Additional mould locking device of indirect extrusion casting

A technology of squeeze casting and additional lock, which is applied in the field of squeeze casting, can solve the problems of casting surface quality degradation, difficult to meet, casting performance degradation, etc., and achieve the effects of reduced residence time, small space, and large clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

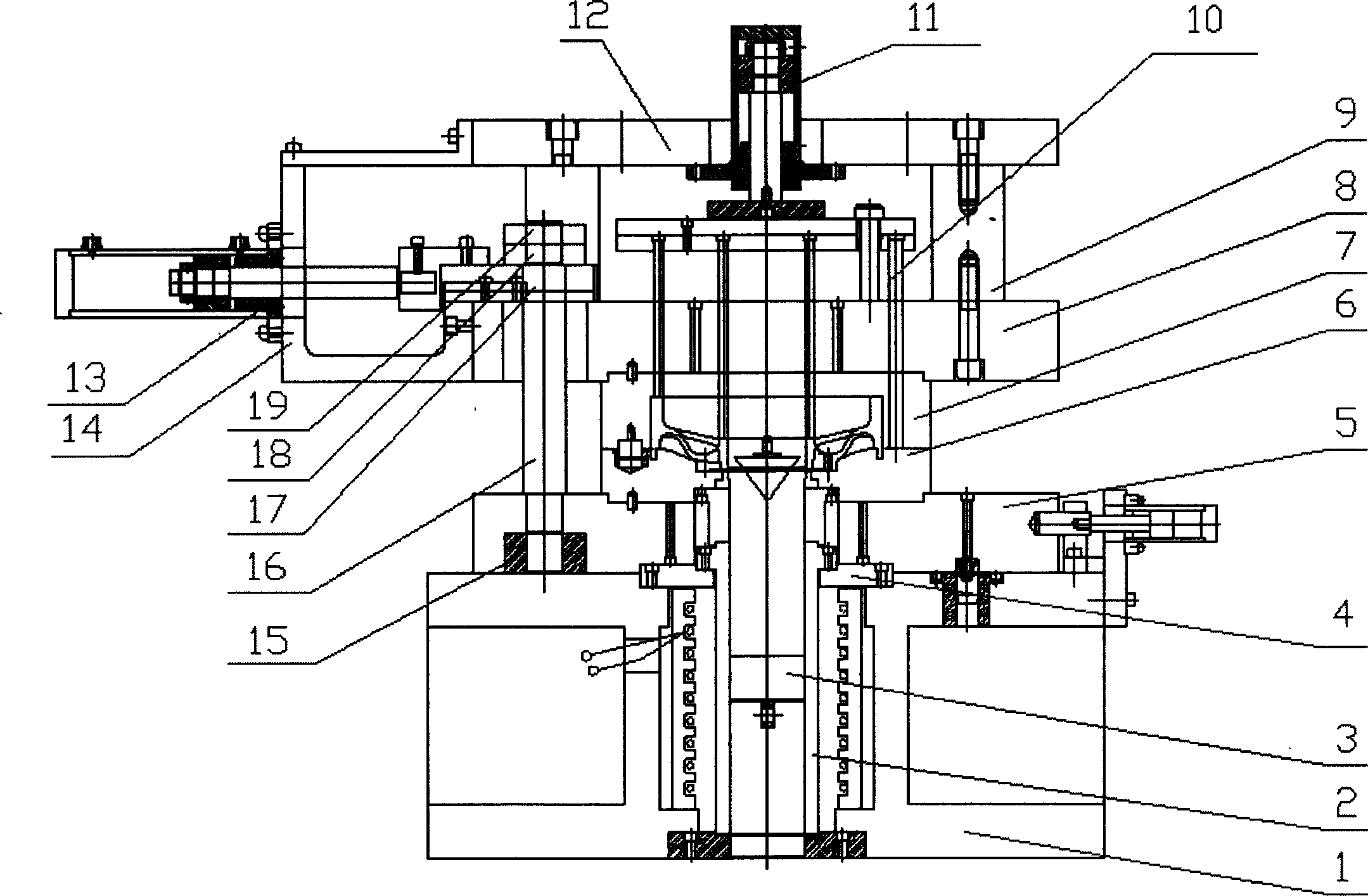

[0018] Taking the indirect extrusion casting production of a certain aluminum alloy wheel hub as an example, the present invention is further clarified:

[0019] 1. Squeeze casting equipment

[0020] Hub squeeze casting is carried out on LY-1600 vertical press, such as figure 1 As shown, the base 1 is connected with the working surface of the press by bolts; the extrusion barrel 2 is fixedly connected with the base 1 through the fixed flange 4; the extrusion head 3 is fixedly connected with the lower cylinder of the press; the lower mold base 5 is connected with the base 1 Contact fit, but no fixed connection; the lower mold 6 is fixedly connected with the lower mold base 5, and the upper mold 7 is fixedly connected with the upper mold base 8; the upper mold base 8 is fixedly connected with the upper mold connecting plate 12 through the connecting column 9; The upper die connecting plate 12 is fixedly connected with the upper cylinder of the press.

[0021] 2. Additional cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com