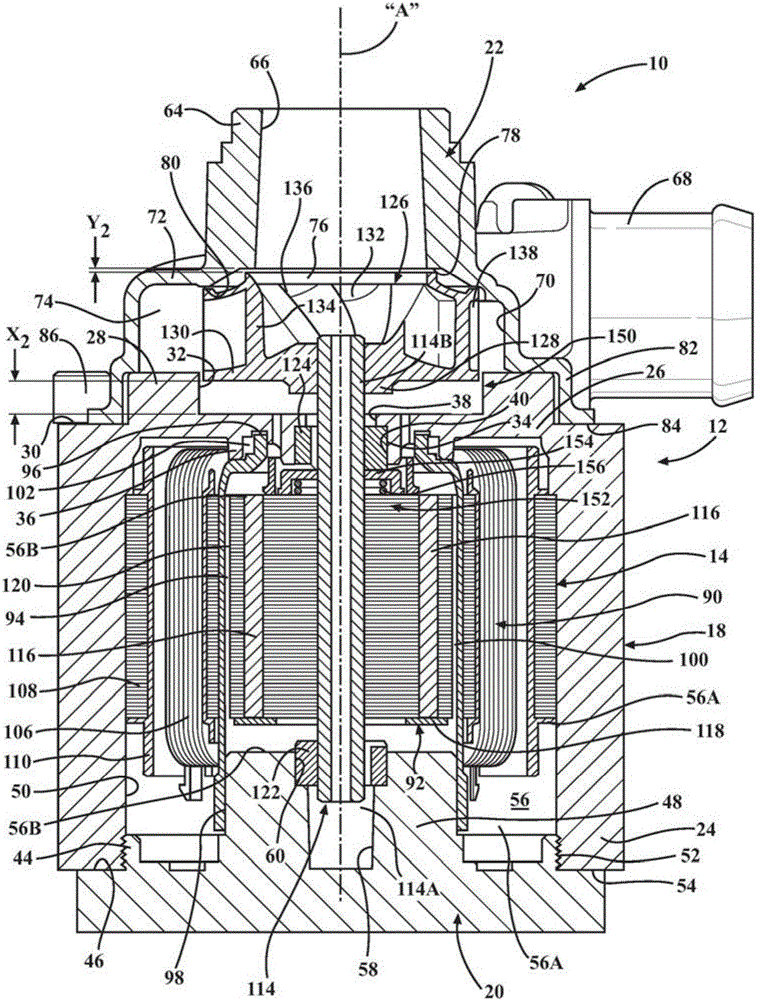

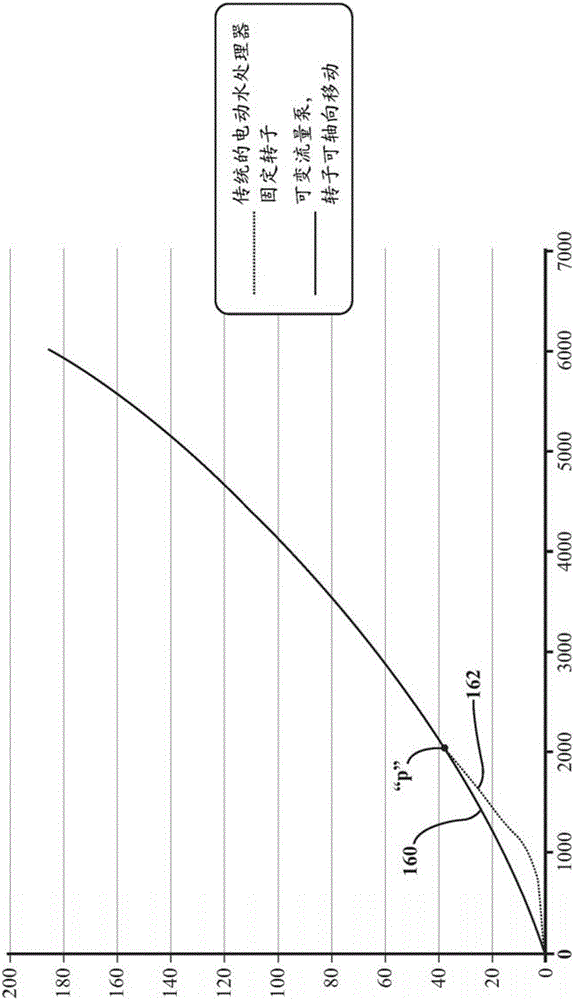

Spring regulated variable flow electric water pump

An electric water pump is disclosed having a motor with an axially moveable rotor unit. A rotary pump member is fixed for axial movement with the rotor unit to vary its position within a pump chamber so as to vary the flow rate through the pump chamber.

Owner:HANON SYST EFP CANADA LTD ONTARIO

Belt-broken protective device with deceleration function

ActiveCN103787048AReduce impact damageExtended service lifeControl devices for conveyorsEngineeringConveyor belt

The invention discloses a belt-broken protective device with a deceleration function. The belt-broken protective device comprises a rack and a capturing mechanism. The capturing mechanism comprises an upper conveyor belt capturing part and a lower conveyor belt capturing part. The upper conveyor belt capturing part comprises a movable upper capturing branch part which can swing upwards under the action of the gravity and a static upper capturing branch part arranged on the upper portion of the rack. The movable upper capturing branch part swings towards and near the static upper capturing branch part which is located above the movable upper capturing branch part, and an upper portion clamping gap is formed by the match of the movable upper capturing branch part and the static upper capturing branch part and is capable of capturing an upper conveyor belt. The static upper capturing branch part is an upper portion capturing beam, and the upper portion capturing beam comprises a regulator for buffering and decelerating. The regulator comprises a static beam, a movable beam and a damping structure, wherein the movable beam locates below the static beam and is capable of moving upwards under the action of the upper capturing movable branch part, and the damping structure is used for supplying resistance for the upward movement of the movable beam. The regulator is arranged to supply a deceleration effect on capturing a conveyor belt, so that the impact and damage on the rack during a capturing process are reduced, and the service life of the rack is prolonged.

Owner:SHANDONG KEDA ELECTROMECHANICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com