Intelligent false support rod device for high-speed wind tunnel

A high-speed wind tunnel and rod device technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problem of collision between the model and the fake tail rod, and the relative position relationship between the model and the tail rod cannot be completely consistent, etc. problem, to achieve the effect of collision avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The implementation process of this embodiment is as follows:

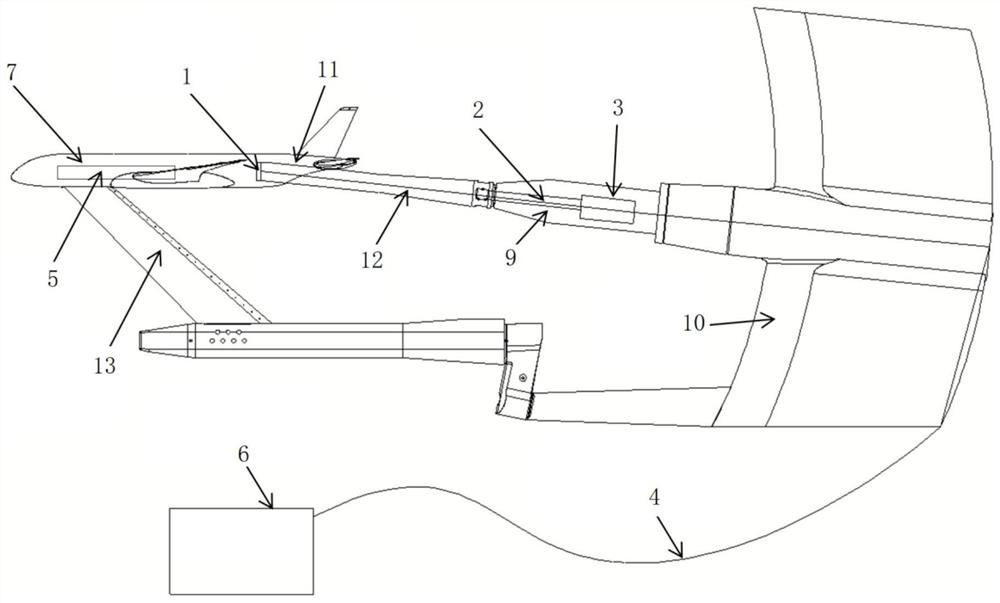

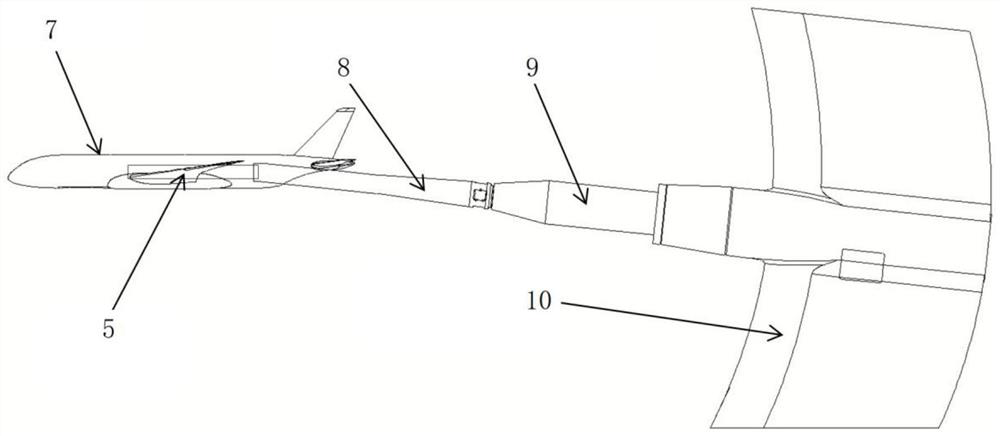

[0029] 1. In the conventional tail brace dynamometer wind tunnel test, if figure 2 As shown, the model 7 is connected to the real tail strut 8 through the balance 5, the real tail strut 8 is connected to the direct head 9, and the direct head 9 is connected to the wind tunnel scimitar mechanism 10; The relative position of data, model 7 and true tail strut 8.

[0030] 2. In the support interference test of the tail support, such as figure 1 As shown, the false tail strut 12 of the present invention is used to replace the original real tail strut 8, the model 7 is connected to the blade support 13 through the balance 5, the blade support 13 is connected to the wind tunnel machete mechanism 10, and the false tail strut 12 It is connected with the direct head 9, and the direct head 9 is connected with the scimitar mechanism 10 of the wind tunnel.

[0031] 3. Utilize the transmission mechanism 2 and driver 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com