Suspension fork mechanism with three adjustable axial-direction angles for robot

A robot and suspension technology, which is applied in the field of robot and vehicle engineering, can solve problems such as slow moving speed, large landing area, and weak ability to cross obstacles, and achieve reliable and stable motion, increased range, and reliable motion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

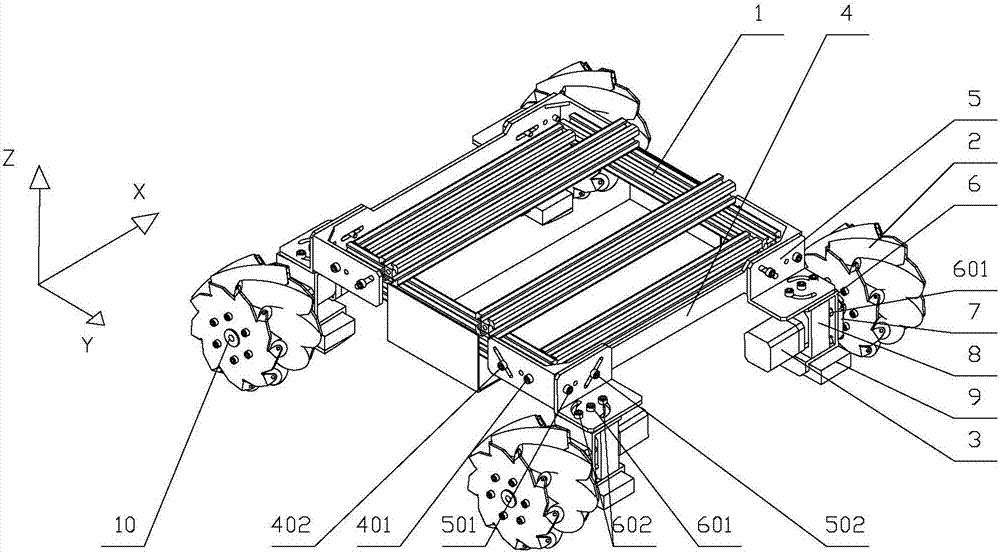

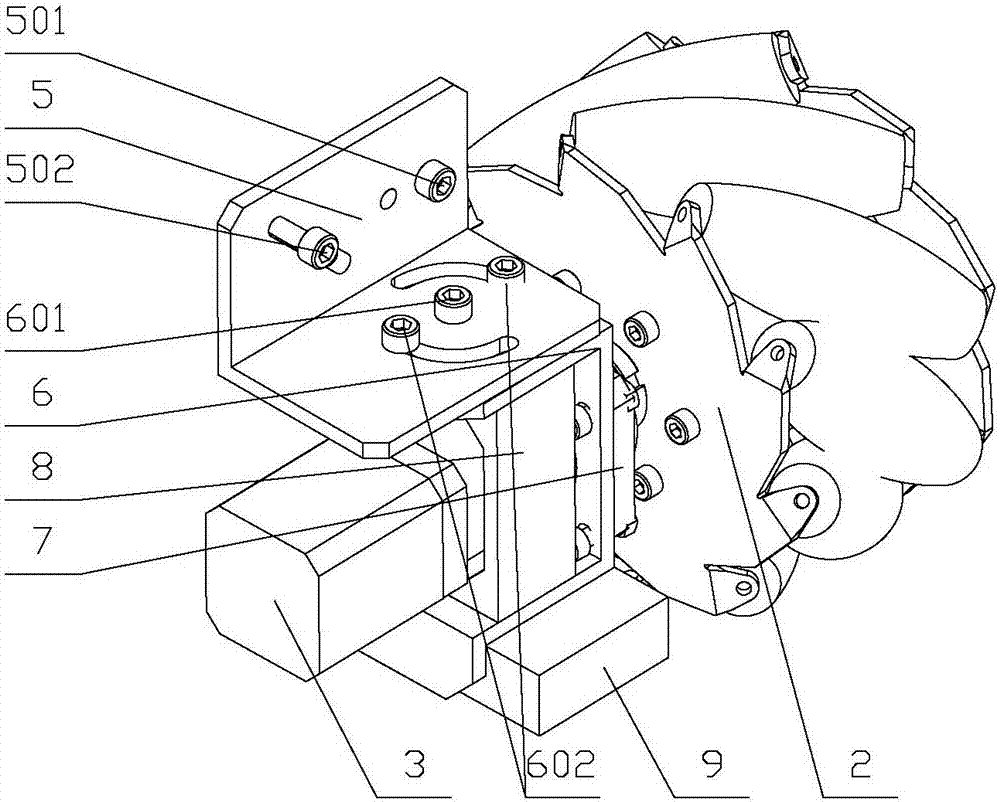

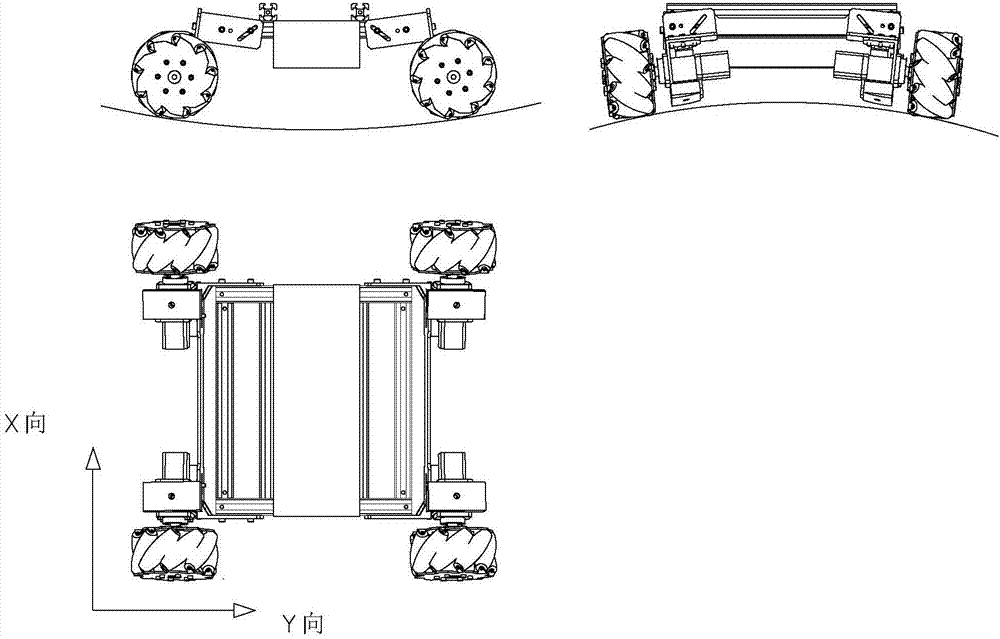

[0026] like figure 1 and figure 2 As shown, the present invention discloses a three-axis adjustable suspension mechanism for a robot, including a vehicle frame 1, two Y-direction rotating frames 4 arranged in parallel on the vehicle frame 1, and four groups independently arranged on The suspension sub-mechanism on the Y-rotation frame 4, two suspension sub-mechanisms are arranged on each Y-direction rotation frame 4, and each suspension sub-mechanism includes an X-direction rotation frame installed on the Y-direction rotation frame 4 5. The Z-direction fixed seat 6 installed on the X-direction rotating frame 5, the wheel 2 installed on the Z-directed fixed seat 6 through the wheel shaft 10 and the bearing seat 7, is installed on the Z-directed fixed seat by countersunk bolts The magnet 9 at the bottom of 6 is installed on the fastener 8 inside the Z-direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com